What Is the Connection Between Logistics and Warehouse Operations

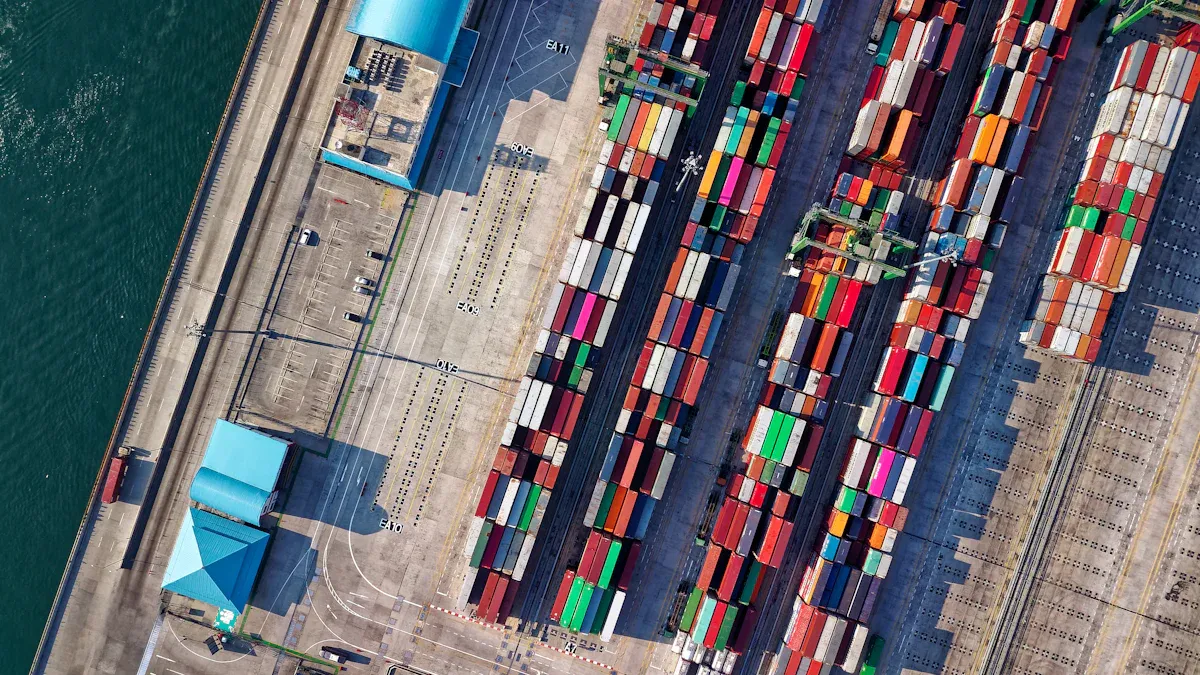

You see the connection between logistics and warehouse operations every time a product arrives on time. Businesses rely on trust and commitment between these functions to keep supply chains strong. Integrating logistics and warehouse operations boosts efficiency and inventory accuracy. You benefit from faster deliveries and better order processing.

Timely and reliable delivery increases customer satisfaction.

Transparent tracking systems meet your expectations.

Smart warehousing strategies and digital tools optimize throughput and accuracy.

When these systems work together, companies become more competitive and resilient.

Key Takeaways

Integrating logistics and warehouse operations boosts efficiency and accuracy, leading to faster deliveries and improved customer satisfaction.

Effective inventory management and real-time tracking prevent costly mistakes and ensure products are available when needed.

Using technology like warehouse management systems and RFID improves order processing and reduces manual errors.

Setting clear performance indicators helps track progress and optimize operations, ensuring alignment with business goals.

Overcoming challenges like outdated technology and poor visibility is crucial for maintaining a smooth supply chain.

Logistics and Warehouse Operations Defined

What Is Logistics?

You manage logistics every time you plan how products move from one place to another. Logistics covers the steps needed to get goods from the manufacturer to the customer. The Council of Supply Chain Management Professionals (CSCMP) explains:

"Logistics management is that part of the supply chain management that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services and related information between the point of origin and the point of consumption in order to meet customer’s requirements."

You see logistics in action through several main functions:

Order processing

Inventory management

Warehousing

Packaging

Cargo handling

Transportation

Monitoring

Each function helps you deliver products quickly and accurately.

What Is Warehousing?

Warehousing gives you a safe place to store goods before they reach customers. You use warehouses to keep products organized, packed, and ready to ship. Many companies choose locations in industrial parks for better security and easier access. Warehousing also includes inventory management, from handling shipping materials to printing shipping labels.

Here are the main roles of warehousing in the supply chain:

Role | Description |

|---|---|

Storage and Inventory Management | You store goods and keep track of stock levels for better planning. |

Order Fulfillment and Distribution | You pack and ship orders quickly, often using automation to save time. |

Supply Chain Flexibility | You adjust to changes in demand and reduce shipping costs. |

Risk Mitigation | You keep extra stock to protect against supply chain disruptions. |

Key Differences and Overlaps

You notice differences and overlaps when integrating logistics and warehouse operations. Warehousing focuses on storing and organizing inventory. Logistics manages the movement of goods to meet customer needs. Both work together to keep products flowing smoothly.

Warehouse Management | Logistics Management |

|---|---|

Focuses on storage and organization of inventory. | Involves efficient movement of goods from one location to another. |

Manages physical control of inventory. | Oversees the entire flow of products to fulfill customer demands. |

Includes stock management, receiving, and dispatching goods. | Integrates material handling, transportation, and information flow. |

Encompasses fulfillment and distribution centers. | Covers recovery, recycling, and production logistics. |

You improve supply chain performance by integrating logistics and warehouse operations. This teamwork helps you deliver products faster and keep customers happy.

Interaction of Logistics and Warehousing

Flow of Goods and Information

You see the flow of goods and information as the lifeblood of any supply chain. When you manage warehouses well, you help your business fulfill orders faster and keep disruptions low. Efficient warehousing lets you meet growing demands and maintain steady product movement. Intralogistics controls the flow between sites, making sure production lines get what they need. You use data-driven inventory management to avoid stockouts and overstocking, which saves money and boosts efficiency.

Logistics moves inventory between suppliers, manufacturers, distributors, and customers using the best routes.

Real-time tracking gives you visibility into inventory levels across the supply chain.

Monitoring consumption patterns helps you adjust plans and replenish stock on time.

Integrated logistics and inventory data prevent costly mistakes and keep customers happy.

Material handling practices support quick order fulfillment and timely deliveries.

Communication systems and sensors connect warehouse operations, helping you make smart decisions.

Coordination in the Supply Chain

You coordinate logistics and warehousing by using smart tools and systems. These methods help you track inventory, forecast demand, and avoid shortages. You can see how different solutions work together in the table below:

Method | Description |

|---|---|

Warehouse Logistics Solutions | Track inventory in real-time and optimize warehouse operations. |

Inventory Management Software | Forecast demand and keep stock levels balanced. |

Third-Party Logistics (3PL) | Outsource warehousing and inventory control for better efficiency and lower costs. |

RFID and Barcode Systems | Use technology for real-time tracking, improving order accuracy and customer satisfaction. |

RFID tags and barcode systems improve how you track and forecast inventory. Integrating logistics and warehouse operations is crucial for smooth supply chain performance.

Warehousing as the Backbone of Logistics

You rely on warehousing to manage goods and control inventory. Warehousing supports distribution, which is key for optimizing your supply chain. Streamlined warehouse operations help you fulfill orders faster and reduce errors. You also lower operational costs by keeping processes efficient.

Warehousing ensures you manage goods effectively.

You control inventory with accuracy.

Distribution becomes easier and more reliable.

A well-managed supply chain meets demand and keeps customers satisfied.

When you focus on integrating logistics and warehouse operations, you build a strong foundation for your business. You meet customer needs, cut costs, and stay competitive.

Integrating Logistics and Warehouse Operations

Benefits of Integration

You gain many advantages when you focus on integrating logistics and warehouse operations. This approach helps you improve order accuracy, speed up deliveries, and reduce costs. You see measurable improvements in your business performance. For example, companies report order accuracy rates rising from 95% to 99.5%. Operational efficiency can increase by 20-30%. Inventory accuracy often jumps from below 95% to above 99.5%. These gains mean fewer mistakes and happier customers.

Benefit | Improvement Rate |

|---|---|

Order Accuracy | 95% to 99.5% |

Operational Efficiency | 20-30% increase |

Inventory Accuracy | 95% or lower to 99.5% or higher |

When you integrate logistics and warehouse operations, you reduce customer service costs and boost productivity. Faster order processing leads to shorter delivery times. Enhanced productivity translates to lower operational expenses.

Many companies have seen dramatic results. A global retailer used AI-powered warehouse management systems and achieved a 30% reduction in operational costs, a 25% increase in order fulfillment speed, and 99.8% accuracy in inventory management. Weiling GmbH doubled its revenue by combining automated storage with scalable logistics. Lehner Versand managed 20,000 containers and 25,000 products efficiently during peak demand.

Inventory and Order Fulfillment

You improve inventory management and order fulfillment when you integrate logistics and warehouse operations. You track inventory more accurately and avoid stockouts. You also identify waste and hidden obstacles in your supply chain. This leads to better stocking strategies and improved cash flow.

Measurement Method | Benefits | |

|---|---|---|

Inventory Turnover Ratio | COGS / Average Inventory | Shows how often you sell and replace inventory, helping you spot overstocking. |

Inventory To Sales Ratio | Average Inventory Value / Net Sales | Gauges inventory health and highlights stockouts or excess capital tied up in inventory. |

Carrying Cost Of Inventory | Inventory Holding Cost / Average Inventory Value | Reflects the cost of holding inventory, helping you cut unnecessary expenses. |

Inventory Shrinkage | Lost Inventory Value / Average Inventory Value | Tracks lost inventory, helping you prevent losses. |

Inventory Accuracy | N/A | Ensures stock levels are correct, which is crucial for effective management. |

You also see improvements in order fulfillment times. Optimized storage layouts reduce handling times and space usage. Automated picking systems make picking faster and more accurate. Real-time data tracking helps you manage inventory and avoid delays. Automation in warehouse management systems can double your picking rate, which shortens order cycle times.

Integrated logistics combines supply chain functions into one system. This approach breaks down silos and encourages teamwork. You benefit from enhanced efficiency, cost-effectiveness, and better customer satisfaction.

Northern Tool + Equipment streamlined order fulfillment and reduced packing costs by freeing up 50,000 square feet of warehouse space. Bleker reduced its footprint by 70% while maintaining 85,000 parts in stock. These examples show how integrating logistics and warehouse operations leads to real improvements.

Cost and Efficiency Gains

You save money and boost efficiency when you integrate logistics and warehouse operations. Labor costs often make up 50% to 70% of a warehouse budget. Companies that focus on integration report overall cost reductions of up to 30%. Labor cost reductions account for 12% of total savings, transportation cost reductions for 9%, and inventory cost reductions for 7%.

Cost Category | Benchmark/Percentage |

|---|---|

Labor Costs | Below 55% of total expenses |

Space Utilization | At least 85% utilization |

Energy Efficiency | Reduce utility costs by up to 30% |

Inventory Turnover | Ideal rate of 5-10 times per year |

You also see gains in supply chain efficiency. Research shows that 69% of logistics professionals cite cost reduction as the top advantage. Companies use AI-driven forecasting and digitized inventories to improve speed and accuracy. Integrated logistics providers help you manage risks with advanced tracking. Many managers invest in visibility tools for real-time troubleshooting and optimized KPIs.

Evidence Type | Statistic/Insight |

|---|---|

Cost Optimization | 69% of logistics professionals cite cost reduction as the leading advantage. |

Enhanced Efficiency and Speed | Companies are adopting AI-driven forecasting and digitized inventories. |

Strategic Resilience | Integrated logistics providers mitigate risks through advanced tracking. |

Comprehensive Visibility | Many managers invest in visibility tools for optimized KPIs and real-time troubleshooting. |

Supplier Consolidation | 55% of companies are consolidating suppliers for full-service partnerships. |

Long-term Value Focus | 62% of decision-makers prioritize long-term value over short-term savings. |

Real-World Impact | A FMCG case study showed a 20% reduction in delivery lead times with integrated logistics. |

You measure the return on investment (ROI) by comparing net benefits and total costs. Net benefits include annual savings from labor, inventory management, and operational efficiencies. Total costs cover software, hardware, training, and maintenance. You use metrics like order accuracy rate, inventory turnover, on-time delivery, cost per order, and labor productivity to track your progress.

Tip: Focus on integrating logistics and warehouse operations to achieve higher order accuracy, faster deliveries, and lower costs. This strategy helps you stay competitive and meet customer expectations.

Challenges and Solutions

Common Obstacles

You face many challenges when you try to connect logistics and warehouse operations. These problems can slow down your business and make it harder to meet customer needs. Here are some of the most common obstacles:

Inventory control issues, with over 62% of warehouse professionals naming this as their top challenge.

Outdated technology, which 67% of third-party logistics providers say holds them back.

Trouble integrating new systems with old ones, affecting 58% of companies.

Lack of real-time visibility, reported by more than half of warehouse leaders.

Poor inventory management, misplaced items, and stock shortages or excess.

Rising labor costs and shortages.

Workforce resistance to new technology.

Bottlenecks in operations and poor demand forecasting.

Note: If you ignore these challenges, you risk disorganized storage, safety problems, and costly mistakes.

Optimization Strategies

You can overcome these obstacles by using smart strategies. Start by setting clear key performance indicators (KPIs) to track your progress. Monitor metrics like order accuracy, on-time shipments, and inventory accuracy. Build strong relationships with suppliers and logistics partners to improve coordination. Break down silos between departments so everyone works toward the same goals.

Use an order management system to centralize orders and match them with available stock.

Choose modular warehouse management technology for flexibility during busy seasons.

Commit to regular reviews of your processes and adjust as needed.

Encourage teamwork among sales, operations, finance, and tech teams.

Solution | Description |

|---|---|

Connects systems easily, automates data exchange, and cuts integration time and costs. |

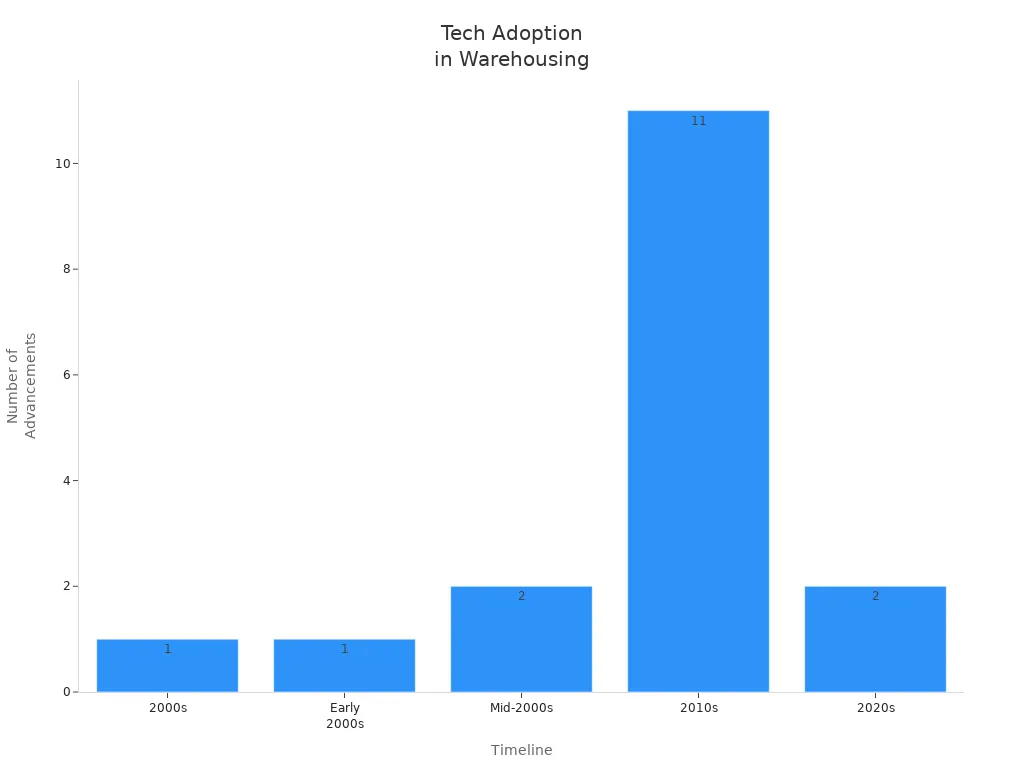

Technology’s Role

Technology helps you solve many integration problems. Warehouse management systems (WMS) improve inventory control and order processing. RFID and barcode systems give you real-time tracking. Advanced robotics and automated vehicles reduce manual work. Data analytics and the Internet of Things (IoT) help you spot trends and make better decisions. Cloud-based solutions offer flexibility and easy scaling.

You can also use augmented reality for training and drones for inventory checks. Machine learning and smart warehousing make your operations even more efficient. By integrating logistics and warehouse operations with the right technology, you build a stronger, more reliable supply chain.

You see how logistics and warehouse operations work together to keep your supply chain strong. Experts say that integration boosts efficiency, lowers costs, and improves customer satisfaction. Recent research shows that most warehouses invest in automation, cloud platforms, and real-time visibility. To optimize your operations, you can:

Define clear product locations.

Choose the right storage solutions.

Label aisles for easy navigation.

Indicate the best routes for inventory flow.

Tip: Align your warehouse operations with business goals and use automation to increase accuracy and speed.

FAQ

What is the main difference between logistics and warehouse operations?

Logistics manages the movement of goods. Warehouse operations focus on storing and organizing products. You use logistics to plan deliveries. You use warehouse operations to keep inventory safe and ready.

How does technology help you in logistics and warehousing?

Technology gives you real-time tracking and better inventory control. You use tools like barcode scanners, warehouse management systems, and automation to speed up processes and reduce mistakes.

Why should you integrate logistics and warehouse operations?

Integration helps you save money and time. You get faster order fulfillment, fewer errors, and better customer satisfaction. You also improve inventory accuracy and reduce waste.

What challenges might you face when connecting logistics and warehouse operations?

You may face outdated systems, poor data sharing, or resistance to new technology. You can solve these problems by training your team and using modern software.

How can you measure success in logistics and warehouse integration?

You track key performance indicators (KPIs) like order accuracy, delivery speed, and inventory turnover. These numbers show you where you improve and where you need to focus.

See Also

Key Strategies for Effective Global Logistics Operations

Connecting Warehouses and Optimizing Supply Chains with PGL

Enhancing Global Operations Through Innovative Logistics Solutions

PGL's Miami Warehouse Solutions for Rapid East Coast Shipping

PGL's Strategic Warehousing in Miami and LA for Supply Chain Efficiency