What Is the California Logistics Centers Network and How It Works

The california logistics centers network connects you to a vast system of transportation. You see advanced infrastructure for air, ground, rail, and water. This network supports California’s economy and helps businesses grow. Southern California and the Inland Empire serve as major hubs.

You rely on this network for faster shipping, better access to global markets, and stronger supply chains.

Key Takeaways

The California Logistics Centers Network connects various transportation methods, enhancing shipping speed and access to global markets.

Southern California and the Inland Empire are key logistics hubs, providing access to major ports and advanced infrastructure for efficient goods movement.

Advanced warehousing technologies, like real-time inventory tracking, improve order fulfillment and reduce errors in the supply chain.

The network supports economic growth by creating job opportunities and offering incentives for businesses to thrive in California.

Sustainability initiatives, such as zero-emission trucks and renewable energy use, aim for a cleaner environment and healthier communities.

California Logistics Centers Network Overview

Definition and Scope

You experience the california logistics centers network as a powerful system that connects goods and people across California. This network uses many types of transportation, such as air, ground, rail, and water. You see how each part works together to move products quickly and safely.

International gateways help you reach global markets. Southern California has major airports and deepwater ports. For example, LAX ranks as the third busiest air cargo facility in the world.

Interstate multimodal corridors let you move goods across the state. You use highways like I-5, I-15/I-40, and I-10 to transport large volumes of freight by truck.

Metropolitan roadway systems support local deliveries. Thousands of miles of freeways and arterial roads connect you to warehouses and distribution centers.

Tip: When you use the california logistics centers network, you benefit from a system designed for speed and reliability. You can ship products by air for fast delivery, send bulk items by rail, or use trucks for flexible routes.

Key Regions and Hubs

You find the largest logistics hubs in Southern California and the Inland Empire. These regions give you access to the busiest ports and most advanced infrastructure in the United States.

The Port of Los Angeles and the Port of Long Beach stand out as the two largest ports in the country. They cover thousands of acres and handle over 250 million metric tons of cargo each year.

The Inland Empire supports your business with massive warehouse space and direct links to highways and railroads. You can store, sort, and ship goods efficiently.

The Bay Area offers you a prime location for eCommerce. Its strong infrastructure helps you scale your operations and deliver products quickly.

Region | Key Features | Benefit to You |

|---|---|---|

Southern California | Largest ports, major airports, freeway network | Fast global and domestic shipping |

Inland Empire | Huge warehouses, highway and rail access | Efficient storage and distribution |

Bay Area | Advanced infrastructure, tech-driven logistics | Quick delivery, easy scaling |

You rely on these hubs to keep your supply chain strong. Each region gives you unique advantages, whether you need to reach international markets or deliver locally.

How the Network Operates

Multi-Modal Transport System

You see how the california logistics centers network uses many types of transportation to move goods. Ports, airports, and rail terminals work together to keep products flowing. You rely on the Port of Los Angeles and the Port of Long Beach for shipping large volumes. These ports handle millions of containers every year. Airports like LAX move air cargo quickly across the globe. Rail terminals connect you to other states and regions.

Port Name | Annual Handling Capacity (TEUs) |

|---|---|

Port of Los Angeles | |

Port of Long Beach | Millions (exact number not specified) |

Tip: You can use trucks, trains, ships, or planes to deliver goods faster and reach more customers.

Advanced Warehousing and Fulfillment

You benefit from advanced warehousing technologies in California. These centers use smart systems to track inventory and manage orders. You see real-time updates on your products. Warehouse Management Systems (WMS) help you make better decisions and keep operations running smoothly. Real-time inventory tracking lets you avoid running out of stock or having too much inventory. Integration with e-commerce platforms gives you full visibility into shipments.

Technology Type | Description |

|---|---|

Warehouse Management Systems (WMS) | Provides real-time visibility into inventory, enhancing decision-making and operational efficiency. |

Real-time Inventory Tracking | Enables accurate demand forecasting and optimized inventory levels, reducing stockouts and overstocking. |

Integration with E-commerce Platforms | Offers end-to-end visibility into shipments, improving supply chain transparency. |

Fulfillment centers use barcode scanning and RFID technology to log product details. You see products stored in special areas for quick retrieval. Skilled professionals process orders with precision.

Supply Chain Integration

You experience smooth supply chain operations because logistics centers use digital platforms. These tools give you real-time visibility across warehouses. Automated ordering processes help you avoid mistakes and save time. Barcode and RFID integration makes receiving and shipping faster.

Real-time Inventory Tracking

Automated Ordering Processes

Barcode and RFID Integration

Logistics centers work with manufacturers, distributors, and retailers to improve efficiency. You benefit from freight consolidation, which reduces costs and supports sustainability. Shipments are grouped near major ports to make distribution easier. Advanced inventory management systems help everyone work together and keep customers happy.

Economic Impact and Business Benefits

Driving Growth and Trade

You see how the california logistics centers network drives growth and trade across California. The ports in Southern California have seen huge increases in container traffic over the past decades. The Port of Los Angeles and the Port of Long Beach now handle nearly 40% of the nation’s imports and exports. You can view their growth in the table below:

Port | Container Traffic Growth (1980-2022) | Cargo Handled by 2020 (tons) | Percentage of Nation's Imports/Exports |

|---|---|---|---|

Port of Los Angeles | 20-fold increase | Nearly 60 million | 40% |

Port of Long Beach | Virtually identical growth | Nearly 80 million | 40% |

You benefit from this growth because it opens new markets and helps you reach more customers. The rise of logistics in Southern California also created a demand for workers in shipping, trucking, and warehousing. This shift started in the 1970s and grew quickly after the aerospace industry declined.

Support for Businesses

You gain strong support for your business when you use the california logistics centers network. Many industries rely on these logistics centers, including:

Retail

Food and beverage

Pharmaceuticals

Consumer goods

Chemical and industrial sectors

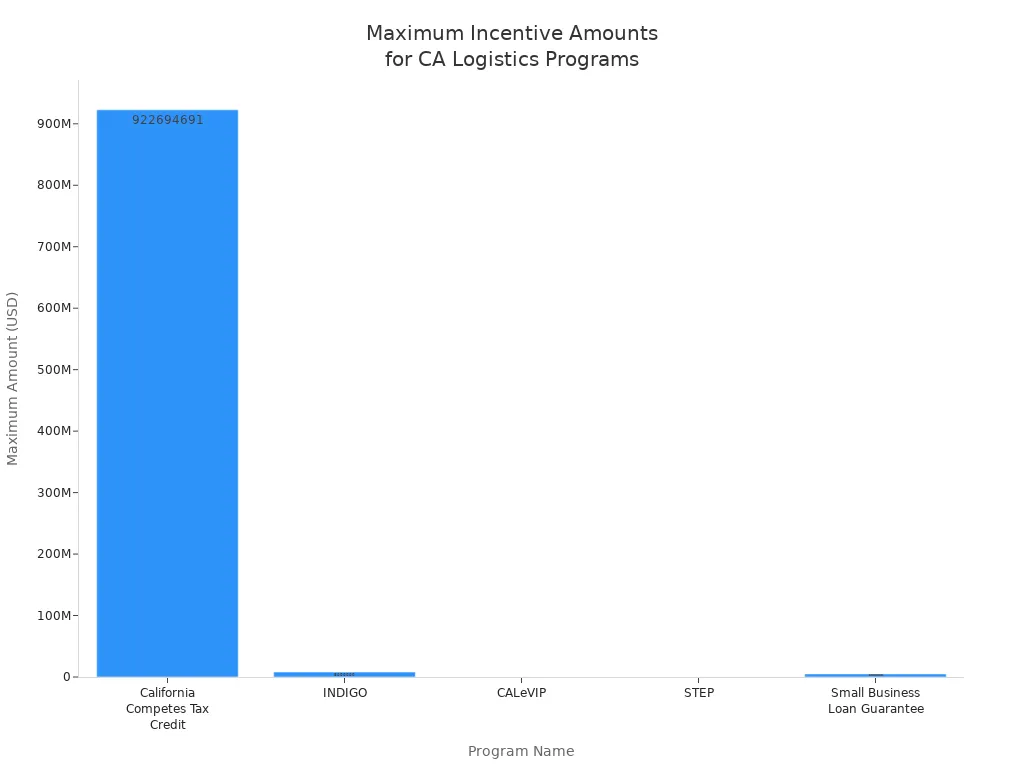

You get access to integrated logistics providers who offer transportation and warehousing solutions. These services help you deliver products on time and manage your supply chain efficiently. California also offers incentives and support programs for businesses. You can see some of these programs in the table below:

Program Name | Type | Description | Maximum Amount | Application Period | Contact | |

|---|---|---|---|---|---|---|

State Income Tax Credit | Supports business development | $922,694,691 | Jan 5, 2026 - Jan 26, 2026 | |||

California Clean Hydrogen Program | State Grant | For clean hydrogen projects | TBD | Q3/Q4 2025 | ||

CALeVIP | Rebate | Incentives for fast chargers | Up to $100,000 per port | Jul 8, 2025 - Sep 30, 2025 | ||

STEP | Export Assistance | For export businesses | $10,000 | Ongoing |

Job Creation and Workforce

You see job opportunities grow as the logistics network expands. The ports and logistics centers have created nearly 600,000 jobs with an average wage of $63,130. Many jobs also appear in related sectors. You can find training programs that help you build skills for these careers:

CMTC Workforce Development: Tailored training programs based on client needs.

Clean Transportation Program: Grants for zero-emission vehicle manufacturing and workforce training.

Center for International Trade & Transportation: Education and research in transportation workforce development.

Riverside County Workforce Development: Customized training for logistics and transportation companies.

UpSkill California: Community colleges providing customized training and education.

You benefit from these programs because they help you learn new skills and find stable work in logistics.

Sustainability and Innovation

Green Logistics Initiatives

You see California logistics centers leading the way in green practices. These centers set strong sustainability goals to reduce their impact on the environment. You notice that each location works to lower energy use intensity by at least 2% every year. Many centers install renewable electricity supplies and storage systems. By 2025, you will find every campus and health location using 100% clean electricity.

California logistics centers aim to reach carbon neutrality by 2045. You benefit from cleaner air and healthier communities.

Goal | Target Year | Description |

|---|---|---|

Carbon Neutrality | 2045 | Achieve carbon neutrality in alignment with campus plans and statewide goals. |

Carbon Emission Reduction | 2040 | Reduce carbon emissions to 80% below 1990 GHG levels. |

Elimination of Natural Gas | 2035 | Work towards eliminating new natural gas assets, with exceptions for academic needs. |

You see more electric and hydrogen-powered trucks on the road. These vehicles help reduce carbon emissions and improve efficiency. Federal grants support zero-emission infrastructure, including EV charging stations and hydrogen refueling sites. Companies like 4 Gen Logistics plan to operate fully zero-emission fleets by 2025 in key hubs such as Long Beach and Rialto.

Technology Advancements

You experience faster and smarter logistics because of new technologies. Warehouse Management Systems (WMS) give you real-time tracking of inventory and help reduce errors. Transportation Management Systems (TMS) optimize delivery routes and improve delivery times. Artificial Intelligence (AI) and Machine Learning (ML) help predict demand and identify bottlenecks. Robotic Process Automation (RPA) automates repetitive tasks, saving time and allowing workers to focus on important jobs.

Technology | Benefits |

|---|---|

Warehouse Management Systems | Real-time tracking, optimized storage, fewer errors, better order fulfillment. |

Transportation Management Systems | Route optimization, cost reduction, improved delivery times. |

Artificial Intelligence & Machine Learning | Better forecasting, smarter supply chain decisions, bottleneck identification. |

Robotic Process Automation | Automates manual tasks, increases efficiency, lets employees focus on specialized roles. |

You see automation boosting productivity. DHL reported a 30% increase in warehouse productivity. Automation lets employees work on tasks that need problem-solving and critical thinking. You notice that companies like Amazon also gain from automated systems, making logistics faster and more reliable.

You see the california logistics centers network as a system that connects warehousing, distribution, and multimodal centers. You benefit from efficient operations like receiving, inventory management, and order fulfillment. This network drives economic growth, supports businesses, and creates jobs. You notice a strong push for sustainability, with zero-emission trucks and green programs shaping the future. As technology advances, you can build eco-friendly supply chains and prepare for new logistics strategies.

Future Trend | Impact on You |

|---|---|

Zero-emission trucking | Cleaner air, lower costs |

Electric vehicle adoption | Easier fleet upgrades |

Green incentives | Financial support |

You can use these trends to strengthen your logistics plans and stay ahead.

FAQ

What is a logistics center?

You find a logistics center as a place where goods are stored, sorted, and shipped. These centers use advanced technology to track products and help you deliver items quickly.

How does the network help my business?

You gain faster shipping, better access to global markets, and reliable supply chains. The network connects you to major ports, airports, and highways for efficient delivery.

Which regions have the largest logistics hubs?

You see the biggest hubs in Southern California, the Inland Empire, and the Bay Area. These regions offer large warehouses, advanced infrastructure, and strong transportation links.

What green initiatives do logistics centers use?

You notice centers using electric trucks, solar power, and energy-saving systems. Many aim for carbon neutrality by 2045. These efforts help you support cleaner air and a healthier environment.

Can I find job opportunities in logistics?

You discover many jobs in warehousing, transportation, and technology. Training programs help you learn new skills. The network creates thousands of jobs with competitive wages.

See Also

Streamlined Supply Chain Solutions Through American Logistics Services

Top-Notch Multi-Channel Fulfillment Offered By Premier Global Logistics

Addressing Rapid Logistics Needs In Los Angeles With PGL

Reasons Southern California eCommerce Businesses Prefer PGL Warehousing