Step-by-Step Project Cargo Logistics Guide for Beginners

You might feel overwhelmed when you first hear about project cargo logistics. Don’t worry—you can manage it if you take it one step at a time. Project cargo logistics means moving large, heavy, or complex items, which are common in industries like construction and energy. A clear, step-by-step process helps you stay organized and avoid mistakes. For example, you start with planning, then prepare your team and equipment, handle transportation, and finish with delivery and commissioning. Here’s a quick look at how each phase fits together:

Phase | Description |

|---|---|

Planning | Find out cargo size, weight, and route; get permits; survey the route. |

Preparation | Gather equipment, package cargo, and train your team. |

Transportation | Move cargo and switch between transport types as needed. |

Customs & Freight Clearance | Clear cargo through customs early to prevent delays. |

Handling & Loading | Use cranes and secure cargo for safe transport. |

Chartering | Arrange for the right ship, plane, or truck. |

Local Transportation | Manage cargo movement at the destination. |

Commissioning | Test and set up cargo at the final site. |

When you follow a project cargo logistics guide, you break down each phase into manageable steps. This makes the process easier to handle, even if you’re new to the field.

Key Takeaways

Start with a solid plan. Define your cargo's size, weight, and route to avoid problems later.

Choose the right logistics provider. Look for experience, customized solutions, and good risk management.

Conduct a thorough route survey. Check for obstacles and ensure the path is safe for your cargo.

Follow all regulations and prepare necessary documents. This helps prevent delays and fines during transport.

Prioritize safety during loading and unloading. Use the right equipment and communicate clearly with your team.

Project Cargo Logistics Guide Overview

What Is Project Cargo?

You might wonder what makes project cargo different from regular shipments. Project cargo includes large, heavy, or high-value items that need special handling. These items often support big projects in industries like construction, oil and gas, or renewable energy. You can’t just pack them in a standard container and send them off. They need careful planning and expert attention.

Here’s a quick comparison to help you see the difference:

Feature | Project Cargo | General Cargo |

|---|---|---|

Nature | Involves large, complex, high-value items | Typically standard items |

Handling | Requires specialized handling and planning | Can be shipped in regular containers |

Size | Often oversized or heavy, cannot fit in standard containers | Fits in standard shipping containers |

Value | High-value items, sometimes worth millions | Generally lower value items |

Impact of Delay | A delay can halt entire projects, causing significant costs | Less impact on overall shipping |

A project cargo logistics guide helps you manage these unique shipments step by step. You start with a solid plan, prepare backup options, and keep communication open during transport. After delivery, you review the process to improve for next time.

Key Challenges

You will face some tough challenges when you handle project cargo. Many people in the industry say obstacles pop up often. Labor shortages make it hard to find skilled workers. Tight schedules can disrupt your plans. Costs may rise because of unexpected problems. Sometimes, you can’t get the materials or equipment you need on time.

Other issues come from outside forces. Political and economic changes can affect supply chains. Shipping prices go up, and travel times get longer. Planning for oversized cargo gets complicated fast.

Tip: Always prepare a backup plan. If something goes wrong, you’ll be ready to adjust and keep your project moving.

A project cargo logistics guide gives you the structure you need to tackle these challenges. You learn how to plan, adapt, and improve with each project.

Planning

Planning is where everything starts in project cargo logistics. If you skip this step or rush through it, you might face big problems later. You want your project to run smoothly, so you need a strong plan from the beginning. This phase helps you see the big picture, spot possible issues, and set clear goals. Let’s break down the planning phase into three main parts.

Define Scope

First, you need to define the scope of your project. This means you figure out exactly what you need to move, where it needs to go, and what makes your cargo special. Every project cargo operation is different. You might have to move a giant turbine, a long pipeline, or a heavy transformer. Each one needs a custom solution.

When you define the scope, focus on these key points:

Measure the size and weight of your cargo as accurately as possible.

Choose the right equipment for lifting and moving your cargo.

Work with experienced logistics providers who know how to handle oversized and heavy items.

Think about any special rules or permits you might need for your cargo.

Project cargo operations need detailed planning and special handling. You can’t use a one-size-fits-all approach. You must look at the unique challenges of your shipment and plan for them. If you skip this step, you might run into trouble with equipment, permits, or even the route.

Tip: Write down every detail about your cargo and your goals. This helps everyone on your team stay on the same page.

Set Requirements

Once you know your scope, you need to set your requirements. These are the things you must have or do to make your project a success. You want to make sure nothing important gets missed.

Here’s a checklist to help you set your requirements:

Bring in experts to inspect your cargo and survey the route.

Coordinate with everyone involved to save time and money.

Make backup plans in case something goes wrong.

Review how long each part of the journey will take.

You might need special equipment, extra insurance, or extra training for your team. You also need to think about customs, permits, and local rules. If you set clear requirements early, you avoid surprises later.

Note: Good coordination helps you avoid delays and extra costs. Always double-check your list before moving forward.

Risk Assessment

Now, let’s talk about risk. Every project cargo move comes with risks. Your cargo might be odd-shaped or very heavy. The route could have tight corners or weak bridges. Weather, strikes, or paperwork problems can also cause trouble.

You need to spot these risks early and make a plan to handle them. Here’s how you can do it:

Keep detailed records of your cargo and your plans.

Think about what could go wrong with your cargo’s shape or size.

Look at every step of your supply chain for possible problems.

Use a risk analysis to decide if you need extra insurance.

A good risk assessment helps you avoid big losses. It also makes it easier to get insurance for your cargo. If you know the risks, you can prepare for them and keep your project on track.

Callout: Don’t skip risk assessment. It’s your safety net when things don’t go as planned.

A solid planning phase sets you up for success. When you follow a project cargo logistics guide, you start with a clear scope, set strong requirements, and assess risks. This foundation makes the rest of your project much easier to manage.

Provider Selection

Choosing a Provider

You want your project to run smoothly, so picking the right logistics provider matters a lot. Not every company can handle big, heavy, or unusual cargo. You need a partner who knows what they are doing. Here are the most important things to look for when you choose a provider:

Expertise and Experience: Look for a team that has handled complex shipments before. They should know the rules and how to solve problems fast.

Customized Solutions: Your project is unique. The provider should offer plans that fit your needs, not just a standard package.

Risk Management: Ask how they handle risks. Good providers have backup plans for delays, damage, or other surprises.

Global Network: If your cargo crosses borders, you need a provider with connections around the world. This helps with customs and local rules.

Comprehensive Services: It helps if the provider can do everything from planning to delivery. You do not want to juggle many companies.

Customer Support: You want updates and quick answers. Good support keeps you in the loop.

Cost-effectiveness: Price matters, but value is more important. The cheapest option may not be the best.

Tip: Ask for references or case studies. A good provider will gladly share their success stories.

Building a Team

You cannot do project cargo alone. You need a strong team to make things work. Start by picking people with the right skills. You want experts in logistics, safety, and equipment handling. Make sure everyone knows their job and can talk to each other easily.

Hold regular meetings to keep everyone updated.

Use clear checklists so no one misses a step.

Encourage team members to share ideas and spot problems early.

A good team helps you follow the project cargo logistics guide and avoid mistakes. When everyone works together, your project has a better chance of success.

Route Survey

You need to know the route before you move any big cargo. A route survey helps you spot problems early and plan for safe delivery. You look at every part of the journey, from start to finish. This step keeps your project on track and helps you avoid surprises.

Route Assessment

When you start a route assessment, you walk or drive the path your cargo will take. You check for tight turns, low bridges, and wires that might get in the way. You also look for railroad crossings and construction zones. Here’s how you can break down the process:

Check for sharp turns, low-hanging wires, and bridge underpasses.

Write down any hazards like railroad tracks or roadwork.

Measure overhead clearances and turning space.

Plan for help from pilot cars or local police if you need it.

You will run into obstacles. Take a look at some common ones:

Obstacle | Description |

|---|---|

Securing Load Permits | Getting permits can take time because rules change from state to state. |

Navigating Route Restrictions | Big loads face limits on certain roads, so you need to plan and talk to local officials. |

Ensuring Safety with Escort Vehicles | You may need escort cars, but setting them up can be tricky. |

Scheduling Around Travel Restrictions | Some roads have time limits, so you must adjust your schedule. |

Managing Equipment and Freight | Picking the right gear matters; wrong tools can cause delays or accidents. |

Compliance with Regulations | You must follow all laws, or you risk fines and delays. |

Tip: Always double-check your route before moving your cargo. A small mistake can cause big problems.

Feasibility Study

A feasibility study helps you decide if your plan will work. You look at your cargo and the route to see if you can move everything safely. Here are the main things you need to check:

Pick the best way to move it, like by truck, ship, or special equipment.

Make sure you can get all the permits and follow the rules.

Think about risks and how you can avoid them.

Plan how you will carry out the move from start to finish.

You use the project cargo logistics guide to help you through each step. When you do a good route survey and feasibility study, you make sure your cargo gets where it needs to go without trouble.

Compliance

Regulations

You need to follow strict rules when you move project cargo. Every country has its own set of laws. If you skip a rule, your cargo could get stuck or you might pay a big fine. Let’s look at the main types of regulations you will face:

Regulation Type | Description |

|---|---|

Permits | You must get special permits to move oversized or heavy cargo across regions. |

Safety Standards | You need to follow safety rules to protect people and equipment. |

Documentation | You must fill out all the right paperwork to meet local laws. |

You should always check the rules for each country on your route. Some places have extra safety checks or need more permits. If you plan ahead, you can avoid delays and problems.

Tip: Make a checklist of all permits and safety rules before you start your project. This helps you stay organized and ready for inspections.

Documentation

You cannot skip paperwork in project cargo logistics. Each document has a job. Some prove what you are shipping. Others show where your cargo comes from or how to handle it safely. Here are the most common documents you will need:

Bill of Lading: This is your contract for the shipment. It lists what you are sending and where it is going.

Commercial Invoice: This shows the deal between you and the buyer. Customs officers use it to check the value.

Certificate of Origin: This tells where your cargo was made. Some countries use this to set taxes.

Safety Data Sheet (SDS): You need this if your cargo is dangerous. It explains how to handle and store it.

Service Contract: This is the agreement between you and the transport company.

Shipper’s Letter of Instructions (SLI): This tells the carrier exactly how to handle your shipment.

In international project cargo shipments, you need the right documents to clear customs and follow the law. Each paper helps your cargo move smoothly from one country to another. If you miss a document, your shipment could get delayed or even stopped.

Note: Double-check your paperwork before shipping. One missing form can hold up your whole project.

Transport Modes

Land, Sea, Air

You have a few choices when you move project cargo. Each transport mode has its own strengths and weaknesses. Picking the right one depends on your cargo, your budget, and your timeline. Let’s look at the main options:

Transport Mode | Advantages | Disadvantages |

|---|---|---|

Air Freight | Speed, Security, Global Reach | Cost, Limited Capacity, Weather Dependency |

Sea Freight | Cost-Effectiveness, Large and Secure Capacity, Environmental Impact | Speed, Weather Dependency, Customs and Logistics |

Flexibility, Cost, Speed | Traffic and Delays, Cargo Capacity, Border Crossings and Customs |

Air freight works best when you need to move something fast or send it far away. You pay more, but you get speed and security. Sea freight lets you ship huge items for less money. Ships carry heavy loads and keep cargo safe, but the trip takes longer. Land freight gives you flexibility. Trucks and trains can reach places ships and planes cannot. You might face traffic or border checks, though.

Tip: Match your cargo’s size and urgency to the right transport mode. If you rush, you might spend too much or run into delays.

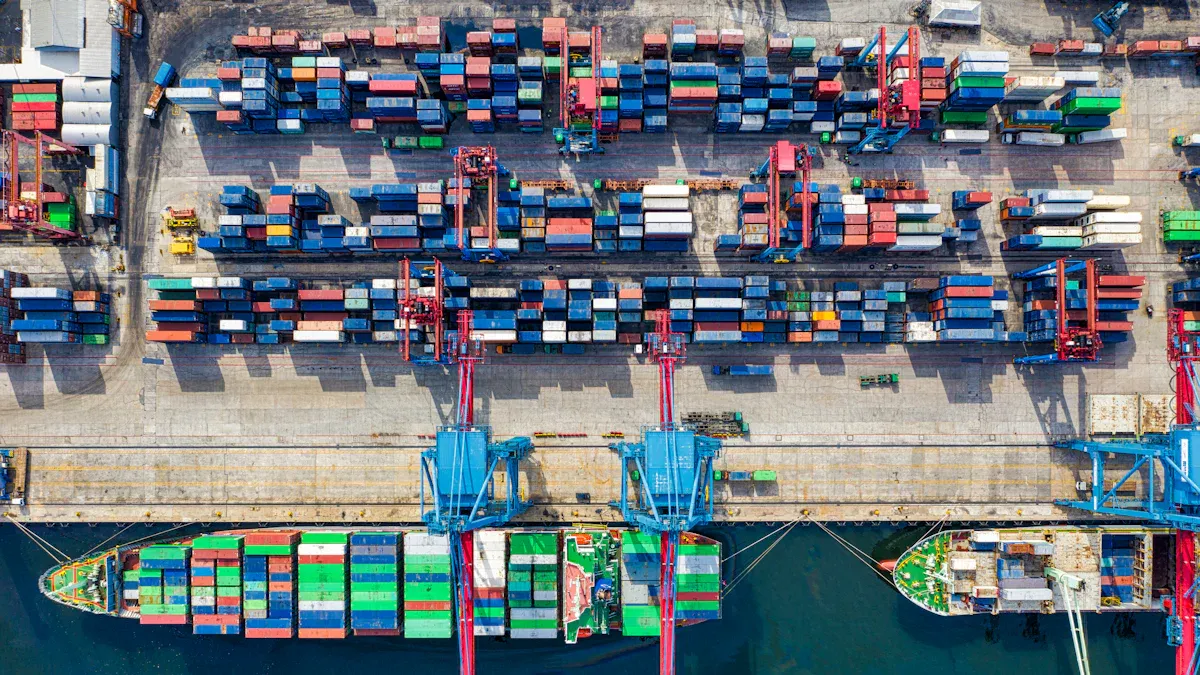

Port Roles

Ports play a big part in project cargo logistics. They help you move cargo from one transport mode to another. Ports use special equipment and skilled workers to handle all kinds of cargo. Here’s what happens at a port:

Description | |

|---|---|

Container operations | Loading and unloading containers using specialized cranes |

Bulk operations | Transferring loose commodities via conveyor systems |

Liquid bulk operations | Pumping fluids through pipelines |

Break-bulk operations | Handling individual packages or non-containerized cargo |

Roll-on/Roll-off (Ro-Ro) | Driving vehicles on and off specialized vessels |

Value-added logistics | Steel-cutting operations and packaging at general cargo terminals |

You might see cranes lifting containers or conveyor belts moving grain. Workers pump liquids through pipelines or drive trucks onto ships. Some ports even cut steel or package goods before sending them out. Each operation helps your cargo move safely and quickly.

Note: Always check if your port has the right equipment for your cargo. The right port can save you time and money.

Cargo Handling

Loading & Equipment

You need the right tools to handle project cargo. Regular forklifts and pallet jacks just won’t cut it for oversized or heavy shipments. You’ll see cranes and rigging equipment at almost every project cargo site. These machines lift and move items that can’t fit into standard containers. Cranes help you raise huge pieces safely. Rigging equipment keeps everything steady and secure. Heavy lifts are also common. They let you move items that weigh several tons.

Here’s a quick list of specialized equipment you might use:

Cranes

Rigging equipment

Heavy lifts

You should always match your equipment to your cargo. If you use the wrong gear, you risk damage or delays. Talk to your team before you start loading. Make sure everyone knows how to use the equipment. Double-check that your gear can handle the weight and size of your shipment.

Tip: Test your equipment before the big day. A quick check can save you from costly mistakes.

Safety

Safety comes first when you handle project cargo. You deal with big, heavy items, so you need strong safety rules. Start with a solid plan for your route. Walk through every step before you move anything. Get all the right permits and follow local laws. Hire drivers who know how to handle oversized loads. Use escort vehicles, like pilot cars, to guide your shipment.

Here are some top safety protocols you should follow:

Plan your route and do pre-trip surveys.

Get proper permits and follow regulations.

Hire certified, experienced drivers.

Use escort vehicles for guidance.

Secure your cargo and inspect vehicles.

Use advanced technology for tracking.

Prepare for emergencies and keep communication open.

You want everyone to stay safe. Check your cargo often. Make sure it’s secure before you hit the road. If you spot a problem, fix it right away. Good safety habits protect your team and your shipment.

Note: Safety isn’t just a rule—it’s your best tool for a successful project.

Delivery & Commissioning

Final Delivery

You’ve made it to the last stretch—final delivery. This is where your cargo reaches the destination site. You want everything to go smoothly, so you need a solid plan. Start by mapping out your route and checking for any obstacles. Give your drivers a detailed report with all the travel info they need. If your cargo needs pilot cars, make sure you coordinate with them for safe transport. Double-check your schedule so every part of the journey lines up. Stay in touch with your project manager and site supervisors during the trip.

Before you hand over the cargo, follow these steps:

Review all your documents to make sure you meet every rule.

Let customs officials inspect the cargo if needed.

Show the right papers to prove what you’re delivering.

Tip: Keep your phone handy and stay in contact with everyone involved. Quick updates can help you fix problems before they grow.

Unloading

Unloading is a big moment. You want to avoid damage and delays, so planning is key. Start with a detailed plan that covers every step. Use special equipment and advanced rigging to handle heavy or odd-shaped items. Make sure your team talks to each other and works together. Only let trained professionals handle the unloading. Keep an eye on the cargo as it comes off the truck or ship, and be ready to adjust if something changes.

Here’s a simple checklist for safe unloading:

Plan every detail and look for risks.

Use the right machines and rigging tools.

Communicate clearly with your team.

Hire skilled workers with special training.

Watch the cargo closely and make changes if needed.

Note: Never rush unloading. Taking your time keeps people safe and protects your cargo.

Commissioning

Now your cargo is on site, but your job isn’t done yet. Commissioning makes sure everything works as it should. Walk through the site and look for any problems. Make a list of anything that needs fixing. Sort these issues by how urgent they are. Gather all the manuals and training plans from your contractors. Get any special tools you need for testing. Decide how you’ll collect test results—maybe with a computer or by hand. Keep everyone updated on your progress and any issues you find. Set up safety systems and make sure energy sources are isolated before you start.

Callout: Good commissioning means your project starts strong and runs safely from day one.

Best Practices

Tips for Beginners

Starting out in project cargo logistics can feel like a big task, but you can make it easier by following some smart habits. Here are the top tips to help you succeed:

Plan Strategically: Always start with a clear plan. Take time to assess your cargo and the route before you move anything.

Work with Experts: Choose logistics partners who have experience with large or complex shipments. They can help you avoid common mistakes.

Use Technology: Track your cargo in real time. Technology gives you updates and helps you spot problems early.

Manage Risks and Get Insurance: Think about what could go wrong and get the right insurance. This protects you if something unexpected happens.

Follow Rules and Handle Paperwork: Make sure you know the customs rules and have all the documents ready. This keeps your cargo moving without delays.

Tip: If you ever feel stuck, go back to your plan and check each step. The project cargo logistics guide is there to help you stay on track.

Common Pitfalls

Even with good planning, beginners sometimes run into trouble. Watch out for these common mistakes:

Skipping a full route survey can lead to big problems on the road.

Not thinking about the weather or busy seasons may cause delays.

Using basic insurance might not cover your cargo if something goes wrong.

Poor communication with your team can slow down the whole project.

Securing the load the wrong way can be dangerous.

Giving the wrong size or weight details can mess up permits and schedules.

Forgetting to share technical drawings or handling instructions can cause accidents.

Not being clear about equipment needs can waste time and money.

Note: Double-check your details and talk with your team often. Small mistakes can turn into big issues if you ignore them.

Quick Recap

Checklist

You have learned a lot about project cargo logistics. Now, let’s make sure you remember the most important parts. Here’s a handy checklist you can use before you start your next project. This table shows different cargo categories and what you need for each one:

Cargo Category | Description | Key Requirements |

|---|---|---|

Category A cargo | Transformers, generators, and similar equipment with lifting provisions. | Dimensional drawings, center of gravity locations, securing point arrangements, breaking strength specifications. |

Category B cargo | Pressure vessels and large cylindrical equipment transported horizontally. | Custom cradles for support, securing points with breaking strength of at least 2.8 times the unit weight. |

Category C units | Prefabricated steel structures with defined lifting and securing provisions. | Structural design for timber blocking, friction enhancement through dunnage placement. |

Tip: Always check your cargo type and match it with the right requirements. This step helps you avoid mistakes and keeps your project safe.

Further Learning

You might want to dig deeper into project cargo logistics. Here are some great resources and ideas to help you keep learning:

Explore guides that explain how to plan and move oversized or time-sensitive goods. These guides show why careful coordination and using more than one transport type matter.

Read articles that talk about project cargo in industries like oil and gas, wind power, and construction. You will see how detailed engineering helps control costs and timelines.

Look for resources that describe moving large, heavy, or complex equipment. These often discuss how to find materials from around the world and why planning is so important.

Check out materials that highlight the need to follow customs rules and handle paperwork the right way.

Note: The more you learn, the more confident you will feel. Keep asking questions and stay curious. Project cargo logistics gets easier with practice and knowledge!

You can handle project cargo logistics if you follow each step and stay organized. Start with small projects, ask experts for help, and keep learning as you go. When you keep your knowledge fresh, you boost safety, improve performance, and stay ready for new changes.

You lower risks and feel more confident.

You help your team grow and keep your company strong.

You stay up to date as technology and supply chains change.

Keep moving forward—every project helps you grow in this exciting field!

FAQ

What is the first thing I should do before starting a project cargo shipment?

You should always start with a clear plan. Write down your cargo details, route, and team roles. This helps you avoid mistakes and keeps everyone on track.

How do I choose the right transport mode for my cargo?

Think about your cargo’s size, weight, and how fast you need it delivered. Use this table to help:

Cargo Type | Best Mode |

|---|---|

Oversized | Sea, Land |

Urgent | Air |

Heavy | Sea, Land |

What documents do I need for project cargo logistics?

You need a bill of lading, commercial invoice, certificate of origin, and safety data sheet. Always double-check your paperwork before shipping. Missing one can cause delays.

How can I keep my cargo safe during transport?

Tip: Use strong equipment and secure your cargo tightly. Train your team and check everything before moving. Safety checks help you avoid accidents and protect your shipment.

See Also

Key Strategies for Effective Global Logistics Operations

Premier Global Logistics – Vital LCL Shipping Steps for Panama

Transport Large Loads Economically – FTL Solutions by Premier Global

Premier Global Logistics – Streamlined Project Hauling on the West Coast

Selecting LTL, FTL, or Drayage with PGL for Trucking Solutions