How to Ensure Compliance with Hazardous Materials Transportation Safety Rules

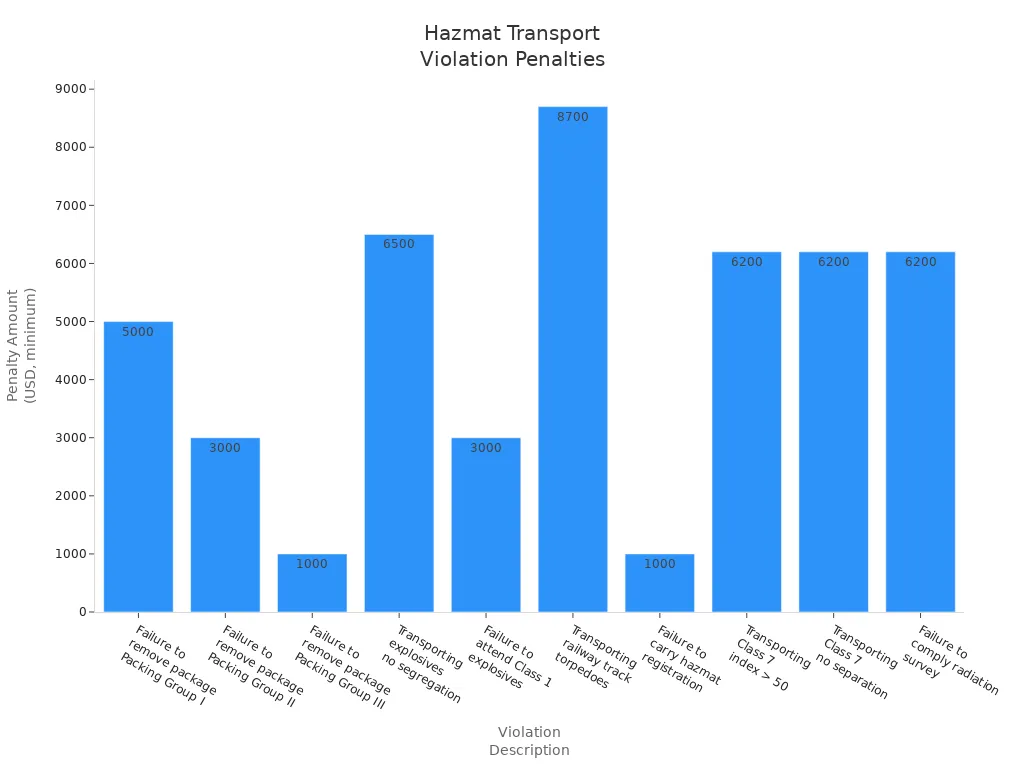

You must follow hazardous materials transportation safety rules to protect people and the environment. Federal and state agencies issue strict penalties if you fail to comply. For example, transporting explosives without proper segregation can cost $6,500 or more. The table below shows common violations and their penalty amounts.

Violation Description | Penalty Amount |

|---|---|

Failure to remove a package containing hazardous materials from a motor vehicle before discharge of its contents (Packing Group I) | $5,000 |

Failure to remove a package containing hazardous materials from a motor vehicle before discharge of its contents (Packing Group II) | $3,000 |

Failure to remove a package containing hazardous materials from a motor vehicle before discharge of its contents (Packing Group III) | $1,000 |

Transporting explosives in a motor vehicle without proper segregation | $6,500 and up |

Failure to attend Class 1 explosive materials during transportation | $3,000 |

Transporting railway track torpedoes outside of flagging kits | $8,700 |

Failure to carry a hazmat registration letter or number | $1,000 |

Transporting Class 7 (radioactive) material with a total transport index greater than 50 | $6,200 and up |

Transporting Class 7 (radioactive) material without maintaining required separation distance | $6,200 and up |

Failure to comply with radiation survey requirements for Class 7 (radioactive) material | $6,200 and up |

You need to understand local, state, and federal requirements, keep accurate records, and prepare for emergencies. These steps help you avoid costly mistakes and keep your business safe.

Key Takeaways

Understand what hazardous materials are. Check the Hazardous Materials Table to identify regulated substances.

Follow all packaging and labeling requirements. Proper packaging prevents leaks and ensures safety during transport.

Keep accurate shipping papers. Complete all required information to avoid confusion and legal issues.

Train employees regularly. Provide initial training within 90 days and refresher courses every three years to maintain compliance.

Prepare for emergencies. Create and practice an emergency response plan to ensure quick action during incidents.

Hazardous Materials Defined

What Are Hazardous Materials

You need to know what counts as hazardous materials before you can follow the rules. The Department of Transportation says hazardous materials are substances or materials that can cause harm to health, safety, or property when moved from place to place. These include things like chemicals, waste, and even some items that get very hot during transport. The Secretary of Transportation decides which materials are hazardous. You can find these materials listed in the Hazardous Materials Table. Each one fits into a hazard class based on how it can cause harm.

Here is a table showing the main hazard classes and some common examples:

Hazard Class | Description | Common Examples |

|---|---|---|

Class 1 | Explosives | Ammunition, fireworks |

Class 2 | Gases | Aerosols, lighters, butane cans, oxygen |

Class 3 | Flammable Liquid | Paints, adhesives, hand sanitizers |

Class 4 | Flammable Solid | Strike-anywhere matches |

Class 5 | Oxidizer, Organic Peroxide | Oxygen generators, hydrogen peroxide cleaners |

Class 6 | Poison (Toxic) | Insecticides, regulated medical waste |

Class 7 | Radioactive | Radiopharmaceuticals, smoke detector sources |

Tip: Always check the Hazardous Materials Table to see if your product is regulated.

Who Must Follow Safety Regulations

You must follow hazardous materials transportation safety rules if you take part in moving these materials. The law covers many people and businesses. Here are some examples:

You work for a company that ships chemicals.

You drive a truck carrying fireworks or oxygen tanks.

You own a business that sends out medical waste.

You are part of a public utility that moves hazardous goods.

Anyone involved in shipping, handling, or transporting hazardous materials must follow the rules. This includes individuals, companies, partnerships, and public utilities. You must make sure you classify, describe, package, mark, label, and handle hazardous materials the right way. If you skip any step, you risk fines and put people in danger.

Regulatory Responsibilities

You must follow many rules when you handle hazardous materials. These rules come from federal, state, and local agencies. The requirements can change based on what you ship, how much you ship, and how you package it. If you do not follow these rules, you risk fines and safety hazards.

Shipper Duties

As a shipper, you have several important jobs. You must make sure your team gets the right training and keeps it up to date. You need to pay for safe and legal shipments. You must also identify, classify, and package hazardous materials the right way. If your team does not know what to do, you should ask for help from Environmental Health & Safety.

Responsibility | Description |

|---|---|

Make sure all hazardous materials employees get and keep proper training. | |

Fund shipments | Pay for safe and legal hazardous materials shipments. |

Identify, classify, package, and ship materials by the rules. | |

Request assistance | Ask Environmental Health & Safety for help if your team needs more training. |

Note: The word "WASTE" must come before the shipping name for hazardous waste on shipping papers. You must keep shipping papers for two years, or three years for hazardous waste.

Carrier Duties

Carriers also have key responsibilities. You must follow all federal rules from the Pipeline and Hazardous Materials Safety Administration. You need to make sure your workers have the right training and equipment. You must manage risks during transport to keep everyone safe.

Duty | Description |

|---|---|

Follow all PHMSA rules for safe transport. | |

Proper training and equipment | Make sure workers are trained and have the right tools. |

Risk management | Take steps to lower risks during hazardous materials transportation. |

Multi-Agency Oversight

Many agencies watch over hazardous materials transportation safety. Each agency has a special job. Some focus on trucks, others on trains or ships. Some protect the environment or check for security threats.

Agency | Role | Responsibilities |

|---|---|---|

RSPA | Multimodal research/safety | Regulates safe transport across all modes and pipelines. |

FRA | Rail transportation | Regulates hazardous materials by rail. |

FMCSA | Truck transportation | Regulates hazardous materials by truck. |

USCG | Maritime sector | Regulates hazardous materials at sea and does research. |

EPA | Environmental protection | Works with DOT and checks environmental risks. |

TSA | Transportation security | Looks for threats and keeps transport systems safe. |

USACE | Waterways management | Maintains waterways and supports commerce, including hazardous goods. |

Tip: Always check which agency’s rules apply to your shipment. The rules can change based on what you ship and how you ship it.

Hazardous Materials Transportation Safety Compliance Steps

Packaging and Labeling

You must package hazardous materials with care to prevent leaks and spills. The Department of Transportation has clear steps for safe packaging. Each step helps protect people and the environment during transport.

Step | Requirement |

|---|---|

1 | Use a watertight primary receptacle. |

2 | Use a watertight secondary packaging, ensuring fragile primary receptacles are separated. |

3 | Use a rigid outer packaging of adequate strength, measuring at least 100 mm (3.9 inches) at its smallest dimension. |

4 | For liquids, include absorbent material between primary and secondary packaging. |

5 | Include an itemized list of contents between secondary and outer packaging. |

6 | Ensure primary and secondary packaging can withstand a pressure differential of at least 95 kPa (0.95 bar, 14 psi). |

7 | Ensure packaging can withstand temperatures from -40 °C to +55 °C (-40 °F to +131 °F). |

You also need to label each package correctly. Labels tell everyone what type of hazard is inside. The table below shows some common labels and their hazard classes.

Hazard Class | Label Name | Reference |

|---|---|---|

1.1 | EXPLOSIVES 1.1 | 172.411 |

2.1 | FLAMMABLE GAS | 172.417 |

3 | FLAMMABLE LIQUID | 172.419 |

4.1 | FLAMMABLE SOLID | 172.420 |

5.1 | OXIDIZER | 172.426 |

6.1 | POISON INHALATION HAZARD | 172.429 |

Tip: Always double-check that you use the right label for each hazard class. Failing to label and declare hazardous goods properly is a common mistake.

Shipping Papers and Documentation

Shipping papers are a key part of hazardous materials transportation safety. You must fill out these documents with care. They help inspectors and emergency responders know what you are carrying.

Requirement | Description |

|---|---|

Identification Number | The identification number prescribed for the material as shown in Column (4) of the § 172.101 table. |

Proper Shipping Name | The proper shipping name prescribed for the material in Column (2) of the § 172.101 table. |

Hazard Class | The hazard class or division number prescribed for the material, as shown in Column (3) of the § 172.101 table. Subsidiary hazard class(es) must be entered in parentheses if applicable. |

Additional Requirements | If a hazardous material is described with a non-hazardous material, it must be clearly distinguished on the shipping paper. |

Contact Information | A 24-hour phone number must be included, along with the company name if outsourced. |

You must avoid common errors on shipping papers. These include missing information, incorrect hazard classes, or not listing the emergency contact. Mistakes can cause confusion, delays, and even legal trouble. Accurate shipping papers help keep everyone safe and support compliance with hazardous materials transportation safety rules.

Note: You must also keep records of HazMat employee training. Improper documentation of training is a frequent violation.

Hazard Communication

Hazard communication helps everyone understand the risks of hazardous materials. You need to keep a chemical inventory, label all containers, and provide Safety Data Sheets (SDS) for each chemical. Employees must know how to read labels and SDS, and you must train them on emergency procedures.

Key Element | Description |

|---|---|

Chemical Inventory | A complete list of all hazardous chemicals used on-site, updated regularly, and accessible to employees. |

Labels | Containers must have labels with product identifiers, hazard statements, and precautionary information. |

Safety Data Sheets (SDS) | Detailed documents for each chemical, available in a standardized format and accessible to employees. |

Employee Training | Training on recognizing hazards, reading labels, and emergency procedures must be provided to all employees. |

Written Hazard Communication Plan | A documented plan outlining compliance with HazCom requirements, including inventory, labeling, and training protocols. |

Alert: Hazmat employers must train each employee. Training must cover general awareness, job-specific tasks, safety, and security. You must complete initial training within 90 days of starting work and repeat it every three years.

Vehicle Operation and Parking Rules

You must follow special rules when operating vehicles that carry hazardous materials. These rules help prevent accidents and protect the environment.

You need special permits and training to drive vehicles with hazardous cargo.

You must park only in approved areas. Many places do not allow parking near schools, hospitals, or crowded areas.

You must follow stricter rules than drivers of non-hazardous cargo.

Tip: Always check local and federal parking rules before you stop your vehicle. Following these rules is a key part of hazardous materials transportation safety.

Training, Recordkeeping, and Emergency Response

DOT Training Requirements

You must train all employees who handle hazardous materials. Training helps your team understand the risks and follow the rules. New employees need initial training within 90 days. You must provide refresher training every three years to stay compliant with DOT regulations. Some workers need annual refresher training or must show they still know the rules each year. Facility staff at large quantity generator sites must complete annual RCRA refresher training, usually near the anniversary of their last session.

Initial training within 90 days for new roles

Refresher training every three years for all hazmat employees

Annual refresher or competency checks for specific regulations

Yearly RCRA refresher training for large quantity generator facilities

Tip: Keep a record of all training dates and topics for each employee.

Recordkeeping Standards

You must keep records to prove you follow hazardous materials transportation safety rules. These records help inspectors check your compliance and protect your business.

Requirement | Description |

|---|---|

Registration Statement | Keep a copy of the registration statement filed with PHMSA for three years. |

Certificate of Registration | Hold the Certificate of Registration from PHMSA for three years. |

Onboard Documentation | Carry the current Certificate or registration number on each truck. |

Furnishing Records | Provide all records to DOT officials when asked. |

Requirement | Duration |

|---|---|

Retention of hazardous waste manifest |

Emergency Preparedness

You must prepare for emergencies before they happen. Create an emergency response plan that includes alarm systems, evacuation drills, and clear procedures. Review and update your plan every year. Equip your vehicles with communication devices and fire extinguishers.

Measure Type | Description |

|---|---|

Emergency Response Training Plan | Internal alarms, emergency procedures, annual evacuation drills |

Required Equipment | Communication devices, fire extinguishers |

Evaluation and Review | Annual reviews and updates based on feedback |

Alert: Practice your emergency plan with your team so everyone knows what to do.

Incident Reporting and Cleanup

If an accident happens, you must act quickly and safely. Shut off ignition sources and keep combustibles away. Do not touch spilled material unless you need to rescue someone. Detour traffic and wait for authorities before cleaning up. Cover spills with tarps or absorbent material to stop them from spreading. For large spills, build a dike to contain the material.

Report releases over the legal limit to the National Response Center.

Report major incidents, like fatalities or big disruptions, within 12 hours.

Send a detailed written report to DOT within 30 days using the correct form.

Note: Always follow your emergency plan and report incidents as required by law.

Ongoing Safety Practices

Regular Audits

You need to check your safety processes often to keep your team and the public safe. Regular audits help you find problems before they become serious. Start by reviewing records like Daily Vehicle Inspection Reports (DVIRs). These reports show if your vehicles have any issues. Work with drivers to make sure all paperwork is up to date.

Here are some best practices for audits:

Review all records, including DVIRs, to spot safety issues early.

Make sure drivers keep accurate and current paperwork.

Prepare for audits by knowing what inspectors look for, such as driver qualifications and vehicle repairs.

You should also:

Compare your current processes to Department of Transportation rules.

Update your policies so everyone knows their responsibilities.

Train employees regularly on how to handle hazardous materials.

Use technology to track shipments and check compliance.

Monitor and report on your safety practices to catch risks quickly.

Tip: Regular audits help you fix small problems before they lead to big fines or accidents.

Staying Current with Regulations

Rules for hazardous materials transportation safety change often. You must stay informed to avoid mistakes. Use different methods to keep up with new rules and best practices.

Method | Description |

|---|---|

Stay Informed | Check updates to national and international rules often. |

Invest in Training | Give employees training programs about new regulations. |

Utilize Technology | Use software to help with paperwork and tracking shipments. |

Engage Experts | Ask compliance specialists or legal advisors for help with complex rules. |

You can also use resources like "Handling Hazardous Materials: 10 Basic Safety Rules" for safety tips. Reports such as "Monitoring Hazardous Materials Shipments - Regulation of Drivers" explain new federal rules and the need for better reporting systems.

Note: Staying current with regulations protects your business and keeps everyone safe.

You can maintain hazardous materials transportation safety by following key steps.

Complete shipping papers with care.

Train your team often and keep records.

Inspect vehicles and equipment before each trip.

Prepare for emergencies with clear plans.

Benefit Type | Description |

|---|---|

Community Safety | |

Risk Minimization | Lowers the chance of spills, fires, and injuries. |

Effective Response | Helps you act fast during incidents to reduce harm. |

Use checklists and best practices to keep your business, community, and environment safe.

FAQ

What is the Hazardous Materials Table?

You can find the Hazardous Materials Table in the DOT regulations. This table lists all regulated hazardous materials. It shows the proper shipping name, hazard class, and identification number for each material.

Do I need special training to transport hazardous materials?

Yes. You must complete DOT-required training before you handle or transport hazardous materials. This training teaches you how to stay safe and follow the rules. You need refresher training every three years.

How do I know if my shipment needs special labels?

Always check the Hazardous Materials Table. If your material is listed, you must use the correct label for its hazard class. Labels warn others about the risks inside each package.

What should I do if there is a spill during transport?

Stay calm. Move away from the spill if it is safe. Call emergency services and follow your company’s emergency plan. Do not try to clean up large spills by yourself.

See Also

Rely On PGL For Safe HAZMAT Freight Transportation

Key Strategies For Effective Global Logistics Operations

Important LCL Shipping Guidelines For Panama Exports By PGL

Streamlined Freight Services Throughout The Southeast By PGL

Reliable Trucking Solutions In California And Surrounding Areas