PGL Connects You to Your Final Customer, Efficiently

Premier Global Logistics helps businesses reach their final customers by being great at the last mile. In e-commerce and retail, the last mile is very important for customers. Companies have big problems when they need fast order work, correct labels, and quick delivery. Last mile warehousing USA is a main answer to these problems. Industry trends show:

E-commerce sales in South Africa went up 30% in one year, so more people need last mile solutions.

Merchants using AliExpress semi-managed logistics grew to 20,000 each month, so better last mile management is needed.

New EU customs rules in 2024 made last mile delivery harder.

Digital changes in logistics help companies with last mile speed and cost.

PGL uses smart last mile plans to help businesses deliver fast and on time.

Key Takeaways

Last mile warehousing puts small warehouses close to customers. This helps packages arrive faster and lowers shipping costs. - PGL uses smart technology and good warehouse locations. This lets them deliver packages quickly and helps businesses save money. - Real-time inventory tracking stops stock problems. It also keeps orders moving without delays. - PGL works with big sales platforms like Amazon and Walmart. This makes order and inventory management easier. - PGL has strong partnerships with local and big carriers. This helps them give reliable, flexible, and fast last-mile delivery.

Last Mile Warehousing USA

What Is Last Mile Warehousing

Last mile warehousing usa means putting small warehouses near customers. These places keep products until they are ready to go out. Companies use last mile warehousing to make shipping faster. People want their orders delivered quickly. These warehouses are not like big, old ones. They handle smaller shipments and use smart technology. The last mile delivery market was worth $131.5 billion in 2021. It could grow to $288.9 billion by 2031. Last mile warehousing now makes up more than half of shipping costs. This change is because e-commerce is growing fast. People also want quick and reliable service. Companies use automation and smart inventory tools to keep up. This helps them save money and meet demand.

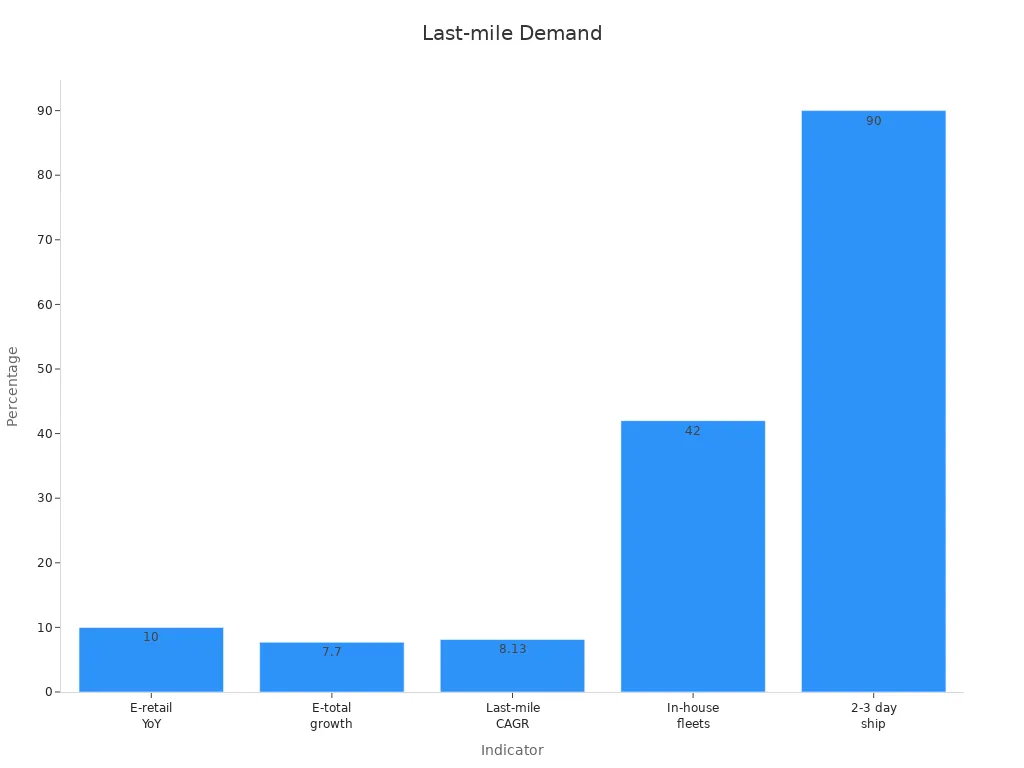

Indicator | Value | Timeframe/Notes |

|---|---|---|

U.S. e-commerce retail sales | $250 billion | Q3 2022, 10% YoY increase |

U.S. e-commerce total sales | Over $1 trillion | 2022, 7.7% annual growth rate |

Last-mile delivery market size (USA) | $131 billion | 2021 valuation |

Projected CAGR for last-mile delivery market | 8.13% | 2022 to 2031 (global projection) |

Businesses using in-house delivery fleets | 42% | According to APQC data |

Shoppers expecting 2-3 day shipping | 90% | Drives demand for local warehousing |

Role in Modern Supply Chains

Last mile warehousing usa is very important in supply chains today. Companies use these places to move products fast to customers. The national industrial vacancy rate was only 3.8% in 2022. This shows that many people want warehouse space. E-commerce is growing, and people want fast shipping. Last mile warehousing helps companies send out products and save money. More delivery trucks and longer drive times show the stress on last mile work. Warehouses near cities help companies deliver faster. This keeps customers happy and helps brands do well.

Metric | Value | Percentage Change | Impact Description |

|---|---|---|---|

Delivery vehicles worldwide | +36% | Growing demand and pressure on last-mile logistics capacity | |

Congestion (average commute times per minute) | Increase from 53 to 64 | +21% | Operational challenges and inefficiencies in urban last-mile delivery |

Greenhouse Gas (GHG) emissions | Increase from 19 MT to 23 MT | +21% | Environmental impact of last-mile logistics growth |

Urban and Regional Hubs

Urban and regional hubs are the main part of last mile warehousing usa. These hubs use small warehouses and cross-docking to move things faster. Smart inventory tools keep products close to people. Warehouse management systems track items right away. Automation like robots and AI sorting help fill orders quickly. Working with third-party logistics gives companies more ways to deliver. Smart route planning and real-time tracking help drivers skip traffic. This lets them deliver on time. Cities like Riverside and Allentown have seen lots of new warehouses and higher rent. Stockton’s rent went up 50% in five years. This shows people really need last mile warehousing. These hubs help companies get products to customers fast and keep them happy.

Last Mile Logistics Challenges

Speed and Flexibility

Speed and flexibility are big parts of the last mile problem. People want their packages very fast. About 70% of people say speed matters most. Almost 90% want their orders in two or three days. One out of three people want same-day delivery. Companies have a hard time meeting these high demands. Fuel costs are more than half of shipping costs. This affects how fast and cheap deliveries can be. Big companies like FedEx and UPS use smart routes and rules. For example, they avoid left turns to save time and fuel. Amazon uses software for electric and bike deliveries. This helps lower costs and pollution. Last mile logistics now use real-time tracking and smart routes. These tools help drivers skip traffic and deliver on time. Cloud systems help companies handle busy times without problems.

Note: Last-mile delivery software helps speed and flexibility. It gives real-time updates and better route planning.

Multi-Platform Compliance

The last-mile problem gets harder with many sales platforms. Each marketplace, like FBA, WFS, or Target, has its own rules. They need special labels and shipping steps. Labor shortages have caused problems for 61% of logistics companies. More than half say these issues hurt customer service. Delays often happen because of wrong addresses or paperwork mistakes. Sometimes there are not enough delivery vehicles. During busy seasons, the last-mile challenge is even tougher. Smart parcel lockers and better routes help stop failed deliveries and delays. Companies must stay flexible to keep up with new rules and customer needs.

Cost and Efficiency

Cost and efficiency are big parts of the last-mile problem. Last mile logistics can be 53% of all shipping costs. Drivers spend about nine minutes looking for parking. They walk almost eight kilometers each day. One grocery delivery can cost $10 to $20. Labor, traffic, and delivery problems make costs go up. Strict delivery times can cause overtime and waste. Flexible delivery times can lower costs by up to 12%. Bad cost control in last-mile logistics can cut profits by 26% in three years. Companies that use flexible schedules and smart tools can save money and work better.

Table: Key Cost Drivers in Last Mile Logistics

Cost Driver | Impact on Last Mile |

|---|---|

Labor | High |

Traffic Variability | High |

Delivery Complexity | High |

Fuel Expenses | High |

PGL’s Last Mile Delivery Solutions

Strategic Warehouse Locations

Premier Global Logistics has warehouses in big cities like Miami, Los Angeles, Chicago, Houston, and Dallas. These warehouses are close to where many customers and suppliers are. This helps packages get to people faster and saves money on shipping. When companies use warehouses in good spots, they can deliver 15-40% faster. They also spend 15-25% less on transportation. Most companies use five to eight warehouses to cover the whole country. This helps them deliver everywhere and keep costs low. Warehouses near customers mean companies do not need to keep as much extra stock. They can restock 10-20% faster and keep less backup inventory.

Metric / Aspect | Statistic / Insight | Explanation / Impact |

|---|---|---|

Delivery time reduction | 15-40% | Warehouses closer to customers reduce average delivery times. |

Total logistics cost savings | 10-30% | Optimized locations lower logistics expenses. |

Transportation cost decrease | 15-25% | Shorter travel distances cut transportation costs. |

Number of distribution centers | 5-8 (typical for national coverage) | Enables faster deliveries across wide areas. |

Transportation cost proportion | 50-70% of total logistics costs | Shows the importance of warehouse location. |

Inventory investment reduction | 10-20% | Closer warehouses improve replenishment efficiency. |

Service improvement | 15-40% reduction in average delivery time | Better customer delivery performance. |

Premier Global Logistics looks at where customers, suppliers, and workers are. They pick the best places for warehouses. This planning helps them deliver faster and makes customers happier.

Real-Time Inventory Sync

PGL uses special technology to keep track of products in all warehouses. Every product’s location and status updates right away. This stops running out of stock or having too much. When someone orders, the system finds the closest warehouse with the item. That warehouse gets the order ready and ships it fast. Customers and businesses can see where their order is at every step.

Real-time inventory sync saves money and stops mistakes. It also makes last-mile delivery quicker and more dependable.

With real-time data, PGL can help many clients at once. The system lets them restock quickly and handle returns easily. This technology works well even when there are lots of orders during busy times.

Platform Integration

Premier Global Logistics connects with big sales sites like Amazon FBA, Walmart WFS, and Target. This makes it easier for businesses to sell on many websites. PGL is the main place for managing orders and inventory for all these sites. The system updates stock levels by itself, so there are fewer mistakes. Businesses do not run out of stock or have too much because the system updates in real time.

3PL providers like PGL handle inventory for Amazon FBA, Walmart WFS, and more, so there is less paperwork.

Centralized inventory management updates stock automatically, stopping stockouts and overstocking.

Using one warehouse and order system costs less than using only FBA storage.

PGL takes care of returns for Amazon and Walmart, making it easy and following each site’s rules.

Smart technology gives one place for tracking, reports, and order data, helping companies make good choices.

PGL can handle more orders during busy times, so customers get their packages fast.

Integration platforms send orders, track inventory, and update data without people doing it by hand. This means fewer mistakes and faster work. Real-time data helps companies work better and makes customers happier. The system works with old computer systems, so companies can grow without changing everything.

Last-Mile Carrier Partnerships

PGL works with both big and local last-mile carrier companies. These partnerships help make last-mile delivery cheaper and more flexible. Big carriers cover lots of places, and local ones know the area and offer good prices. PGL picks partners who can handle more packages during busy times and use technology for tracking. This makes last-mile delivery fast and reliable.

Good drivers and steady pay mean packages arrive on time and in good shape.

Fast systems connect with other logistics tools, so deliveries leave warehouses quickly.

Smart technology, like matching drivers and real-time updates, helps make last-mile delivery fast and correct.

Different carrier business models change how deliveries go, so PGL picks the best partners.

Amazon and UPS show that spending on last-mile delivery and technology makes customers happier. PGL does the same by using new ideas and strong partnerships. This gives customers more ways to ship and better service. Real-time tracking lets customers watch their packages the whole way. This openness builds trust and makes the last-mile experience better.

Case Studies and Results

E-commerce Success

Many online sellers do better with ecommerce fulfillment by using Premier Global Logistics. They keep products in PGL’s warehouses close to customers. This helps them ship orders faster and save money. One online store made deliveries 30% faster after switching to PGL. Another business had fewer stockouts because real-time inventory updates helped them restock fast. These changes help companies give customers the fast and reliable shipping they want.

Companies that use PGL’s fulfillment services get more accurate orders and faster delivery. This means customers come back more and leave better reviews.

Retail Distribution

Retailers need good fulfillment systems to keep shelves full and customers happy. PGL helps stores with flexible delivery choices and real-time inventory tracking. Many retail leaders now care about convenience and seeing where products are. Almost half say last-mile delivery and inventory tools help them connect with customers and make them happier. About one-third want to spend more on omnichannel fulfillment, like buy online and pick up in store (BOPIS). Retailers using AI for inventory management have up to 50% fewer stockouts and 30% lower inventory costs.

Statistic Description | Impact on Customer Experience | Source |

|---|---|---|

83% of consumers want flexible fulfillment options like BOPIS, which grew 28% in a year | Shows people want flexible ways to get products, making shopping easier and better | NRF, 2023 |

Retailers using AI for inventory management see 20-50% fewer stockouts and 25-30% lower inventory costs | Makes products available and saves money, which makes customers happier | IBM Retail Industry Report, 2023 |

Companies using personalization technologies see 40% higher average order value and 20% higher customer lifetime value | Shows better customer experience with special offers, making people loyal and raising sales | Boston Consulting Group, 2023 |

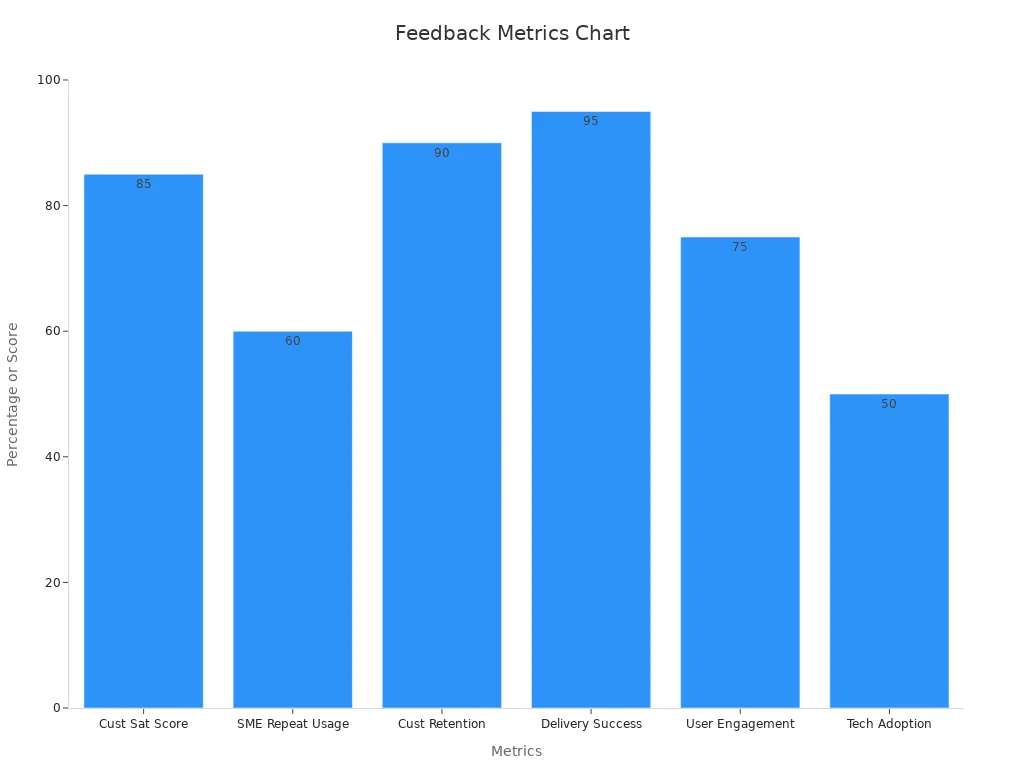

Customer Feedback

Customer feedback shows how PGL’s logistics make things better. Most customers say they are happy with on-time deliveries and easy order tracking. PGL’s Net Promoter Score (NPS) stays above 50, which means customers are very loyal. Over 60% of small businesses use PGL again and again, showing they trust the service. The customer retention rate is about 90%. PGL delivers at least 95% of orders on time. Customers also save about $50 per shipment because of better route planning and freight consolidation.

93% of people are more likely to come back after great service. Most like brands that give personal experiences, which PGL does with digital tools and flexible fulfillment.

Benefits of Last-Mile Delivery with PGL

Faster Delivery

Premier Global Logistics helps companies deliver faster by using smart technology and many warehouses. Their system watches every order as it moves and picks the nearest warehouse for each package. This helps with two-day shipping and sometimes even same-day delivery in some places. Studies show customers want fast shipping, and most like getting their orders in two days. When companies deliver on time, people trust them more and buy again. One study found that cutting delivery from three days to two days can raise daily sales by over 13%. Fast and on-time last-mile delivery makes customers loyal and keeps them coming back. Stores that meet these needs get better reviews and have fewer people leave their carts without buying.

Cost Savings

PGL’s last-mile delivery saves money in many ways. Automation means companies need fewer workers, which cuts office costs by 38%. AI helps plan routes, making trips shorter by up to 25%. This lowers fuel and worker costs. The table below shows how these savings add up:

Cost Saving Aspect | Numerical Data / Percentage | Explanation |

|---|---|---|

Reduction in back-office staffing | 38% | Automation reallocates staff to strategic tasks |

Decrease in travel distances | 15-25% | AI route optimization cuts fuel and labor costs |

Improvement in SLA compliance | 24% | Better on-time deliveries reduce penalties |

Reduction in delivery errors | Nearly 20% | AI detection minimizes costly mistakes |

Fuel cost proportion | Roughly 30% | Optimized routing lowers fuel consumption |

Companies like PGL use technology to keep inventory steady and do less work by hand. This makes last-mile delivery cheaper and more dependable than old ways.

Customer Satisfaction

PGL’s last-mile delivery makes customers happier with many helpful features:

Real-time tracking and smart tools give clear updates on orders.

Good inventory management means products are ready to ship fast.

A strong warehouse network helps with quick and reliable delivery.

PGL checks delivery accuracy and customer happiness to get better.

Support teams answer questions fast, building trust and loyalty.

Flexible delivery choices help businesses keep service high even when things change.

These features make delivery better for every customer. When companies use PGL, they see happier customers, more repeat orders, and stronger brand loyalty.

Premier Global Logistics helps companies reach customers with fast last-mile delivery. Their warehouses and smart technology make shipping quick and tracking easy. Companies spend less money and make customers happier. Good service helps brands get bigger and keep loyal buyers. Businesses can ask PGL for help with special last-mile delivery plans.

FAQ

What is last-mile delivery?

Last-mile delivery is when products go from a warehouse to the customer. It is the last step before the package gets to the buyer. Companies use last-mile delivery to make sure packages get there fast and safe.

How does PGL help with last-mile logistics?

PGL uses smart warehouses and technology to watch orders. They work with trusted carriers to move packages. Their system picks the best way for each package to travel. This helps businesses deliver faster and spend less money.

Can PGL connect with different sales platforms?

Yes. PGL connects with Amazon FBA, Walmart WFS, Target, and others. Their system updates inventory and orders right away. This helps businesses handle sales on many sites without extra work.

Why do companies need real-time inventory sync?

Real-time inventory sync lets companies know what they have all the time. This stops running out of products or having too many. It also helps fill orders faster and keeps customers happy.

Where are PGL’s warehouses located?

PGL has warehouses in Miami, Los Angeles, Chicago, Houston, and Dallas. These places help reach customers across the country fast. Businesses can keep products close to buyers for quicker delivery.

See Also

Accelerating West Coast Trucking For Today’s Supply Chain Needs

Begin Your Freight Shipping Journey With PGL FTL Services

PGL Addresses Rapid Logistics Challenges In Los Angeles Efficiently

PGL Delivers Expert LTL And FTL Freight Shipping Services

Strategic Warehousing Hubs In Miami And LA Optimize U.S. Supply Chains