What Are Modern Shipping Hub Operations and How Do They Work

Modern shipping hub operations help you move goods quickly and accurately across the globe. You see real-time tracking and automated systems working together to manage inventory and speed up order processing. Strategic locations and robotics reduce lead times and lower costs. Advanced analytics give you better forecasts and help optimize every step. These processes make your supply chain more efficient and reliable.

Key Takeaways

Modern shipping hubs streamline the movement of goods, ensuring faster and more accurate deliveries.

The hub-and-spoke model optimizes routes, reduces costs, and enhances efficiency in logistics.

Automation and real-time tracking technology minimize errors and improve order processing speed.

Cross-docking reduces storage time, leading to quicker deliveries and better inventory control.

Intermodal connections at shipping hubs support sustainability by lowering carbon emissions and optimizing logistics.

Modern Shipping Hub Operations Overview

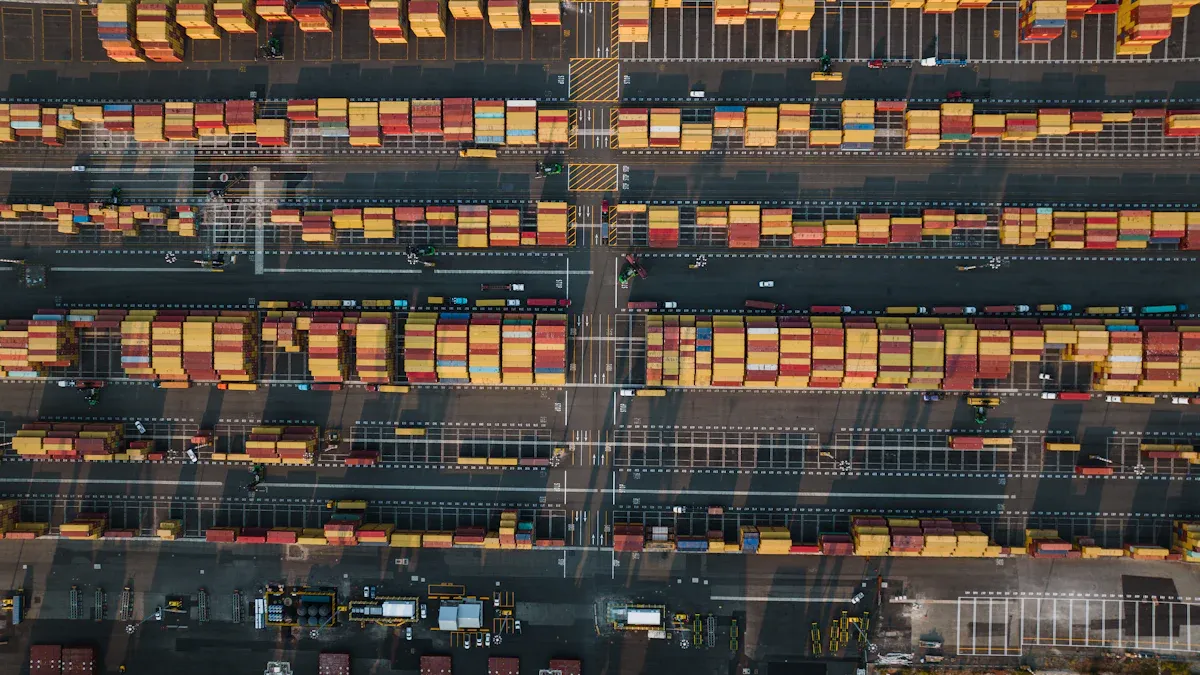

What Is a Shipping Hub

You interact with shipping hubs every time you order products online or see goods move across continents. A shipping hub is a special area where companies handle transportation, sorting, dispatch, and distribution of goods for both national and international delivery. These hubs sit near big cities or major transport points like ports and airports. Their location helps companies move products faster and more efficiently.

Shipping hubs include offices, warehouses, and distribution centers. You see workers and machines working together to receive shipments, store inventory, process orders, pick items, pack boxes, and send out deliveries. Some hubs even offer extra services like product assembly or labeling. Quality control teams check goods for damage before they leave the hub. You benefit from these activities because they make sure your packages arrive safely and on time.

Tip: Shipping hubs use advanced tracking and sorting systems. This technology helps companies manage cargo accurately and deliver orders quickly.

Here is a table that shows how modern shipping hub operations stand out compared to traditional logistics centers:

Feature | Modern Shipping Hubs | Traditional Logistics Centers |

|---|---|---|

Centralized Operations | Facilitates efficient sorting and distribution | Often less centralized, leading to inefficiencies |

Scalability | Handles large volumes and diverse product types | Limited scalability due to infrastructure constraints |

Technology Integration | Utilizes advanced systems for automation and data management | May rely on outdated systems, lacking automation |

You notice that modern shipping hub operations use automation and data management to handle more products and work faster than older logistics centers.

Hub-and-Spoke Model

Modern shipping hub operations rely on the hub-and-spoke model to move goods efficiently. Imagine a bicycle wheel. The hub sits at the center, and the spokes connect the hub to the rim. In shipping, the hub acts as the main point where goods arrive, get sorted, and then travel out along the spokes to their final destinations.

You see this model in action when cargo from different places arrives at a central hub. Workers and machines sort the cargo, then send it out to smaller locations or directly to customers. This system helps companies plan better routes, use bigger trucks or ships for long trips, and save money.

Here is how shipping hubs help move goods between regions and continents:

Shipping hubs optimize transportation efficiency by consolidating cargo from various sources, allowing for better resource utilization.

They reduce transit times by strategically positioning near major transportation routes, facilitating faster delivery.

Hubs enhance cargo management with advanced tracking and sorting systems, ensuring accurate handling and delivery.

You can follow the journey of a package using these steps:

Cargo leaves the origin but may not travel directly to the destination.

The cargo arrives at a transshipment hub, where workers store and sort it.

Containers transfer to different vehicles for the next part of the journey.

The hub-and-spoke model brings several benefits to shipping operations. Here is a table that explains these advantages:

Benefit | Description |

|---|---|

Efficient Route Planning | Centralized hubs allow for optimized route planning, reducing point-to-point routes. |

Reduced Labor Costs | Fewer workers are needed to manage inventory and process shipments due to consolidation. |

Lower Transportation Costs | Utilizing larger capacity vehicles for long-haul portions minimizes per mile transportation costs. |

Improved Inventory Management | Centralized stock management reduces overhead costs associated with multiple distribution centers. |

You experience faster deliveries, lower costs, and better order tracking because companies use the hub-and-spoke model. Modern shipping hub operations make global logistics smoother and more reliable for everyone.

Core Processes and Components

Consolidation and Sorting

You see consolidation and sorting as the backbone of modern shipping hub operations. When shipments arrive, workers and machines receive and profile each item. They check the SKU and categorize shipments to make sure everything matches the order. You watch as smaller shipments combine into larger loads, which helps save money and space.

Here is how the consolidation and sorting process works:

You receive inbound shipments and verify each item.

The hub stores items safely to keep them in good condition.

Smaller shipments combine to create full truckloads.

Outbound loading and dispatch planning maximize trailer capacity.

You benefit from advanced logistics technology that tracks and manages inventory. Smart algorithms help consolidate orders based on geography and load compatibility. Hubs organize and coordinate shipment collections, which lets companies negotiate better rates with carriers. A consolidated warehouse collects small shipments from different suppliers, sorts them by destination, and combines them into larger truckloads for cost-effective shipping.

Modern shipping hub operations use technology to improve sorting accuracy and speed. You see vision systems with cameras and AI scan and identify items. Smart control systems manage item flow using real-time data. Warehouse management system integration gives you real-time inventory visibility and faster replenishment cycles. Automated sorting machines and high-speed sortation systems process parcels quickly and reduce errors. Dimension-capturing systems provide accurate weight and size data, streamlining operations and reducing human error.

Tip: Automated sorting and real-time tracking help you get your packages faster and with fewer mistakes.

Cross-Docking and Order Processing

You experience faster deliveries because of cross-docking in modern shipping hub operations. Cross-docking means workers unload goods from incoming shipments and load them directly onto outbound transport with little or no storage time. This process streamlines the flow of goods and reduces costs.

Here are the main benefits of cross-docking:

Benefit | Description |

|---|---|

Cost Reduction | Cross-docking minimizes storage time, reducing warehousing costs for space and labor. |

Speed of Delivery | The method allows for faster delivery to customers by streamlining the flow of goods. |

Inventory Control | Reduces the risk of overstocking or stockouts by better controlling inventory levels. |

You see order processing improve because cross-docking reduces handling and storage. This practice fosters collaboration among supply chain partners. You notice that companies pick, pack, and prepare orders more efficiently. Real-time visibility plays a big role in this process. You track your order from the moment it enters the hub until it leaves for delivery.

Real-time visibility impacts order processing in several ways:

KPI Category | Key Metrics | Impact Areas |

|---|---|---|

Order Accuracy | Order fill rate, picking accuracy | Efficiency in operations |

Delivery Performance | On-time delivery rate | Customer satisfaction |

Inventory Management | Turnover rate, stockouts | Better resource use |

Customer Service | Resolution time, satisfaction score | Quality of service |

Cost Efficiency | Cost per order, labor efficiency | Financial performance |

You benefit from higher order accuracy and faster deliveries. On-time delivery performance improves by up to 25% with better supply chain visibility. Inventory turns increase by up to 30% when hubs use accurate demand forecasting. Companies often see logistics cost reductions of 10-20% in the first year after implementing real-time tracking.

Intermodal Connections

You rely on intermodal connections at shipping hubs to move goods between ships, trucks, trains, and barges. Modern shipping hub operations make these transfers smooth and efficient. Ports like Duisburg, South Louisiana, Virginia, Houston, Long Beach, and Memphis use advanced technology to connect different transportation modes.

Here is a table showing how major ports facilitate intermodal connections:

Port Name | Description |

|---|---|

Port of Duisburg | Integrates barge and rail systems, handling millions of containers with advanced technology. |

Port of South Louisiana | Transfers cargo between river barges, ocean ships, and railroads. |

Port of Virginia | Offers facilities for transferring goods between ships, trucks, and trains. |

Port of Houston | Provides comprehensive intermodal services for Gulf cargo. |

Port of Long Beach | Features advanced container terminals and rail/truck connectivity. |

Port of Memphis | Specializes in barge-to-truck transshipment for urban deliveries. |

You see automated tracking systems and RFID technology ensure smooth cargo transitions. The Port of New Orleans uses sophisticated technology to improve efficiency in cargo transfers. These systems reduce human error and speed up processing times.

Intermodal connections offer several advantages:

You help reduce carbon emissions by up to 75% compared to road transport alone.

You optimize logistics costs by using the best transportation mode for each leg of the journey.

You support global sustainability goals by choosing greener shipping options.

You may face challenges with intermodal connections. Delays in one mode can disrupt the whole shipment process. Switching between transportation modes can add extra fees. Some areas lack specialized terminals, which limits shipping options. Navigating regulations can create confusion and delays, especially across borders.

Note: Intermodal connections make global shipping more efficient, but you need careful planning to avoid delays and extra costs.

You see how modern shipping hub operations use consolidation, sorting, cross-docking, and intermodal connections to deliver goods quickly and accurately. Technology and real-time visibility help you track shipments, improve order processing, and support sustainable logistics.

Types of Shipping Hubs and Technology

Seaports, Airports, Rail Terminals

You find three main types of shipping hubs: seaports, airports, and rail terminals. Each plays a unique role in moving goods around the world.

Seaports act as major gateways for global trade. You see them handle huge ships and containers every day. Seaports do more than just load and unload cargo from ships. They also transfer goods between ships, trucks, and trains. This process, called transshipment, helps connect local deliveries with long-distance shipping. Seaports often serve as both water and land terminals. You notice warehouses, repair shops, and other services that support cargo movement. These features make seaports vital for linking regions and supporting the global economy.

Airports move goods quickly over long distances. You rely on them for fast delivery of high-value or time-sensitive products. Airports use advanced security and tracking systems to keep shipments safe and on schedule.

Rail terminals connect cities and regions by land. You see them handle large volumes of goods, especially heavy or bulky items. Rail terminals often face challenges because many sit in old locations where cities have grown around them. Their shape and track layout can limit how much cargo they handle. Rail operations also need special yards to assemble and break down trains, which adds complexity.

Note: Each hub type faces unique challenges. Rail terminals, for example, may struggle to expand due to their location and design.

Technology in Hub Operations

You benefit from advanced technology every time you receive a package. Automation speeds up work at shipping hubs. Machines sort packages, load containers, and track shipments. This reduces mistakes and helps your orders arrive faster. Real-time tracking gives you updates on your shipment’s location and status.

Here are some ways technology improves hub operations:

Automation streamlines workflows, so packages move through hubs quickly.

Fewer errors occur, which means you get the right order.

Real-time tracking lets you and companies see where shipments are at any moment.

Teams can focus on planning and solving big problems instead of fixing small mistakes.

Real-time data also helps companies avoid delays. You get timely updates about weather or congestion at ports. This allows businesses to plan ahead and keep your deliveries on time. With over 80% of global trade moving through these hubs, technology plays a key role in meeting your expectations for fast and reliable shipping.

Benefits, Challenges, and Trends

Advantages for Logistics

You gain many advantages from modern shipping hub operations. These hubs help you move goods faster and more accurately. You see lower costs because companies combine shipments and use resources better. You benefit from advanced technology that improves sorting and tracking. Here are some key benefits:

Centralized hubs make operations smoother and reduce mistakes.

You get faster deliveries, especially for items that need quick transport.

Companies save money by combining loads and using fewer trucks.

Specialized equipment and automation speed up cargo handling.

Hubs connect different transport modes, making global supply chains work better.

Security measures at hubs lower risks for your shipments.

Major hubs create jobs and help local economies grow.

You see companies adjust quickly to market changes and scale up as needed.

Businesses meet your expectations even during busy times or disruptions.

Tip: Shipping hubs help companies keep costs low and deliveries on time, which means you get better service.

Operational Challenges

You may notice some challenges in shipping hub operations. Managers must handle staff, organize space, and deal with busy seasons. Transportation management can become complex and costly. Congestion at hubs causes delays in loading and unloading cargo. These delays disrupt delivery schedules and can lead to higher prices for goods. Sometimes, shortages stop production in factories. You see longer wait times for products when vessels cannot dock quickly. Businesses pay extra fees when shipments get stuck. These problems can affect customer satisfaction and company profits.

Future Trends

You will see new trends shaping shipping hubs. Automation is growing fast. Hubs use robots, drones, and automated vehicles to move goods quickly. AI-powered systems help pick and sort items with high accuracy. Predictive forecasting keeps inventory levels just right and reduces waste. Companies use electric and hydrogen-powered fleets to cut emissions. Real-time route optimization helps reduce delays and pollution. Many hubs now track their carbon footprint and invest in renewable energy.

Trend | Description |

|---|---|

Automated Guided Vehicles & Drones | Speed up order fulfillment and improve accuracy. |

Automated Storage Systems | Use vertical lifts and carousels for better storage efficiency. |

AI-Powered Picking | Use robotics and computer vision for faster operations. |

Predictive Forecasting | Keep inventory levels optimal and reduce waste. |

Electric & Hydrogen Fleets | Lower emissions and improve sustainability. |

Route Optimization | Adjust delivery routes to save time and energy. |

Carbon Tracking & Offsetting | Invest in clean energy and balance emissions. |

You also see companies respond to new environmental rules. For example, California ports require zero-emission trucks by 2035. European laws push companies to report climate goals and use cleaner fuels. Big brands like DHL and Walmart work together to make shipping greener. You benefit from these changes through cleaner air and more reliable deliveries.

You depend on modern shipping hub operations to keep goods moving quickly and accurately worldwide. These hubs use smart technology and automation to boost efficiency, but they also face challenges like congestion and last-mile delivery limits. As you look ahead, you see new trends shaping logistics.

Technology | Impact on Hubs |

|---|---|

Digital Tools | Faster, data-driven decisions |

Robotics | Quicker picking and packing |

AI | Better route planning and forecasting |

Sustainability | Cleaner, greener shipping |

You benefit from faster deliveries and better tracking.

Companies work hard to meet your need for speed and reliability.

The future will bring even more innovation to global supply chains.

Appreciate the complex work behind every package you receive.

FAQ

What is the main job of a shipping hub?

You see shipping hubs collect, sort, and send out goods. Workers and machines help move packages quickly. Hubs make sure your orders travel safely from one place to another.

How does technology help shipping hubs work better?

You benefit from automation and real-time tracking. Machines sort packages faster. Computers show where your shipment is at any moment. Technology helps you get your orders on time.

Why do companies use the hub-and-spoke model?

You see companies use this model to save money and time. Hubs let them combine shipments and plan better routes. This system helps you get faster deliveries.

What happens if a shipping hub gets too busy?

You may notice delays. Trucks and ships wait longer to load or unload. Sometimes, your package arrives late. Companies work hard to fix these problems and keep things moving.

Can shipping hubs help protect the environment?

You support greener shipping when hubs use electric trucks and trains. Many hubs track carbon emissions and choose cleaner energy. These changes help you enjoy cleaner air and safer communities.

See Also

Effective Strategies by PGL for Efficient U.S. Warehousing

Enhancing Global Operations Through Innovative Logistics Solutions

Boosting Global Efficiency with Point-to-Point Logistics Systems

PGL's Port-Side Support Ensures Quick and Easy Shipping

PGL's Strategic Warehousing in Miami and LA for Supply Chain Success