Construction logistics management explained in simple words

Construction logistics management means making sure that everything needed for a building project—like materials, equipment, and workers—arrives at the right place and time. You can think of it as organizing a big puzzle, where each piece must fit perfectly to keep work moving. When you manage logistics well, you help projects avoid delays and finish on schedule.

Studies show that using smart technology, such as RFID and inventory management software, helps teams track supplies and make quick decisions. This keeps projects running smoothly and saves money.

Evidence Type | Description |

|---|---|

Study | Advanced inventory systems reduce waste and boost efficiency in building projects. |

Technology | Digital tools like drones and project management software improve safety and speed on-site. |

Key Takeaways

Construction logistics management ensures materials, equipment, and workers arrive on time, keeping projects on schedule.

Effective planning reduces waste and saves money, making your project more efficient and cost-effective.

Using technology like GPS and RFID improves tracking and coordination, helping to avoid delays and mistakes.

Good logistics management enhances safety on-site by keeping the workspace organized and reducing the risk of accidents.

Proactive communication and collaboration with team members and vendors prevent misunderstandings and keep projects running smoothly.

What is construction logistics management?

Simple meaning

You can think of construction logistics management as the way you organize everything needed for a building project. This includes planning how materials, equipment, and workers move to and around the site. Your goal is to make sure that everything arrives at the right place and at the right time. When you do this well, you help the project run smoothly and avoid delays.

In simple terms, construction logistics management means making sure people and resources get to where they are needed, whether they are on-site, in storage, or on the way. You plan, carry out, and control how materials and workers move. This helps prevent problems like running out of supplies or having too many people waiting around.

Good logistics management keeps your project on track and helps you avoid extra costs.

Main goals

The main goals of construction logistics management focus on making your project efficient, safe, and cost-effective. You want to save money, finish on time, and keep everyone safe. You also want to make sure that the quality of the work stays high by having the right materials available when needed.

Here are the key objectives:

Objective | Description |

|---|---|

Cost Savings | You cut costs by reducing waste and making the supply chain work better. |

Time Management | You keep the project on schedule by making sure materials and equipment arrive when needed. |

Safety | You lower the risk of accidents by keeping the site organized and safe. |

Quality Control | You maintain high standards by delivering materials on time and in good condition. |

You also have several important responsibilities in construction logistics management. These include planning the site, managing deliveries, keeping the site safe, and making sure everyone knows what to do. Here is a quick look at some of your main tasks:

Responsibility Category | Key Responsibilities |

|---|---|

Planning/programming | Plan site set-up, logistics routes, and use of key assets. |

Mobilisation | Set up a secure site, manage traffic, and create procedures. |

Control materials in and out, plan movements, and manage suppliers. | |

Programme support | Organize resources to meet deadlines and keep the project moving. |

Safety | Follow safety policies, inspect the site, and provide training. |

Site communications | Set up communication systems and update safety information. |

Delivery management | Manage all deliveries and make sure loads are used well. |

Vehicles, plant, equipment | Keep track of equipment and make sure it is used safely. |

Security | Guard the site and follow security rules. |

Workforce | Manage workers and provide training. |

Environmental | Assess risks and manage waste. |

Corporate social responsibility | Share project news and support the community. |

When you manage these tasks well, you help your project succeed. You keep everything organized, save money, and make the site safer for everyone.

Why is construction logistics management important?

Project benefits

You want your building project to finish on time and stay within budget. Construction logistics management helps you reach these goals by keeping everything organized. When you plan and control how materials and workers move, you avoid many common problems. You make sure supplies arrive when you need them, so your team does not have to wait. You also reduce waste and save money.

Here are some ways good logistics management helps you avoid project delays:

You plan and schedule tasks to spot problems before they happen.

You match deliveries with your work schedule, so you never run out of materials.

You watch your plans closely and change them quickly if something unexpected happens.

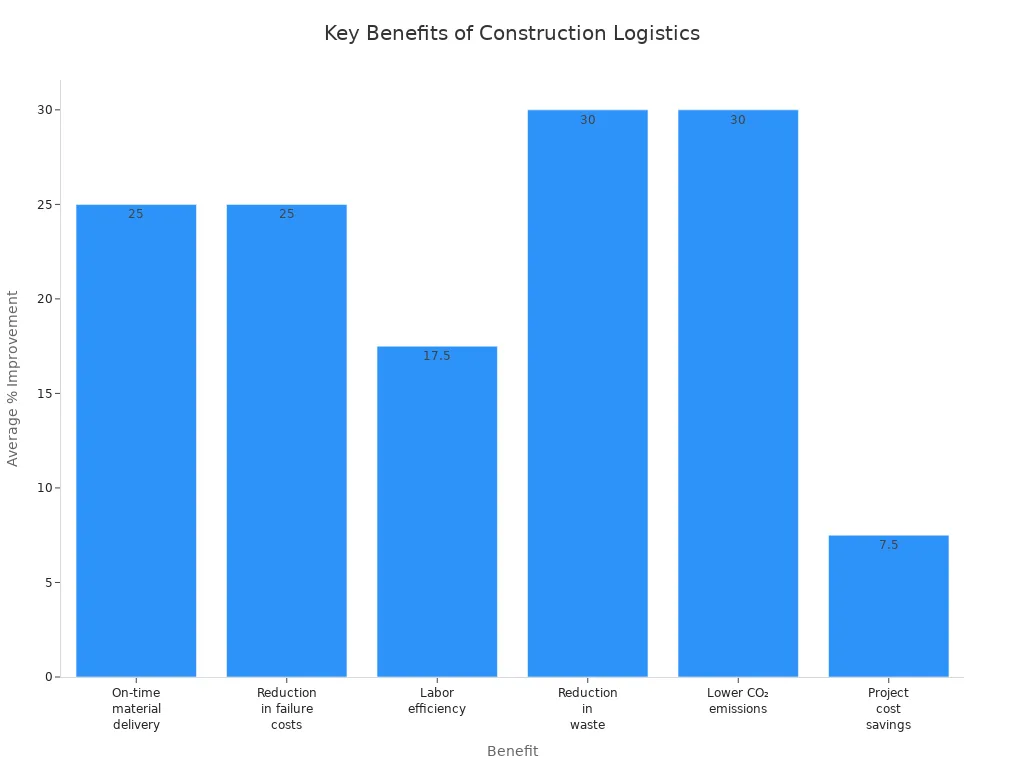

Industry reports show that construction logistics management brings many benefits. The table below highlights some of the most important improvements:

Benefit | Impact/Improvement |

|---|---|

On-time material delivery | 20 to 30 percent improvement |

Reduction in failure costs | At least 25 percent reduction |

Labor efficiency | 15 to 20 percent increase in productivity |

Reduction in construction waste | Up to 30 percent reduction |

Lower CO₂ emissions from transport | 20 to 40 percent reduction |

Total project cost savings | 5 to 10 percent savings |

Tip: When you organize your deliveries and resources well, you help your team work faster and safer.

Impact on efficiency and safety

You want your job site to run smoothly and keep everyone safe. Construction logistics management makes this possible. When you keep the site tidy and plan where everything goes, you help workers avoid accidents. You also make sure everyone knows what to do and where to go.

Effective logistical planning keeps your site organized. A clean and orderly site helps workers stay healthy and safe. You lower the risk of injuries and improve safety records. You also boost efficiency because your team spends less time searching for tools or waiting for supplies.

When you use construction logistics management, you create a better work environment. You save time, cut costs, and protect your team. This makes your project more successful and helps everyone feel confident about their work.

Key components of construction logistics management

Planning and scheduling

You start every project with a solid plan. Planning and scheduling help you decide when materials, equipment, and workers should arrive. If you plan well, you avoid delays and keep everything moving. Good planning means you know what comes next and can spot problems before they happen.

You make sure materials arrive on time.

You match deliveries with your work schedule.

You reduce waste by ordering only what you need.

You keep the site organized and safe.

If you delay one delivery, it can slow down other jobs. Careful planning helps you avoid this domino effect.

Transportation and delivery

You need to move materials and equipment from suppliers to your site. Transportation and delivery make sure everything gets where it needs to go.

Schedule deliveries to avoid clutter and keep the site safe.

Use on-site storage for items you use often.

Track materials with barcodes or RFID tags.

Work with reliable transport companies and use GPS to follow shipments.

Inform your community about deliveries to keep everyone safe.

Plan routes for large shipments and use technology to make deliveries faster and safer.

Storage and handling

You must store materials safely and handle them with care. Good storage and handling protect your supplies and save money.

Key Findings | Description |

|---|---|

Cost Impact | Materials make up about 57% of project costs. Good management saves money. |

Time Management | Proper storage prevents delays and keeps work on track. |

Quality Control | Safe handling stops materials from getting damaged or ruined. |

Coordination and communication

You need everyone working together. Coordination and communication help your team share updates and solve problems quickly.

Hold regular meetings to keep everyone informed.

Use digital tools for real-time updates and document sharing.

Set clear channels for communication so everyone knows who to contact.

When you communicate well, you avoid mistakes and keep your project on schedule.

Safety and compliance

You must follow rules to keep your site safe and legal. Safety and compliance protect workers and the environment.

Compliance Area | Description |

|---|---|

Health & Safety | Follow OSHA rules to prevent accidents and injuries. |

Contract | Meet contract deadlines and budgets to avoid legal trouble. |

Environmental | Follow EPA rules for waste and pollution. |

Labor | Respect worker rights and pay fair wages. |

Building Codes | Build to local standards to avoid fines and delays. |

Train your team, reward safe behavior, and use technology to report safety issues quickly.

Construction logistics management in action

On-site operations

You see construction logistics management at work every day on a busy job site. You organize materials, tools, and equipment so your team can work without interruptions. You plan routes for trucks and cranes to move safely and quickly. You track supplies with smart technology, making sure nothing gets lost or delayed.

Smart route planning helps you save time and money. You keep the workspace tidy and safe by storing materials in the right places. You train your team to follow safety rules and use equipment correctly.

Here is a table showing how you coordinate on-site operations:

Operation Description |

|---|

You plan routes for deliveries to improve efficiency and save costs. |

You organize materials and equipment to keep the workspace clear and productive. |

You follow strict safety protocols and provide regular training for your team. |

You plan every step of the logistics process to avoid problems and delays. |

You allocate resources so everyone has what they need to do their job. |

You buy materials at the right time to avoid shortages or waste. |

You track inventory to make sure supplies are always available. |

You schedule transportation and work with partners for on-time deliveries. |

You choose the best routes for moving materials, thinking about distance and traffic. |

Real-world scenarios

You can find examples of construction logistics management in action on large projects. Moving wind turbine parts, heavy machinery, or power plant generators takes careful planning and teamwork. You use advanced technology like GPS and IoT to track shipments and keep everything on schedule.

Example | Description |

|---|---|

Wind Turbine Components | You move huge parts for energy projects with precise planning and expert skills. |

Heavy Industrial Machinery | You transport oversized machines by planning routes and following regulations. |

Power Plant Generators | You coordinate teams to move large generators safely and prevent damage. |

You notice differences between small and large projects. On small sites, you might rent equipment and use simple methods. On big sites, you own equipment and use advanced technology. Large projects often focus on green practices and publicize their efforts.

Aspect | Small Projects | Large Projects |

|---|---|---|

Maintenance | You hire specialists for repairs. | You use dedicated teams or contracts. |

Technology Adoption | You use basic tools and methods. | You use GPS and smart devices. |

Cost Management | You rent equipment to save money. | You own equipment for long-term savings. |

Environmental Concerns | You use fuel-efficient machines and manage waste. | You use eco-friendly technology and share green results. |

You make every project run smoothly by planning, organizing, and using the right tools. You help your team work safely and efficiently, no matter the size of the job.

Challenges and solutions

Common issues

You face many challenges when you manage construction logistics. These problems can slow down your project and increase costs. Here are some of the most common issues:

Lack of collaboration: When you do not communicate clearly with vendors and team members, misunderstandings happen. This can lead to project delays.

Manual freight reconciliation: If you rely on manual paperwork, you risk making mistakes. Duplicate invoices and errors can cause financial problems.

Poor in-transit visibility: Without real-time tracking, you do not know where your materials are. This makes it hard to plan and can cause delays.

Vendor management difficulties: You need to make sure vendors meet quality standards. If they do not, your project can go over budget or fall behind schedule.

Tip: You can avoid many of these issues by using digital tools and clear communication.

How logistics management helps

You can solve these challenges with smart logistics management. Here are some proven solutions:

Set up systems to monitor performance all the time. This helps you spot problems early.

Identify issues before they grow. You can act quickly and keep your project on track.

Use solutions that stop small problems from becoming big ones.

You can also use these strategies to improve your project:

Strategy | Benefit |

|---|---|

You boost efficiency, cut costs, and help your project succeed. | |

Just-in-time (JIT) inventory | You reduce storage costs and make sure materials arrive exactly when needed. |

Effective procurement | You choose reliable vendors and get the best value for your money. |

Transportation planning | You save money and avoid delays by planning the best delivery routes and schedules. |

You should build strong relationships with suppliers and technology partners. These connections help you find solutions together when problems come up.

A study shows that up to 46% of work in some building projects involves moving materials. Good logistics management cuts down on wasted time and resources. For example, with JIT delivery, you get materials like concrete right before you need them. This means you do not need to store extra supplies, which saves space and money.

When you plan logistics well, you reduce waste, improve efficiency, and keep your project running smoothly. 🚚

You play a key role in keeping your construction project organized and efficient. Construction logistics management means planning how materials, equipment, and workers move so your project finishes on time and within budget. Technology helps you coordinate tasks and reduce delays.

Description | |

|---|---|

Importance of Logistics | You need logistics for efficient, cost-effective projects. |

Structured Logistics Plan | A clear plan brings timely delivery and safer worksites. |

Role of Technology | Tools like GPS and mobile apps improve coordination. |

Rising Costs | Proactive planning protects your budget. |

You reduce delays by scheduling deliveries.

You solve problems before they grow.

You adapt quickly with backup plans.

You boost efficiency with skilled teams.

You can make every project a success by staying organized and using smart logistics. 🚀

FAQ

What does a construction logistics manager do?

You organize deliveries, track materials, and make sure workers have what they need. You plan schedules and solve problems to keep the project moving.

How can technology help with construction logistics?

You use tools like GPS, RFID, and mobile apps to track supplies and manage deliveries. Technology helps you avoid mistakes and save time.

Why is planning important in construction logistics?

You prevent delays and reduce waste when you plan well. Good planning helps you match deliveries with your work schedule and keep the site safe.

What happens if you ignore logistics management?

You risk running out of materials, causing delays, and spending more money. Poor logistics can lead to accidents and confusion on the job site.

Can small projects benefit from logistics management?

You improve efficiency and save money, even on small projects. Simple planning and organization help you finish faster and avoid problems.

See Also

Key Strategies For Effective Global Logistics Operations

Top East Coast B2B Warehousing And Distribution Solutions

Enhancing Global Operations Through Innovative Logistics Strategies

PGL's Miami Warehouse Solutions For Quick East Coast Shipping

Simplifying Supply Chain Efficiency With American Logistics Services