Effective Green Supply Chain Strategies for Modern Businesses

Sustainability shapes how you run your business today. Green supply chain strategies help you use fewer resources, find eco-friendly suppliers, and cut waste. Green supply chain management means making choices that protect the planet while keeping your business strong. You gain lower costs, build trust, and meet new rules. See how these strategies benefit your company:

Aspect | Benefit |

|---|---|

Technology improves transparency and logistics, reducing your expenses. | |

Trust | Working with suppliers builds reliable and sustainable partnerships. |

Regulatory Compliance | Eco-friendly actions help you meet environmental laws. |

Key Takeaways

Implement green supply chain strategies to save money and reduce waste. Streamlining operations leads to lower costs and a smaller environmental footprint.

Choose eco-friendly suppliers to align your business with sustainable values. This builds trust with customers and enhances your brand reputation.

Adopt sustainable packaging practices to minimize waste. Use recyclable materials and design smaller packages to reduce environmental impact.

Utilize digital technologies like AI and blockchain to improve supply chain efficiency. These tools help track products, reduce waste, and enhance transparency.

Set clear sustainability goals and measure progress regularly. Use key performance indicators to track your impact on the environment and ensure compliance with regulations.

What Is Green Supply Chain Management

Definition and Scope

You can think of green supply chain management as a way to connect your business with environmental goals. This approach means you look at every step in your product’s journey, from design to delivery and even disposal. You focus on reducing waste and cutting carbon emissions. Many experts define green supply chain management as the integration of environmental considerations throughout the product lifecycle. You do not just focus on one part. You look at the whole process.

Green supply chain management covers more than just buying and selling. You include activities like reverse logistics, which means you manage the return and recycling of products at the end of their life. This helps you minimize waste and protect the environment.

Here is a quick look at the main components:

Component | Description |

|---|---|

Green Procurement | Sourcing materials and products with less environmental impact, such as recycled materials. |

Green Manufacturing | Using processes that reduce waste, energy use, and emissions. |

Green Distribution | Optimizing logistics to lower transportation emissions and fuel use. |

Reverse Logistics | Managing product returns and recycling at the end of their life cycle. |

You aim to integrate environmental thinking into every stage, from raw materials to end-of-life management. This approach helps you minimize negative impacts and maximize resource efficiency.

Business Benefits

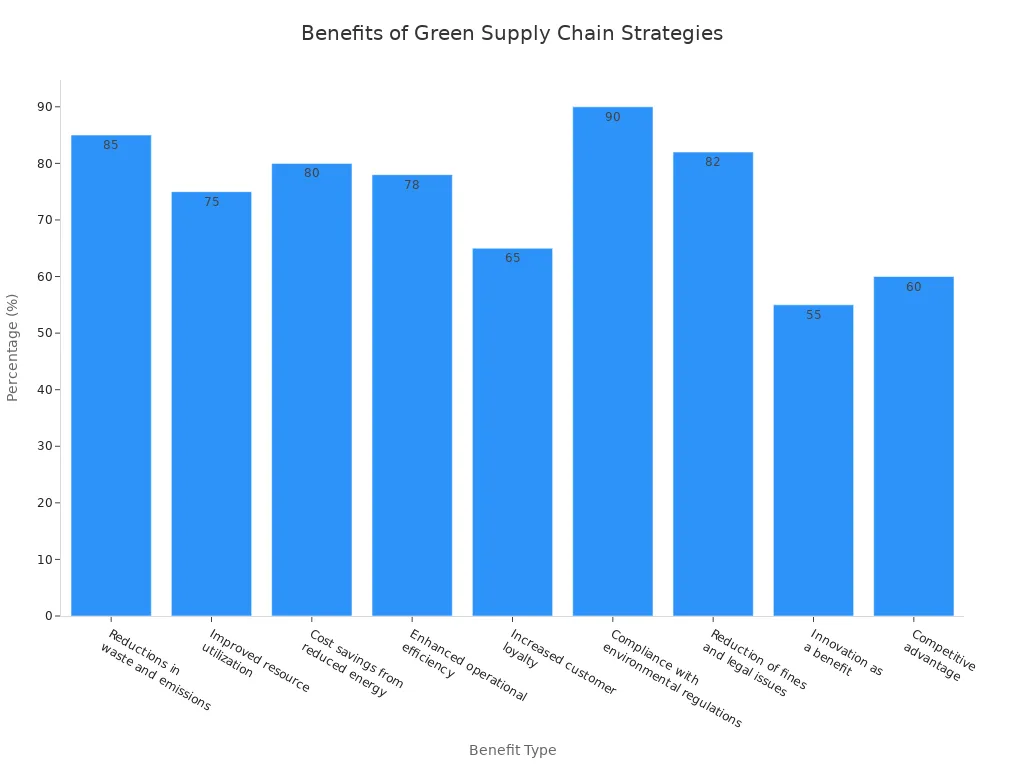

When you use green supply chain strategies, you see real business results. Companies that focus on reducing their environmental impact often improve their brand reputation. In fact, 82% of consumers prefer brands that share their values. You also avoid costly fines by meeting new compliance standards. Many businesses find that energy-efficient operations lead to lower costs over time.

You can save money by streamlining your supply chain and cutting waste.

VCNY Home, for example, reduced shipping package sizes and carbon emissions, saving money with new emissions strategies.

Today, 78% of global consumers want to buy from environmentally conscious brands.

You build trust with customers and prepare your business for the future by making these changes.

Core Green Supply Chain Strategies

Resource Efficiency

You can make your supply chain more efficient by using fewer resources and cutting waste. This helps you save money and protect the environment. Many companies use resource efficiency to meet emission targets and lower their carbon footprint. You can find areas to improve by looking at how much energy and materials you use. When you use resources wisely, you also work better with suppliers and lower your energy costs.

Use less energy and water in your operations.

Recycle and reuse materials whenever possible.

Work with suppliers to find ways to use fewer raw materials.

Tip: Try to follow circular economy principles. This means you recycle and reuse materials instead of throwing them away. Companies like Cascades focus on making all packaging recyclable, compostable, or reusable by 2030.

Eco-Friendly Sourcing

You can choose suppliers who care about the environment. This helps you build a supply chain that supports your values. Many global companies use eco-friendly sourcing to protect forests, support fair trade, and use renewable materials.

Pick suppliers who use recycled or renewable materials.

Ask for proof that suppliers follow environmental rules.

Set clear goals for buying sustainable products.

Here are some ways top companies use eco-friendly sourcing:

IKEA uses renewable or recycled materials to reduce the use of new resources.

Danone asks suppliers to avoid deforestation and respect human rights.

H&M Group builds strong partnerships with local suppliers and uses systems to check responsible purchasing.

Patagonia uses recycled materials and supports social responsibility.

You can also:

Add sustainability rules to your buying process.

Give rewards to teams that choose eco-friendly options.

Work with others in your industry to set standards.

Ask suppliers for detailed information about their practices.

Set SMART goals for buying sustainable products.

Sustainable Packaging

You can help the planet by using packaging that is easy to recycle or reuse. Most companies still use regular packaging, but some are making changes. Only 7% of companies have switched to sustainable packaging in the last five years. You can stand out by making this change.

Use recycled materials for boxes and containers.

Make packaging smaller and lighter to use less material.

Choose packaging that customers can recycle or compost.

Note: Cascades aims for all packaging to be recyclable, compostable, or reusable by 2030. You can follow their example to improve your green supply chain strategies.

Waste Reduction

You can cut waste by making smart choices about products and packaging. Start by designing products that use less material. Use right-sizing technology to avoid extra packaging. Switch to recyclable and biodegradable materials. Teach customers how to recycle packaging.

Use just-in-time delivery to avoid making too much product.

Use data and artificial intelligence to predict demand and avoid waste.

Work with suppliers to improve packaging and reduce waste during shipping.

Here are some proven methods for waste reduction:

Design products and packaging to prevent waste.

Minimize packaging with right-sizing technology.

Use recyclable and biodegradable materials.

Educate customers about recycling.

Use just-in-time delivery to avoid overproduction.

Use data to optimize inventory levels.

Work with suppliers to reduce waste in transportation.

Smarter Transport Planning

You can lower emissions by planning transport better. Many companies use route optimization to cut fuel use. They switch to electric or hybrid vehicles for short trips and use rail or sea for long distances. Some use electric cargo bikes for city deliveries. You can also work with partners who use green fleets and invest in carbon offset projects.

Strategy | Description |

|---|---|

Route Optimization | Plan the shortest routes to save fuel and time. |

Sustainable Transport Options | Use electric or hybrid vehicles and choose rail or sea for long trips. |

Last-Mile Delivery Solutions | Use electric bikes for city deliveries to cut emissions. |

Employee Engagement | Teach workers about commuting impacts and use carbon calculators. |

Collaboration with Partners | Work with logistics providers who use electric fleets. |

Carbon Offsetting | Invest in projects like planting trees to balance out emissions. |

Tip: Novo Nordisk uses renewable energy and aims for zero emissions by 2045. You can learn from their transport planning to improve your own green supply chain strategies.

Table: Leading Companies and Their Green Supply Chain Strategies

Company | Core Green Supply Chain Strategy |

|---|---|

Cascades | Circular business model; all packaging recyclable, compostable, or reusable by 2030. |

IKEA | Sustainable materials; zero fossil fuels by 2030; promotes sustainable lifestyles. |

Pact | Organic cotton; fair trade; carbon-neutral shipping. |

Novo Nordisk | 'Circular for Zero' program; zero emissions by 2045; 100% renewable energy. |

You can use these green supply chain strategies to make your business stronger and more sustainable. When you follow these steps, you save money, build trust, and help the planet.

Systems Thinking

Systems thinking helps you see your supply chain as a connected system. You do not look at each part alone. You study how every step affects the others. This approach lets you find better ways to protect the environment and improve your business. When you use systems thinking, you can solve complex sustainability problems and make smarter decisions.

You analyze how supply chain components connect and interact.

You improve how you measure environmental impacts.

You develop proactive sustainability plans by understanding the whole supply chain.

You address tough sustainability challenges with a broad view.

You boost performance in economic, environmental, and social areas.

Life Cycle Assessment

Life cycle assessment (LCA) gives you a clear picture of your product’s journey. You study each phase, from raw materials to disposal. This method helps you spot waste and find ways to save energy. LCA measures carbon footprints and shows where you can improve your supply chain.

You analyze every stage of a product’s life to find inefficiencies.

You measure environmental impacts, such as carbon emissions.

You use LCA to guide your sustainability plans and product design.

You reduce negative impacts by making changes based on LCA results.

You help your team create strategies that protect the environment.

Tip: Use LCA to compare products and choose the most sustainable option. This helps you make smart choices for your business and the planet.

Holistic Approach

A holistic approach means you look at your supply chain as one flowing operation. You do not manage each part separately. You align sourcing, manufacturing, delivery, and customer service to work together. This method helps you reach your sustainability goals and improve efficiency.

You add environmental goals to every phase of your supply chain.

You minimize waste and pollution.

You increase operational efficiency.

You improve your business performance.

Key elements of a holistic approach:

Transparency and accountability

Sustainable sourcing

Energy efficiency

Waste reduction and recycling

Life cycle management

Note: When you use a holistic approach, you create synergy across your supply chain. This leads to better results for your business and the environment.

Digital Technologies in Green Supply Chains

Digital technologies help you make your supply chain greener and more efficient. You can use tools like artificial intelligence, blockchain, and digital twins to track products, reduce waste, and cut emissions. These technologies give you real-time data and help you make smarter decisions. You can see how each part of your supply chain works and find ways to improve it.

Here is a table showing how different technologies support green supply chain management:

Technology | Role in Green Supply Chain Management |

|---|---|

Internet of Things (IoT) | Monitors supply chains in real time and improves traceability. |

Blockchain | Increases transparency and security in transactions and data sharing. |

Artificial Intelligence | Uses predictive analytics for smarter decision-making. |

Big Data Analytics | Provides insights for efficiency and sustainability. |

Digital Twins | Simulates and optimizes supply chain processes. |

Digital Twins

You can use digital twins to create a virtual copy of your supply chain. This tool lets you see how changes affect your operations before you make them. Companies using digital twins report a 15% drop in CO2 emissions. You get real-time visibility and can predict problems before they happen. Digital twins help you optimize processes and reduce waste.

You monitor supply chain operations as they happen.

You use predictive analytics to make better choices.

You find ways to save energy and cut costs.

Tip: Digital twins let you test ideas without risking your real supply chain.

Artificial Intelligence

Artificial intelligence helps you make smart decisions by analyzing large amounts of data. You can use AI to find the best routes for shipping and spot areas where you waste resources. Multimodal AI combines different types of data, like satellite images and environmental reports, to help you choose sustainable transport options. AI also supports circular economy efforts by optimizing how you use materials.

AI improves efficiency and predicts supply chain risks.

Large Language Models help you manage risks and make better decisions.

You can use AI to support recycling and reduce waste.

Blockchain Applications

Blockchain technology gives you a secure way to track products and share data. You can see where each item comes from and how it moves through your supply chain. Blockchain helps you monitor carbon emissions and prevent counterfeits. Only 18% of Chief Procurement Officers have full visibility of risks in their suppliers, so blockchain can help you improve transparency.

Evidence | Description |

|---|---|

Real-time tracking | You track products and actions at every stage, increasing transparency. |

Trust and accountability | Blockchain builds trust among partners, which is key for sustainability. |

Visibility issues | Most companies lack full visibility, making blockchain a valuable solution. |

Blockchain helps you audit vendors automatically.

You can give customers detailed information about your supply chain.

You reduce resource waste and streamline shipping.

Note: Blockchain makes it easier to eliminate forced labor and improve ethical sourcing.

Building Resilience

Risk Management

You need to build a supply chain that can handle surprises. Start by looking for risks in your supply chain. Many companies use risk assessments to spot problems early. Work closely with your suppliers to share information and solve issues together. Make sustainability part of your main business plan, not just a side project. This helps you stay strong when things change.

Here are some ways to manage risk in your green supply chain:

Adopt agile practices so you can react quickly to changes.

Stress test your supply chain to find weak spots.

Diversify your supplier base to avoid relying on just one source.

Use strategic inventory management to keep enough stock on hand.

Go local when possible to reduce shipping risks.

Tip: Companies that treat sustainability as a core business goal often bounce back faster from disruptions.

Adapting to Regulations

New rules about sustainability can affect your business. You must keep up with these changes to avoid fines and keep your reputation strong. For example, the Corporate Sustainability Due Diligence Directive (CSDDD) now makes supplier oversight a legal requirement. Other laws, like the EU Deforestation Regulation and Corporate Sustainability Reporting Directive (CSRD), also set strict standards.

70% of supply chain experts say ESG compliance is a top priority.

About 47.5% of North American companies have not added sustainability to their main supply chain plans.

73% of consumers will pay more for products if they trust the sourcing.

Stay ahead by tracking new regulations and training your team. Make sure your suppliers follow the rules, too.

Future-Proofing

You can prepare your supply chain for the future by setting clear sustainability goals. Get your leaders involved and check how your suppliers perform on environmental issues. Choose partners who care about the planet. Use green logistics and carbon offset programs to lower your impact.

Invest in circular supply chains that reuse and recycle materials.

Pick low-carbon carriers for shipping.

Diversify your supply chain to handle risks better.

Collect data to measure your progress and adjust your plans.

Note: When you future-proof your supply chain, you protect your business and help the environment at the same time.

Implementing Green Supply Chain Strategies

Setting Goals

You start by setting clear goals for your supply chain. Align these goals with your company’s main objectives. For example, you might want to lower your carbon footprint or use more biodegradable packaging. You can set a target like sourcing 75% of your packaging from vendors who use biodegradable materials within one year. When you set measurable goals, you make it easier to track progress and show results.

Supplier Engagement

You need strong partnerships with your suppliers to succeed. Work together to create new solutions and share environmental guidelines. Some companies, like GE and IBM, team up with suppliers to build better systems. You can use suppliers as force multipliers by asking them to follow environmental management practices. Focus on suppliers who make up most of your spending. Keep requests simple so you do not overwhelm them. Build trust by explaining how you use their data. Help smaller suppliers with training and support.

Best Practice | Description |

|---|---|

Collaborate to innovate | Work with suppliers to create new environmental solutions. |

Use suppliers as multipliers | Ask suppliers to maintain environmental management systems. |

Measuring Progress

You measure your progress using key performance indicators (KPIs). These KPIs help you see how well your green supply chain strategies work. Track things like greenhouse gas emissions, energy use, and waste reduction. You can also look at supplier engagement and fair labor practices. Use global standards such as the Global Reporting Initiative (GRI) and Carbon Disclosure Project (CDP) to guide your reporting.

Metric Category | Key Metrics |

|---|---|

Carbon & Energy Metrics | GHG Emissions, Energy Efficiency |

Ethical Sourcing & Social Responsibility | Supplier Engagement, Fair Labor Practices |

Circular Economy & Waste Reduction | Product Lifecycle, Waste Diversion |

Financial & ESG Performance | Financial Impact of Sustainability |

Overcoming Challenges

You may face challenges when you start. High initial costs can make it hard to invest in new equipment or training. Begin with small changes and build up over time. Mistakes can happen as you learn new systems, but automation helps reduce errors. Complex logistics can slow you down, so consider using third-party providers to improve efficiency. Roll out green initiatives in phases and show the return on investment at each stage to get support for bigger projects.

Tip: Start simple and grow your efforts. Show results early to build support for your green supply chain strategies.

You can make your business stronger and greener by using smart supply chain strategies. These steps help you cut waste, save money, and build trust with customers. The table below shows how these strategies boost both sustainability and efficiency:

Strategy | Sustainability Impact | Efficiency Impact |

|---|---|---|

Circular Supply Chains | Less waste, lower environmental harm | Big cost savings |

Supplier Engagement | Better transparency, higher quality | Up to 20% more efficient, 5-10% cost cut |

Proactive Sustainability | 15% fewer greenhouse gases | 12% less energy used |

When you act now, you help your business and the planet.

Work with others to cut emissions

Set bold goals for 2030

Invest in new ideas and partnerships

Support suppliers with science-based targets

Use circular supply chains for lasting results

FAQ

What is a green supply chain?

You use a green supply chain to lower pollution and waste. You choose eco-friendly suppliers and materials. You focus on recycling and saving energy. This helps your business protect the environment.

How do you measure green supply chain success?

You track key numbers like energy use, waste, and carbon emissions. You check supplier practices. You use tools such as the Global Reporting Initiative (GRI) and Carbon Disclosure Project (CDP).

Tip: Set clear goals and review your progress every month.

Why should you work with eco-friendly suppliers?

You build trust with customers. You meet new laws. You lower risks in your supply chain. You also help the planet by choosing suppliers who care about the environment.

Benefit | Description |

|---|---|

Trust | Customers value green choices |

Compliance | You meet legal requirements |

Risk Reduction | Fewer supply chain problems |

What are common challenges in going green?

You may face high costs at first. You need to train your team. You must find reliable suppliers. You also need to track your progress. Start small and grow your efforts over time.

High initial costs

Training needs

Supplier selection

Tracking progress

See Also

Key Strategies for Effective Global Logistics Operations

Simplifying Supply Chain Optimization with U.S. Logistics Solutions

PGL’s Knowledge Ensures Smooth Operation of U.S. Supply Chains

Point-to-Point Logistics: Enhancing Efficiency Across the Globe

Transforming International Operations with Innovative Logistics Strategies