California logistics centers network connectivity made easy today

You find california logistics centers network connectivity easy because of strong highways, busy rail lines, major ports, and large air cargo hubs. Southern California and the Inland Empire stand out as key spots for moving goods quickly. This strong network helps your business reach customers faster and cut costs.

The California Trade Cluster:

Supports about 3.2 million jobs, or 17.6% of all jobs in the state

Makes up 14.3% of California’s GDP (2023)

Adds $277.6 billion in labor income and $502.0 billion in value

Key Takeaways

California's logistics network includes highways, railroads, ports, and airports, making it easy to move goods quickly.

Utilize intermodal connections to transfer cargo seamlessly between different transport modes, reducing handling and damage risks.

Leverage technology like real-time tracking and AI for efficient logistics management and faster delivery times.

Take advantage of California's strategic location near Asia to improve shipping efficiency and reduce costs.

Embrace sustainability initiatives in logistics to lower carbon emissions and enhance your business's eco-friendliness.

California logistics centers network connectivity

You can see how california logistics centers network connectivity supports your business with a strong mix of transportation options. These options include highways, railroads, ports, and airports. Each mode plays a unique role in moving goods quickly and efficiently across the state and beyond. Southern California and the Inland Empire stand out as major hubs, but Northern California also has a strong logistics presence.

Road and highway links

You rely on California’s highways to move goods between logistics centers and to customers. The state’s highway system connects every major logistics hub. Some of the most important routes for freight include:

I-5: This highway runs the length of California and connects to the rest of the West Coast, Canada, and Mexico. It is a major route for freight moving to and from the Ports of Los Angeles and Long Beach.

I-10: Known as the "Southwest Passage," this route links California to the Sun Belt and is key for east-west freight movement.

I-15 and I-40: These highways connect California to the interior United States, supporting long-haul trucking.

SR-99: This route is important for freight traffic within California’s Central Valley.

I-580: This highway sees heavy truck volumes, especially in Northern California.

In Southern California and the Inland Empire, you benefit from a network of highways such as Interstates 10, 15, and 40, as well as State Highways 60, 91, and 210. These roads link logistics centers to Interstate 710, which leads directly to the major seaports. This network makes california logistics centers network connectivity reliable and fast.

Rail infrastructure

You can move large volumes of goods by rail, which is essential for long-distance shipping. California’s rail system includes two major Class I railroads: Burlington Northern Santa Fe Railway and Union Pacific Railroad. These railroads connect logistics centers in Southern California, the Inland Empire, and Northern California to the rest of the country.

The state is also investing in high-speed rail. The California high-speed rail system will connect major regions, including San Francisco, Los Angeles, Sacramento, and San Diego. Trains will travel at over 200 miles per hour, making it possible to go from San Francisco to Los Angeles in under three hours. The plan includes up to 24 stations and 800 miles of track. This system will help you move goods and people faster, supporting economic growth and sustainability.

Each year, California receives about 95 million tons of rail freight. Major ports like Los Angeles and Long Beach use rail to distribute imported goods across the country. This volume shows how important rail is for california logistics centers network connectivity.

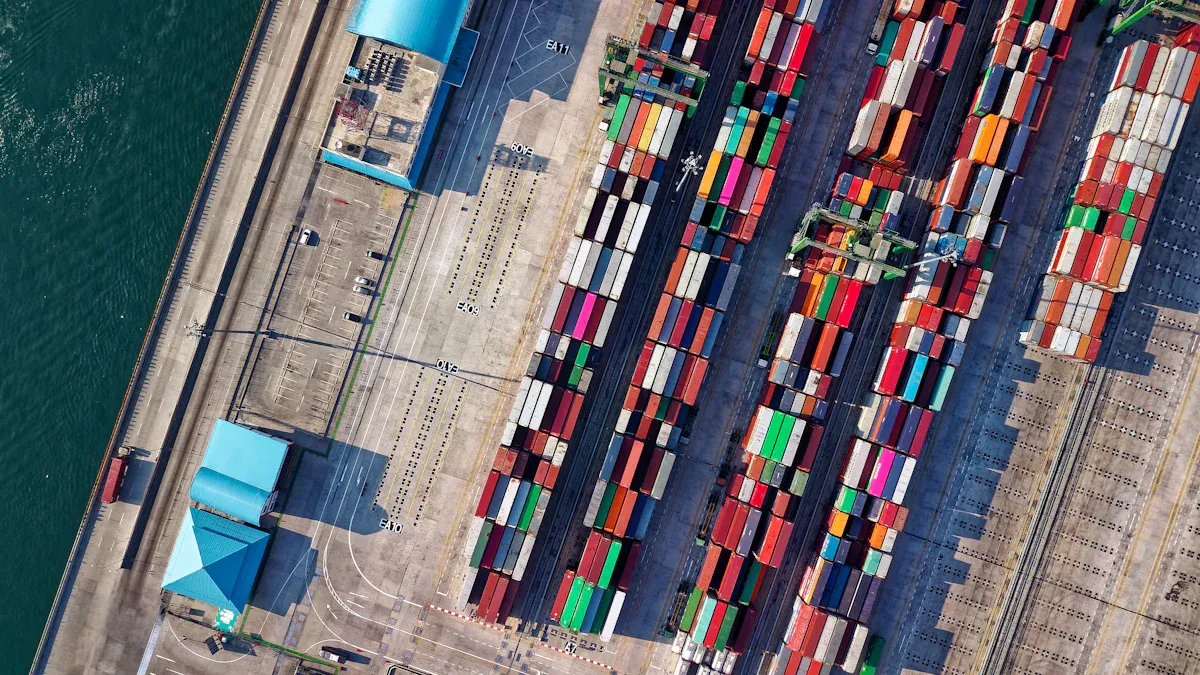

Ports and maritime routes

You depend on California’s ports to connect with global markets. The Port of Los Angeles and the Port of Long Beach are the largest in the state and handle the highest volume of cargo. Together, they process a significant share of containerized imports and exports in the United States. Southern California ports often see near-record import volumes, especially when businesses bring in goods ahead of tariff changes.

Did you know? The Port of Los Angeles handled 8.6 million TEUs (twenty-foot equivalent units) in 2023, making it the busiest container port in the country. The Port of Long Beach moves about $200 billion in cargo each year, with 90% of goods coming from East Asia.

You can see how california logistics centers network connectivity extends across the Pacific Ocean. Here are some of the main maritime routes:

Maritime Route | Description |

|---|---|

Trans-Pacific Green Shipping Corridor | A route for zero-emission ships, connecting California ports with Asia-Pacific ports. |

Los Angeles - Long Beach - Shanghai | A green shipping corridor focused on reducing carbon emissions and using clean marine fuel. |

Air cargo hubs

You can move high-value or time-sensitive goods quickly using California’s air cargo hubs. Los Angeles International Airport (LAX) serves as the primary West Coast cargo hub and is critical for trade with Asia. Ontario International Airport is also growing as a major air cargo center, with DHL Express planning a large hub there. This new facility will start partial operations by 2025 and reach full capacity by 2029.

Airport Name | Role in Air Cargo Hub |

|---|---|

Los Angeles International Airport | Primary West Coast cargo hub, vital for Asian trade lanes |

Ontario International Airport | Major air cargo hub, expanding with DHL Express operations |

In 2022, LAX processed over 2.7 million tons of cargo. Even with a slight decrease from the previous year, this volume stayed above pre-pandemic levels. These airports help you reach customers around the world quickly, making california logistics centers network connectivity even stronger.

You can see how the diversity of transport modes—road, rail, sea, and air—makes california logistics centers network connectivity one of the best in the country. This network helps you move goods efficiently, whether you operate in Southern California, the Inland Empire, or Northern California.

Integration of transport networks

Intermodal connections

You benefit from intermodal connections that link road, rail, air, and sea for smooth logistics. These connections allow you to move cargo from one mode to another without unloading at each stop. Standardized containers help you transfer goods quickly and safely. Intermodal trucking connects all transportation modes, making long-distance shipping more efficient. You see less handling and lower risk of damage when goods stay in their containers.

Some facilities make these connections possible:

BNSF Hobart and Commerce Facilities near downtown Los Angeles handle the largest volume of domestic intermodal freight. You find extensive parking and ground-stacking operations there.

Weber Logistics Distribution Centers in Irvine and San Diego offer strong rail capacity and specialize in rail-to-truck transloading.

Weber’s San Diego Warehouse has six rail doors and a double rail spur for twelve boxcars. You can move goods easily between rail and road.

These facilities show how california logistics centers network connectivity supports your business with seamless transfers.

Technology and coordination

You rely on technology to coordinate logistics across different transport modes. Digital platforms match capacity with demand and give you real-time shipment visibility. IoT and sensor technology track cargo and collect data for optimization. Automated and autonomous systems improve efficiency and reduce errors. Blockchain provides secure records of transactions. Sustainability initiatives help you lower carbon emissions.

Technology Type | Description |

|---|---|

Digital Platforms | Streamline matching capacity with demand, optimize routes, and provide real-time shipment visibility. |

IoT and Sensor Technology | Track and monitor cargo, collect real-time data for optimization and integrity. |

Automated and Autonomous Systems | Improve efficiency, reduce human error, and enhance delivery times through automation and AI. |

Blockchain | Enhance traceability and security with immutable records. |

Sustainability Initiatives | Reduce carbon emissions through eco-friendly practices and technologies. |

Real-time data sharing helps you communicate effectively across shifts. You get structured information flow, so important details do not get lost. Visibility into operations lets you track performance and respond quickly to changes.

Benefits for logistics operations

Speed and cost efficiency

You gain a clear advantage when you use California’s logistics networks. Fast delivery keeps your customers happy and helps you stay ahead of competitors. Technology plays a big role in this process. The Internet of Things (IoT) lets you track shipments in real time. Modern GPS systems show you exactly where your trucks are. Artificial intelligence helps you find the best routes, so your goods arrive faster.

Real-time tracking and monitoring improve how you manage shipments.

GPS technology reduces delivery times and boosts customer satisfaction.

Route optimization with AI and IoT speeds up your logistics process.

Cost savings matter to your business. California’s integrated logistics networks help you cut costs in many ways. You can see the main benefits in the table below:

Evidence Type | Description |

|---|---|

Cost Savings | Over two-thirds of businesses believe cost reduction is the most immediate and impactful advantage of integrated logistics. |

Cost Optimization | 69% of logistics professionals say cost reduction comes from working with fewer suppliers and cutting inefficiencies. |

You also save money by lowering storage costs, reducing transportation errors, and improving order accuracy. Outsourcing logistics functions helps you lower overhead costs for staff, equipment, and warehouse space.

Flexibility and scalability

You need flexibility to handle changes in demand. California’s logistics centers give you this edge. Their location near Asia and major ports means you get goods faster and at a lower cost. You can use just-in-time inventory management, so you only keep what you need on hand.

Strategic location gives you easy access to transportation routes.

Proximity to Asia and major ports improves efficiency.

Just-in-time inventory keeps your stock levels low and saves money.

Scalability is important as your business grows. You can start small and increase your order volume quickly. Some companies grow from 100 to 15,000 orders per month with the right logistics solutions. Warehousing options in California adjust to seasonal peaks and long-term growth. Real-time tracking technology gives you visibility and helps you solve problems fast.

Real-world examples

Inland Empire distribution centers

You see the Inland Empire as a powerhouse for logistics. This region sits east of Los Angeles, mainly around Riverside and San Bernardino. About 40% of goods entering the United States move from the nearby Port of Los Angeles to this area. You benefit from strong connections to Interstates 10 and 15, as well as major railroads and airports. Many companies choose the Inland Empire for its location and cost advantages.

Lineage’s regional hub supports food distribution for West Coast retailers. You find integrated cold storage here, which makes large-scale retail logistics easier.

Millions of containers from the Ports of Los Angeles and Long Beach pass through the Inland Empire each year.

Moreno Valley’s distribution centers sit at the crossroads of major highways and rail lines. You gain quick access to Ontario International Airport and the ports.

Watson Industrial Park Chino offers low shipping and warehouse costs, helping you save money.

Southern California rail and port hubs

You rely on Southern California’s ports and rail lines to move goods quickly. The Ports of Los Angeles and Long Beach handle over 40% of all containerized imports to the country. These ports serve as the main entry point for goods from Asia. The Intermodal Container Transfer Facility (ICTF) links the ports to major rail yards, making transfers fast and efficient. The Alameda Corridor acts as a freight rail expressway, connecting the ports to the national rail network. This region supports millions of jobs and keeps your supply chain strong.

Northern California clusters

You find advanced logistics clusters in Northern California. Many facilities use state-of-the-art features to improve efficiency and sustainability.

Requirement | Description |

|---|---|

Solar panels and battery storage lower energy costs. | |

Electrical Hookups | Loading bays have electrical hookups for cold storage needs. |

Truck Loading Orientation | Bays face away from sensitive areas to reduce impact. |

Separate Entrances | Heavy-duty trucks use separate entrances for safety. |

Landscaped Buffers | Green spaces buffer facilities from nearby communities. |

High-Efficiency HVAC | Modern HVAC systems save energy and improve comfort. |

Zero-Emission Forklifts | Larger projects use zero-emission forklifts for cleaner air. |

You learn that strong collaboration, new technology, and workforce training help these centers stay ahead. These examples show how you can use best practices to improve your own logistics operations.

You see how California’s transportation networks help you move goods quickly and easily. The state’s highways, rail lines, and ports handle almost 40% of the nation’s containerized cargo. This unmatched infrastructure gives you cost savings, access to skilled workers, and advanced technology.

You gain operational efficiency

You reach global markets faster

You support sustainability and customer satisfaction

Take advantage of these networks to grow your business and strengthen your supply chain.

FAQ

How do California logistics centers connect to global markets?

You use ports like Los Angeles and Long Beach to ship goods worldwide. These ports link you to Asia, Europe, and other regions. Air cargo hubs like LAX also help you reach international customers quickly.

What makes the Inland Empire important for logistics?

You find the Inland Empire near major highways, rail lines, and airports. Many companies choose this area for fast shipping and lower costs. You can move goods easily between ports and distribution centers here.

Can you use multiple transport modes for one shipment?

Yes, you can. Intermodal connections let you move goods by truck, train, ship, or plane without unloading. This process saves time and reduces damage. You get more flexibility for your shipments.

How does technology improve logistics center operations?

You use digital tools to track shipments, manage inventory, and plan routes. Real-time data helps you solve problems fast. Automated systems make your work easier and reduce mistakes.

Are California logistics centers eco-friendly?

Many centers use solar panels, electric forklifts, and energy-saving systems. You see more green spaces and better air quality. These efforts help you lower your carbon footprint and support sustainability.

See Also

Top-Notch Trucking Solutions Across California And Beyond

Streamlined Supply Chain Solutions Across The United States

Enhancing West Coast Operations Through LA Warehousing Services

Addressing Fast Logistics Needs In Los Angeles With PGL

Reasons Southern California E-Commerce Companies Prefer PGL Warehousing