7 Steps to Manage Time Critical Shipments Efficiently

You achieve fast, reliable, and error-free delivery when you focus on time critical shipment management. Proactive planning gives you the ability to spot risks early and prevent mistakes. Accurate forecasting helps you anticipate demand, so you avoid last-minute shipments that often cause delays. When you use technology for real-time tracking, you make quick decisions and solve problems before they grow. These strategies give you control and keep urgent shipments on track.

Spot risks early and prevent mistakes.

Anticipate demand and avoid last-minute shipments.

Use real-time tracking to solve problems quickly.

Key Takeaways

Proactive planning helps you spot risks early and avoid mistakes in shipment management.

Clear communication with your team and stakeholders reduces confusion and keeps shipments on track.

Using real-time tracking technology allows you to monitor shipments and make quick decisions.

Secure packaging and accurate labeling prevent damage and ensure compliance with shipping regulations.

Choosing the right carrier and maintaining regulatory compliance are crucial for timely and safe deliveries.

Proactive Communication

Clear and ongoing communication forms the backbone of time critical shipment management. You need to share information at every stage to keep shipments moving smoothly. When you communicate early and often, you prevent confusion and reduce the risk of delays. Many problems in urgent logistics come from communication breakdowns. These can disrupt operations and increase risks.

Breakdown Type | Impact on Shipment Management |

|---|---|

Lack of coordination between departments | Can lead to delays, machine downtime, or bottlenecks. |

Neglecting equipment issues | Results in unexpected downtime and safety hazards. |

Inaccurate communication with suppliers | Causes materials shortages and delayed shipments. |

Outdated communication methods | Slows information flow and can lead to lost messages. |

Incorrect inventory information | Disrupts schedules and causes delays in production. |

Internal Team Coordination

You improve shipment speed and accuracy when your teams work together. Regular meetings and updates help everyone stay on the same page. Collaborative groups finish projects on time 33% more often. When teams work in pairs, they complete tasks faster than larger groups. Still, 39% of workers feel their workplace lacks enough cooperation. You can boost performance by encouraging teamwork and sharing updates often.

Stakeholder Updates

You build trust with stakeholders by keeping them informed. Best practices include sending real-time delivery confirmations and uploading proof of delivery with GPS location. You should also update your client’s system right after delivery. Clear communication with logistics partners about expectations helps avoid surprises. Using freight communication platforms gives everyone reliable and timely information.

Tip: End-to-end shipment visibility helps stakeholders feel confident about urgent deliveries.

Customer Notifications

You increase customer satisfaction by sending timely updates. Shipping notifications give real-time tracking information, so customers know where their shipment is. These updates reduce the number of questions about order status. Customers feel less anxious when they know the estimated arrival time. Keeping customers informed leads to a better experience and fewer complaints.

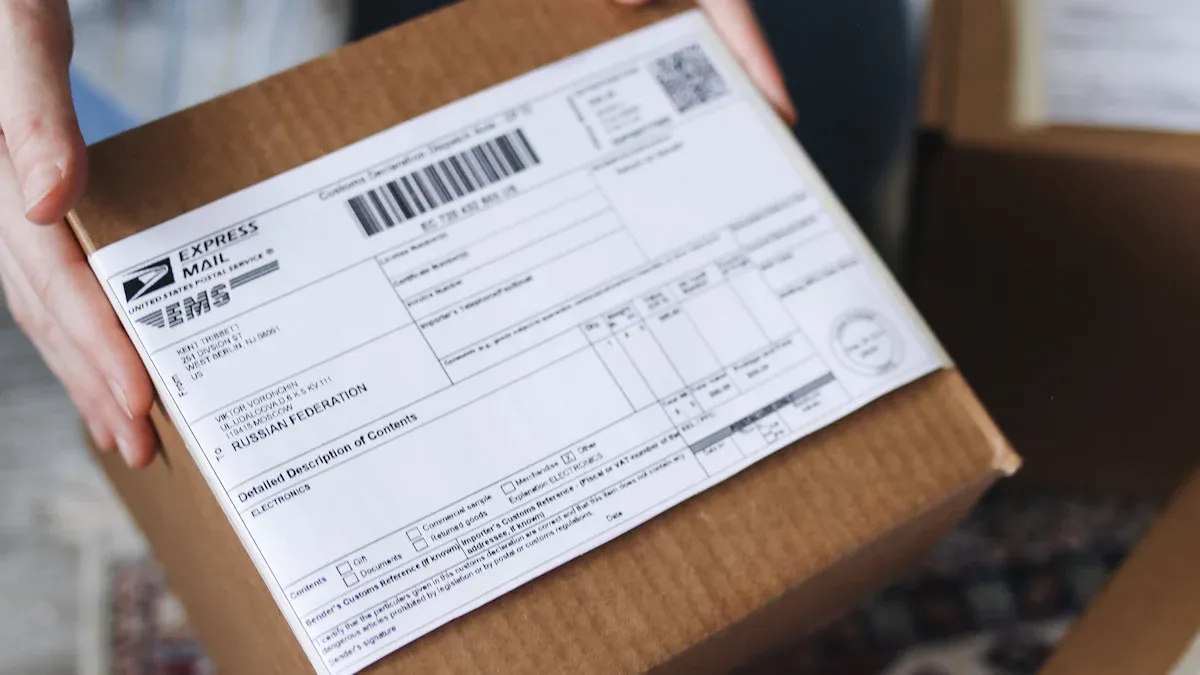

Packaging and Labeling Essentials

Secure Packaging

You protect shipments by choosing strong packaging materials. Bubble wrap and foam inserts cushion fragile items, reducing the risk of damage. Double boxing adds another layer of safety, keeping goods secure during transport. Tamper-evident seals and unique barcodes help you spot any interference quickly. Many companies now use sustainable options like recycled cardboard, which supports eco-friendly shipping. You can also add RFID tags and GPS tracking to monitor packages in real time. These steps keep your shipments safe and give you peace of mind.

Tip: Secure packaging is not just about protection. It also helps you meet international shipping regulations and avoid costly delays.

Aspect | Contribution to Compliance |

|---|---|

Ensures safe containment of goods, especially dangerous items, and withstands transport rigors. | |

Provides hazard information, helping with proper handling and customs clearance. | |

Documentation (DGD) | Supplies detailed information about goods, supporting compliance with international standards. |

IATA and IMO Regulations | Promotes safety and faster customs clearance through correct labeling and documentation. |

Local Regulations Awareness | Meets country-specific packaging and documentation requirements. |

Accurate Labeling

You lower the risk of misrouted or lost shipments by using clear and correct labels. Shipping labels show the recipient’s details, carrier codes, and service levels. Barcodes allow scanning at every step, so you can track packages in real time. Well-printed labels help workers identify and process packages quickly.

Accurate routing sends packages to the right place.

Real-time tracking keeps you updated and helps solve problems fast.

Loss prevention reduces mistakes and keeps shipments safe.

Documentation Checks

You avoid delays by checking all documents before shipping. Common errors include missing information, wrong country of origin, and incorrect product descriptions. You should review every detail to make sure it matches the shipment. Missing signatures or wrong codes can stop your package at customs. Careful documentation supports time critical shipment management and keeps your deliveries on schedule.

Incomplete documentation

Missing consignee or shipper information

Incorrect country of origin

Wrongly declared currency

Inaccurate product description

Wrong HS code

Incorrect value or quantity of goods

Missing signature on invoice or contract

Carrier Selection and Compliance

Choosing the right carrier is a key part of time critical shipment management. You need to make sure your shipments arrive on time and in perfect condition. Reliable carriers help you avoid delays and keep your customers happy.

Reliable Carrier Choice

You should use clear criteria when picking a carrier for urgent shipments. Here is a list to guide your decision:

Safety record shows how well the carrier follows rules and handles incidents.

Experience and expertise matter for special types of shipments.

Licensing and insurance protect your goods and meet legal requirements.

Equipment and fleet must match your shipment needs.

Network and coverage area decide how far and fast your shipment can go.

Reliability and on-time delivery keep your promises to customers.

Pricing and cost transparency help you avoid hidden fees.

Customer service and communication make problem-solving easier.

Environmental practices show the carrier’s commitment to sustainability.

References and reviews give you real feedback from other shippers.

Tip: You can ask for references or check online reviews before making your final choice.

Regulatory Compliance

You must follow all rules and regulations for shipping. Carriers need proper licenses and insurance. You should check if the carrier meets local and international standards. This step helps you avoid fines and delays at customs. You also need to make sure your carrier understands special rules for hazardous or sensitive goods. Good compliance keeps your shipments safe and legal.

Special Services (e.g., Temperature Control)

Some shipments need extra care, like temperature control. You can use special services to protect your goods. Here is a table that shows common options and how they help:

Special Service | Description |

|---|---|

Temperature Monitoring Devices | Gives real-time updates on shipment temperature during transit. |

Specialized Packaging | Uses foam coolers and thermal bubble wrap to keep items at the right temperature. |

Specific Coolants | Uses dry ice and gel packs to cool goods without damage. |

Experienced Carriers | Uses carriers with skills in temperature control to keep shipments safe. |

You should also think about cost and reliability when choosing a carrier. Here is a table that compares popular options:

Carrier | Cost Implications | Reliability | Special Services | Surcharges |

|---|---|---|---|---|

USPS | Budget-friendly for small shipments, no residential surcharges, flat-rate for packages under 20 lbs | 94.3% on-time delivery | None specified | None specified |

UPS | Higher costs due to various surcharges, especially for residential deliveries | 97.5% on-time delivery | Insurance up to $50,000, technology investment for tracking | Residential delivery fees, fuel adjustments |

FedEx | Premium pricing for expedited services, most expensive for routine shipments | Not specified | Advanced cold chain capabilities, insurance up to $100,000 | None specified |

You improve delivery success rates when you match your shipment needs with the right carrier and special services. Careful carrier selection and compliance checks help you manage time critical shipment management with confidence.

Technology in Time Critical Shipment Management

You gain more control and visibility over urgent shipments when you use technology. Modern tools help you track packages, receive instant updates, and connect data from different systems. These solutions make time critical shipment management faster and more reliable.

Real-Time Tracking

You can follow your shipment every step of the way with real-time tracking. GPS tracking shows the exact location using satellites. RFID tags let you scan packages along the route. IoT sensors collect data about temperature, humidity, and movement. Mobile apps give you easy access to tracking information.

Benefit | Description |

|---|---|

You see live updates on cargo movement, which makes the supply chain clear. | |

Proactive Decision-Making | You spot delays early and change routes quickly. |

Improved Communication | You keep everyone informed about shipment status. |

Real-time tracking helps you monitor freight across borders. You can anticipate problems and use resources better. Delivery commitments become more reliable, so you avoid penalties for late shipments.

Automated Alerts

You receive instant notifications when something changes with your shipment. Automated alerts help you act fast and avoid delays. For example, a tyre company used real-time alerts to reroute shipments during a crisis, preventing small problems from becoming big ones.

Automated alerts give you immediate updates on critical movements.

You make fewer manual errors because the system sends notifications automatically.

Early warnings let you adjust routes and logistics quickly.

Automated alerts turn carrier performance analysis from reactive to proactive. You get notified about issues right away, which helps you optimize routes and improve forecasting.

Data Integration

You connect different logistics platforms to share information easily. Data integration lets you track shipments, transfer data automatically, and improve customer service. You solve problems before they happen and make better decisions using trends and performance metrics.

Real-time tracking gives you visibility into shipment status.

Automated data transfer reduces mistakes and speeds up processes.

You improve customer trust with accurate updates.

You minimize errors in shipment details and billing.

Companies that use technology in logistics manage schedules better and respond quickly to disruptions. This leads to higher on-time delivery rates. If you avoid technology, you risk falling behind and missing deadlines in time critical shipment management.

Route Optimization and Contingency Planning

Efficient Route Planning

You improve delivery speed and reliability when you plan your routes carefully. Advanced route planning software helps you analyze traffic patterns, weather conditions, and customer preferences. You should know your fleet’s capacity and match each vehicle to the right job. Aligning routes with customer delivery windows makes your service more dependable. Always prepare a backup plan for unexpected events. Regularly review your routes to find better options and keep drivers safe.

Strategic logistics route planning lets you maximize payloads, reduce empty miles, and balance workloads. You use fewer vehicles and get more done, which saves time and money.

Here are some effective strategies for route planning:

Use technology to analyze routes and conditions.

Understand your fleet’s strengths.

Focus on customer needs.

Prepare for surprises.

Review and improve routes often.

Keep driver safety in mind.

Adjust quickly to changes.

Advanced Analytics

You make smarter decisions when you use analytics in time critical shipment management. Analytics help you plan better routes and forecast delivery times. Real-time data lets you update routes and manage risks. Companies like Maersk use analytics to track containers and avoid waste. You can collect data from vehicles, drivers, and sensors. Integrate traffic updates and weather reports to stay ahead. IoT and AI tools help you optimize routes and predict delays.

Analytics improve efficiency and decision-making.

Real-time tracking allows you to adjust routes quickly.

Machine learning finds weak spots in your supply chain.

UPS Capital uses real-time data streaming and analytics to predict risks and optimize logistics. You can spot shipment delays a week in advance and plan resources based on smart recommendations.

Agile Response to Disruptions

You keep shipments moving when you prepare for disruptions. Develop clear contingency plans with steps for handling problems and communicating with your team. Build safety stocks to buffer against delays. Consider nearshoring to shorten transit times. Use digital tools to predict disruptions and assess risks. Partner with trusted shippers to strengthen your supply chain.

Method | Description |

|---|---|

Create steps for managing disruptions and keeping operations running. | |

Build safety stocks | Use extra inventory to avoid delays. |

Consider nearshoring | Move production closer to reduce shipping risks. |

Leverage forecasting and technology | Use digital tools to predict and prevent problems. |

Partner with preferred shippers | Work with reliable partners to improve resilience. |

Regularly update your plans and run drills to make sure your team is ready. Address different scenarios with specific actions. You respond faster and minimize losses when you prepare for the unexpected.

You can boost efficiency and customer satisfaction by following these seven steps for time critical shipment management. When you combine strong communication, compliance, technology, and planning, you create a connected logistics system. Integrated platforms and AI-driven support tools help you solve problems fast and keep customers happy. Logistics providers offer advanced tracking and faster delivery options. Common challenges include resistance to change and skills gaps, but you can overcome these with training and new systems.

Integrated platforms improve efficiency and customer satisfaction.

AI tools automate support and optimize delivery accuracy.

Advanced tracking meets urgent delivery needs.

Quick issue resolution keeps operations smooth.

KPI | Description |

|---|---|

On-time delivery | Percentage of shipments delivered by the promised date |

Order accuracy | Correctness of orders fulfilled for each customer |

Inventory turnover | Frequency of inventory sold and replaced, showing efficiency |

You can measure success with on-time delivery, order accuracy, and inventory turnover. Adopting these best practices helps you achieve reliable results and meet customer expectations.

FAQ

What is a time critical shipment?

A time critical shipment is a delivery that must arrive by a specific deadline. You use this service for urgent items like medical supplies, machine parts, or event materials.

How can you reduce delays in urgent shipments?

You can reduce delays by double-checking documents, using real-time tracking, and choosing reliable carriers. Communicate with your team and customers at every step.

What technology helps manage time critical shipments?

Real-time GPS tracking

Automated alerts

Data integration platforms

These tools help you monitor shipments, spot problems early, and keep everyone updated.

Why is packaging important for urgent deliveries?

Reason | Benefit |

|---|---|

Protection | Prevents damage |

Compliance | Meets shipping rules |

Tracking | Supports real-time scans |

You keep your shipment safe and on schedule with the right packaging.

See Also

Key Strategies for Effective Global Logistics Operations

Top LCL Shipping Guidelines for Panama Exports by PGL

The Impact of Point-to-Point Logistics on Global Efficiency

PGL Ensures Timely Movement of Your eCommerce Inventory

Eliminate Delay Concerns with PGL's Reliable Warehousing Solutions