How Retailers Can Adapt Logistics to Demand Fluctuations

You face constant changes in customer demand. Quick moves and smart decisions keep you ahead. Nearly 60% of global merchants lose sales when products go out of stock because demand shifts fast. Data-driven logistics let you use real-time data and predictive analytics. This helps you act before problems grow and keeps your supply chain strong. Think about your current approach to retail logistics demand fluctuation solutions. Are you ready to handle the next big shift?

Key Takeaways

Understand the causes of demand fluctuations, such as seasons and events, to better prepare your inventory.

Utilize data-driven forecasting methods to predict customer demand accurately and avoid stockouts or excess inventory.

Implement scalable logistics networks that can adjust to changing demand, ensuring efficient inventory management.

Adopt micro-fulfillment centers to store popular products closer to customers, speeding up delivery times and improving customer satisfaction.

Enhance team collaboration with cloud-based tools and clear communication to tackle logistics challenges effectively.

Causes and Impact of Demand Fluctuations

Key Drivers of Demand Changes

You see demand change for many reasons. Some of the biggest drivers come from the seasons. When winter arrives, people buy more soup and cookies. During summer, ice cream sales jump. These changes happen because households shift their buying habits. Nearly 90% of seasonal demand swings come from what families choose to buy.

You also deal with events like back-to-school and holidays. These times push sales higher for certain products. Take a look at how different seasons affect retail demand:

Seasonal Pattern | Impact on Retail Demand |

|---|---|

Back-to-school season | Peak in apparel sales |

Holiday season | Increased consumer spending |

Summer | Rise in ice cream demand |

New Year | Surge in fitness equipment sales |

Promotions and sales events can shake things up, too. Flash sales and bundle offers make shoppers buy more in a short time. Clearance discounts often cause unpredictable spikes.

External factors play a role. Economic changes affect how confident people feel about spending. Tariffs and global tensions can make products harder to find. Supply chain disruptions lead to shortages and delays.

The bullwhip effect is another challenge. Small changes in customer demand can cause big swings in orders up the supply chain. This happens because of things like long lead times, poor coordination, and local decisions that don’t match overall goals.

Effects on Retail Logistics

Demand swings hit your logistics hard. You may face inventory imbalances, with too much stock or not enough. Forecasting gets tough when demand shifts quickly. You might pay more for storage or lose sales if you run out of products.

Shipping costs can rise fast. Freight rates change when you need to move products quickly. Transportation makes up about 60% of logistics costs, so these changes matter. You may need to hold extra inventory to cover delays, which increases expenses.

Order processing and delivery times can become unpredictable. Missed delivery dates lead to back-orders and unhappy customers. These challenges show why you need strong retail logistics demand fluctuation solutions to stay ahead.

Retail Logistics Demand Fluctuation Solutions

Data-Driven Forecasting

You want to predict what your customers will buy next week, next month, or even next season. Data-driven forecasting helps you do just that. You use high-quality data and smart tools to spot patterns and trends. When you clean and validate your data, you get a clear picture of what’s happening in your stores.

Many leading retailers use these methods to forecast demand:

Data-driven forecasting

AI-enabled forecasting

Proactive planning

You can also try these approaches:

Regression analysis

Time series forecasting

AI-powered forecasting

Machine learning models give you an edge. They often predict demand better than older methods. These models can look at things like weather, holidays, and local events. When you add weather data, you can cut forecast errors by up to 40% for groups of products and stores.

Tip: The more factors you include in your forecasts, the more accurate your predictions become. Don’t forget to update your data often!

Here’s a quick look at how machine learning helps with forecasting:

Evidence Type | Description |

|---|---|

Forecasting Accuracy | Machine learning models often beat traditional methods in predicting demand. |

Error Reduction | Weather data can lower forecast errors by 5% to 15% for single products. |

Factor Incorporation | Machine learning uses many factors to improve predictions. |

When you use these retail logistics demand fluctuation solutions, you can plan ahead and avoid running out of stock or having too much inventory.

Scalable Logistics Networks

Your logistics network needs to grow and shrink as demand changes. Scalable networks help you handle busy seasons and slow periods without wasting money. You can use just-in-time systems and demand forecasting tools to keep your inventory at the right level.

Check out these key features of scalable logistics networks:

Feature | Description |

|---|---|

Use JIT systems and forecasting tools to manage stock efficiently. | |

Adopt Flexible Transportation | Try dynamic routes and smart software to adjust deliveries. |

Partner with 3PL Providers | Work with third-party logistics for extra support and flexibility. |

Implement Data-Driven Decision-Making | Use analytics to make smart choices and spot ways to improve. |

Enhance Supply Chain Visibility | Use tech like blockchain for real-time updates on inventory and shipments. |

You can measure how flexible your network is during busy times. Here are some metrics to watch:

Metric | Description |

|---|---|

See how well you schedule workers. | |

Schedule Adherence | Track if staffing matches your plans. |

Overtime Percentage | Watch for too much overtime and adjust schedules. |

Fill Rate Speed | Check how fast you fill open shifts. |

Employee Experience Metrics | Ask workers about their schedules and work-life balance. |

Productivity Correlation | Find out which shift patterns work best for your team. |

You can also use perpetual inventory systems. These systems track your stock in real time, so you always know what you have. Automation helps you move products faster and with fewer mistakes. Some retailers use a two-speed approach, combining fast-moving goods with slower ones to balance their supply chain.

When you use these retail logistics demand fluctuation solutions, you stay ready for anything—big sales, slow weeks, or sudden changes.

Micro-Fulfillment Centers

Micro-fulfillment centers are small warehouses close to your customers. You store popular products nearby, so you can deliver orders faster. These centers use robots and conveyor belts to pick, pack, and ship items quickly.

Here’s how micro-fulfillment centers help you:

Store products closer to customers, which means faster delivery.

Use automation like robots for quick picking and packing.

Manage inventory better, so you sell products faster and get paid sooner.

Let’s look at a real example:

A regional grocery chain set up micro-fulfillment inside stores.

Delivery times dropped from 3 days to less than 24 hours.

Repeat orders went up by 18%.

Note: Micro-fulfillment centers make your supply chain more flexible and help you keep up with demand spikes.

You can combine micro-fulfillment with other retail logistics demand fluctuation solutions. This way, you boost order speed and accuracy, keep customers happy, and grow your business.

Technology and Automation in Logistics

Real-Time Inventory Visibility

You want to know exactly what’s in stock at any moment. Real-time inventory visibility gives you that power. With the right technology, you can track every item as it moves through your supply chain. Here are some of the most popular tools retailers use:

Technology | Function |

|---|---|

Cloud-based Order Management | Creates order and inventory visibility from a single platform, enhancing customer experience. |

RFID Tags | Provides real-time tracking for every item, improving accuracy. |

IoT Sensors | Enables real-time tracking, enhancing operational efficiency. |

Barcode Scanners | Streamlines processes like receiving and cycle counts, reducing errors. |

When you use these tools, you get up-to-date information on stock levels. You can respond quickly to changes and customer needs. Real-time tracking helps you avoid stockouts, keeps products available, and reduces overstock. You also save money by cutting excess inventory and keeping customers happy.

Accurate stock counts help you avoid disappointing shoppers.

You can minimize extra inventory and lower costs.

Fast updates let you react to demand swings with confidence.

Automated Replenishment

Automated replenishment systems make inventory management easier. You set rules and let the system reorder products when stock runs low. This means less manual work for you and fewer mistakes.

Automated stock reordering reduces manual tasks.

The system uses algorithms to trigger reorder notifications.

You can set parameters based on past sales, so popular items stay in stock.

U.S. companies have seen inventory turnover rates jump from 3–4 to 5–6.

AI-driven optimization drives this improvement.

Organizations report a 15–30% boost in supply chain efficiency.

You keep shelves stocked and improve turnover rates. Automated replenishment is one of the retail logistics demand fluctuation solutions that helps you stay ahead.

Integrating Supply Chain Tools

You need supply chain tools that work together. Integration helps you manage orders, track inventory, and ship products smoothly. Here are two top tools:

Software Tool | Key Features | Target Users |

|---|---|---|

Blue Yonder | AI and machine learning for optimization, real-time visibility, demand forecasting | Retail businesses of all sizes |

Fishbowl | Real-time inventory tracking, order management, shipping integration | Small to mid-sized businesses |

Integrated platforms improve communication between you and your suppliers. You can respond quickly to demand changes, reduce lead times, and boost efficiency.

Level of Integration | Description |

|---|---|

Operational | Improves processes like production scheduling and inventory management. |

Tactical | Links departments for better material flow and shared data. |

Strategic | Builds partnerships for collaboration with suppliers and customers. |

"Communication between the different links of an integrated supply chain makes it possible to eliminate cost overruns and bring down the cost of the processes."

You get faster responses, fewer delays, and a stronger supply chain. These tools make your logistics more flexible and ready for anything.

Overcoming Logistics Challenges

Managing Data Overload

You probably see a flood of data every day. It can feel overwhelming. You want to use this information to make smart decisions, but too much data can slow you down. Many retailers face these common challenges:

Challenge | Description |

|---|---|

Rising Customer Expectations | Shoppers want fast, affordable, and easy service. You need to keep up with their demands. |

Lack of Real-Time Inventory | If you can’t track inventory right away, you risk losing sales and trust. |

High Shipping Costs and Delays | Shipping is unpredictable. You need better planning to avoid surprises. |

Issues with Returns Processing | Slow returns hurt profits and frustrate customers. |

Almost all shoppers care about shipping cost and speed. If you don’t meet their needs, they may shop somewhere else.

So, how do you handle all this data? Start by turning raw data into useful insights. Analyze trends and spot problems early. Use real-time data to react quickly when things change. Make sure your data is clean and accurate. Centralize your information so everyone sees the same numbers. When you use dashboards and AI tools, you can see patterns and make better choices. Try using a Delivery Management System (DMS) to bring all your logistics data together.

Tip: Clean, real-time data helps you stay ahead of demand swings and keeps your team on the same page.

Enhancing Team Collaboration

You can’t solve logistics challenges alone. Your team needs to work together, share information, and make quick decisions. Cloud-based tools help everyone stay connected. Instant messaging and shared dashboards keep your team in sync. When everyone knows what’s happening, you avoid mistakes and delays.

Here are some ways to boost teamwork:

Set clear roles and responsibilities.

Give your team the right tools and resources.

Define goals everyone understands.

Appoint someone to oversee the whole process.

Keep communication open and simple.

Cross-train team members so they understand each other’s jobs.

Meet regularly to check progress.

Ask for feedback and listen to ideas.

Get support from leaders.

Celebrate wins together! 🎉

When you build a strong, connected team, you solve problems faster and keep your logistics running smoothly.

You can stay ahead of demand swings by using smart technology, building flexible networks, and working closely with partners. Many top retailers focus on these key strategies:

Key Strategy | Description |

|---|---|

Leveraging Technology | Boosts logistics speed and accuracy |

Helps you respond fast to changes | |

Unified Visibility | Lets you see inventory and orders in real time |

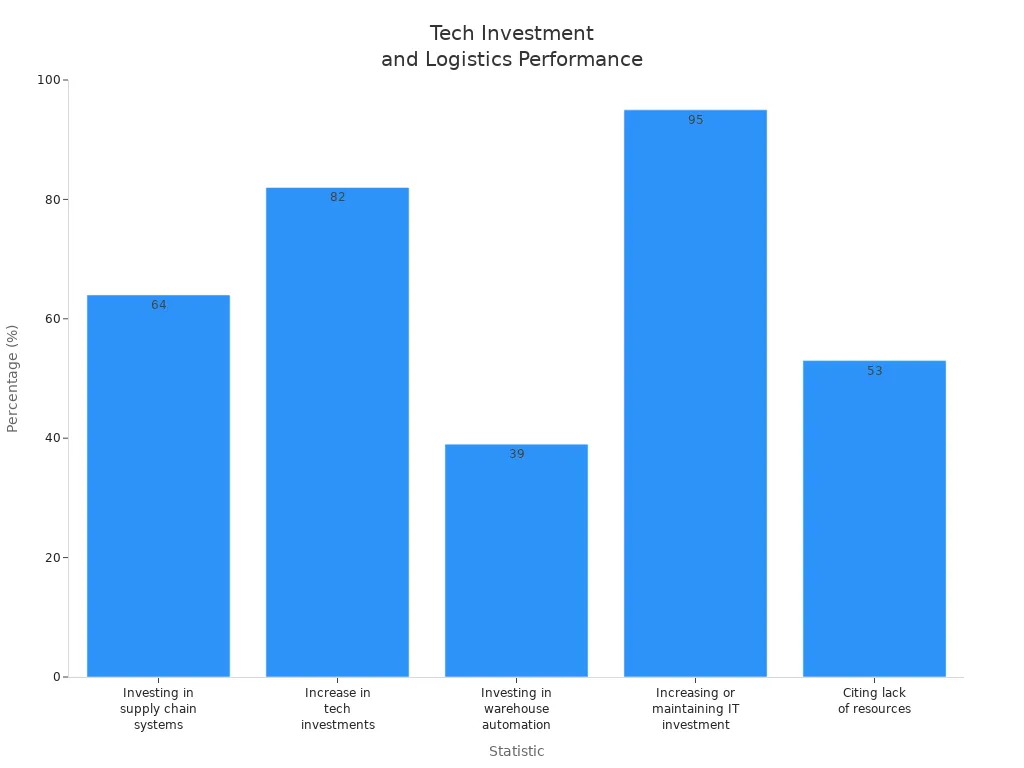

Most companies now invest in digital tools to improve performance:

Take a fresh look at your logistics systems. Upgrade where needed. Keep learning and improving so you’re always ready for what comes next. 🚀

FAQ

How can you predict demand changes in your store?

You can use sales data, weather reports, and local events. AI tools help you spot patterns. Update your forecasts often to stay ahead.

What is a micro-fulfillment center?

A micro-fulfillment center is a small warehouse near your customers. You store popular products there. Fast delivery keeps shoppers happy.

Why does real-time inventory matter?

Real-time inventory lets you see what you have right now. You avoid running out of stock. You also cut costs by not over-ordering.

How do you handle too much data in logistics?

Start by cleaning your data. Use dashboards to see trends. Focus on the numbers that matter most for your business.

What tools help your team work better together?

Cloud-based platforms, instant messaging, and shared dashboards keep everyone connected. Regular meetings and clear roles make teamwork easier.

See Also

PGL Ensures Timely Movement Of Your eCommerce Inventory

Prepare For Holiday Demand With PGL’s Logistics Services

Streamline Your Supply Chain With American Logistics Solutions