How to Optimize Supply Chain Connectivity for Maximum Efficiency

You optimize supply chain connectivity for maximum efficiency by integrating systems, improving communication, and leveraging technology across your operations. Connectivity drives faster decision-making and reduces costly mistakes. Poor connectivity increases operational errors, resource overuse, and transportation costs.

Impact on Costs | Description |

|---|---|

Operational errors | Mislabeled packages and barcode mistakes raise expenses. |

Overuse of resources | Inefficient packaging and shipping methods increase handling costs. |

Increased transportation costs | Overdelivering leads to unnecessary shipping charges. |

Overutilization of resources | Insufficient staffing and poor logistics management cause delays and errors. |

Optimizing supply chain connectivity helps you avoid these issues and supports a more efficient, reliable supply network.

Key Takeaways

Integrate your systems to improve data flow and align goals across departments. This reduces errors and enhances overall efficiency.

Enhance visibility in your supply chain by using real-time data. This helps you respond quickly to disruptions and avoid stockouts.

Automate routine tasks to cut down on errors and labor costs. Automation can boost productivity by 20-30% and streamline operations.

Foster strong communication with supply chain partners. Clear communication minimizes risks and ensures timely responses to changes.

Invest in training and upskilling your team. Continuous improvement empowers employees to drive change and adapt to market shifts.

Key Challenges in Supply Chain Connectivity

Siloed Systems and Data

You often face siloed systems and fragmented data in your supply chain. When departments use separate platforms, you lose the ability to measure performance across the entire network. Disjointed metrics focus on isolated goals, which can create inefficiencies and missed opportunities. Siloed systems also block end-to-end visibility, making it hard to adjust procurement or logistics quickly.

Tip: Integrate your data streams to align your KPIs with broader business objectives.

Challenge | Description |

|---|---|

Fragmented digital landscape | Multiple providers use different systems, making integration difficult. |

High manual work for data completeness | Manual data gathering leads to incomplete information and higher costs. |

Limited and hard-to-access data | Poor visibility causes unexpected costs and operational challenges. |

Limited Visibility

Limited visibility remains a major obstacle for most organizations. You may not see the full picture of your supply chain, which leads to delays and extra costs. In fact, 62% of companies report limited visibility in their supply chain operations. Without real-time data, you cannot respond quickly to disruptions or prevent stockouts.

You risk missing sales opportunities when you cannot track inventory or shipments.

Timely adjustments become impossible without accurate information.

Optimizing supply chain connectivity requires you to improve visibility at every stage.

Communication Gaps

Communication gaps between partners can slow down your supply chain. Missed shipment updates often result in missed delivery windows. When responsibilities are unclear, bottlenecks form at transfer points. Uninformed teams struggle to adjust plans when problems arise.

Delayed responses damage relationships and reduce confidence in your operation.

Real-time communication helps you spot issues and inform customers about delays.

Strong collaboration with suppliers and logistics partners minimizes risks and ensures product availability.

Note: Even with advanced technology, clear communication remains essential for effective supply chain management.

Assessing and Mapping Supply Chain Performance

Before you can improve your supply chain, you need a clear picture of your current network and processes. Start by assessing every step, from sourcing to delivery. This approach helps you spot inefficiencies and plan for better connectivity.

Process Mapping

Mapping your supply chain processes gives you a visual overview of how goods and information flow. You can use this map to find risks and weak points. Follow these best practices to get started:

Create a visual map of your supply chain to understand each step and identify risks.

Collect detailed data on suppliers, materials, and logistics.

Build a supplier risk index to evaluate and prioritize potential issues.

You can also use a step-by-step approach:

Gather data on key supply chains, including supplier details and part numbers.

Identify important supplier relationships, including Tier 2 and 3 suppliers.

Map the supply chain, noting routes and transportation modes.

Develop a supplier risk index based on performance.

Analyze the data and create action plans to address risks.

Tip: A clear process map helps you communicate with your team and partners, making it easier to align goals and improve efficiency.

Identifying Bottlenecks

Bottlenecks slow down your supply chain and increase costs. According to McKinsey & Company, companies that find and fix bottlenecks can boost productivity by up to 30%. Use analytics to monitor capacity and spot delays. Here are some ways to identify and address bottlenecks:

Analyze capacity at each stage to find delays and resource waste.

Make sure bottlenecks run at peak efficiency.

Align upstream activities so bottlenecks do not get overloaded.

Increase capacity with faster equipment or by moving resources.

You can also use predictive analytics to forecast demand and prevent overloads. Intelligent automation and cross-functional teamwork help clear bottlenecks and keep your supply chain moving.

Technology Evaluation

Choosing the right technology is key to optimizing supply chain connectivity. Evaluate your current tools and look for gaps. Use the table below to guide your review:

Criteria | Description |

|---|---|

Real-time Visibility | Monitor shipments and inventory with up-to-date data and analytics. |

Integration Capabilities | Connect with other systems and platforms easily. |

Scalability | Grow with your business and handle more demand. |

User-friendly Interface | Reduce training time and errors with an easy-to-use design. |

Advanced Analytics | Make decisions using predictive analytics and custom reports. |

Mobile Accessibility | Access supply chain data from any device. |

Security and Compliance | Protect data and meet industry rules. |

Cost-effectiveness | Get value for your investment. |

Customer Support and Training | Access help and training when you need it. |

Future-proofing | Stay ready for new trends and technologies. |

Note: Regularly review your technology to make sure it supports your goals and adapts to changes in your supply chain.

By following these steps, you lay the groundwork for optimizing supply chain connectivity and building a more efficient operation.

Optimizing Supply Chain Connectivity

Streamlining Workflows

You can streamline workflows by diversifying suppliers and developing contingency plans for critical supply chain components. Involving stakeholders in risk management discussions helps you leverage their insights and prepare for disruptions. Technology and automation play a key role in improving decision-making and reducing manual work. Implementing ERP systems gives you better integration and visibility across your supply chain. Real-time data and analytics allow you to make quick adjustments and informed decisions. Adopting lean methodologies helps you eliminate waste and optimize processes. Supplier collaboration reduces lead times and improves alignment.

Diversify suppliers to reduce risks.

Develop contingency plans for critical components.

Involve stakeholders in risk management.

Use technology and automation to streamline processes.

Implement ERP systems for better integration.

Utilize real-time data and analytics.

Adopt lean methodologies to eliminate waste.

Foster supplier collaboration for better alignment.

Streamlining workflows impacts lead times and inventory turnover rates. The table below shows how different strategies improve efficiency:

Evidence | Explanation |

|---|---|

Inventory turnover data is a powerful tool for streamlining supply chain operations. | Analyzing product movement helps identify waste reduction opportunities, which can lead to shorter lead times and improved turnover rates. |

Just-in-Time (JIT) inventory management focuses on aligning stock levels with actual demand. | This approach minimizes excess inventory, thus enhancing turnover rates and reducing lead times. |

Speeding up inventory turnover can trim expenses and boost profits. | Efficient operations lead to reduced waste and improved cash flow, which can positively affect lead times. |

Effective demand forecasting helps you predict future needs and plan orders, reducing lead times and improving inventory turnover. Analyzing turnover rates for each product category strengthens supplier relationships and shortens lead times.

Leveraging Technology and Analytics

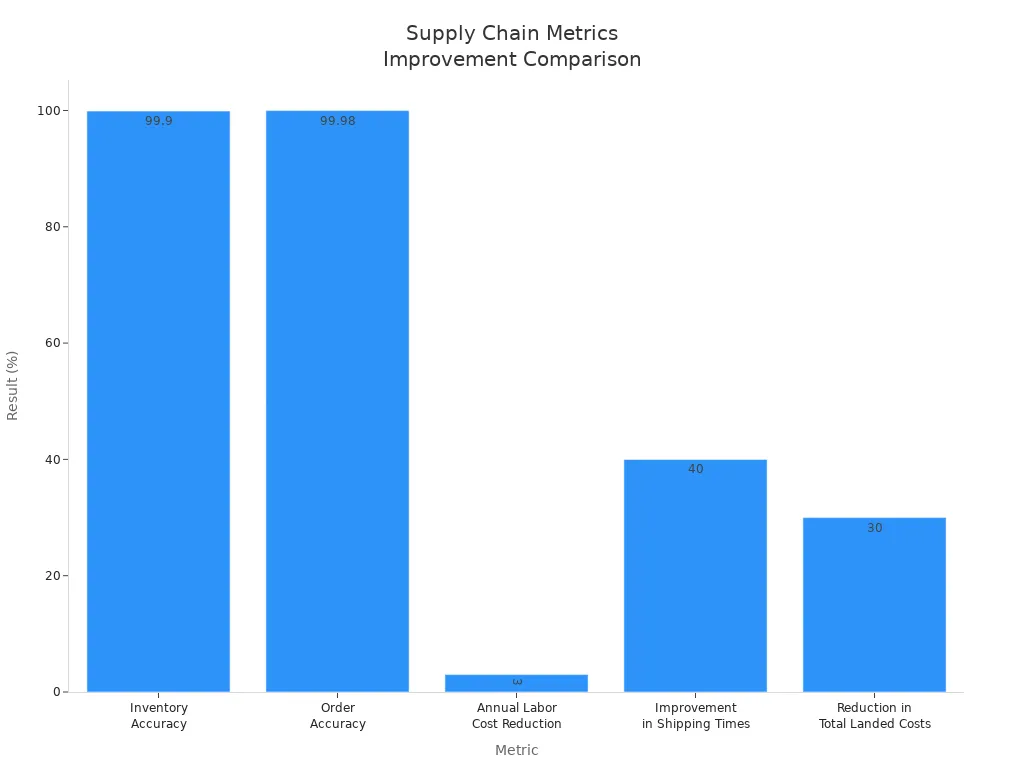

You can enhance supply chain connectivity by adopting advanced technologies such as AI, IoT, digital twins, and supply chain visibility software. These tools improve efficiency, visibility, and decision-making. Advanced analytics provide real-time insights, helping you respond quickly to disruptions and optimize inventory levels.

AI and IoT enable real-time monitoring and predictive maintenance.

Digital twins simulate supply chain scenarios for better planning.

Visibility software tracks shipments and inventory across locations.

Advanced analytics improve supply chain decision-making and efficiency. The table below highlights key metrics:

Metric | Result |

|---|---|

Inventory Accuracy | |

Order Accuracy | 99.98% |

Annual Labor Cost Reduction | 3% |

Improvement in Shipping Times | 40% |

Reduction in Total Landed Costs | Up to 30% |

Advanced analytics tools improve demand predictions, reduce inefficiencies, and allow for just-in-time strategies. Real-time inventory monitoring minimizes holding costs. Predictive analytics help you anticipate disruptions and enhance supply chain resilience.

Automating Routine Tasks

Automating routine tasks reduces error rates and labor costs. You can increase labor productivity by 20–30 percent through automation. Firms with manual-heavy supply chains face 15-20 percent higher operating costs compared to automated workflows. Automation can reduce error-related losses by up to $1.3 million annually for mid-sized retailers. Labor savings account for nearly half of operational cost reductions.

Automation minimizes risks by streamlining processes and ensuring accuracy.

It reallocates labor to higher-value activities, boosting efficiency.

Automated workflows lower financial exposure and improve productivity.

Enhancing Collaboration

Enhancing collaboration with supply chain partners increases responsiveness and flexibility. You can use tools like RELEX, Kinaxis, and Coupa to improve communication and visibility.

Tool | Key Features | Ideal For |

|---|---|---|

RELEX | AI-driven collaboration, visibility, efficiency, sustainability | Complex, multichannel supply chains, medium and large companies, organizations focused on sustainability |

Kinaxis | Real-time collaboration, end-to-end visibility, scenario simulation | Large companies, organizations with high variability in demand, complex supply chains |

Coupa | Centralized information, real-time communication, supply chain visibility | Companies needing to optimize flow of goods and information across multiple stakeholders |

Breaking down silos and facilitating seamless communication enables smoother information flow and integrated decision-making. Shared visibility and real-time data allow all stakeholders to access the same information, leading to quicker responses to changes in demand and supply disruptions. Regular communication about successes and bottlenecks helps you adapt to shifting market demands and unforeseen disruptions with greater agility.

Evidence Description | Impact on Supply Chain Responsiveness and Flexibility |

|---|---|

Heightened responsiveness ensures performance maintenance | Allows the supply chain to meet customer expectations even in the face of uncertainty. |

Sustainable and Efficient Practices

You can improve supply chain efficiency by adopting sustainable practices. Enhancing brand reputation and consumer trust leads to increased loyalty and willingness to pay a premium for sustainable products. Reducing environmental impact minimizes waste and lowers carbon footprints, with a potential 40%-50% reduction in logistics emissions by 2030. Improving risk management and compliance prepares you for regulations and mitigates legal and financial risks. CSR-driven strategies enhance efficiency and reduce costs, with a potential 20% reduction in greenhouse gas emissions by 2030. Ethical practices strengthen supplier and stakeholder relationships.

Walmart aims to power 50% of its operations with renewable energy by 2025, having already avoided over 2.3 million metric tonnes of CO2e emissions through its renewable energy projects. IKEA is transitioning to electric vehicles for deliveries, saving over 300,000kg of CO2 emissions annually. These initiatives show how companies can enhance supply chain efficiency while committing to sustainability.

Sustainable Transportation: IKEA is phasing out gas-guzzling vehicles, aiming for all deliveries in major cities to use electric vehicles by 2025.

Water Conservation: PepsiCo aims to replenish more water than it uses in high water-risk areas by 2030, improving water-use efficiency by 15% since 2015.

Sustainable Packaging Innovation: Procter & Gamble is developing fully recyclable packaging, aiming to eliminate single-use plastics by 2030.

You can measure efficiency gains from sustainable practices by setting SMART goals, benchmarking against industry standards, and regularly reporting performance data to stakeholders. These steps build trust and accountability while driving continuous improvement.

Optimizing supply chain connectivity requires you to integrate digital procurement, automate tasks, and maximize truckloads. Technology, analytics, and sustainability drive efficiency and resilience in your supply chain.

Continuous Improvement and Team Development

Training and Upskilling

You strengthen your supply chain by investing in training and upskilling. Start by analyzing skill gaps and setting clear learning goals for your team. Focus on strategic skills such as risk management and sustainable sourcing. You can use online learning platforms, host in-house workshops, and create mentorship programs. Partnering with universities for advanced courses also helps your team stay ahead. When you provide continuous improvement expertise, you empower employees to drive change and solve problems. Lean, Six Sigma, and Kaizen models encourage your team to streamline work, reduce waste, and make small, steady improvements.

Feedback and Monitoring

You improve supply chain performance by collecting regular feedback and monitoring operations. Feedback helps you spot areas for improvement and align processes with customer needs. When you review feedback often, you detect trends early and adjust operations in real time. Use AI-driven analytics to turn raw data into insights. IoT sensors monitor conditions and alert you to hazards. Collaborative dashboards let you and your partners track metrics and respond quickly. By seeking input from stakeholders, you reduce inefficiencies and enhance product quality.

Regular feedback identifies improvement opportunities.

Monitoring aligns your supply chain with changing expectations.

Real-time tools help you manage risks and prevent delays.

Adapting to Change

You build resilience by adapting to market shifts and global disruptions. Diversify suppliers and routes to distribute risk. Decentralize operations to improve visibility and communication. Establish multiple supplier relationships to ensure continuity. During the Covid pandemic, companies that managed variability and volatility succeeded. The automotive industry responded to chip shortages by forming new supplier partnerships and changing procurement strategies. When you treat disruptions as opportunities, you drive innovation and growth.

Evidence Type | Description |

|---|---|

Collaboration | Team building fosters communication and quick decision-making. |

Adaptability | Cohesive teams respond to challenges and maintain customer satisfaction. |

Employee Engagement | Engaged employees show commitment and ownership. |

Innovation | Diverse teams create new solutions for supply chain processes. |

Risk Management | Teams identify risks and develop contingency plans together. |

Tip: Continuous improvement and team development keep your supply chain agile, efficient, and ready for future challenges.

You can optimize supply chain connectivity by following these steps:

Use analytics for better planning.

Remove slow-moving inventory.

Improve collaboration.

Train your team.

Take action now and review your processes often. This approach boosts agility, visibility, and resilience. Technology like AI and blockchain helps you make quick decisions and track goods. Working with partners supports sustainability and efficiency.

Benefit Type | Description |

|---|---|

Risk Management | Use management systems to analyze and reduce risks. |

Local Sourcing | Choose local suppliers to cut transport and improve freshness. |

Investing in Human Resources | Train employees for growth and commitment. |

FAQ

What is supply chain connectivity?

Supply chain connectivity means linking all parts of your supply chain. You use technology and clear communication to share data and track goods. This approach helps you make faster decisions and avoid mistakes.

How does technology improve supply chain efficiency?

You use technology to automate tasks and monitor shipments. Real-time data helps you spot problems early. Advanced analytics let you plan better and reduce waste. You save time and money with smart tools.

Why is collaboration important in supply chain management?

Collaboration lets you share information with suppliers and partners. You solve problems faster and adjust plans quickly. Strong teamwork reduces risks and keeps products moving. You build trust and improve results.

What are some quick wins for optimizing supply chain connectivity?

You can start by integrating your systems and automating routine tasks. Use real-time tracking for shipments. Train your team on new tools.

Tip: Focus on one improvement at a time for faster results. 🚀

See Also

Simplifying Supply Chain Optimization With U.S. Logistics Solutions

Connecting Warehouses and Enhancing Supply Chains Through PGL

The Role of Point-to-Point Logistics in Global Efficiency

Boosting International Operations With Innovative Logistics Solutions