What Project Cargo Logistics Means and Why It’s Essential in 2025

Project cargo logistics means moving large, heavy, or complex items that need special planning and equipment. In 2025, you see this service grow as global demand rises.

The global market size for project cargo logistics in 2025 reaches XX Million.

The industry’s CAGR from 2025 to 2033 stands at XX%.

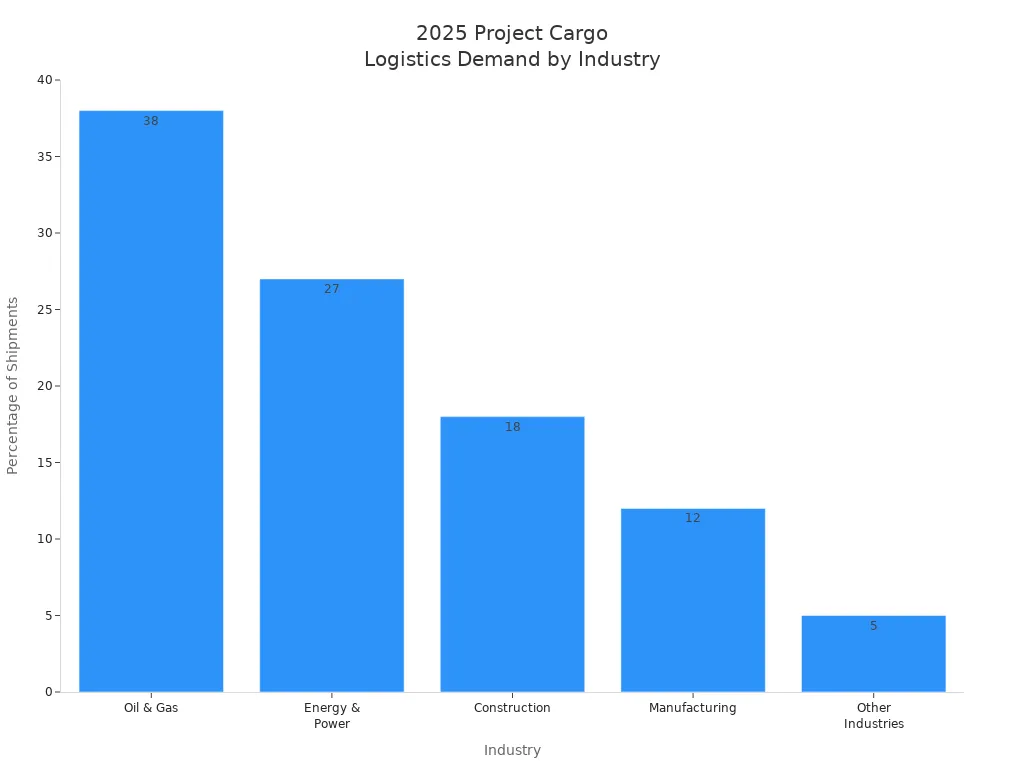

Many industries rely on these solutions.

Industry | Percentage of Shipments |

|---|---|

Oil & Gas | |

Energy & Power | 27% |

Construction | 18% |

Manufacturing | 12% |

Other Industries | 5% |

You need a project cargo logistics guide to manage risks and meet strict requirements.

Key Takeaways

Project cargo logistics is essential for moving oversized and complex items that standard shipping cannot handle. Understanding its unique requirements helps ensure safe and timely delivery.

Effective planning is crucial. Start early by measuring cargo, choosing routes, and securing permits to avoid delays and control costs.

Collaboration with various stakeholders, including engineers and local authorities, is necessary for successful project cargo logistics. Teamwork helps manage risks and meet compliance standards.

Embrace technology and automation. Use digital tools for real-time tracking and route planning to improve efficiency and reduce errors.

Stay informed about regulatory changes. Understanding new rules helps you avoid delays and additional costs in your logistics operations.

What Is Project Cargo Logistics

Definition and Scope

You encounter project cargo logistics when you need to move items that are too large, heavy, or complex for regular shipping methods. Leading industry organizations describe project cargo logistics as the transportation of oversized goods that often require special accommodations. You might see road surveys, police escorts, or even custom-built equipment for these moves. This service plays a key role in industries like oil and gas, wind power, and construction.

You use project cargo logistics when you need to transport large, complex, or high-value equipment. These shipments often come in multiple parts and require careful planning. You must meet strict delivery dates and follow detailed schedules. The process involves significant pre-planning, execution, and constant improvement. Because of this, project cargo logistics stands out as one of the most complex types of transportation.

You can see the wide scope of project cargo logistics in the types of shipments and the regions it covers:

Shipment Types | Description |

|---|---|

Heavy Lift Cargo | Includes large and technically demanding items like generators and construction machinery. |

Break Bulk Cargo | Comprises goods too large for containers, such as steel pipes and construction materials. |

Oversized Cargo | Refers to shipments exceeding standard size limits, including industrial components and wind turbine blades. |

Other Specialized Cargo | Encompasses hazardous materials and high-value machinery requiring specialized handling. |

Note: Project cargo logistics operates worldwide. You find services in North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. Countries like the United States, Canada, Germany, France, China, Japan, Brazil, and Saudi Arabia all rely on these solutions.

Unique Features

You notice several unique features when you use a project cargo logistics guide:

You transport oversized, heavy, or complex items that standard logistics cannot handle.

You often need tailored solutions for each project. Standard procedures rarely work for these shipments.

You work with many stakeholders. Planning and execution require input from engineers, logistics experts, and local authorities.

A project cargo logistics guide helps you manage these unique challenges. You learn how to coordinate with different teams and ensure every step meets safety and legal requirements.

Differences from Standard Logistics

You see clear differences between project cargo logistics and standard logistics. The table below shows how requirements change:

Feature | General Cargo | Project Cargo |

|---|---|---|

Size & Weight | Standardized dimensions, manageable weight | Oversized, overweight, may require escort |

Packaging | Packaged in containers or pallets | Custom packing, often unpackaged or rigged |

Handling | Forklifts, conveyor belts | Cranes, lowbed trailers, heavy-lift tools |

Planning Complexity | Minimal pre-shipment planning | High-level coordination, engineering input |

Transport Mode | Sea, air, road (standard options) | Often multimodal and route-specific |

Customs & Permits | Standard clearance | Special permits, escorts, port coordination |

You need a project cargo logistics guide because you face more complex planning and handling than with regular shipments. You must secure special permits, arrange for escorts, and use custom equipment. You also coordinate with ports and local authorities to ensure safe and timely delivery.

By understanding these differences, you can choose the right approach for your next big shipment. You make sure your cargo arrives safely, on time, and within budget.

Project Cargo Logistics Guide for 2025

Step-by-Step Process

You need a clear process to manage project cargo logistics in 2025. Each step helps you avoid delays and control costs. Here is a practical guide you can follow:

Planning Phase

Start by measuring your cargo’s size, weight, and dimensions. Choose the best route and get all necessary permits. Early planning gives you more options and helps you avoid last-minute problems.Preparation Phase

Gather the right equipment and package your cargo. Train your team to handle special requirements. Good preparation keeps your cargo safe.Transportation Phase

Move your cargo using trucks, ships, trains, or planes. Coordinate each transfer point. You may need to switch between different transportation modes.Customs and Freight Clearance

Prepare all documents before your cargo reaches customs. Make sure you follow every rule for international shipments.Handling and Loading Phase

Use cranes or other heavy equipment to load and unload your cargo. Check that everything stays stable and secure.Vessel or Freighter Chartering Phase

Find the right ship or plane for your cargo. Book space early to avoid delays.Managing Local Transportation at the Destination Country

Work with local companies to move your cargo to its final site. Plan for local rules and road conditions.Commissioning Phase

Test your cargo at the destination. Make sure it works as planned and arrange for any needed maintenance.

Tip: Always build in extra time for each step. Delays can happen at any stage, so a flexible schedule helps you stay on track.

You can improve your results by using cross-functional teams. Bring together experts from different fields to plan and solve problems. Many companies use a mix of traditional and agile planning methods. This approach helps you adapt to changes and work more efficiently.

Stakeholders and Expertise

You work with many people and organizations during a project cargo move. Each group brings special skills and responsibilities. The table below shows the main stakeholders:

Stakeholder Type | Description |

|---|---|

Business Institutions | Companies that manage the commercial side of your project cargo logistics. |

Social Sectors | Community groups that may be affected by your cargo movement. |

Governmental Sectors | Agencies that set and enforce rules for safety and compliance. |

Logistics Players | Experts who handle the actual transportation and cargo management. |

You also need a team with the right expertise. Project cargo logistics requires special knowledge and skills. Here are some of the key roles you should include:

Area of Expertise | Role in Project Cargo Logistics Guide |

|---|---|

Supply Chain Specialists | Plan and coordinate the entire cargo journey. |

Carriers | Provide the vehicles, ships, or planes for moving your cargo. |

Regulatory Experts | Help you get permits and follow all legal requirements. |

Heavy-Lift Operators | Use cranes and other equipment to handle large or heavy items. |

Cost Analysts | Help you understand and control transportation costs. |

Note: Your project cargo logistics guide should always include experts who know how to handle permits, special equipment, and local rules. This teamwork helps you avoid mistakes and keeps your cargo safe.

Risk and Compliance

You face many risks when you move project cargo in 2025. Some of the most common risks include:

Geopolitical changes, such as conflicts or new government policies, can disrupt your plans.

Ongoing conflicts in regions like Ukraine and the Middle East make international shipping less predictable.

New environmental rules, such as higher emissions surcharges in the EU, can increase your costs.

Cyber-attacks are a growing threat because logistics now rely on digital systems.

To manage these risks, you need strong compliance practices. The table below shows the main compliance standards you must meet:

Compliance Aspect | Description |

|---|---|

Permits | You must get special permits for overweight or oversized cargo. Rules change by country and state. |

Route Planning | You need a detailed route plan to avoid obstacles and follow travel restrictions. |

Cargo Insurance | Insurance is not always required, but it protects your high-value cargo during transit. |

Alert: Always check the latest rules before you ship. Regulations can change quickly, especially for international moves.

A good project cargo logistics guide helps you plan for these risks and meet all compliance needs. You should always have backup plans and review your process after each project. This way, you learn from every shipment and improve your results for the future.

Why It Matters in 2025

Industry Trends

You see big changes shaping project cargo logistics in 2025. Many companies face labor shortages, which makes it hard to find skilled workers. Rising costs also challenge your ability to meet goals. Sustainability is now a top priority, with almost half of businesses focusing on green targets. You notice more companies using AI to improve planning and forecasting. Hyperautomation is changing how you manage logistics, making each step faster and more accurate.

Labor shortages make it tough to fill jobs and keep projects on schedule.

Costs keep rising, so you must find ways to save money.

Sustainability goals drive new practices, even when rules change.

AI and automation help you predict demand and boost efficiency.

Companies plan to invest in automation and ecosystem integration to solve these problems. Many see sustainability as a critical goal for the future.

Technology and Automation

You rely on technology to handle complex cargo moves. Automation helps you avoid mistakes and speeds up your work. Real-time tracking lets you see where your cargo is at every step. You can use digital tools to plan routes and manage resources better. When you automate routine tasks, you make decisions faster and cut costs. This means you can focus on solving bigger problems and keeping your cargo safe.

Automation reduces human error and streamlines operations.

Real-time tracking improves visibility and control.

Digital planning tools help you allocate resources and avoid delays.

A project cargo logistics guide often includes tips on using these tools to improve your results.

Challenges and Opportunities

You face many challenges in project cargo logistics. Oversized cargo needs special equipment and careful planning. Every shipment requires a unique route, and you must check for obstacles. You often use several types of transport, like ships, trains, and trucks. Ports can get crowded, causing delays. You need special permits for large loads, and paperwork can slow you down. Changing customs rules and strict safety standards add more steps.

Size and weight extremes require heavy-lift cranes and special trailers.

Route planning must consider road conditions and obstacles.

Multimodal transport means you coordinate air, sea, rail, and road.

Port congestion and evolving customs rules can delay shipments.

You also see new opportunities. Capacity limits push you to try new shipping methods, like using multipurpose vessels. The growing demand for renewable energy projects, such as wind and solar, creates more work for logistics providers. If you stay flexible and use the right project cargo logistics guide, you can turn these challenges into success.

Industry Use-Cases

Construction Projects

You often see project cargo logistics in large construction projects. Moving wind turbines is a good example. These turbines have huge parts like nacelles that can weigh up to 120 tons and tower sections that reach 90 tons. You need careful planning to move them safely. Companies like YQN Logistics have delivered 16 sets of wind turbine equipment to Southeast Asia, showing strong skills in this field. During the Shanghai lockdown, teams used creative solutions such as 'land-to-water' and 'multi-point cargo consolidation' to keep projects on track. Sometimes, you must use a dual-ship strategy to meet tight deadlines and save costs. If a roadblock appears, you might switch to a waterway to avoid delays. Safety always comes first. Teams use millimeter-level control systems and IoT devices to watch the cargo in real time.

Wind turbine transportation needs special planning and equipment.

Creative strategies help you solve problems during tough times.

Real-time monitoring keeps your cargo safe.

Tip: Always plan for backup routes and use technology to track your shipments.

Energy Sector

You play a key role in the energy sector when you manage project cargo logistics. The shift to renewable energy means you must move more solar panels and wind turbines each year. In 2025, the U.S. plans to install over 30 GW of solar and wind capacity every year. This growth brings new challenges. You must handle large equipment, manage supply chains, and meet strict sustainability goals. The energy industry faces changes from new government rules and global trade. Tariffs can raise costs, so you need to plan carefully. You also help move equipment for solar panel factories and offshore oil rigs. Special handling is needed for these big, heavy items.

The energy sector relies on moving oversized equipment.

Demand for renewable energy increases the need for project cargo services.

You must adapt to changing rules and rising costs.

Infrastructure Moves

You face many challenges when moving large infrastructure. You must keep an accurate inventory before the move. If you lose track of items, you risk delays and extra costs. Moving heavy machines and setting up new infrastructure takes special skills and tools. You need to keep business running during the move to avoid losing money or upsetting customers. Timing matters. You must plan the move to fit business cycles and finish on time. Safety and following the rules are always important. You must protect workers and goods during every step.

Accurate inventory helps you avoid losses.

Special equipment is needed for heavy moves.

Careful timing and safety checks keep your project on track.

Note: Always check local rules and train your team before starting a big move.

Future Outlook

Sustainability

You see sustainability shaping the future of project cargo logistics. Companies now focus on reducing emissions and using cleaner fuels. Many logistics providers invest in electric vehicles and energy-efficient ships. You notice more businesses choosing routes that lower their carbon footprint. Some companies use digital tools to track emissions and report progress. Customers want greener solutions, so you must adapt your logistics plans. You help the planet by making smarter choices in transportation and packaging.

🌱 Tip: Choose partners who share your commitment to sustainability. This helps you meet new environmental goals and build trust with clients.

Digitalization

You experience rapid digitalization in project cargo logistics. Smart technologies change how you plan and manage shipments. You use AI to find the best routes and schedules. Real-time tracking gives you better control and helps you avoid risks. Digital twins let you test transportation plans before moving cargo, so you can spot problems early.

AI automates route and schedule planning.

Real-time tracking improves risk management.

Digital twins simulate moves for safer outcomes.

You benefit from digitalization in many ways:

You work more efficiently.

You save money.

You use greener transport options.

You deliver faster and more reliably.

You gain an edge over competitors.

Digitalization makes your job easier and helps you meet customer needs. You see logistics become faster, smarter, and more sustainable.

Regulatory Changes

You must stay alert to new rules in 2025. Governments update regulations to improve safety and security. For example, the De Minimis Rule changes in May 2025. Imports from China and Hong Kong will no longer get duty-free treatment. This means higher costs and more paperwork for you. You also need to report cyber incidents under new laws. In September 2025, the EU will require advanced cargo information before shipments arrive.

Regulatory Change | Description |

|---|---|

De Minimis Rule Update | Imports from China and Hong Kong lose duty-free status, raising costs and compliance work. |

Cyber Incident Reporting | Some logistics firms must report cyber incidents, changing how you handle digital security. |

EU Import Control System 2 | You must provide detailed cargo information before entering the EU, starting September 2025. |

You keep your business strong by learning about these changes and updating your processes. Staying informed helps you avoid delays and extra costs.

Project cargo logistics helps you move oversized and heavy cargo for industries like energy, aerospace, and construction. You see its value in renewable energy and large infrastructure projects, where timely delivery is critical. To succeed in 2025, you must stay adaptable and use new technology.

Use digital tools and real-time tracking for better control.

Train your team and follow new rules.

Measure your progress with clear KPIs.

Stay connected with industry groups and keep learning to improve your logistics strategy.

FAQ

What is the main difference between project cargo logistics and standard shipping?

You move items that are too large or heavy for regular shipping. Project cargo logistics uses special equipment and planning. Standard shipping handles smaller, packaged goods.

How do you ensure safety during project cargo transport?

You use trained teams, secure equipment, and follow strict safety rules. Real-time tracking and regular checks help you prevent accidents.

What documents do you need for project cargo shipments?

You need permits, cargo insurance, and customs paperwork. Each country may ask for different documents. Always check local requirements before you ship.

Can technology help you manage project cargo logistics?

Yes! You use digital tools for route planning, real-time tracking, and risk management. Technology helps you save time and avoid mistakes.

See Also

Key Strategies for Effective Management of Global Logistics

Top Global Logistics Solutions for West Coast Trucking Projects

Enhancing International Operations with Innovative Logistics Strategies

Exploring Future Trends in LCL Shipping to Panama

Boosting Global Efficiency Through Point-to-Point Logistics Systems