Essential Practices for Successful Global Logistics Management

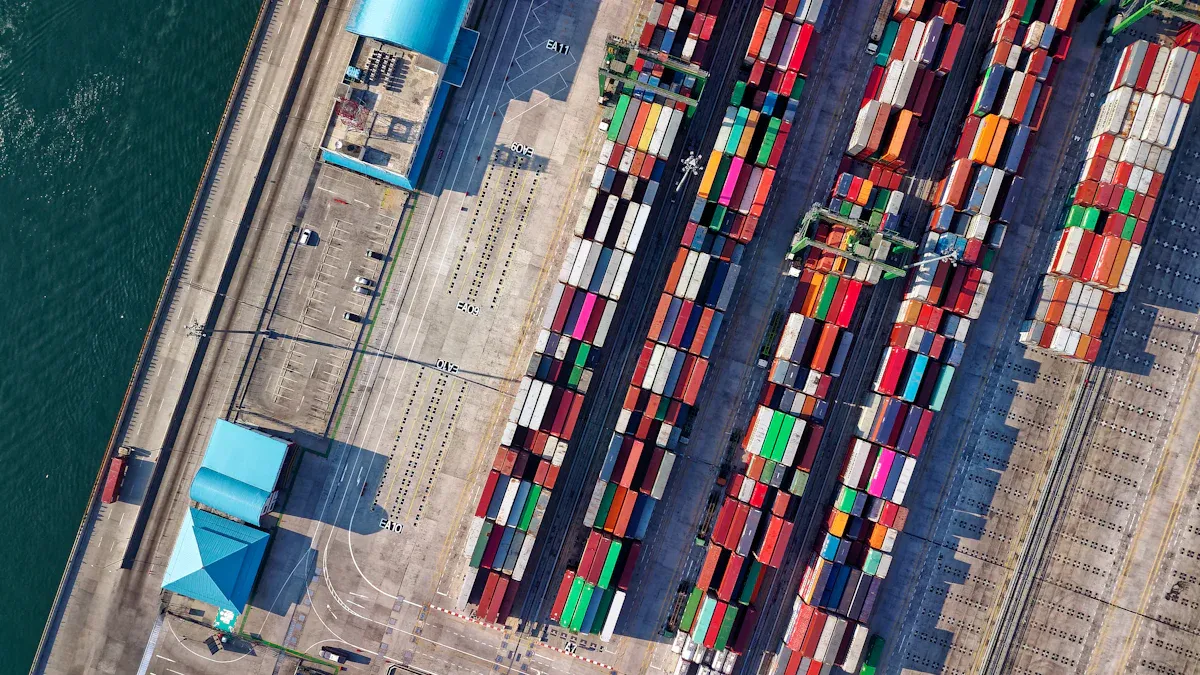

Effective global logistics management helps you grow your business and improve operations. When you use a global logistics and supply chain guide modern business logistics solutions, you set your company up for success. The logistics market is expected to reach $15.79 trillion by 2028. Ocean freight carries 70% of goods worldwide. Choosing the right transportation mode and using advanced tracking systems can save money and make deliveries faster. You gain more control and keep customers happy when you follow proven practices.

Essential Practice | Benefit |

|---|---|

Process Standardization | Efficiency |

Advanced Tracking Systems | Real-time visibility |

Customer-Focused Strategies | Responsive service |

Key Takeaways

Effective global logistics management can significantly enhance your business operations and customer satisfaction.

Implementing advanced tracking systems provides real-time visibility, helping you manage shipments and improve delivery times.

Building strong cross-functional teams fosters collaboration, leading to faster problem-solving and improved supply chain efficiency.

Regularly reviewing your logistics processes helps identify inefficiencies and implement continuous improvements.

Establishing local partnerships allows you to leverage regional expertise, ensuring quicker deliveries and compliance with local regulations.

Comprehensive Planning

A strong global logistics and supply chain guide modern business logistics solutions starts with comprehensive planning. You need to look at every part of your supply chain and make sure each step works with your business goals. Good planning helps you avoid problems, save money, and keep your customers happy.

Centralized Strategy

You should create a centralized strategy for your logistics operations. This means you set clear goals and make sure every region follows the same plan. When you use a global logistics and supply chain guide modern business logistics solutions, you can:

Stay up to date with changing regulations and avoid legal issues.

Use technology to make your logistics network stronger and more efficient.

Tip: Mapping out your supply chain helps you spot bottlenecks and fix them before they cause delays.

A centralized approach lets you streamline operations and cut costs. You can also make sure your deliveries arrive on time, which keeps your customers satisfied.

Implementation

Once you have a strategy, you need the right tools to put your plan into action. Many companies use a global logistics and supply chain guide modern business logistics solutions to help with this process. Some of the best tools include:

Network optimization software to test different distribution models.

Transportation Management Systems (TMS) to manage shipments.

Warehouse Management Systems (WMS) to track inventory.

Task management tools to keep teams organized and on schedule.

You can also use analytics tools to make better decisions based on real data. Lean principles help you reduce waste and improve how you handle materials. When you coordinate across regions and use these tools, you make your logistics more efficient and reliable.

Cash Flow Management

Managing cash flow in global logistics keeps your business strong and ready for growth. You need to watch your finances closely and use smart strategies to avoid problems. Good cash flow management helps you pay suppliers on time, invest in new technology, and handle unexpected costs.

Financial Controls

You can use financial controls to track your money and make better decisions. These controls help you see where your money goes and how you can save more.

Some effective financial controls include:

Monitor key performance indicators (KPIs) to check how well your logistics operations work.

Analyze profitability by service lines to use your resources wisely.

Automate accounts receivable processes to avoid mistakes and speed up collections.

Evaluate customer risk to set the right credit limits and protect your cash flow.

Regularly review cash flow metrics and KPIs to spot problems early.

Encourage timely payments with incentives and easy payment options.

Streamline dispute resolution to keep your cash flow steady.

Tip: You can build strong financial controls by following a few steps:

Develop budgets that include all costs and expected income.

Use forecasting models to predict cash flow and changes in demand.

Implement cost control measures to keep expenses low.

When you use these controls, you make your logistics business more stable and ready for growth.

Payment Optimization

Optimizing payments makes your logistics operations smoother and safer. You can use payment strategies to save money and reduce risks.

Here are some ways payment optimization helps your business:

Streamline payment flows to boost efficiency and speed up transactions.

Reduce costs linked to international payments.

Improve transaction security to lower risks.

Manage cash and liquidity better for daily operations.

Mitigate risks from currency changes.

Ensure compliance with global regulations.

You can use digital payment platforms to make payments faster and safer. When you optimize payments, you keep your business flexible and ready for new opportunities.

Cross-Functional Teams

Collaboration

You can boost your logistics results when you build strong cross-functional teams. These teams bring together people from different departments, such as sales, operations, and technology. When you work together, you solve problems faster and share ideas that improve your supply chain.

Many leading companies use cross-functional teams to achieve big goals:

Procter & Gamble increased production by 45% during high demand for hygiene products.

Amazon uses teams from different areas to add AI and machine learning, making inventory management smarter and deliveries quicker.

Ford brings together research, manufacturing, and marketing to support electric vehicle growth and meet sustainability targets.

Walmart expanded its e-commerce and grocery delivery, leading to a 79% jump in online sales during the pandemic.

You can see that teamwork across departments helps you respond to changes and reach new levels of success.

Strategy | Example/Impact |

|---|---|

Breaking Down Silos | 41% of supply chain professionals say siloed operations block integration (ISM study). |

Clear Objectives | Amazon’s focus on customer satisfaction unites cross-functional teams. |

Open Communication Channels | PepsiCo’s weekly meetings align production, distribution, and sales strategies. |

Shared Data and Technology | Gartner reports end-to-end visibility tools can cut costs by up to 20%. |

Culture of Collaboration | Unilever’s Sustainable Living Plan encourages teamwork for better efficiency. |

Empower Cross-Functional Leaders | Procter & Gamble’s Category Business Leaders guide collaboration across teams. |

Tip: You can set up regular meetings and use shared technology platforms to keep everyone informed and working toward the same goals.

Efficiency

You gain speed and accuracy when you encourage cross-functional teamwork. Teams that share information and resources can spot problems early and fix them before they grow. You also reduce wasted time and avoid repeating tasks.

When you break down barriers between departments, you create a smooth flow of goods and data. You can use shared dashboards and real-time tracking tools to help everyone see what is happening. This makes your logistics network stronger and more flexible.

You can reach higher efficiency by setting clear roles and letting team members make decisions. When everyone knows their job and trusts each other, you move products faster and keep customers happy. Cross-functional teams help you stay ahead in global logistics.

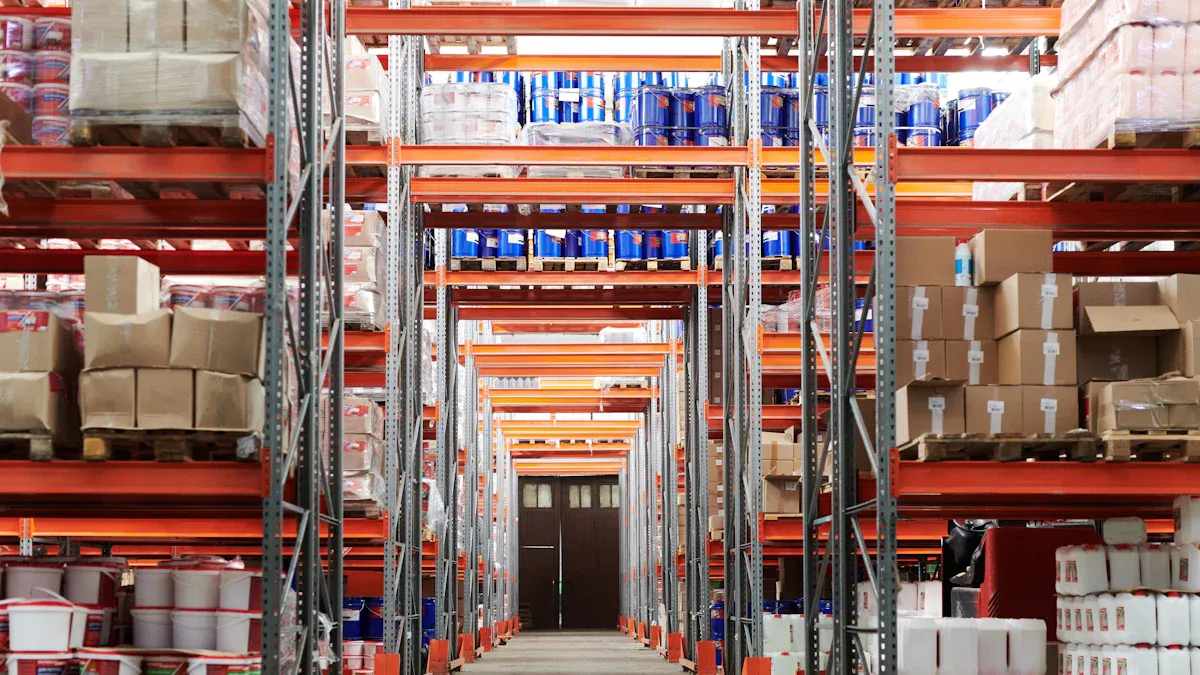

Space Utilization

Efficient space utilization helps you get the most out of your logistics facility. You can store more products, move items faster, and save money. A systematic approach to layout design lets you maximize every inch of available space. Regular assessments of your warehouse layout and storage solutions keep your operations running smoothly. You can invest in high-density storage solutions, such as mobile shelving units, to enhance your storage capacity.

Vertical Storage

Vertical storage lets you use overhead space that often goes unused. You can stack products higher and fit more items in the same area. This strategy reduces the need for costly warehouse expansions. You make better use of your existing space and avoid spending money on new buildings.

Vertical storage increases the number of products you can store without taking up more floor space.

You can retrieve items faster, which boosts productivity and streamlines your workflow.

Pallet racking systems and mobile shelving units help you organize products and keep your warehouse tidy.

Tip: Use racks with different designs to increase storage density and make the most of your vertical space.

You can automate warehouse operations with a Warehouse Management System (WMS). This technology helps you track inventory and find items quickly.

Item Placement

Smart item placement makes your warehouse more efficient. You should analyze traffic patterns and product turnover rates to decide where to put each item. Place fast-moving products near shipping areas for quick access. Store slow-moving items higher up or farther from main aisles.

Directed put-away techniques help you place items in the best spots.

Geographic cycle counts and product consolidation minimize wasted space.

Allocating products based on size, weight, and demand keeps your warehouse organized.

Practice | Benefit |

|---|---|

Facility Layout | Enhances space utilization |

Inventory Allocation | Maximizes storage capacity |

Reporting Capabilities | Identifies inefficiencies |

You can use key reports to monitor space utilization and spot areas for improvement. When you focus on vertical storage and smart item placement, you make your logistics facility more productive and cost-effective.

Data Management

Managing data well helps you make better decisions in global logistics. You need to collect accurate information and analyze it to improve your supply chain. Good data management lets you see what is happening in real time and plan for the future.

Collection

You can use many methods to collect data in your logistics operations. Each method gives you different types of information. When you combine these methods, you get a complete view of your supply chain.

Manual surveys help you gather feedback from workers and customers.

Automated barcodes and RFID tags track products as they move through your warehouse.

IoT devices and GPS tracking show where your shipments are at any moment.

Real-time visibility systems let you watch your supply chain and respond quickly to changes.

Tip: Use technology to collect data faster and with fewer mistakes.

You can also use data to create demand forecasts. AI tools help you predict what products you will need and when. Inventory management systems keep your stock at the right level. You can also plan for risks by looking at past data and setting up backup plans. Blockchain technology makes your data more secure and easy to trace.

Analysis

After you collect data, you need to analyze it. This step helps you find patterns and make smart choices. You can use different types of analytics to get the most out of your data.

Analytical Technique | Description | Impact on Decision-Making |

|---|---|---|

Predictive Analytics | Uses statistical models to forecast future outcomes based on historical data. | Helps you anticipate trends and prepare for changes. |

Prescriptive Analytics | Recommends specific actions based on analysis of potential scenarios. | Guides you to choose the best strategies for your operations. |

When you use these tools, you can spot problems before they happen. You can also find ways to save money and improve delivery times. Data analysis gives you the power to make decisions that help your business grow.

Network Optimization

Optimizing your logistics network helps you meet the needs of your business and your customers. You want your supply chain to work smoothly and bring in more profit. To do this, you must look at transportation methods, where your facilities are, how you manage inventory, and how much everything costs. When you focus on these areas, you can make your logistics network stronger and more efficient.

Route Planning

You need to plan your delivery routes carefully. Good route planning helps you save money and deliver products faster. Start by centralizing and cleaning your logistics data. This step gives you a clear picture of your network. Next, run a transportation network analysis. This means you look at where your warehouses are, which routes work best, and what transportation modes fit your needs. You should also build strong partnerships with your carriers and warehouse teams. These relationships help you solve problems quickly.

Here are some steps you can follow to optimize your network:

Centralize and clean your logistics data for better analysis.

Analyze your transportation network, including facility locations and routes.

Build strong partnerships with warehousing and carrier partners.

Keep improving your processes to adapt to changes.

Use smart technology to make better decisions.

Tip: Use route planning software to find the fastest and most cost-effective paths for your deliveries.

Frequent Review

You should review your logistics routes often. This helps you spot problems early and make changes before they grow. When you check your routes regularly, you can save money, deliver faster, and keep your customers happy. Route management software lets you adjust your plans in real time, so you can avoid delays and reduce the distance your trucks travel.

Evidence Point | Description |

|---|---|

Cost Savings | Optimizing routes can lead to significant cost savings by reducing fuel consumption. |

Improved Delivery Times | Enhanced operational efficiency results in faster delivery times. |

Real-time Adjustments | Route management software allows for adjustments based on real-time changes, minimizing delays. |

Reduced Mileage | Planning deliveries considering various factors ensures faster deliveries and minimizes distance traveled. |

Increased Customer Satisfaction | Adhering to realistic delivery times improves customer satisfaction. |

Regular reviews help you keep your logistics network flexible and ready for any changes in demand or shipping conditions. You can use these reviews to make sure your network always supports your business goals.

Demand Forecasting

Accurate demand forecasting helps you plan your logistics operations and meet customer needs. You can use data-driven methods to predict what products your customers will want and when they will need them. This approach gives you a clear picture of future demand and helps you make smart decisions.

Data-Driven Methods

You can use statistical tools and technology to improve your demand forecasts. These methods rely on real numbers and patterns from past sales. When you use data-driven forecasting, you get more reliable results.

Quantitative methods use statistical data to predict logistics needs. You can trust these numbers because they come from real business activity.

Artificial intelligence (AI) can analyze historical data and market trends. AI helps you spot patterns that people might miss. This makes your forecasts more accurate.

Data-driven forecasting helps you optimize inventory and reduce costs. You can avoid buying too much or too little stock.

Tip: Try using AI-powered forecasting tools to get faster and more precise predictions.

When you use these methods, you make your supply chain stronger and more flexible. You can respond quickly to changes in demand and keep your customers happy.

Inventory Levels

Managing inventory levels is key to successful demand forecasting. You need to know how much stock you have and how fast it moves. Accurate forecasts help you keep the right amount of products on hand.

Good demand forecasting lets you plan your supply chain. You can adjust production, buying, and shipping to match customer needs.

Strong forecasting reduces stockouts and overstocks. This saves you money and keeps customers satisfied.

Integrating forecasting with inventory management creates a responsive supply chain. You can adapt quickly to market changes.

Accurate forecasts help you avoid holding too much inventory. You also prevent running out of products when customers need them.

Businesses lose $1.7 trillion each year from overstocking and stockouts. You can avoid these losses by improving your forecasts.

Note: Check your inventory levels often and update your forecasts to match real sales trends.

When you manage inventory well, you support your business goals and stay competitive in global logistics.

Technology Solutions

Modern business logistics relies on technology to keep supply chains running smoothly. You can use a global logistics and supply chain guide modern business logistics solutions to choose the right tools for your needs. These solutions help you track shipments, manage inventory, and make better decisions every day.

Real-Time Visibility

You need real-time visibility to know where your shipments are at all times. IoT sensors and GPS tracking give you up-to-the-minute information about your goods. This technology lets you see accurate delivery timelines and spot any delays before they become bigger problems. When you use real-time tracking, you can:

Improve supply chain visibility

Manage inventory better

Communicate quickly about issues

Reduce costs and boost customer satisfaction

A global logistics and supply chain guide modern business logistics solutions often includes platforms that show you the status of every shipment. These platforms help you make fast decisions and keep your customers informed.

Tip: Real-time tracking helps you respond to changes right away, so you avoid costly mistakes.

Monitoring Tools

Monitoring tools help you watch every part of your logistics process. Automated warehouses use robots and sensors to track products as they move. AI systems analyze this data to find patterns and suggest ways to improve. Blockchain technology keeps your transactions secure and easy to trace.

Some of the most impactful monitoring tools include:

Automated sorting centers and delivery vehicles

Cloud-based supply chain management platforms

AI for demand forecasting and inventory control

IoT sensors for real-time data collection

You can use these tools to spot problems early and fix them fast. When you combine these technologies, you create a strong system that supports your business goals. A global logistics and supply chain guide modern business logistics solutions helps you pick the best tools for your company.

Technology | Benefit |

|---|---|

IoT Sensors | Real-time shipment tracking |

AI Systems | Smarter inventory management |

Blockchain | Secure, transparent records |

Automation | Faster, more accurate handling |

Local Partnerships

Relationship Building

You can strengthen your global logistics by building strong local partnerships. When you work with local companies, you gain access to their knowledge and experience. These partners help you understand the market and avoid common mistakes. You also learn about local customs and regulations, which keeps your operations running smoothly.

Many successful companies use joint ventures to improve their logistics. For example, UPS teamed up with SF Holding in China. UPS brings global expertise, while SF Holding offers deep local knowledge. This partnership helps both companies deliver packages faster and more reliably.

Joint Venture | Description |

|---|---|

UPS and SF Holding | This partnership enables UPS to utilize its global expertise alongside SF Holding's local knowledge to enhance express delivery services in China. |

Local Knowledge | Joint ventures allow companies to navigate local regulations and cultural nuances effectively, leveraging local expertise for operational efficiency. |

Tip: You can build trust with local partners by sharing information and setting clear goals. Regular meetings and open communication help you solve problems quickly.

Regional Expertise

Regional expertise from local partners gives you a big advantage in logistics. You can respond to changes in demand and optimize your warehouse space. Local partners know the area well, so they choose the best routes and avoid delays. You save money on fuel and equipment because your deliveries travel shorter distances.

Regional logistics reduces vulnerabilities in global networks. You gain more control and accountability.

Local partners help you pivot quickly when demand changes. You keep your customers happy and your warehouse organized.

Closer delivery routes lead to cost savings. You spend less on fuel and maintenance.

Benefit | Description |

|---|---|

Local partners know the area better, have optimized delivery routes and can deliver goods more quickly without long delays. | |

Lower Shipping Costs | By eliminating long-distance shipping and reducing the need for cross-country transportation, businesses can save money on logistics. |

Familiarity with Local Regulations | Local logistics providers are already familiar with the rules and regulations in their regions, ensuring smoother operations. |

You can see that regional expertise helps you deliver products faster, save money, and follow local rules. Working with local partners makes your logistics network stronger and more flexible.

Continuous Improvement

Continuous improvement helps you keep your logistics operations strong and competitive. You can use proven methods to make small changes every day. These changes add up and help your business grow. You learn from your mistakes and find new ways to solve problems. You also make sure your team stays focused on getting better.

Process Review

You need to review your processes often. This helps you find areas that slow down your work or cost too much money. You can use different methods to guide your reviews. Many companies use Kaizen, the Deming Cycle, Six Sigma, and Lean Methodology. Each method gives you tools to improve step by step.

Methodology | Description |

|---|---|

Kaizen (5S) | Focuses on continuous, incremental improvements through five principles: Sort, Set in order, Shine, Standardize, Sustain. |

Deming Cycle (PDCA) | A cyclical approach involving Plan, Do, Check, Act to detect inefficiencies and implement solutions. |

Six Sigma | Aims to reduce defects to no more than 3.4 per million opportunities, enhancing customer satisfaction. |

Lean Methodology | Identifies and eliminates non-value-adding stages to improve product quality. |

When you review your processes, you look for ways to increase efficiency, cut costs, and improve service quality. You also find and remove bottlenecks. You can use new technology to make your work easier. Regular reviews help you stay ahead of problems and keep your customers happy.

Aspect | Description |

|---|---|

Efficiency | Improving and enhancing various aspects of logistics operations to achieve greater efficiency. |

Cost Reduction | Implementing strategies that lead to reduced costs in logistics operations. |

Service Quality | Enhancing service quality to meet customer demands and business objectives. |

Bottleneck Elimination | Identifying and eliminating bottlenecks in the logistics process. |

Technology Implementation | Utilizing new technologies to streamline logistics operations. |

Feedback Loops

Feedback loops help you learn from your team and your customers. You ask for ideas and listen to what people say. You use this information to make changes and improve your logistics. You focus on making your processes better every day.

You work to enhance your systems and processes.

You look for ways to boost efficiency and lower costs.

You pay attention to customer satisfaction.

You use technology and data to make smart decisions.

You involve your employees in finding solutions.

Tip: Set up regular meetings to gather feedback. Encourage everyone to share their thoughts. Small changes can lead to big improvements over time.

Continuous improvement keeps your logistics flexible and ready for new challenges. You build a culture where everyone works together to get better each day.

Risk Management

Common Risks

You face many risks in global logistics. These risks can slow down your business and hurt your reputation. You need to know what can go wrong so you can prepare.

Transportation delays happen because of accidents, severe weather, or mechanical breakdowns.

Regulatory noncompliance can lead to fines or even product recalls.

Security breaches during cargo handling may compromise product integrity and customer confidence.

Accidents and collisions often result from human error or equipment problems.

Infrastructure wear and tear affects reliability and can cause unexpected stops.

Environmental hazards like hurricanes or floods disrupt transportation routes.

Cyber attacks or data breaches threaten your information and systems.

Business interruption can occur from many sources, including economic slowdowns.

Failure to attract or keep top talent weakens your logistics team.

Changes in laws or regulations force you to adjust your operations.

Supply chain or distribution failures stop products from reaching customers.

Traffic congestion slows down deliveries and increases costs.

Tip: You should review your logistics process often to spot these risks early.

Mitigation

You can manage these risks by using smart strategies. Start by conducting thorough risk assessments. This helps you find weak spots in your supply chain. Develop contingency plans for possible disruptions. These plans keep your business running when problems arise.

Build strong relationships with your suppliers. Reliable partners help you avoid delays and mistakes. Diversify your suppliers and manufacturing locations. This reduces your dependency on one source and makes your supply chain stronger.

Use technology to track shipments in real time. Predictive analytics help you forecast demand and spot issues before they grow. Just-In-Time inventory practices lower your holding costs and keep your operations flexible.

Leverage predictive analytics for better demand forecasting.

Utilize real-time tracking for enhanced supply chain visibility.

Build collaborative partnerships with logistics providers to improve resilience.

Strategy | Benefit |

|---|---|

Risk Assessment | Identifies vulnerabilities |

Contingency Planning | Minimizes disruptions |

Supplier Diversification | Reduces dependency risks |

Technology Adoption | Improves visibility and control |

Note: You can lower your risk by staying informed and updating your plans regularly.

Compliance

Regulations

You face many rules when you manage global logistics. Each country sets its own standards to protect its economy and security. You must follow these regulations to keep your shipments moving and avoid trouble. Some rules focus on safety, others on trade, and some on protecting personal data. If you ignore these rules, you risk fines, delays, and even criminal charges.

Here is a table showing important regulations and what happens if you do not follow them:

Regulation | Description | Consequences of Noncompliance |

|---|---|---|

Customs Trade Partnership Against Terrorism (CTPAT) | A U.S. program enhancing supply chain security against terrorism. | Removal from the program, shipment delays, increased inspections. |

International Maritime Organization (IMO) | Governs safety, environmental, and security standards for maritime transport. | Hefty fines, legal repercussions, reputational damage. |

General Data Protection Regulation (GDPR) | EU law on processing, storing, and sharing personal data. | Fines, legal repercussions, reputational damage. |

United States-Mexico-Canada Agreement (USMCA) | Establishes a trade-free zone across North America. | Criminal charges, denial of preferential tariff treatment. |

Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) | Regulates the use and safe handling of chemicals in the EU. | Fines, product recalls, criminal charges. |

Advanced Filing Rules (AFR) | Requires detailed cargo information submission to Japanese Customs. | Cargo delays, denial of entry. |

Saudi Standards, Metrology and Quality Organization (SASO) | Sets national standards for imported goods in Saudi Arabia. | Rejection or confiscation of noncompliant goods at customs. |

Tip: You should stay updated on new regulations. Regular training helps your team avoid costly mistakes.

Documentation

You need proper documentation to prove you follow the rules. Documents show ownership, safety, and compliance. They help you clear customs faster and avoid delays. Accurate paperwork builds trust with buyers and partners. If you make mistakes or leave out details, you risk losing money and slowing down shipments.

Proper documentation serves as proof of compliance, ownership, and safety.

It leads to faster customs clearance and fewer delays.

Accurate documentation improves trust with buyers and logistics partners.

Incomplete or incorrect documentation can result in financial losses and shipment delays.

International trade depends on clear and complete paperwork. Each country checks your documents to make sure you follow trade agreements, tariffs, and laws. Good documentation protects your shipments from being seized or destroyed. You keep your business safe and your customers happy when you pay attention to every detail.

Note: You should review your documents before shipping. Double-checking helps you avoid problems at the border.

You can boost your global logistics success by focusing on inventory accuracy, shipment tracking, and cost control. Measure your progress with on-time delivery rates, order accuracy, and warehouse utilization.

Leverage technology like AI and IoT

Build strong supply chain relationships

Stay alert to new trends such as automation, blockchain, and sustainability. Keep improving your operations and set clear goals for your team. 🚀

FAQ

What is the most important skill for global logistics management?

You need strong planning skills. You must organize shipments, track inventory, and solve problems quickly. Good planning helps you avoid delays and keeps your customers happy.

How does technology improve logistics operations?

Technology gives you real-time data. You can track shipments, manage inventory, and spot issues early. Tools like IoT sensors and AI systems help you make better decisions and save money.

Why should you work with local partners?

Local partners know the area well. They help you follow local rules and find the best delivery routes. You save time and avoid mistakes by using their expertise.

How do you reduce risks in global logistics?

You should review your process often. Use risk assessments and backup plans. Build strong relationships with suppliers. Technology helps you track shipments and spot problems before they grow.

What documents do you need for international shipping?

You need invoices, bills of lading, and customs forms. These documents prove ownership and show you follow the rules. Accurate paperwork helps you clear customs faster and avoid delays.

See Also

Optimized Inventory Management Through Premier Global Logistics Solutions

Key LCL Shipping Steps for Panama Exports by Premier Global Logistics

Enhanced Inventory Control and Distribution via Premier Global Logistics

Comprehensive Multi-Channel Fulfillment Solutions from Premier Global Logistics

Maximizing Efficiency in LA Warehousing with Premier Global Logistics