How Automation is Transforming Project Cargo Shipping Operations in 2025

You now see automation in project cargo shipping drive rapid change across the industry in 2025. Smart ports use digital twins, IoT sensors, and AI to monitor and optimize cargo movement in real time. This shift reduces errors and lowers labor costs. You also gain safer workplaces as machines handle hazardous tasks. Predictive analytics help you make faster, more accurate decisions. Consider how these advancements can reshape your daily operations and keep you ahead in a competitive market.

Key Takeaways

Automation in project cargo shipping enhances efficiency by using AI and IoT for real-time monitoring and decision-making.

Predictive analytics help you forecast demand accurately, reducing stockouts and improving customer satisfaction.

Robotics streamline cargo handling, increasing speed and safety while lowering labor costs.

Automated route optimization saves fuel and time, ensuring timely deliveries and reducing environmental impact.

Investing in workforce training is crucial for adapting to new technologies and maximizing the benefits of automation.

Automation in Project Cargo Shipping: 2025 Transformation

Key Drivers and Trends

You see several powerful forces shaping automation in project cargo shipping in 2025. Aging fleets and strict decarbonization rules push you to adopt digital tools and smarter systems. Real-time data and AI help you optimize supply chains and boost efficiency. You notice more companies using digital platforms for booking, tracking, and documentation. E-commerce growth increases demand for faster shipping, so you invest in express services. Sustainability matters more than ever, leading you to choose greener technologies. Multimodal transportation becomes common, making logistics smoother. Geopolitical changes also affect your routes and freight volumes.

Note: In 2025, you shift from reacting to risks to using data-driven strategies. Automation in project cargo shipping helps you build resilience and make better decisions.

You also see hyperautomation take center stage. This approach combines AI, machine learning, and IoT to create smart systems. These systems speed up innovation and support your team, making your supply chain more connected and efficient.

Major Operational Shifts

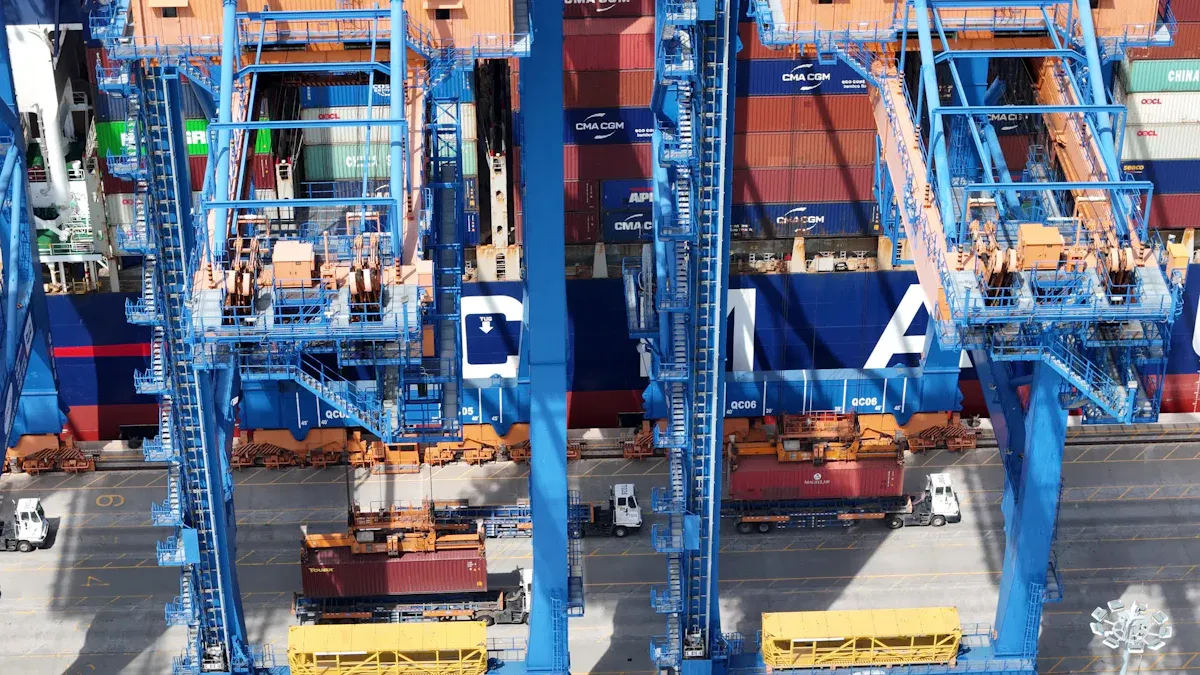

You experience big changes in daily operations. Automated systems in ports work around the clock, moving cargo faster and reducing manual labor. AI improves route planning and fuel use, which cuts shipping times and costs. You see more automated cranes and vehicles, which handle larger cargo volumes and keep workers safe by limiting dangerous tasks.

Singapore’s Tuas Port uses electric-powered vehicles and fully automated terminals to speed up loading and unloading.

The Port of Rotterdam relies on automated cranes and vehicles to manage more cargo and meet green goals.

The Port of Los Angeles uses autonomous trucks and AI to predict cargo volumes and reduce congestion.

You notice that automation in project cargo shipping reduces errors and speeds up port operations. AI-driven fleet management coordinates vehicles, making transport smoother. Advanced technology lets you handle bigger ships and complex trade networks with ease.

Key Automation Technologies

Artificial Intelligence and Predictive Analytics

You now rely on artificial intelligence and predictive analytics to make smarter decisions in project cargo shipping. AI reviews real-time data, such as weather, traffic, and port conditions, to find the best shipping routes. This technology helps you save fuel and avoid delays. Predictive analytics uses machine learning to forecast problems before they happen. You can adjust routes quickly and avoid costly setbacks. AI also automates paperwork, which speeds up customs checks and reduces errors. When you use these tools, you see fewer delays and better reliability in your supply chain.

Tip: AI can match your cargo with the right carrier, cutting down waiting times and improving delivery speed.

Robotics and Automated Handling

You see robotics and automated handling systems change how you move cargo. Robots now unload ships and trucks much faster than people. For example, Boston Dynamics’ Stretch robot can unload up to 700 cases per hour. Amazon’s Vulcan system handles most warehouse inventory, showing how advanced these machines have become. Automated picking systems can cut errors by up to 70%. You also notice that robots keep workers safe by handling dangerous tasks in tight spaces.

Improvement Type | Description |

|---|---|

Speed and Efficiency | Faster unloading and more consistent operations |

Safety Enhancement | Less manual work in risky areas |

Cost Effectiveness | Lower labor costs and higher productivity |

You can run your terminal 24 hours a day, which means you move more cargo and reduce overtime costs.

IoT and Real-Time Data

You use IoT devices to track cargo and equipment at every step. Wireless sensors monitor temperature, humidity, and location. If something goes wrong, you get an alert right away. This helps you protect sensitive goods and respond quickly to problems. IoT also improves planning and scheduling, since you always know where your cargo is. Many shippers now require real-time visibility before they choose a carrier. When you share data with partners, you plan better and avoid surprises.

Real-time tracking gives you updates on shipment location.

Environmental sensors keep goods safe during transit.

Predictive maintenance tools help you fix equipment before it breaks.

You see that automation in project cargo shipping depends on these smart technologies. They help you work faster, safer, and with more confidence.

Operational Impact of Automation

Demand Forecasting

You now use advanced tools to predict demand with much higher accuracy. AI reviews large amounts of data, including past shipments and market trends. This helps you plan better and avoid surprises. You can match your inventory to real needs, which means you do not run out of stock or hold too much.

AI analyzes big datasets to improve forecasting accuracy.

You see better inventory management, which is vital for project cargo shipping.

Automation in project cargo shipping helps you optimize the supply chain and reduce costs.

You can predict customer demand, which lowers the risk of stockouts and overstocking.

These improvements lead to higher customer satisfaction.

AI algorithms also combine real-time and historical data. This lets you forecast demand more precisely. You can then adjust your workforce and resources, which cuts overtime and staffing problems. You also notice that better forecasting helps you fulfill customer needs faster.

Note: Accurate demand forecasting is a game changer for logistics. It lets you make smarter decisions and stay ahead in a fast-moving market.

Route Optimization

You use automated systems to find the best routes for your shipments. These systems look at traffic, weather, and delivery windows. They help you avoid delays and save fuel. You can also balance vehicle loads and follow road rules, which makes your trips more efficient.

Feature | Benefit |

|---|---|

Dynamic route optimization | Finds the best stop order using delivery times and traffic patterns |

Algorithmic order assignment | Balances vehicle loads and road limits, reducing empty trips |

Real-time GPS processing | Reroutes drivers around delays to keep deliveries on time |

Automated route planning streamlines your operations. You spend less on fuel and meet delivery promises more often. In fact, these tools can cut fuel use by 10-15%. This helps you meet green shipping rules and lower your costs. You also see fewer empty trips, which means you use your fleet more wisely.

Automated route optimization shortens transit times.

You improve cost-effectiveness and keep deliveries on schedule.

Lower fuel use means you save money and help the environment.

Inventory and Order Management

You now manage inventory and orders with much greater efficiency. Automation in project cargo shipping lets you automate repetitive tasks and track shipments in real time. This reduces mistakes and speeds up your work. You can also use ERP systems to manage inventory, which cuts down on tracking errors and prevents costly delays.

Automation helps you keep the supply chain error-free.

You make decisions faster and with more confidence.

Fewer mistakes mean lower costs and better data quality.

When you use automated systems, you do not need to enter data by hand. This prevents financial losses from delivery mistakes or extra inventory. You also avoid penalties from paperwork errors. Your team can focus on more important tasks, which boosts overall efficiency.

Tip: Real-time monitoring lets you spot problems early and fix them before they grow.

Real-Time Tracking and Risk Mitigation

You rely on real-time tracking to keep your shipments safe and on schedule. Automation in project cargo shipping gives you instant updates on cargo location and condition. You can spot delays before they happen and take action right away. This helps you avoid costly setbacks and keeps your customers informed.

Evidence Point | Description |

|---|---|

Delay prediction and prevention | You can spot and fix problems before they cause delays. |

Uses data analytics | Advanced tools predict delays and help you cut them by up to 25%. |

Improves planning | Accurate forecasts let you adjust schedules and resources to avoid problems. |

Enhances communication | Automated updates keep everyone informed about possible delays. |

Reduces costs | Preventing delays saves money by avoiding penalties and extra charges. |

Supports contingency planning | You can make backup plans for disruptions, so your operations keep running smoothly. |

You see that real-time tracking not only improves planning but also builds trust with your customers. You can share updates quickly and show that you are in control. This level of transparency sets you apart in the industry.

Benefits and Implementation Challenges

Cost, Accuracy, and Customer Experience

You see clear benefits when you use automation in project cargo shipping. Automated systems help you lower labor and transportation costs. You can optimize packaging, which reduces order weight and saves money on shipping. Software finds the best shipping prices, so you spend less. You track inventory in real time, which helps you avoid running out of stock or having too much. Fewer picking errors and shipping mistakes mean fewer returns and less wasted money.

Automation tools improve order accuracy and reduce returns.

You cut utility costs by optimizing energy use.

Faster processing leads to shorter lead times and fewer delays.

Customers notice these improvements. You process export paperwork, like bills of lading, much faster—sometimes five times quicker. Companies such as Hapag-Lloyd have saved hundreds of thousands of hours, letting staff focus on customer needs. Intelligent automation lets your team work on creative tasks, which improves service quality.

Integration and Workforce Adaptation

You face challenges when you try to integrate new automation technologies. Some shipyards do not prioritize advanced solutions, and the slow pace of digitalization makes integration harder. Retrofitting ships with new technology costs a lot and can be complex because of different data systems. You need a centralized data server to make automation work well.

Adapting your workforce is important. You invest in training programs to help workers learn new skills. Many companies, like Amazon, have reskilled hundreds of thousands of employees. You redesign jobs so people work with AI, focusing on creative problem-solving and decision-making.

Upskill and reskill your team for tech-enabled roles.

Redesign jobs for human–AI collaboration.

Leverage human strengths such as leadership and adaptability.

Data Security and Change Management

You must protect your systems from cyber threats. Automated terminals can be targets for hackers. External vendors and operating systems may let cybercriminals in. Phishing attacks and ransomware can disrupt shipping and cause financial losses. Modern ships can spread viruses to port systems, and human error can make risks worse.

Change management helps you succeed with automation. You focus on clear communication and training. You address fears and encourage open dialogue. Good change management makes employees more likely to accept new technology.

Prosci research shows that projects with strong change management are seven times more likely to succeed.

You see automation in project cargo shipping reshape logistics by boosting efficiency, reducing costs, and improving real-time visibility. You gain new opportunities as robotics, AI, and IoT transform supply chain management.

Streamlined warehouse and yard operations cut delays and errors.

Predictive analytics and route optimization improve delivery times.

To stay competitive, you can:

Automate freight and inventory management.

Rely on data-driven decisions.

Keep adapting and innovating to lead the future of logistics.

FAQ

What is project cargo shipping automation?

You use automation to handle large, complex shipments with smart machines and software. These tools help you move, track, and manage cargo faster and safer. Automation reduces errors and saves you money.

How does automation improve safety in shipping operations?

You see robots and sensors take over dangerous tasks. Machines lift heavy loads and monitor conditions. This keeps you and your team safe from accidents.

What are the main challenges when adopting automation?

You may face high costs and need to train your team. You must also protect your systems from cyber threats. Integration with old equipment can be hard.

Tip: Start with small projects to test automation before scaling up.

Can automation help you meet sustainability goals?

Yes! You use AI to plan efficient routes and reduce fuel use. Automated systems cut waste and energy use. This helps you lower your carbon footprint.

See Also

Enhancing Global Operations Through Innovative Logistics Strategies

Exploring LCL Shipping Trends to Panama with Premier Logistics

Efficient Project Trucking Solutions by Premier Global Logistics