Top 10 Actionable Tips to Improve Domestic Logistics Operations

You want to see real improvements in your logistics operations. Applying domestic logistics best practices increases efficiency and cuts costs. When you lower logistics expenses, you can offer better prices, boost profit margins, and deliver products on time. These changes make your business more competitive.

Description | Impact on Competitiveness |

|---|---|

Lower logistics costs | Attract more customers with pricing |

Increased profit margins | Strengthen financial performance |

Timely, reliable delivery | Enhance customer satisfaction |

Key Takeaways

Identify areas for improvement in your logistics operations. Review processes from inventory to invoicing to find inefficiencies.

Set clear objectives for inventory, cost, delivery, and customer satisfaction. Measurable goals help track progress and support continuous improvement.

Implement real-time tracking systems to manage inventory effectively. This reduces stock discrepancies and improves order fulfillment.

Optimize your warehouse layout and workflow. Organize items to minimize movement and enhance productivity, leading to faster order processing.

Use data-driven decisions to monitor key performance indicators (KPIs). Regularly analyze metrics like delivery time and order accuracy to identify areas for improvement.

Domestic Logistics Best Practices

Identify Improvement Areas

You can start improving your logistics by looking closely at your current operations. Domestic logistics best practices encourage you to review each step, from inventory to invoicing. Many companies find that supply chain strategies, supplier coordination, tracking systems, and inventory management need attention. You can use the table below to see how other businesses have improved these areas:

Area for Improvement | Example Case Study |

|---|---|

Enhancing supply chain strategies | A healthcare provider improved its supply chain by warehousing near high-demand areas and using dedicated routes for urgent shipments. |

Improving coordination with suppliers | An auto manufacturer partnered with logistics providers to better coordinate component deliveries, reducing delays. |

Implementing advanced tracking systems | The healthcare provider used advanced tracking systems to provide real-time visibility of shipments, cutting delivery times by 25%. |

Optimizing inventory management | The auto manufacturer implemented just-in-time inventory strategies to minimize stockpiling and ensure timely availability of parts. |

You should also pay attention to the latest trends in domestic logistics best practices. Experts recommend focusing on sustainability, using advanced technologies like AI, and improving last-mile delivery with drones and autonomous vehicles. Blockchain technology and third-party logistics providers help increase transparency and efficiency. Real-time visibility and proactive analysis make it easier to manage your logistics operations.

Set Clear Objectives

Setting clear goals helps you measure progress and stay on track. Domestic logistics best practices suggest using specific objectives for inventory, cost, delivery, and customer satisfaction. The table below shows common objectives and strategies:

Objective | Key Strategies |

|---|---|

Inventory Optimization | Demand Forecasting, Safety Stock, ABC Analysis, JIT Inventory, Inventory Tracking Systems, Supplier Collaboration |

Cost Efficiency | Route Optimization, Consolidation, Inventory Management, Vendor Negotiation, Automation, Process Optimization |

Timely Delivery | Efficient Route Planning, Real-time Tracking, Inventory Management, Demand Forecasting, JIT, Effective Communication, Contingency Plans |

Customer Satisfaction | Accurate Order Fulfillment, Transparent Communication, Efficient Returns Management, Product Quality Assurance, Proactive Issue Resolution, Customer Feedback |

Tip: When you set measurable objectives, you can track your success and make changes quickly. This approach supports continuous improvement and helps you follow domestic logistics best practices.

Inventory Management

Real-Time Tracking

You need real-time tracking to manage inventory efficiently. When you see your stock levels instantly, you avoid stock discrepancies and slowdowns. Many logistics providers struggle with a lack of visibility. This problem leads to mistakes and delays. You can use barcode scanners, RFID tags, and inventory management software to track every item as it moves through your warehouse.

Tip: Real-time tracking helps you spot issues before they become costly problems.

If you do not have accurate tracking, you risk overstocking or understocking. Overstocking ties up your money and increases storage costs. Understocking means you lose sales and disappoint customers. You can solve these problems by updating your systems and training your team to use them well.

Challenge | Impact on Operations |

|---|---|

Stock discrepancies | Slowdowns, lost sales |

Overstocking | Higher storage costs |

Understocking | Missed sales, unhappy buyers |

Demand Forecasting

You can improve your inventory management by predicting demand. Demand forecasting uses past sales data and market trends to estimate future needs. When you forecast accurately, you keep the right amount of stock and avoid waste.

Enhanced forecast accuracy lowers inventory and operating costs.

Better forecasting improves service and sales.

You see recurring savings from reduced carrying costs.

Accurate forecasts prevent overstocking, which lowers storage and holding costs.

Effective demand planning increases inventory turnover rates.

Just-In-Time (JIT) strategies minimize inventory reserves and carrying costs.

If you do not forecast well, you may end up with too much or too little stock. Poor forecasting frustrates customers and hurts your cash flow. You can use software tools to analyze data and adjust your inventory levels. When you combine real-time tracking with demand forecasting, you create a strong system that supports your logistics goals.

Note: Accurate demand forecasting and real-time tracking work together to reduce costs and improve customer satisfaction.

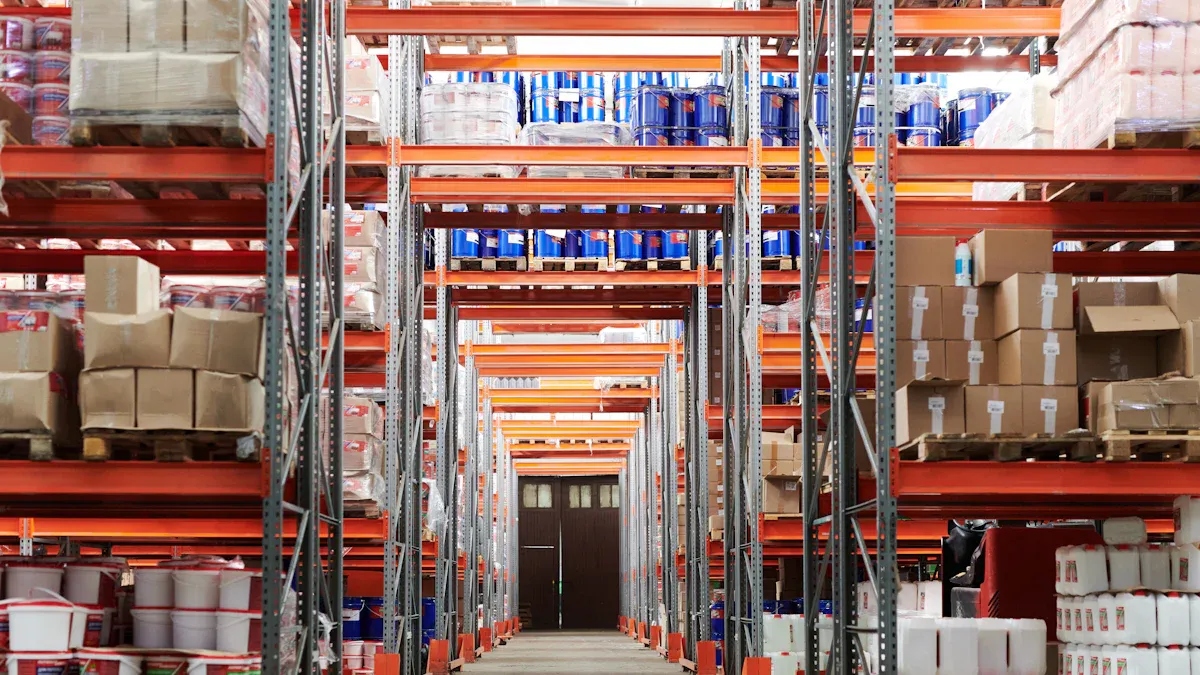

Warehouse Optimization

Layout & Workflow

You can boost productivity in your warehouse by improving the layout and workflow. When you organize shelves, workstations, and pathways, you help your team move faster and safer. Place high-demand items close to packing and shipping areas. This simple change cuts down on walking time and speeds up order fulfillment.

Here are some proven benefits of optimizing your warehouse layout and workflow:

Benefit | Description |

|---|---|

Improved Efficiency | You create a smooth flow of goods and respond quickly to orders. |

Enhanced Employee Safety | You reduce heavy lifting and risky tasks, keeping your team safe. |

Accuracy in Order Fulfillment | You pick, pack, and ship the right products, which lowers mistakes. |

Optimized Labor Resources | You let employees focus on important jobs, which boosts morale. |

Increased Customer Satisfaction | You deliver products on time, so customers stay happy. |

Tip: Use clear signs and labels to guide your team. This helps everyone find products quickly and reduces confusion.

You can also see the benefits in this list:

Improved efficiency in operations.

Enhanced employee safety by reducing manual tasks.

Increased accuracy in order fulfillment, leading to fewer returns.

Better allocation of labor resources, allowing focus on important tasks.

Higher customer satisfaction due to timely and accurate deliveries.

Space Utilization

You can save money by using your warehouse space wisely. When you optimize space, you cut down on wasted movement and make every square foot count. Place popular products near shipping zones. Use vertical racks to store more items without expanding your warehouse.

Optimizing warehouse layout and space utilization can significantly reduce operational costs by minimizing unnecessary travel and streamlining processes. For example, placing high-demand products closer to shipping areas decreases retrieval time, while vertical storage systems increase storage density without needing more space.

Warehouse optimization strategies differ based on the size of your operation. You can compare approaches in the table below:

Warehouse Size | Key Strategies |

|---|---|

Small | Space Optimization: Use vertical space and narrow aisles. |

Large | Automated Systems: Invest in robotics. |

Note: You should review your warehouse layout every year. Small changes can lead to big gains in speed, safety, and cost savings.

Logistics Technology

Software Integration

You can transform your logistics operations by using software integration. When you connect warehouse management systems (WMS), transportation management systems (TMS), and inventory platforms, you create a seamless flow of information. This integration helps you track shipments, manage inventory, and process orders without delays. You see fewer errors and faster decision-making.

Software integration often requires an initial investment. You may spend money on new systems and training. Over time, you save money because automation reduces manual work. You also lower payroll expenses. Smart routing features help you plan delivery routes, which cuts fuel costs and delivery times. You keep inventory levels accurate, so you avoid waste and stockouts.

Tip: Choose software that works well with your current systems. This makes the transition easier and helps your team adapt quickly.

Here is a table showing the cost implications of adopting new logistics technologies:

Cost Implication | Description |

|---|---|

Initial Investments | Significant upfront costs associated with acquiring new technologies. |

Long-term Savings | Potential for reduced operational costs through increased efficiency and automation. |

Ongoing Maintenance and Updates | Continuous costs related to maintaining and updating technology systems. |

Reduced Labor Costs | Automation minimizes the need for manual labor, leading to lower payroll expenses. |

Improved Inventory Management | Enhanced tracking and management of inventory reduces waste and costs associated with overstocking or stockouts. |

Smart Routing | Technology aids in optimizing delivery routes, reducing fuel consumption and delivery times. |

Mobile & IoT Solutions

Mobile and IoT solutions give you real-time visibility and control over your logistics. You can track assets, monitor shipments, and check cargo conditions from your phone or tablet. iBeacons help you find equipment and products quickly. GPS tracking shows you where shipments are and when they will arrive. Sensor technologies monitor temperature and humidity, keeping cargo safe.

You improve efficiency by using these tools. You minimize loss and avoid delays. Customers get better service because you know exactly where their orders are. You also keep products in good condition during transit.

Here is a table showing how mobile and IoT technologies contribute to logistics operations:

Technology | Contribution to Logistics Operations |

|---|---|

iBeacons | Provide real-time location data for tracking assets, minimizing loss and operational inefficiencies. |

GPS Tracking | Enables real-time visibility into shipment routes and arrival times, improving route planning and customer satisfaction. |

Sensor Technologies | Monitor conditions like temperature and humidity, ensuring cargo remains in optimal conditions throughout transit. |

Note: You should update your mobile and IoT solutions regularly. This keeps your logistics operations running smoothly and helps you stay ahead of competitors.

Transportation Efficiency

Route Optimization

You can boost your logistics performance by focusing on route optimization. When you plan the best delivery paths, you save time and money. Route optimization software helps you find the fastest and most efficient routes. It considers traffic, delivery windows, and road conditions. This planning reduces fuel use and cuts operational expenses. You also increase your delivery capacity and keep customers happy with accurate delivery times.

Here is how route optimization impacts your transportation costs and delivery times:

Aspect | |

|---|---|

Time Efficiency | Shortens delivery times, enhances service speed. |

Better Fleet Management | Reduces vehicle wear, lowers maintenance costs. |

Fuel Consumption | Decreases fuel costs through optimized routes. |

Calculating efficient delivery paths cuts fuel use and labor hours.

Optimized routing helps you follow safety and legal rules.

Customers receive accurate ETAs and better communication.

Tip: Use route optimization tools to improve last mile delivery and reduce costs.

Fleet Management

You can improve your logistics by using advanced fleet management systems. These systems automate tasks like route planning and vehicle tracking. Automation lowers manual work and saves on labor costs. Your team can focus on important jobs instead of routine tasks.

Fleet management systems boost productivity with better route planning and less downtime.

Real-time tracking and data analytics help you spot problems quickly and make fast decisions.

You can allocate resources more effectively and avoid bottlenecks.

Experts say these systems also improve customer satisfaction. Timely deliveries and efficient resource use keep your clients happy. When you manage your fleet well, you lower costs, increase reliability, and stay ahead of your competition.

Note: Review your fleet management tools often. Up-to-date systems keep your logistics running smoothly and efficiently.

Data-Driven Decisions

Monitor KPIs

You can improve your logistics operations by tracking key performance indicators (KPIs). KPIs help you measure progress and spot problems early. When you monitor the right metrics, you make smarter decisions and keep your logistics running smoothly.

Here is a table showing important KPIs for domestic logistics:

KPI | Role and Impact | Significance |

|---|---|---|

Financial Leverage | Measures the ratio of debts to assets, showing financial risk and return. | Balancing leverage helps you manage debt and boost returns. |

Inventory to Sales Ratio | Compares inventory levels to sales, preventing overstock and supply chain issues. | Keeping this ratio balanced leads to efficient inventory management. |

Capacity Utilization | Tracks how well you use resources, lowering costs and boosting production. | Efficient use of capacity keeps goods flowing and controls costs. |

Pick and Pack Cycle Time | Measures how long it takes to pick and pack products, showing process speed. | Short cycle times improve employee satisfaction and performance. |

Lead Time | Tracks the time from order to receipt, revealing delays and bottlenecks. | Lower lead times increase customer satisfaction and supply chain speed. |

Delivery Time | Measures how long it takes for customers to get their orders. | Faster delivery times improve customer trust and loyalty. |

You should also watch these KPIs:

Dwell Time: Shows how long trucks stay at loading docks. Shorter times mean better efficiency.

Freight Billing Accuracy: Tracks invoice correctness. High accuracy saves money and time.

Redelivery Rate: Measures how often shipments need a second delivery. Lower rates mean better first-time success.

Tip: Review your KPIs every month. Regular checks help you catch issues before they grow.

Analyze Performance

You can use data analysis to find ways to improve your logistics. When you study your KPIs, you see what works and what needs fixing. Data helps you make changes that boost efficiency and cut costs.

Here is a table with common performance metrics:

KPI | Description |

|---|---|

On-time delivery rates | Shows the percentage of deliveries made on time. |

Order accuracy | Measures how many orders are correct. |

Inventory turnover | Tracks how often you sell and replace inventory. |

You can analyze your data in several ways:

Evaluate the impact of expanding into new markets.

Assess risks and rewards of new product lines.

Study the effects of renegotiating supplier contracts.

Analyzing customer feedback, order history, and service performance gives you insight into what your customers want. You can adjust your logistics to meet their needs.

"Route optimization uses data to find the best delivery paths. By studying traffic, weather, and schedules, you can cut travel time and save fuel."

You can also:

Use vehicle data to maximize asset use.

Find chances to combine trips and adjust schedules.

Match loads to the right vehicle size to avoid waste.

Note: Data-driven decisions help you stay ahead in logistics. When you use data, you make your operations faster, cheaper, and more reliable.

Team Training

Skill Development

You need strong skills to succeed in logistics. Training helps you and your team keep up with new technology and changing industry standards. Continuous learning prepares you for automation and real-time tracking. When you invest in skill development, you build a team that can solve problems and adapt quickly.

Here is a table showing recommended courses for important logistics skills:

Skill | Recommended Course |

|---|---|

Adaptability by SC Training | |

Collaborative Leadership | Connection and Collaboration by SC Training, How to be a Team Player by SC Training, Embracing Teamwork by SC Training |

Digital Proficiency | Cyber Security by SC Training, Strategies to Combat Phishing Attacks by SC Training, Cybersecurity and Internal Threats by SC Training |

Soft Skills Training | Soft Skills Training for Logistics Teams by Edstellar |

Tip: Regular training helps you stay ahead of industry changes and prepares your team for future challenges.

Collaboration

You improve logistics operations when your team works together. Collaboration lets you respond faster to market changes and manage risks. Companies that focus on teamwork see better results and more innovation.

Cross-functional collaboration helps you adapt to new business needs.

Streamlined processes make your supply chain more agile.

Teams that share information solve problems faster and reduce costs.

Toyota’s success comes from empowering front line operators to drive efficiencies and solve problems. This approach encourages continuous improvement and keeps the supply chain strong.

You can see these benefits when your team collaborates:

You increase efficiency and productivity by removing redundancies.

Diverse perspectives help you find creative solutions.

Regular communication helps you spot risks early.

Your team responds quickly to changes in the market.

Better internal communication leads to cost savings.

Note: Encourage open communication and teamwork. These habits help your logistics team stay competitive and resilient.

Proactive Partnerships

Communication

You build strong logistics partnerships when you communicate clearly and consistently. Good communication helps you avoid mistakes and keeps everyone on the same page. You should choose the right channels for each situation. Sometimes a quick phone call works best. Other times, you need to send a detailed email or use logistics management software for real-time updates.

Here are best practices for effective communication in logistics partnerships:

Set clear expectations from the start. Define what success looks like for both sides.

Pick communication channels that match the urgency and preference of your partners.

Keep a regular schedule for updates and check-ins.

Foster trust by encouraging open dialogue and respect.

Use technology to share real-time information and updates.

Document all interactions to prevent misunderstandings.

Prepare a crisis communication plan for emergencies.

Consider cultural and language differences to improve collaboration.

Align your goals with your partners to work toward common objectives.

Review your communication strategies often to find areas for improvement.

Tip: Consistent communication builds trust and helps you solve problems before they grow.

Service Agreements

You improve logistics reliability when you use well-defined service agreements. Service Level Agreements (SLAs) set clear expectations and responsibilities for both you and your partners. These agreements help you measure performance and prevent disputes.

SLAs outline what services you expect and who is responsible for each task.

You can track performance using specific KPIs, such as on-time delivery rates and order accuracy.

Clear terms reduce misunderstandings and make it easier to resolve issues.

SLAs help logistics providers organize workflows to meet your needs.

Reliable service agreements increase customer satisfaction by ensuring quality and consistency.

Key Element | Description |

|---|---|

Scope of Services | Lists all logistics activities covered |

Performance Metrics & KPIs | Sets measurable targets for service quality |

Roles & Responsibilities | Defines what each party must do |

Note: Review your service agreements regularly. Updates keep your partnerships strong and your logistics operations running smoothly.

Sustainable Logistics

Reduce Waste

You can make your logistics operations more sustainable by focusing on waste reduction. Waste comes from many sources, such as packaging, unused materials, and inefficient processes. When you reduce waste, you save money and help the environment. Customers notice your efforts and trust your brand more.

Here are some effective strategies for reducing waste in logistics:

Strategy | Description |

|---|---|

Waste Audits | Conduct regular audits to find waste sources and improve efficiency. |

Recycling Programs | Start recycling initiatives to cut waste and reuse resources. |

Employee Training | Teach your staff about waste reduction to build a strong commitment to sustainability. |

Partnerships with Eco-friendly Suppliers | Work with suppliers who care about sustainability to reach your waste reduction goals. |

You can train your team to spot waste and suggest improvements. Recycling programs help you reuse materials and lower disposal costs. When you work with eco-friendly suppliers, you show your customers that you care about the planet. Sustainable practices increase the value of your logistics and build customer loyalty. Many customers now prefer companies that protect the environment.

Tip: Regular waste audits help you find new ways to save resources and improve your operations.

Energy-Efficient Fleet

You can boost sustainability by using an energy-efficient fleet. Energy costs make up a large part of logistics expenses. Saving energy helps you keep more profit and lower your impact on the environment.

Efficient route planning saves fuel and shortens travel time.

Upgrading to fuel-efficient or electric vehicles cuts costs and emissions.

Digital fuel monitoring systems help you track fuel use and manage expenses.

Electric machinery lowers operating costs and reduces pollution.

When you use energy-saving strategies, you help the environment and improve your bottom line. Customers notice your commitment to sustainability. Many people now choose companies that use green practices. Sustainable logistics increases perceived value and builds strong customer loyalty.

Note: Review your fleet regularly. Modern vehicles and smart planning help you save money and protect the environment.

Performance Monitoring

Set Benchmarks

You need clear benchmarks to measure your logistics performance. Benchmarks help you see where you stand and where you can improve. You can track productivity by counting how many order lines your team picks each hour. In a regular warehouse, you should expect 25 to 35 order lines picked per labor hour. Automated systems can reach over 100 lines per hour. Quality matters too. You want error rates below 0.05%, which means 99.95% accuracy. Inventory accuracy should be higher than 99.5%.

You should also watch how well you use your labor. Direct labor utilization should stay between 85% and 90%. Overtime should not go above 5%. Turnover rates show how often employees leave. You want annual turnover below 15%. Many companies see rates between 30% and 45%. Absenteeism affects your workflow. Unplanned absences should be less than 3% of scheduled shifts. The industry average is 5% to 8%.

Productivity: 25-35 order lines picked per labor hour; 100+ with automation

Quality: Error rates below 0.05%; inventory accuracy above 99.5%

Utilization: 85-90% direct labor; overtime below 5%

Turnover: Annual rates below 15%

Absenteeism: Unplanned absences below 3%

Tip: Set benchmarks that match your business goals. Review them often to keep your logistics on track.

Regular Audits

Regular audits help you catch problems early and keep your logistics running smoothly. You should plan audits based on the value and turnover of your items. High-value items need cycle counts every month. Low-value items can wait for quarterly checks. You should do a full physical inventory once a year.

Audit Type | Frequency |

|---|---|

Cycle Counts (High-Value) | Monthly |

Cycle Counts (Low-Value) | Quarterly |

Full Physical Inventory | Annually |

You can also audit items based on how quickly they move. High turnover items need daily checks. Moderate turnover items do best with weekly audits. Low turnover items can be checked monthly.

Weekly audits for moderate turnover items

Monthly audits for low turnover items

Note: Regular audits help you spot errors, prevent losses, and improve accuracy. Make audits part of your routine to keep your logistics strong.

You can improve logistics efficiency and save money by using these actionable tips. When you track KPIs like delivery time, cost per mile, and order accuracy, you see real progress.

KPI | Benefit |

|---|---|

Delivery Time | Faster shipments |

Cost per Mile | Lower expenses |

Order Accuracy | Fewer mistakes |

Continuous improvement helps you find waste and fix weak spots. Lean practices and strong supplier relationships make your operations better. Choose the strategies that fit your business and keep learning new best practices.

FAQ

What is the best way to start improving my logistics operations?

You should begin by reviewing your current processes. Make a list of areas that slow you down or cost too much. Focus on inventory, warehouse layout, and delivery routes.

How can technology help my logistics team?

Technology gives you real-time data and automates tasks. Use software to track shipments, manage inventory, and plan routes. This helps you save time and reduce mistakes.

Why is team training important in logistics?

Team training builds skills and keeps everyone updated. You learn new tools and safety practices. Well-trained teams work faster and make fewer errors.

What are common KPIs for logistics performance?

KPI | What It Measures |

|---|---|

Delivery Time | Speed of shipments |

Order Accuracy | Correct orders shipped |

Inventory Turnover | Stock movement rate |

Tip: Track these KPIs every month to spot problems early.

See Also

Key Strategies for Effective Global Logistics Operations

Enhancing International Operations Through Innovative Logistics Solutions

Boosting Global Efficiency with Point-to-Point Logistics Systems

Simplifying Supply Chain Optimization with American Logistics Solutions

Top Global Logistics Services for Efficient East Coast Imports