What Are the Main Components of a Logistics Chain in 2025

The logistics chain in 2025 includes five key components: transportation, warehousing, packaging, inventory management, and information. Transportation moves products between locations. Warehousing stores goods safely. Packaging protects items during transit. Inventory management tracks stock levels. Information systems help you coordinate each step and respond to customer needs quickly.

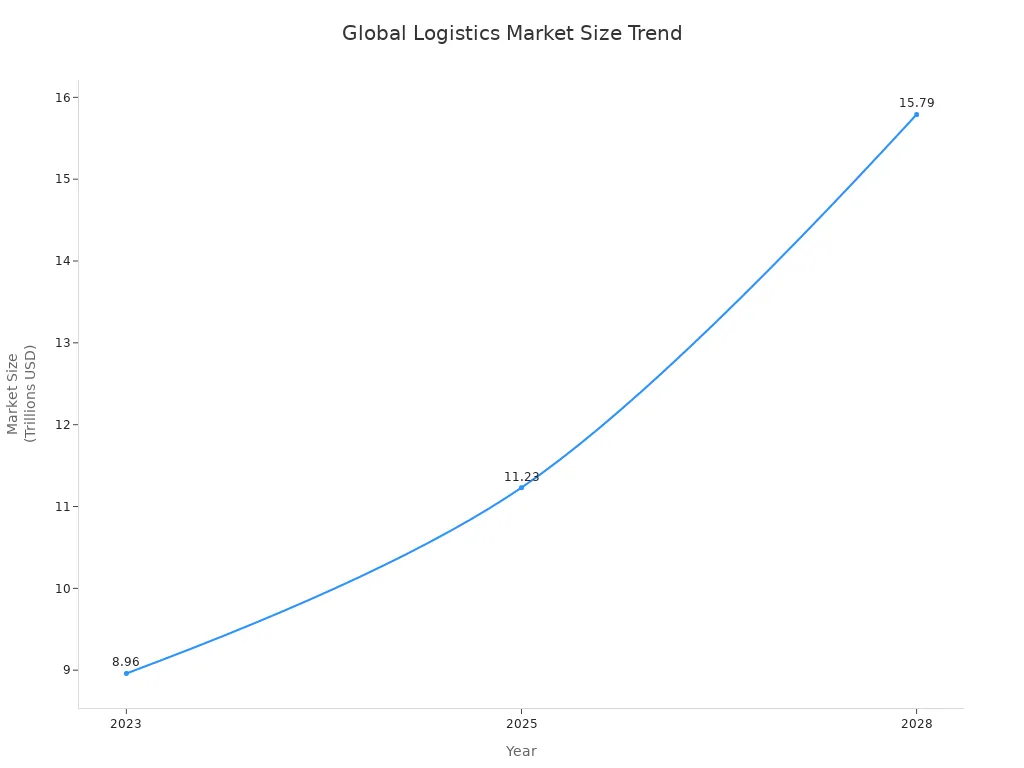

Understanding logistics chain components and processes helps you improve supply chain performance. Technology like AI and cloud-based tools make logistics more efficient and flexible. The global logistics market shows strong growth, reaching $11.23 trillion by 2025.

Year | Market Size (Trillions USD) | Growth from Previous Year (%) |

|---|---|---|

2023 | 8.96 | N/A |

2025 | 11.23 | 25.4 |

2028 | 15.79 | 40.5 |

AI and predictive analysis help you plan better and handle uncertainty, making logistics chains more resilient.

Key Takeaways

The logistics chain in 2025 consists of five key components: transportation, warehousing, packaging, inventory management, and information systems. Understanding these helps improve supply chain performance.

Automation and AI are transforming logistics by enhancing efficiency and flexibility. Companies can respond quickly to customer needs and reduce costs through these technologies.

Sustainable practices, like using electric vehicles and eco-friendly packaging, are essential for modern logistics. They not only help the environment but also lower operational costs.

Real-time data and analytics improve visibility and control in logistics. This allows for better planning, timely deliveries, and enhanced customer satisfaction.

To optimize logistics, businesses should adopt real-time tracking, offer flexible delivery options, and streamline inventory management to meet customer demands effectively.

Logistics Chain Components and Processes

The logistics chain components and processes form the backbone of every supply chain in 2025. You need to understand how each part works to deliver products quickly, safely, and efficiently. Let’s look at each component and see how they connect to meet customer needs.

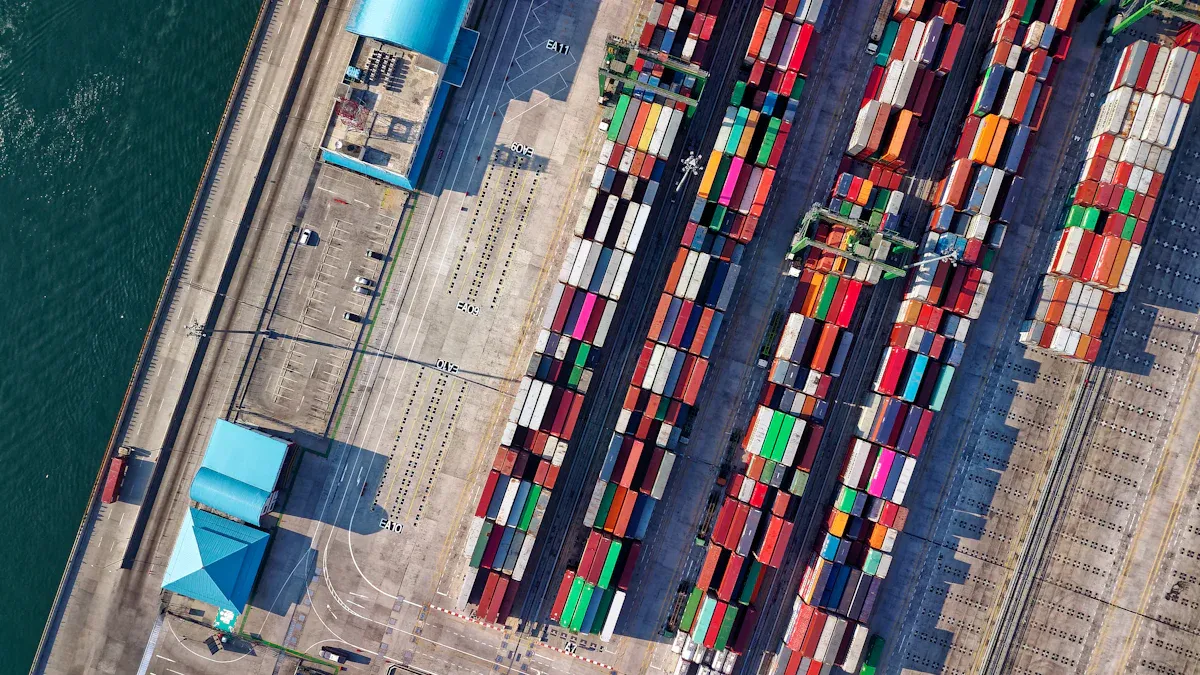

Transportation

Transportation links every part of the supply chain. You use it to move goods from suppliers to manufacturers, then to distributors, retailers, and finally to customers. This step forms the foundation of logistics chain components and processes.

Transportation connects suppliers, manufacturers, distributors, retailers, and consumers.

Efficient transportation prevents stockouts and overstocking.

Timely deliveries keep customers happy and loyal.

You will find several transportation modes in 2025:

Roadways dominate because they reach almost everywhere and cost less.

Airways grow fast, helping you deliver goods quickly.

Railways and waterways play roles, but they have smaller market shares.

People working in transportation need strong analytical skills, good communication, and problem-solving abilities. They also use advanced software to plan and track shipments.

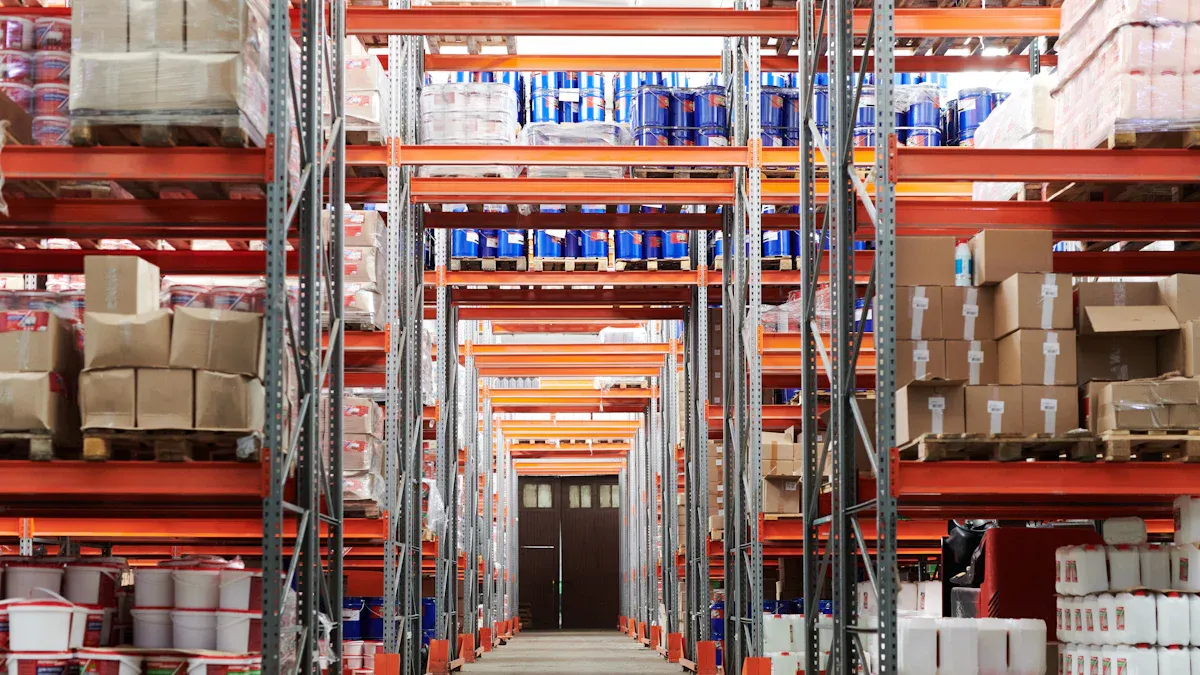

Warehousing

Warehousing gives you a safe place to store goods until you need them. Good warehouse management helps you deliver orders on time and avoid running out of stock.

Efficient warehouses help you deliver products quickly, which makes customers happy.

Better inventory management lowers costs by reducing extra stock and shortages.

Companies like Amazon use automation in warehouses to gain a competitive edge.

When you place warehouses in smart locations, you shorten delivery times and make restocking easier. Automation, like robotic arms and guided vehicles, speeds up order picking and reduces mistakes.

Packaging

Packaging protects your products during shipping and storage. In 2025, you see many new packaging solutions that help the logistics chain components and processes run smoothly.

Sustainable Packaging Materials: You use biodegradable, recyclable, and reusable materials to help the environment.

Smart Packaging Technologies: RFID chips and sensors let you track packages and keep supply chains transparent.

Modular and Standardized Packaging: Uniform designs save space and make shipping more efficient.

Active Packaging Solutions: These keep products fresh and reduce waste.

Automation in Packaging Processes: Machines pack goods faster and more accurately.

Advanced Protective Packaging: Stronger materials keep items safe from damage.

3D Printing for Custom Packaging: You can create packaging that fits products perfectly, reducing waste.

Aspect | Details |

|---|---|

Market Growth | The logistics-optimized packaging market is set to grow quickly from 2025 to 2034. |

Efficiency Focus | Companies focus on making packaging more durable and sustainable. |

E-commerce Impact | Online shopping increases demand for lightweight, reusable, and tough packaging. |

Technological Integration | Biodegradable materials, automation, and RFID tracking improve security and cut waste. |

Regional Leadership | Asia Pacific leads in returnable packaging solutions. |

Reusable Packaging Containers (RPCs) lower greenhouse gas emissions by up to 62% compared to cardboard. You can reuse them over 100 times, which cuts waste and costs, especially for fresh food.

Inventory Management

Inventory management helps you keep the right amount of stock at all times. This part of the logistics chain components and processes makes sure you do not run out of products or waste money on extra stock.

Technique | Description |

|---|---|

ABC Analysis | Sorts inventory by value and popularity to meet customer demand. |

Perpetual Inventory Management | Tracks inventory as it arrives for real-time stock updates. |

Economic Order Quantity (EOQ) | Finds the best order size to lower total costs. |

Safety Stock Inventory | Keeps extra goods to handle supply chain problems. |

Batch Tracking | Monitors expiration dates and finds defective items. |

Dropshipping | Ships products straight from suppliers, saving storage costs. |

FIFO and LIFO | FIFO sells older stock first; LIFO sells newer stock first for tax reasons. |

Just-in-time Inventory Management | Orders items only when needed to avoid dead stock. |

Modern inventory systems use real-time tracking, automation, and analytics. These tools help you:

Cut storage costs by 15-30%.

Lower labor costs by 20-35%.

Information Systems

Information systems help you manage and share data across the logistics chain components and processes. These systems make your supply chain faster and more reliable.

Information systems manage the flow of information in logistics.

They boost efficiency and performance.

Data-driven logistics shape the future of the industry.

Real-time data and analytics give you better visibility and control. You can plan and coordinate shipments, reduce delays, and keep customers informed with accurate updates. Technologies like 5G, AI, and machine learning help you predict problems and fix them before they grow. Autonomous vehicles and drones, with real-time tracking, make last-mile delivery faster and cheaper.

When you combine transportation, warehousing, packaging, inventory management, and information systems, you create a strong logistics chain. Automation and AI help you respond quickly to customer needs, focus on sustainability, and keep your supply chain flexible. Each part supports the others, making sure you deliver the right product to the right place at the right time.

Order Fulfillment and Customer Service

Fulfillment Steps

Order fulfillment starts when you receive a customer order. You pick products from storage, pack them, and ship them to the customer. You need to follow each step carefully to avoid mistakes and delays. In 2025, you use automation and technology to speed up these steps and improve accuracy. You track orders in real time and use centralized systems to manage inventory. This helps you deliver products faster and with fewer errors.

Aspect | Impact on Delivery Speed and Accuracy |

|---|---|

Efficient Order Management | Streamlines operations, reducing delays and errors. |

Automation | Minimizes human input, enhancing accuracy and speed. |

Centralized Operations | Improves inventory control and order accuracy. |

Technology-Driven Tracking | Ensures timely processing and shipping of orders. |

Real-Time Reporting | Provides oversight to prevent errors in the fulfillment process. |

You avoid problems like lack of inventory accuracy and error-prone workflows by using automated systems. Automation also speeds up picking, packing, and shipping tasks.

Customer Impact

Customer service plays a big role in logistics. You keep customers happy by delivering orders on time and making sure products arrive in good condition. You communicate clearly and provide updates about order status. Customers want fast, accurate, and transparent service.

Timely deliveries prevent frustration and boost satisfaction.

Accurate orders help you build trust and a good reputation.

Clear communication reduces uncertainty and sets expectations.

Products in good condition keep customers coming back.

Cost-efficient shipping encourages repeat business.

You see that the quality of customer service directly affects customer satisfaction. You need to focus on every detail to meet customer needs.

Service Innovations

In 2025, you use new service innovations to improve customer experience. You offer personalized delivery options and keep customers informed about their orders. Automation helps you process orders quickly. AI lets you understand customer preferences and offer better services. You also use eco-friendly practices to attract customers who care about the environment.

Innovation Type | Description |

|---|---|

Personalized Services | Tailored delivery options and transparent communication regarding order status to meet individual needs. |

Automation | Streamlining processes to enhance efficiency and reduce delivery times. |

AI Integration | Utilizing data analytics to understand customer preferences and behaviors for better service offerings. |

Sustainability | Implementing eco-friendly practices to appeal to environmentally conscious consumers. |

You use technology for real-time issue resolution and build a positive brand image through excellent customer service. Strong customer service gives you a competitive advantage and helps you form long-term partnerships. When you combine logistics chain components and processes with these innovations, you create a better experience for your customers.

Technology and Trends in Logistics 2025

Tech Trends

You see technology changing logistics faster than ever in 2025. Automation, artificial intelligence (AI), and real-time tracking help you move goods more efficiently. AI agents now work alongside people, making decisions and solving problems quickly. Drones and robots check inventory, reducing mistakes and saving time. You use decision intelligence tools to analyze data and choose the best routes or suppliers. New systems give you real-time updates, so you always know where your shipments are.

Description | |

|---|---|

Agentic AI | AI agents boost supply chain efficiency by working independently. |

Autonomous Data Collection | Drones and robots speed up inventory checks and reduce errors. |

Decision Intelligence (DI) | AI and analytics automate smart decision-making. |

Ambient Invisible Intelligence | Real-time monitoring gives you full supply chain visibility. |

Augmented Connected Workforce (ACWF) | Digital tools help workers make better decisions faster. |

AI helps you cut costs and reduce risks by over 67%. Most supply chain companies now use AI to track equipment, predict maintenance, and spot delivery problems before they grow.

Sustainability

Sustainability shapes how you run logistics in 2025. Companies use electric trucks and solar-powered warehouses to lower emissions. For example, IKEA’s Sydney warehouse gets 70% of its energy from solar power. The International Maritime Organization enforces rules to cut greenhouse gases from ships. Green logistics not only helps the planet but also saves money. Studies show that sustainable actions can lower labor costs by up to 70%. You focus on reducing waste and using renewable energy to create long-term value.

Green logistics helps you protect the environment and improve efficiency at the same time.

Digital Integration

Digital integration connects every part of your logistics chain. Cloud-based platforms let you share data in real time with partners and customers. You use dashboards to track shipments and manage risks together. Digital tools help you respond quickly to changes and make better decisions. You also improve customer service with real-time tracking and faster communication. Digital integration gives you a competitive edge by making your operations faster, cheaper, and more reliable.

Real-time data sharing boosts teamwork and efficiency.

Digital platforms help you adapt quickly to market changes.

Stronger decision-making comes from better data visibility.

You face some challenges, like system integration and cybersecurity risks, but digital tools help you stay ahead in a fast-changing world.

You see how each logistics chain component supports the others. When you optimize transportation, warehousing, packaging, inventory, and information, your supply chain works better. Staying updated on new technology and trends helps you stay ahead. Many companies use automation, AI, and IoT to boost efficiency and cut costs. To improve your logistics in 2025, try these steps:

Use real-time analytics and IoT sensors for better tracking.

Offer flexible and reliable delivery options.

Switch to electric vehicles and eco-friendly packaging.

Plan for disruptions and diversify suppliers.

Streamline returns and keep customers informed.

FAQ

What technology helps you track shipments in 2025?

You use real-time tracking tools powered by AI and IoT sensors. These systems show you where your shipments are at any moment.

Tip: Check your dashboard for instant updates.

How do you make logistics more sustainable?

You switch to electric vehicles, use solar-powered warehouses, and choose reusable packaging.

Electric trucks

Solar energy

Reusable containers

🌱 These steps help you lower emissions.

Why is inventory management important?

Inventory management helps you avoid running out of products and wasting money on extra stock. You keep your supply chain efficient and meet customer demand.

Good inventory control means fewer mistakes and happier customers.

What is the role of automation in logistics?

Automation speeds up tasks like picking, packing, and shipping. You use robots and smart machines to reduce errors and save time.

Faster order processing

Fewer mistakes

Lower costs

See Also

Simplifying Supply Chain Efficiency With U.S. Logistics Services

Key Strategies for Effective Management of Global Logistics

Optimized Inventory Management Through Leading Global Logistics Warehousing

Enhanced Inventory Control Using Top Global Logistics Warehousing

Boosting International Operations With Cutting-Edge Logistics Solutions