How to Handle Project Cargo Safely and Efficiently in 2025

Imagine you must move oversized turbines across continents in 2025. You need project cargo handling protocols that keep you compliant, minimize risk, and leverage advanced technology. Real-time GPS tracking and predictive analytics give you visibility and control every step of the way. Reliable partners streamline customs, optimize costs, and ensure timely delivery. Sustainability matters, with hybrid cranes and renewable-powered equipment gaining traction. You face challenges like digitalization gaps and aging infrastructure, but modern logistics software and tailored solutions help you overcome them.

Key Takeaways

Establish clear project cargo handling protocols to ensure safe and efficient transport. Focus on planning, execution, and compliance to avoid costly mistakes.

Utilize advanced logistics software for real-time tracking and analytics. This technology enhances visibility and helps streamline operations.

Conduct thorough pre-shipment planning. Inspect goods, secure necessary permits, and ensure all documentation is accurate to prevent delays.

Implement effective communication strategies among team members. Use centralized tools to keep everyone informed and aligned throughout the project.

Adopt sustainable practices by using eco-friendly equipment and planning for environmental factors. This approach protects both cargo and the planet.

Project Cargo Handling Protocols

Establishing and following project cargo handling protocols ensures safe and efficient movement of oversized and high-value shipments. You must focus on every stage, from planning to execution, to avoid costly mistakes and delays. In 2025, you rely on data-driven processes and advanced technology to manage cargo, not just physical movement. You use integrated software platforms to coordinate stakeholders, automate documentation, and monitor shipments in real time. These protocols help you maintain compliance, improve transparency, and reduce risks.

Pre-Shipment Planning

Pre-shipment planning forms the foundation of successful project cargo handling protocols. You start by inspecting goods and verifying quality. You pack, label, and mark each item according to export requirements. If you handle hazardous or perishable cargo, you disclose all details to authorities. You obtain a Delivery Order from the shipping line before picking up containers. You load and seal containers to secure them for transit. You transport containers to the port using trucks, rail, or trailers. You complete customs clearance at the origin, verifying documents and paying export duties.

Tip: Always use digital copies of shipment documents. These records improve precision and help you optimize transport routes.

Inspect and pack goods.

Disclose special cargo details.

Obtain Delivery Order.

Load and seal containers.

Transport to port.

Complete customs clearance.

Engineering Procedures

Engineering procedures play a critical role in project cargo handling protocols, especially for oversized or heavy items. You conduct rigorous pre-load planning to ensure safe operations. Federal guidelines require you to inspect cargo and equipment before any lift or securement. You check the structural integrity of cargo and the condition of slings, chains, hooks, and cranes. You maintain detailed inspection records for audits and insurance claims. You follow routine inspections mandated by FMCSA before every movement. You use heavy-duty chains, tensioners, and custom blocking devices for securement. You inspect each tiedown for wear, angle, and tension. You recommend two-person verification for critical shipments. You adjust securement devices throughout transit, checking every 50–100 miles.

Note: Live tracking with IoT sensors and advanced GPS systems lets you monitor cargo location and condition in real time.

Communication and Coordination

Clear communication and coordination keep your project cargo handling protocols effective. You define team member responsibilities to enhance collaboration. You map out information flow to clarify roles. You train your team to communicate across the supply chain. You establish an initial plan that aligns with client expectations and maintains visibility throughout the project lifecycle.

Best Practices for Communication and Coordination:

Use one centralized management tool to consolidate timelines, tasks, and updates.

Keep communication clear and open with regular check-ins.

Develop customized plans for each site to address unique challenges.

Implement automated resource management tools to allocate people, equipment, and materials efficiently.

Industry | Key Handling Protocols | Integration Focus | Transport Considerations |

|---|---|---|---|

Energy | Emphasis on safety evaluations and technical assessments for oversized cargo handling | Integration of commercial, technical, and safety aspects in planning | Selection of optimum marine transport fleet and suitable port infrastructure |

Construction | Focus on heavy lifting and haulage operations | Relationship marketing to reduce project failure risk | Comprehensive planning for berthing, mooring, and added value services |

Manufacturing | Implementation of multimodal transport for efficiency | Total delivery cost management and end-to-end visibility | Clear communication with one operator for contract carriage and monitoring of operations |

You must adapt project cargo handling protocols to fit the needs of your industry. In energy, you focus on safety and technical assessments. In construction, you plan for heavy lifting and haulage. In manufacturing, you prioritize multimodal transport and cost management. You always maintain clear communication and monitor operations closely.

Compliance and Documentation

Customs and Regulatory Requirements

You must follow strict customs and regulatory requirements when moving project cargo across borders. International shipping laws set the rules for documentation and compliance. Each country has its own import and export regulations. If you miss a step, you risk delays or penalties. Regulations standardize documentation and help you clear customs quickly. They also make sure you follow national laws and support efficient trade.

Region | Update Description |

|---|---|

European Union | ICS2 Release 3 requires electronic Entry Summary Declarations for all transport modes by April 1, 2025. |

United States | Universal 10% duty rate on imports and no de minimis exemption for shipments from China and Hong Kong. |

China | New retaliatory tariffs on U.S. goods increase customs complexity for imports. |

Southeast Asia | Vietnam enforces stricter cargo manifest submission; Thailand revises import tax classifications. |

You face common compliance challenges during project cargo shipments:

Transportation restrictions, such as height, weight, and width limits on roads and bridges.

Complex handling and loading for oversized or overweight items.

High shipping costs, including customs fees and insurance.

To stay compliant, you should integrate operations with approved customs software, train staff on regulatory updates, and monitor trade bulletins for tariff changes. Reliable customs brokers help you navigate increased scrutiny, especially in regions like China.

Permits and Paperwork

You need the right permits and paperwork to move project cargo safely and legally. Oversize and overweight permits allow you to transport loads that exceed standard limits. Trip permits let out-of-state vehicles operate without full registration. Fuel permits cover vehicles without IFTA credentials. Superload permits are for equipment that goes far beyond weight and size thresholds. International permits include customs documentation and compliance checks.

Permit Type | Description |

|---|---|

Oversize Permits | Required for loads exceeding standard dimensions. |

Overweight Permits | Needed if vehicle and equipment exceed legal weight limits. |

Trip Permits | Temporary permits for out-of-state vehicles. |

Fuel Permits | Temporary fuel tax permits for vehicles without IFTA credentials. |

Superload Permits | For equipment far above weight and dimension thresholds. |

International Permits | Additional permits for cross-border transport and customs compliance. |

You must prepare these documents for customs clearance:

Commercial Invoice: Issued by the seller to the buyer.

Packing List: Details cargo and packing information.

Export/Import Customs Declaration: Lists goods for customs clearance and duty calculation.

Logistics companies help you meet international safety standards by planning shipments carefully and working with reputable partners. Early engagement with service providers ensures you get the necessary permits and approvals. Customs brokerage services guide you through complex clearance processes, keeping your project cargo handling protocols compliant.

Tip: Always double-check permit requirements and paperwork before shipping. Missing documents can cause costly delays.

Equipment and Technology

Heavy-Lift Cranes and Trailers

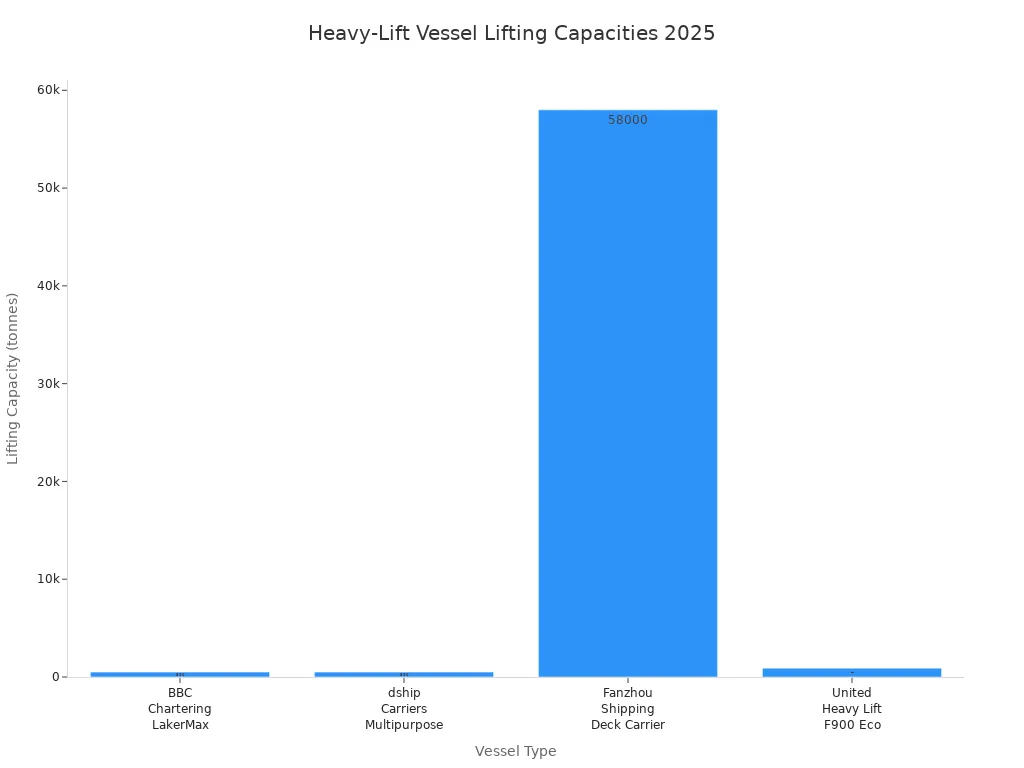

You rely on specialized heavy-lift cranes and trailers to move project cargo safely in 2025. These machines offer advanced lifting capacities and optimized features for oversized loads. Modern vessels like BBC Chartering’s LakerMax and United Heavy Lift’s F900 Eco-Lifters provide fuel-efficient technology and ice-class capabilities. You select equipment based on cargo size, weight, and destination requirements. Purpose-built platforms improve reliability and service integrity, while insurance-based coverage reduces stress for your business.

Company | Vessel Type | Lifting Capacity | Notable Features |

|---|---|---|---|

BBC Chartering | LakerMax | 500 tonnes | Optimized deck layout, ice-classed for Arctic operations, large unobstructed deck space. |

BigLift Shipping | Spliethoff P8/P14 | N/A | State-of-the-art fleet for complex projects, newbuilds expected in 2025-2026. |

dship Carriers | Multipurpose Vessels | 500 tonnes (combined) | New 15,000 dwt vessels with reduced fuel consumption, LS 250 heavy lift cranes. |

Fanzhou Shipping | Self-propelled Deck Carrier | 58,000 tonnes | Large open deck (11,700 sq m), ice-class capability, designed for offshore wind components. |

United Heavy Lift | F900 Eco-Lifters | 900 tonnes | Modern vessels with fuel-efficient technology, biodiesel capability. |

Specialized equipment gives you enhanced safety, time savings, and operational efficiency when transporting oversized cargo.

Advanced Logistics Software

You use advanced logistics software to manage project cargo with precision. These solutions give you total supply chain visibility and real-time analytics. Global Matrix Solution helps you monitor shipments, automate tasks, and reduce manual errors. You streamline procedures and save costs by integrating modern software into your operations. The shift from traditional methods to digital platforms supports innovation and responsive trade systems.

Benefit | Description |

|---|---|

Real-time Data & Analytics | Monitor and manage your supply chain for better decision-making. |

Operational Efficiency | Automate tasks and lower manual errors to save time and costs. |

End-to-End Visibility | Track shipments and resources across all stages of transport. |

Innovation Support | Adapt quickly to new challenges with responsive digital tools. |

Logistics software increases reliability and helps you respond quickly to unexpected changes.

Proper Packaging and Stowage

You protect project cargo by following strict packaging and stowage methods. You check carrier rules for bulky items and select materials based on cargo specifics. You use molded packaging for fragile goods and provide extra protection for furniture. You ensure cargo cannot move inside boxes or containers. You crate heavy or non-uniform items for compact stowage and use boxes that withstand pressure and lateral forces. You stow cargo correctly to prevent movement, add cushioning and blocking, and protect against water damage with desiccants or moisture barriers.

Check carrier requirements for packaging oversized items.

Select packaging materials based on cargo type.

Use molded packaging for fragile goods.

Ensure cargo cannot shift inside containers.

Crate heavy or irregular items for easier handling.

Add cushioning and blocking for protection.

Use moisture barriers to prevent water damage.

Proper packaging and stowage keep your cargo safe and reduce the risk of damage during transit.

Securing and Risk Management

Stabilization Methods (Lashing, Dunnage)

You must secure project cargo with advanced stabilization techniques to prevent movement and damage during transit. Blocking and bracing combine load bars, sturdy wooden blocks, and inflatable airbags to fill gaps and support cargo. Nylon or polyester straps, including ratchet and cam buckle types, keep shipments tightly fastened. Padding materials like foam or bubble wrap protect fragile items, while corner protectors safeguard straps and enhance stability. You should position cargo with careful attention to weight distribution and use fasteners to keep blocking materials in place. Continuous monitoring with GPS tracking and load sensors gives you real-time visibility, allowing you to respond quickly if shifts or irregularities occur. Scheduled inspections during transport help verify lashings and overall cargo stability, especially on long-haul routes.

Regular safety checks identify hazards before they cause incidents. These checks address human error and equipment failures, keeping your cargo secure throughout the journey.

Risk Assessment and Mitigation

You need a thorough risk assessment before moving project cargo. Detailed planning helps you anticipate potential risks, including route selection and vessel coordination. You should analyze contracts and evaluate contractors to match project requirements. Collaboration with legal counsel and insurance brokers determines acceptable risks and transfer methods. Appointing experienced surveyors ensures adherence to transportation and loading plans. You can use container tracking systems for real-time cargo visibility and efficient customs clearance to reduce delays. Security measures such as GPS tracking and surveillance systems guard against theft and tampering. Specialized packaging and handling protocols protect shipments from environmental threats. Transferring risk to insurance providers shifts financial liability for high-value cargo.

Buy the right amount of cargo insurance.

Define the maximum payout for losses in your insurance policy.

Work with logistics providers who have in-house risk management professionals.

Environmental Considerations

You must adapt project cargo operations to changing environmental conditions. Weather windows with calm conditions are essential for safe loading and unloading. High winds or waves increase risks. Seasonal factors like monsoons or snowstorms can halt transportation, requiring careful scheduling.

Factor | Impact on Project Cargo Safety |

|---|---|

Weather Windows | Calm conditions are essential for safe loading and unloading; high winds or waves increase risks. |

Seasonal Factors | Monsoon seasons or snowstorms can halt transportation, necessitating careful scheduling. |

Extreme weather events, severe heat waves, and rising sea levels amplify risks. Intense precipitation can cause flooding, disrupt traffic, and weaken road support. You should invest in cleaner vehicles and alternative fuels to meet stricter emissions standards. The EPA’s Clean Ports Program funds zero-emission equipment for ports, supporting sustainable operations. Upgrading cargo handling machinery and drayage trucks improves air quality and helps combat climate change.

You protect cargo and the environment by planning for weather, using sustainable equipment, and following new safety protocols.

You achieve safe and efficient project cargo handling by following clear protocols and using specialized equipment. Effective planning, compliance, and risk management drive success. Skilled professionals and collaboration with logistics partners help you overcome challenges. Digital checklists and standardized processes reduce errors and improve safety.

"Project cargo isn’t about moving large equipment from point A to point B; it’s about navigating the complexities, overcoming obstacles, and finding innovative solutions to ensure everything gets to its destination safely and efficiently."

Project Cargo Safety Checklist:

Benefit | Description |

|---|---|

Standardized Processes | Ensure your team follows the same steps to reduce mistakes and improve safety. |

Compliance | Meet all regulatory requirements to minimize legal risks and enhance safety protocols. |

Risk Management | Identify hazards and use measures to keep your cargo secure and operations efficient. |

You improve efficiency, coordination, and cost savings by using these best practices.

FAQ

What is project cargo?

Project cargo refers to large, heavy, or high-value items that you cannot ship using standard methods. You often move equipment, machinery, or components for industries like energy, construction, or manufacturing.

How do you ensure project cargo safety during transport?

You secure cargo with proper lashing, blocking, and bracing. You use real-time tracking and schedule regular safety checks. You also follow strict protocols and use specialized equipment for every shipment.

Which documents do you need for project cargo shipments?

You need a commercial invoice, packing list, and customs declaration. You may also require permits for oversize or overweight loads. Always check local regulations before shipping.

What technology helps manage project cargo in 2025?

You use advanced logistics software for real-time tracking and analytics. IoT sensors monitor cargo conditions. Digital platforms automate paperwork and improve communication between all parties.

See Also

Key Strategies for Effective Global Logistics Operations

Top Global Logistics Solutions for West Coast Trucking

Enhancing International Operations Through Innovative Logistics Strategies