How to Optimize Logistics Network Performance for Maximum Efficiency

You can achieve optimized logistics network performance by using a systematic, data-driven approach. Logistics network optimization means improving how goods move through your supply chain to save money and meet customer needs. Studies show that you can reduce logistics costs by 10 to 20 percent when you optimize your network. This process helps you deliver products faster, cut expenses, and provide better service. When you streamline routes and warehouse locations, you respond to customers more quickly and improve their satisfaction.

Key Takeaways

Optimize your logistics network by mapping its structure. This helps identify key players and potential risks, leading to better decision-making.

Use data analytics to find bottlenecks in your supply chain. Addressing these issues can significantly improve performance and customer satisfaction.

Set clear KPIs to measure logistics performance. Tracking these indicators helps you benchmark against industry standards and identify areas for improvement.

Leverage technology like Transportation Management Systems and real-time tracking. These tools enhance visibility and control over your logistics operations.

Adopt sustainable practices in your logistics network. Eco-friendly methods not only reduce costs but also improve your brand reputation.

Assessing and Benchmarking Your Logistics Network

Mapping Network Structure

You need to start by mapping your logistics network. This step helps you see how materials, information, and money move through your supply chain. Supply chain mapping lets you spot key players and understand how they connect. When you map these connections, you can find hidden risks, like relying too much on one supplier or region. You should use advanced mapping tools to create diagrams that show your network’s physical locations, product flows, and geographic spread. Some popular tools for visualizing logistics networks include:

Graphviz

D3.js

Tulip

Sigma.js

Gephi

Cytoscape

These tools help you build clear pictures of your network, making it easier to plan improvements.

Identifying Bottlenecks and Gaps

After mapping your network, you need to look for bottlenecks and gaps. Bottlenecks slow down your supply chain and hurt performance. Common bottlenecks include supplier problems, transportation delays, and sudden jumps in demand. Here is a table showing frequent bottlenecks:

Bottleneck Cause | Description |

|---|---|

Supplier Issues | Unreliable suppliers and long lead times can slow down production. |

Logistical Challenges | Transportation delays and poor infrastructure disrupt the supply chain. |

Demand Surges | Sudden spikes in demand can overwhelm inventory and cause shortages. |

You can use data analytics to find these problems. Data analytics helps you track shipments, optimize delivery routes, and predict issues before they happen. You can also use analytics to spot ways to cut costs and improve customer satisfaction.

Setting KPIs and Using SCOR Metrics

To measure progress, you need to set clear key performance indicators (KPIs). KPIs let you track how well your logistics network works. The SCOR model gives you a set of metrics for benchmarking. Some important KPIs include:

Pick and Pack Costs

Operating Ratio

Net Profit Ratio

Inventory Turnover Ratio

Financial Leverage

Inventory to Sales Ratio

Capacity Utilization

Equipment Utilization Rate

Use of Packing Material

Pick and Pack Cycle Time

Number of Shipments

Truck Turnaround Rate

Driver Performance

Fuel Efficiency

Lead Time

Tracking these KPIs helps you compare your results with industry standards. When you measure and improve these areas, you move closer to optimized logistics network performance.

Strategies for Optimized Logistics Network Performance

Route and Carrier Optimization

You can boost your logistics network by focusing on route and carrier optimization. Start by reviewing your carriers regularly. This helps you find the best partners and negotiate better deals. Regular carrier evaluations lead to cost savings, better service, and fewer delays. You also gain more control over your transportation operations and can adapt quickly to changes in the market.

Tip: Grade your carriers based on performance. This makes it easier to spot issues and improve service levels.

Modern route planning uses advanced algorithms. These tools help you choose the fastest and most efficient paths for your shipments. Artificial intelligence and machine learning can predict disruptions and adjust routes in real time. This reduces fuel costs and helps you deliver products faster. Companies that use geospatial data analysis can save up to 20% on fuel costs.

Advancement Type | Description |

|---|---|

AI and Machine Learning | These technologies allow for real-time route optimization by learning from data and predicting disruptions. |

Sustainability Considerations | Companies are focusing on reducing their ecological footprint through efficient route planning. |

Modular and Interconnected Solutions | The shift towards modular architectures enables customization and flexibility in logistics solutions. |

Consolidating shipments is another smart move. When you combine freight, you lower transportation costs and speed up deliveries. Fewer shipments mean less handling and lower storage costs.

Benefit | Explanation |

|---|---|

Lower Transportation Costs | Companies can combine freight, sharing expenses and benefiting from economies of scale. |

Enhanced Delivery Speed | Optimized routing and scheduling lead to faster arrival of shipments. |

Improved Supply Chain Efficiency | Reducing the number of shipments minimizes handling errors and lowers storage costs. |

By using these strategies, you move closer to optimized logistics network performance and create a more flexible and cost-effective supply chain.

Smart Warehouse Layout and Inventory Management

A smart warehouse layout speeds up order fulfillment and reduces mistakes. Place high-demand items near packing stations. This cuts down on worker travel time and helps orders go out faster. Group items that are often ordered together. Workers can pick several items in one trip, which boosts efficiency.

Principle | Impact on Order Fulfillment |

|---|---|

Logical product placement | Reduces errors and speeds up processing |

Minimizing unnecessary movement | Increases efficiency and accuracy |

Integration of technology | Enhances speed and reduces mistakes |

You should also use technology to track inventory in real time. This gives you a clear view of stock levels and helps you avoid running out or having too much inventory. Just-in-time inventory systems keep stock low but make sure products are available when needed. ABC analysis lets you focus on the most important items, so you never run out of top sellers.

Use demand forecasting tools to predict what customers will buy.

Build strong relationships with suppliers for more flexible orders.

Balance inventory costs with service levels by using advanced systems.

Note: A well-designed warehouse and smart inventory management help you reach optimized logistics network performance by cutting costs and improving order accuracy.

Streamlined Dock-to-Dock Flows

You can make your distribution center more efficient by streamlining dock-to-dock flows. Start by standardizing your processes. Create a manual for receiving and shipping. This keeps everyone on the same page and reduces mistakes. Use a warehouse management system (WMS) to automate tasks and track shipments.

Here are some best practices for dock-to-dock flows:

Standardize processes with clear manuals.

Use technology like WMS for automation.

Train staff regularly on safety and new tools.

Work closely with vendors to improve delivery accuracy.

Audit your operations often to find and fix problems.

Check random shipments for quality.

Make safety a top priority.

Tip: Continuous training and regular audits help you spot problems early and keep your operations running smoothly.

When you follow these steps, you reduce delays, improve shipment accuracy, and create a safer workplace. Streamlined dock-to-dock flows support optimized logistics network performance by making your supply chain faster and more reliable.

Leveraging Technology and Data

Advanced Algorithms and Automation

You can use advanced algorithms to make your logistics network smarter and faster. These tools help you solve problems and make better decisions. Here are some ways algorithms improve your operations:

Dynamic route optimization changes delivery paths based on traffic or weather, saving time and fuel.

Machine learning-powered predictive analytics looks at past data to guess future demand and suggest the best routes.

Multi-modal optimization picks the best mix of trucks, ships, or trains to lower costs and help the environment.

Last-mile optimization finds the fastest way to deliver packages in cities.

Load consolidation and warehouse optimization help you use space better and cut handling costs.

Automation also makes your work easier. Companies use cloud services and robotic process automation to speed up billing and reduce mistakes. Cold storage warehouses use robots to keep products safe. Automated guided vehicles and storage systems move goods quickly and safely.

Automation and smart algorithms help you reach optimized logistics network performance by making your supply chain more reliable and cost-effective.

Transportation Management Systems (TMS)

Transportation Management Systems give you more control over shipping. These systems offer important features:

Carrier management lets you pick the best shipping partners.

Shipment visibility shows you where your goods are at all times.

Load optimization helps you fill trucks and containers efficiently.

Reporting and analytics help you find ways to improve.

Integration capabilities connect TMS with your other business tools.

You can use TMS to track shipments, save money, and keep customers happy.

Real-Time Tracking and Analytics

Real-time tracking gives you instant updates about your shipments. During the COVID-19 pandemic, shipping companies used real-time tracking to avoid crowded ports and deliver goods on time. This technology helps you see where your products are and fix problems quickly.

Source | Description |

|---|---|

Kinetica for Logistics | Analyzes fast-moving data to help you make quick decisions and improve operations. |

Optimize Logistics with Real-time Tracking | Connects with your ERP system to show shipment status and reduce disruptions by up to 30%. |

Why Real-Time Data Processing Matters for Logistics Success | Lets you track goods and predict demand changes, saving time and money. |

88% of customers want to track their orders in real time. Companies that offer this feature see a big jump in customer satisfaction.

Cost Management and Sustainability

Reducing Logistics Costs

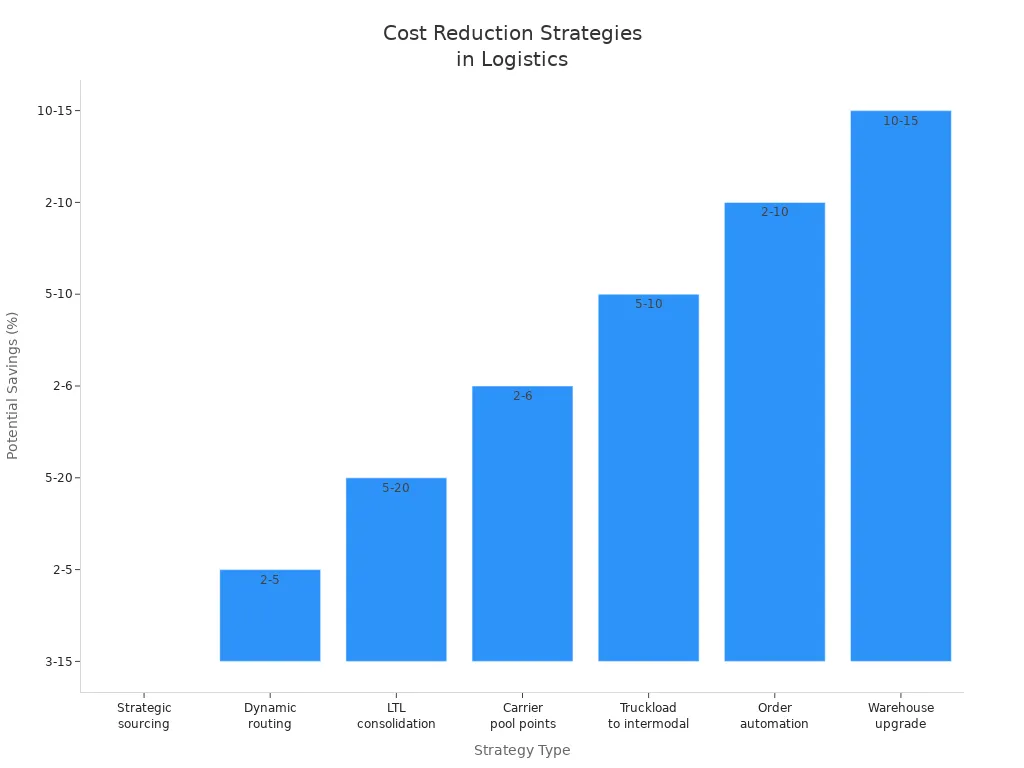

You can lower logistics costs by using smart strategies. Start with transportation optimization. Choose the best shipping mode and use dynamic routing to save money. Consolidate shipments and use carrier pool points to cut expenses. Switch from truckload to intermodal when possible. Demand forecasting tools help you avoid overstocking and reduce inventory carrying costs. Automated order processing and upgraded warehouse management systems also reduce labor costs and errors.

Strategy Type | Description | Potential Savings |

|---|---|---|

Optimize Transportation | Strategic sourcing and dynamic routing save money. | 3 to 15 percent |

LTL Shipment Consolidation | Combine loads to reduce costs. | 5 to 20 percent |

Carrier Pool Points | Save on parcel and LTL costs. | 2 to 6 percent |

Truckload to Intermodal | Use intermodal where possible. | 5 to 10 percent |

Reduce Inventory Carrying Costs | Use forecasting tools to prevent overstocking. | Significant savings |

Streamline Order Management | Automate orders to cut labor costs. | 2 to 10 percent |

Enhance Warehouse Management | Upgrade WMS for better efficiency. | 10 to 15 percent |

Tip: Use technology and automation to find hidden savings in your logistics network.

Sustainable Delivery Methods

You can make your deliveries more sustainable by choosing eco-friendly options. Select ground shipping instead of air freight to lower carbon emissions. Right-size your packaging to maximize truck space and decrease fuel use. Consolidate shipments to reduce delivery frequency and emissions. Educate customers about green choices and use intelligent route optimization to save fuel.

Strategy | Impact on Cost | Impact on Carbon Footprint |

|---|---|---|

Educate consumers about eco-friendly options | Can save money | Meets sustainability goals |

Intelligent route optimization | Reduces fuel costs | Minimizes CO2 emissions |

Efficient fleet operations | Lowers transportation expenses | Reduces miles driven |

Electric and hybrid vehicles help cut emissions.

Solar panels and energy-efficient systems lower warehouse energy use.

Eco-friendly packaging reduces waste.

Note: Sustainable practices can improve your brand reputation and customer loyalty.

Balancing Efficiency and Environmental Impact

You can balance efficiency with environmental impact by optimizing routes and greening warehouse operations. Use advanced technologies to plan better routes and reduce emissions. Collaborate with partners to create circular supply chains and rethink your distribution network for sustainability. Adopt eco-friendly packaging and invest in renewable energy for your facilities.

Optimize transportation routes.

Use recyclable and biodegradable materials.

Invest in energy-efficient warehouse systems.

Work with partners to reduce waste and emissions.

You can achieve both operational efficiency and environmental responsibility by making smart choices in your logistics network.

Overcoming Challenges and Driving Continuous Improvement

Managing Disruptions and Risks

You face many disruptions in logistics. Natural disasters, geopolitical events, and supplier delays can slow down your supply chain and increase costs. You can prepare for these risks by understanding your geographic footprint. Move inventory to safer areas when you expect storms or floods. Keep some buffer stock to avoid production stops during unexpected events. You should also:

Conduct risk assessments to find weak spots in your network.

Build strong relationships with multiple suppliers.

Diversify your supplier base to avoid relying on just one source.

Create contingency plans for emergencies, such as backup carriers or warehouses.

Use technology for real-time monitoring and visibility.

Tip: Predictive analytics help you forecast demand and spot risks before they become problems.

Adapting to Customer Demands

Customer needs change quickly, especially in e-commerce. You must stay flexible to keep up. Invest in advanced technologies like AI and robotics to speed up operations. Build a responsive supply chain that can adjust to sudden changes in demand. Use data analytics to improve demand forecasting and optimize delivery routes. Work with other logistics companies to expand your network and reach new markets.

Strategy | Benefit |

|---|---|

AI and robotics | Faster, error-free work |

Flexible supply chains | Quick response to change |

Data analytics | Better inventory control |

Partnerships | Wider delivery coverage |

🚚 Fast adaptation keeps your customers happy and your business growing.

Embracing Industry Trends

You need to watch industry trends to stay ahead. Supply chain agility helps you compete in a fast-paced market. Labor shortages push you to use more automation, which lowers costs and boosts productivity. Customers now expect real-time updates on their orders. Many companies set sustainability goals to protect the environment.

Stay agile and ready to change.

Use automation to solve labor shortages.

Provide real-time data to customers.

Focus on sustainability in every part of your network.

Note: Following these trends helps you build a strong, future-ready logistics network.

You can optimize your logistics network by streamlining warehousing, transportation, and fulfillment. Remove bottlenecks and use real-time data to make quick decisions. Adopt technology like IoT, automation, and cloud computing to boost efficiency and accuracy. Build strong partnerships with advanced providers for lasting cost savings. Regularly assess your network and use structured change management to improve customer satisfaction. Stay informed about new trends and keep refining your strategy for long-term success.

Technology | Impact on Logistics Performance |

|---|---|

IoT | Improves tracking and decision-making |

Automation | Speeds up operations and reduces errors |

Cloud Computing | Enables flexibility and real-time communication |

FAQ

What is logistics network optimization?

You use logistics network optimization to improve how goods move from suppliers to customers. This process helps you cut costs, speed up deliveries, and boost customer satisfaction.

How can technology improve my logistics network?

You can use technology like Transportation Management Systems and real-time tracking. These tools help you see shipments, plan better routes, and reduce errors.

Which KPIs should I track for logistics performance?

You should track these KPIs:

Lead time

Inventory turnover

Order accuracy

Transportation costs

Tracking these KPIs helps you measure progress and spot areas for improvement.

How do I handle disruptions in my supply chain?

You prepare by building strong supplier relationships and keeping backup plans. You use real-time data to spot problems early. You also keep some extra stock to avoid delays.

See Also

Enhancing Global Efficiency Through Point-to-Point Logistics Systems

Key Strategies for Effective Global Logistics Management

Boosting International Operations With Innovative Logistics Solutions

Simplifying Supply Chain Optimization With American Logistics Solutions

Connecting Warehouses and Streamlining Supply Chains With PGL