7 Proven Strategies to Grow Your Logistics Business in 2025

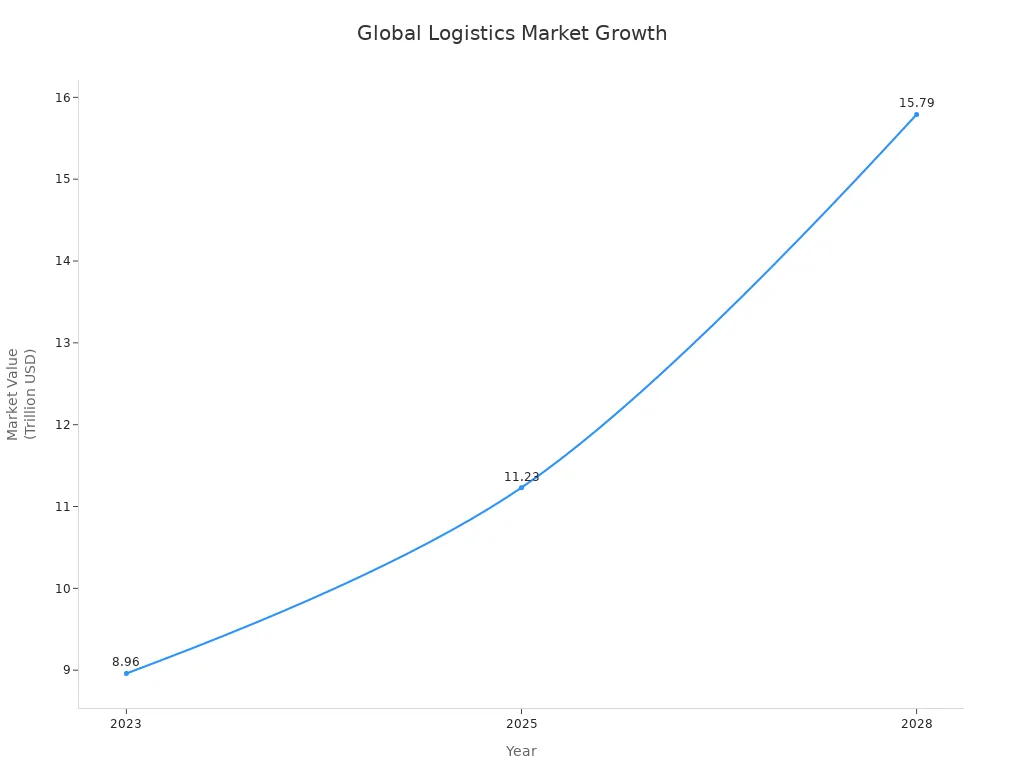

You face a logistics industry that is growing at a rapid pace. The global logistics market will reach $11.23 trillion in 2025, up from $8.96 trillion in 2023. Labor shortages also challenge the industry, with the U.S. expecting over 2 million unfilled positions by 2025.

Statistic | Value |

|---|---|

Global logistics market value in 2025 | $11.23 trillion |

Growth from 2023 to 2025 | From $8.96T to $11.23T |

Projected market value by 2028 | $15.79 trillion |

Logistics industry CAGR through 2028 | 6.3% |

E-commerce logistics market value | Surpassing $535 billion |

Expected labor shortage in U.S. logistics by 2025 | Over 2 million workers |

New technologies and shifting customer demands change how you approach business development in logistics. Automation, AI, and smart warehouses are now essential. You must act quickly, stay flexible, and invest in innovation to stay ahead. Focus on practical steps today to ensure your business thrives tomorrow.

Key Takeaways

Embrace AI and automation to enhance efficiency. These tools can reduce costs and allow your team to focus on more valuable tasks.

Implement predictive analytics to improve inventory management. Accurate forecasts help you meet customer demand and avoid overstocking.

Adopt sustainable practices like electric vehicles and route optimization. These initiatives lower emissions and can save money.

Utilize cloud logistics platforms for real-time data access. This flexibility allows you to scale operations quickly and make informed decisions.

Build strong partner networks to enhance service offerings. Collaborating with experienced partners helps you meet rising demand and avoid operational bottlenecks.

AI & Automation

AI and automation now shape the future of logistics. You can use these tools to reduce costs, boost efficiency, and let your staff focus on more valuable work. Many logistics companies already use AI to improve their operations. These solutions help you make better decisions, avoid waste, and keep your business running smoothly.

Route Optimization

AI-powered route optimization helps you deliver goods faster and save money. These systems analyze traffic, weather, and delivery schedules in real time. For example, UPS uses its ORION system to save 100 million miles and 10 million gallons of fuel each year. This leads to annual savings of $300–400 million. Amazon also uses AI to speed up deliveries for billions of packages.

GPS route optimization reduces fuel waste and ensures trucks take the fastest, most efficient routes. It also helps you avoid delays by adapting to real-time traffic.

Company | Implementation | Delivery Impact | Fuel Consumption Impact | Cost Savings |

|---|---|---|---|---|

UPS | ORION | 100 million miles saved/year | 10 million gallons saved/year | $300–400 million/year |

Amazon | AI-Powered Network | Faster delivery for 8B packages | Improved route efficiency | Not specified |

Task Automation

You can automate many repetitive tasks in logistics. Robotic Process Automation (RPA) reduces errors and frees up your team for more important work. AI tools handle data entry, order processing, and invoice management with high accuracy.

AI improves fulfillment speed and reduces mistakes.

Automated systems help you manage dock scheduling and warehouse operations.

Staff can focus on strategic roles instead of manual tasks.

Automation Focus | Percentage |

|---|---|

Automating non-value-added tasks | |

Co-mingling operations for synergy | 50% |

Predictive Analytics

Predictive analytics uses data to help you plan better. AI studies past sales, market trends, and economic signals to forecast demand. This means you can keep the right amount of inventory and avoid running out or overstocking.

Accurate forecasts improve customer satisfaction and lower costs.

You can deliver on time by predicting what your customers need.

Better planning leads to fewer delays and smoother operations.

Predictive analytics helps you stay ahead by making your supply chain smarter and more efficient.

Sustainability Initiatives

Green Transportation

You can make your logistics business greener by using smart transportation solutions. Many top companies now use electric vehicles, route optimization, and last-mile innovations to cut emissions and save money. These changes help the planet and improve your bottom line.

Initiative | Description |

|---|---|

Efficient Route Optimization | Uses advanced algorithms to cut fuel use and emissions by finding the best delivery routes. |

Adoption of Electric Vehicles (EVs) | Switches to electric trucks and vans to lower greenhouse gases and reduce fuel costs. |

Last-Mile Innovations | Uses micro-fulfillment centers and e-bikes for city deliveries, making them faster and cleaner. |

Blockchain for Transparency | Tracks shipments and proves your green claims with secure digital records. |

Circular Logistics Initiatives | Recycles and reuses materials to cut waste and keep resources in use longer. |

Collaborative Partnerships | Teams up with others in the industry to share ideas and reach green goals together. |

You can see real results from these efforts:

Company | Measurable Result |

|---|---|

BlueGrace | Up to 23% reduction in CO2 emissions, 400,000 lbs of CO2 eliminated |

Breakthrough | 6% drop in transportation emissions in one year, 300,000+ metric tons cut |

Southeastern Freight Lines | 12% better fuel efficiency, 20 million gallons of diesel saved |

TQL | 48 million empty miles cut by 2023, aiming for 65 million by 2024 |

Echo | Prevented more than 38,000 metric tons of CO2 emissions |

A smart routing system can help you cut travel time and lower emissions by using data analytics.

Carbon Reduction

The logistics sector creates over a third of global CO2 emissions. In 2021, transport alone produced 7.7 gigatonnes of CO2, which was 8% higher than before the pandemic. To meet net-zero targets, you must help lower emissions by 20% by 2030. Many companies now set bold goals to reach net zero by 2050 or sooner. Cleaner technology and new standards help you move toward these targets.

Sustainability Communication

You need to share your green progress with customers and partners. Clear and honest communication builds trust and shows your commitment. Try these methods:

Share regular reports and updates about your sustainability work.

Use visuals, like charts and infographics, to explain your goals.

Adjust your message for each group, so everyone understands your efforts.

Show empathy by talking about how your actions help local communities.

When you communicate openly and involve others, you build stronger relationships and improve your green results.

Digital Transformation

Digital transformation changes how you run your logistics business. You use new technology to make your work faster, smarter, and more reliable. This shift helps you stay competitive and meet customer needs.

Cloud Logistics Platforms

Cloud logistics platforms give you powerful tools to manage shipments, inventory, and communication. You access real-time data from anywhere, which speeds up your decision-making. These platforms let you scale your resources quickly when demand rises. You also save money because you do not need extra hardware.

Feature | Benefit |

|---|---|

Enables faster fulfillment and transparent communication, enhancing customer service. | |

Automated processes | Reduces manual workload, increasing efficiency in operations. |

Flexible resource management | Allows scaling of resources up or down instantly, accommodating fluctuating workloads. |

Cloud systems let you add computing power when you need it. You support business growth and handle busy seasons without extra costs.

Data Visibility

You need clear data to make smart choices. Advanced analytics tools show you what happens in your supply chain. You see where your goods are and how much inventory you have. This helps you act quickly when problems arise.

You get real-time insights into goods movement and inventory levels.

Accurate data gives you a full view of your supply chain performance.

You analyze trends and make better decisions about delivery times and order accuracy.

Data visibility helps your team reduce delays and optimize operations.

When you see your data clearly, you respond faster and improve your business results.

Staff Training

Your team must learn new skills to use digital tools well. You provide training and support so employees feel confident. You track progress and adjust your strategies as needed. A culture that welcomes change leads to better results.

Best Practice | Outcome |

|---|---|

Provide training and support | Employees equipped with necessary skills |

Monitor and measure progress | Ability to track success and adjust strategies |

Foster a change-ready culture | Encourages continuous improvement and innovation |

Digital transformation boosts productivity by up to 25% for connected teams.

Employees feel more engaged and satisfied with their jobs.

You see less turnover and more innovation in your company.

Well-trained staff help you get the most from your digital investments.

Warehouse Automation

Warehouse automation helps you run your logistics business more efficiently. You use smart machines and technology to speed up work, reduce mistakes, and save money. Many companies now invest in automation to stay competitive.

Robotics Deployment

Robots in warehouses make order picking faster and more accurate. You can use Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) to move goods quickly. These machines transport items two to three times faster than people. Robotic systems reach order accuracy rates as high as 99.9%, which means fewer returns and happier customers. Staff can focus on important tasks while robots handle repetitive work. According to a recent report, 41% of supply chain leaders use robotics and automation now, and this number will rise to 83% in five years.

Metric | Description | Impact on Fulfillment |

|---|---|---|

Order Accuracy | Robots achieve up to 99.9% accuracy in picking orders | Fewer returns, better customer reviews |

Fulfillment Speed | AMRs move goods 2–3x faster than humans | Faster order processing |

Labor Optimization | Robots free staff for higher-value tasks | Improved morale and efficiency |

IoT Inventory

You can use Internet of Things (IoT) devices to track inventory in real time. These sensors and trackers show you exactly where your goods are at any moment. IoT technology reduces errors by giving you accurate data and constant monitoring. You avoid costly mistakes and keep your warehouse running smoothly.

IoT devices help you streamline warehouse operations.

Real-time visibility lets you spot problems before they grow.

Predictive analytics from IoT tools help you measure performance and find risks.

Evidence Type | Description |

|---|---|

Real-time visibility | IoT devices give instant updates on inventory levels and locations |

Precise location monitoring | Accurate tracking minimizes errors and lost items |

Error reduction | Constant monitoring helps eliminate costly mistakes |

Workflow Optimization

Optimizing your warehouse workflow saves you money and boosts productivity. You can use AI-powered tools to predict busy times and adjust staffing. This helps you match labor to daily needs and avoid extra costs. Streamlined operations reduce waste and improve space use. You can add high-density storage systems and dynamic slotting tools to increase capacity and shorten travel distances for picking.

Tip: Set daily goals to cut waste, like reducing excess travel and re-handling. This improves efficiency and lowers costs.

You see better results when you focus on eliminating packaging inefficiencies and maximizing available space. These strategies help you run a smarter, more cost-effective warehouse.

Risk Management

Logistics businesses face many risks in 2025. You must prepare for challenges like trade disputes, new regulations, and sustainability demands. The table below shows the most significant risk factors:

Risk Factor | Percentage (%) |

|---|---|

Trade Disputes | 68 |

Sustainability Strategy | 61 |

Regulation | 53 |

You also need to watch out for cyber attacks, economic slowdowns, business interruptions, and supply chain failures. Other risks include property damage, work injuries, geopolitical changes, and natural disasters.

Supplier Diversification

You can reduce supply chain disruptions by working with multiple suppliers. This strategy spreads risk and keeps your business running when problems arise. Here are some benefits:

You avoid relying on one supplier.

You keep operations moving during disruptions.

You have backup suppliers ready to help if needed.

Tip: Build relationships with suppliers in different regions. This helps you stay flexible when markets change.

Real-Time Monitoring

Technology helps you track shipments and inventory every minute. You use GPS for vehicle tracking, RFID for automatic identification, and IoT devices for monitoring goods. Cloud-based systems give you instant access to data. The table below shows how these tools help your business:

Technology | Benefits |

|---|---|

GPS | Tracks vehicles and shipments, improves route planning, and ensures timely deliveries. |

RFID | Reduces manual errors, improves inventory management, and gives real-time stock updates. |

IoT | Monitors shipment status and conditions, increases supply chain visibility. |

Cloud-based systems | Processes data instantly, supports quick decision-making. |

You make better decisions, improve efficiency, and keep customers happy with real-time monitoring.

Contingency Planning

You need a plan for emergencies. Good contingency planning helps you respond quickly and keep your business safe. Best practices include:

Predefine message templates for fast communication.

Use two-way communication to keep everyone informed.

Set escalation protocols for serious issues.

Run simulation models to test your readiness.

Case Study: Stuller used logistics intelligence tools to improve shipping visibility. They forecasted rates and made better decisions, which increased profit margins.

You protect your business by planning ahead and staying alert to risks.

Customer Experience

Delivering a great customer experience sets your logistics business apart. When you focus on customer needs, you build loyalty and drive business development in logistics. Happy customers return and recommend your services to others.

Shipment Tracking

Real-time shipment tracking has become a must-have in logistics. You give customers peace of mind when they can see where their packages are at every step. This transparency builds trust and reduces worry. Customers want clear updates about delivery times. When you provide dynamic estimated times of arrival, you show reliability and keep customers informed. Real-time tracking also helps you respond quickly to any issues, which improves satisfaction and keeps your service competitive.

Tip: Use tracking tools that update automatically and send alerts to customers. This small step can make a big difference in how customers view your business.

Personalized Support

You can increase customer loyalty by offering support that meets individual needs. Many logistics companies now:

Enhance communication with real-time updates on shipments and delivery estimates.

Offer multilingual support across different channels.

Use order tracking technology with delivery route alerts for personalized updates.

Collect feedback to improve services and create tailored solutions.

A strong support system keeps customers informed and valued. When you address concerns quickly and clearly, you build trust and encourage repeat business.

Returns Management

Handling returns well is key to customer satisfaction. You can simplify your return process by offering self-service options and clear policies. Proactive communication about return status keeps customers in the loop. Personalized return options based on customer data make the process smoother. Data analytics help you find patterns in returns, so you can improve products and reduce future issues. Optimizing reverse logistics with better routing and working with third-party providers can lower costs and speed up processing.

Simplified returns encourage customers to shop with you again.

Real-time updates and personalized options make returns less stressful.

Data insights help you fix problems and improve your service.

A smooth returns process supports business development in logistics by building trust and encouraging long-term relationships.

Business Development in Logistics

Market Analysis

You need to understand your market and competitors to succeed in business development in logistics. Start by studying customer needs and preferences. Use AI tools to personalize your marketing and address pain points. Focus on what drives purchase decisions, such as cost efficiency, innovation, and sustainability. Regularly review your strategy to keep up with market changes.

Tip: Position your services to stand out in a crowded market. Adapt quickly to new trends and regulations.

Here are some effective strategies:

Strategy Type | Description |

|---|---|

Embracing New Business Models | Adopt digital solutions to meet changing market demands. |

Adapting to Customer Lifestyles | Respond to evolving customer needs and preferences. |

Strategic Positioning | Make your services unique in the market. |

Increasing Resilience and Agility | Build skills to adapt to changes and disruptions. |

Compliance with Regulations | Follow new rules in the logistics sector. |

Diversification | Expand into new industries for growth and risk reduction. |

Strong Partnerships | Form alliances to reach more customers. |

Regular Strategy Review | Update your plans based on performance and market conditions. |

Partner Networks

Building strong partner networks helps you grow your logistics business. Work with experienced partners to scale efficiently. Without outside expertise, you may hit capacity limits and miss orders. A well-planned strategy lets you meet rising demand and expand your reach.

Develop relationships with trusted partners.

Use alliances to enhance your service offerings.

Rely on external expertise to avoid operational bottlenecks.

Key Capabilities | Description |

|---|---|

Warehouse Network | Multiple fulfillment centers reduce shipping times. |

Flexible Infrastructure | Adjusts to business needs, handling spikes and new launches. |

Technology and Automation | Real-time tracking and automated processes keep operations smooth. |

Operational Support | Account managers and customer support help with planning and execution. |

Note: Partnering with a 3PL provider gives you access to technology and expertise that align with your growth strategy.

Scalability & Capacity

Scalability means you can grow or shrink your operations without losing performance. This flexibility is key for business development in logistics. Streamline your processes to reduce costs and improve flow. Manage transportation well to boost delivery speed and customer satisfaction.

Implement route optimization software for efficient deliveries.

Negotiate carrier contracts to lower shipping costs.

Consolidate shipments to save money.

Optimize inventory management to cut holding costs.

Use automation to reduce operational expenses.

Integrate IoT, AI, and blockchain to improve tracking and forecasting. These technologies help you reduce errors and increase efficiency. When your logistics operations scale smoothly, you stay competitive and resilient in a changing market.

A scalable logistics strategy supports long-term growth and cost management.

You need to stay proactive and keep improving your logistics business. Take action on these strategies now to stay ahead in 2025. Use new technology and smart planning to boost your business development in logistics. When you invest in future-ready solutions, you build a strong foundation for growth.

Remember, innovation helps you meet customer needs and keeps your company competitive.

FAQ

What is the best way to start using AI in logistics?

You can begin by automating simple tasks like route planning and inventory tracking. Choose easy-to-use software that fits your business size. Test the system with a small team before expanding.

How do I make my logistics business more sustainable?

Switch to electric vehicles and optimize delivery routes. Track your carbon footprint with digital tools. Share your progress with customers using clear reports and visuals.

Why is real-time shipment tracking important?

Real-time tracking lets you see where shipments are at any moment. You can solve problems quickly and keep customers informed. This builds trust and improves satisfaction.

How can I scale my logistics operations without losing quality?

You should use automation and partner networks to handle more orders. Train your staff on new systems. Monitor performance with data tools to catch issues early.

What technology helps reduce warehouse errors?

IoT sensors and robotics help you track inventory and pick orders accurately. These tools give instant updates and reduce mistakes. You save time and money with fewer errors.

See Also

Key Strategies for Effective Management of Global Logistics

Enhancing Global Operations Through Innovative Logistics Approaches

Prepare for Holiday Demand with PGL’s Logistics Services

Top Global Logistics – Optimizing Import Warehousing on the East Coast