Effective Strategies for Logistics Carrier Management in Modern Supply Chains

Did you know that optimizing transportation processes can boost your supply chain’s performance? When you use logistics carrier management strategies, you help your business save money and satisfy customers. You choose carriers wisely, plan routes, and track shipments in real time. These steps make your supply chain more efficient and responsive. Take a moment to think about your current carrier management. Do you see areas where you could improve?

Key Takeaways

Choose reliable carriers to ensure timely deliveries and customer satisfaction. Evaluate their performance regularly.

Use technology like Transportation Management Systems (TMS) for real-time tracking and efficient route planning. This helps reduce costs and improve service.

Maintain open communication with carriers to build strong partnerships. Set clear expectations and schedule regular check-ins.

Monitor key performance indicators (KPIs) to assess carrier performance. This helps identify issues early and make informed decisions.

Stay updated on regulatory requirements to avoid delays and fines. Regular audits ensure compliance and improve overall efficiency.

Logistics Carrier Management Strategies

Strategic Carrier Selection

You need to choose the right carriers to keep your supply chain strong. Top companies use logistics carrier management strategies to find partners who deliver on time and keep costs low. You should look for carriers that match your business needs and help you reach your goals. Many leading organizations follow these steps:

Evaluate reliability. Reliable carriers help you avoid delays and keep customers happy.

Check coverage. Make sure your carrier can deliver to all the places you need.

Compare costs. Look for competitive rates that fit your budget.

Build strong partnerships. Good relationships lead to better service and faster problem-solving.

Use technology. Real-time tracking systems help you manage shipments and respond quickly.

Tip: Open communication with your carriers builds trust and helps you solve issues faster.

When you use these logistics carrier management strategies, you set your business up for success. You can see better service, lower costs, and more control over your shipments.

Criteria and Evaluation Tools

You must use clear criteria to pick the best carriers. The most common criteria include coverage, performance, price, communication, risk, and terms. You can use a table to compare carriers:

Criteria | Description |

|---|---|

Cost | How much you pay for shipping. |

Reliability | How often the carrier delivers on time. |

Coverage | Where the carrier can deliver your goods. |

Service Level | The quality of service you receive. |

You can use software tools to make this process easier. Transportation Management Systems (TMS) and logistics intelligence platforms help you track carrier performance. Carrier scorecard reporting software lets you see delivery times, costs, and reliability. Some popular tools include Descartes, FreightPOP, Cerasis, Transporeon, and Loadsmart.

Note: Data-driven tools help you make faster decisions and expand your network. They also reduce manual work and improve collaboration with your partners.

When you use standardized data, you can compare carriers fairly. You can check their track records and avoid picking unreliable partners. This helps you save money and avoid delays.

Route Planning and Optimization

You can lower costs and improve delivery times with smart route planning. Logistics carrier management strategies often use advanced technologies to find the best routes. AI-powered route optimization can help you save fuel and reduce delivery costs. For example, some companies have cut fuel costs by 10-20% using these systems. UPS saved 10 million gallons of fuel each year with its ORION optimization system.

Evidence Description | Cost Savings |

|---|---|

Fuel savings from AI-powered route optimization | 10-20% |

Direct savings for a fleet of 20 vehicles ($100,000) | $10,000-20,000 |

UPS annual fuel savings through ORION | 10 million gallons |

Reduction in total delivery costs | 15-20% |

You can use technologies like dynamic routing and real-time visibility to avoid delays and keep customers informed. Automated dispatching helps you assign deliveries quickly and reduces mistakes. Data-driven insights let you see where you can improve and help you make better decisions.

One company reduced fuel costs by 18% after using a route engine.

Real-time tracking builds customer trust and helps you meet service agreements.

When you use these logistics carrier management strategies, you make your supply chain more efficient. You save money, deliver faster, and keep your customers satisfied.

Strengthening Carrier Partnerships

Communication Best Practices

You build strong partnerships with carriers by focusing on clear and open communication. Sharing information quickly and honestly helps everyone work together. You can use these steps to improve your communication:

Set clear expectations with Service Level Agreements (SLAs).

Choose the right channels for updates, such as email or phone.

Keep a regular schedule for check-ins and progress reports.

Foster trust by encouraging open dialogue.

Use logistics management software for real-time updates.

Document all interactions to avoid confusion.

Prepare a crisis communication plan for emergencies.

Respect cultural and language differences.

Align goals with your carrier partners.

Review communication methods often to improve them.

Open and timely communication boosts logistics efficiency and strengthens relationships. When you use technology for real-time updates, you keep drivers and customers informed. This approach builds trust and satisfaction.

Performance Reviews

You improve outcomes by reviewing carrier performance regularly. Monitoring how carriers perform makes them more accountable and helps you spot problems early. You can use these steps:

Track key performance indicators (KPIs) with a scorecard.

Schedule quarterly reviews to find patterns.

Include customer feedback in your analysis.

Evaluating carriers with KPIs, such as on-time delivery and customer satisfaction, helps you make smart decisions. These reviews lead to better service and stronger partnerships. You can use logistics carrier management strategies to guide your review process and keep your supply chain running smoothly.

Conflict Resolution

Conflicts can happen between shippers and carriers. You need to know the common sources and how to solve them. Here is a table showing typical issues and solutions:

Source of Conflict | Description |

|---|---|

Cost Disagreements | Disputes over costs and rate increases. |

Contractual Agreements | Problems with contract terms and adherence. |

Delivery Delays | Delays from customs or other issues affect schedules. |

Billing And Payments | Incorrect charges or late payments cause disputes. |

Damaged or Lost Goods | Damage or loss during transport creates conflict. |

Inventory Management Discrepancies | Differences between actual and recorded inventory levels. |

Regulatory Compliance Issues | Non-compliance with rules leads to disputes. |

Proactive Communication | Open dialogue prevents issues from growing. |

Detailed contracts help avoid misunderstandings. | |

Technology Integration | Using technology reduces errors and disputes. |

Documentation | Records clarify facts and support resolution. |

ADR Methods | Alternative dispute resolution offers flexible solutions. |

Continuous Improvement | Ongoing process changes help prevent future conflicts. |

You solve conflicts by communicating openly, keeping good records, and using clear contracts. Technology helps you track shipments and payments, making it easier to resolve issues. When you focus on continuous improvement, you reduce the chance of future disputes.

Leveraging Technology Solutions

Transportation Management Systems (TMS)

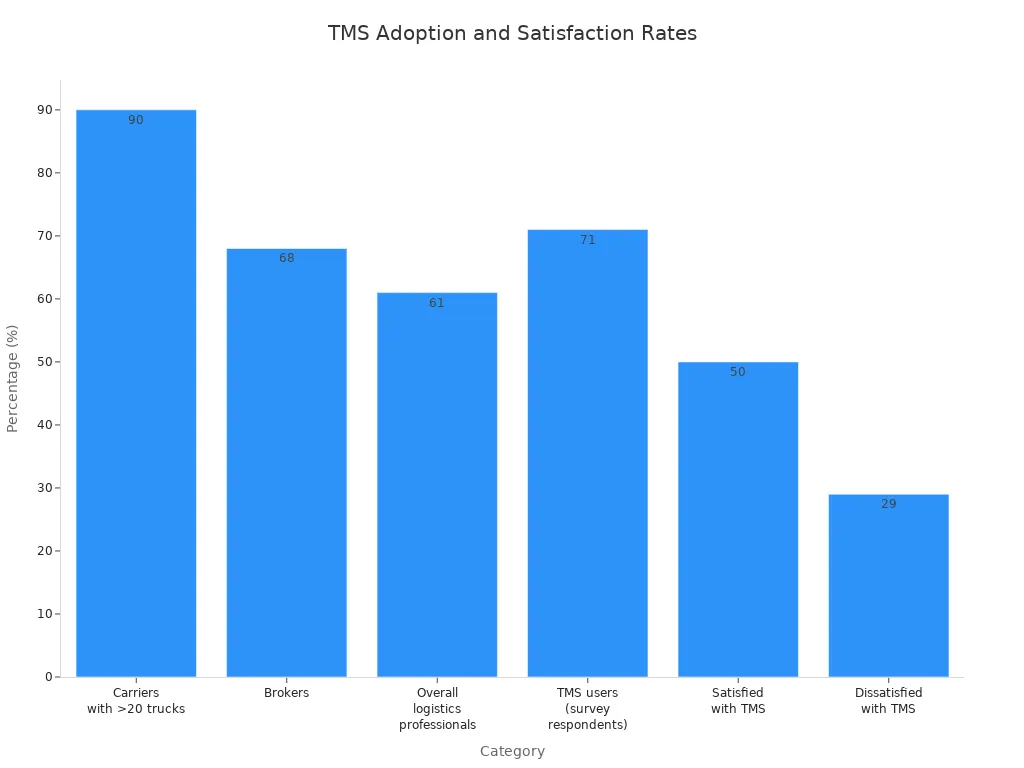

You can improve your logistics carrier management strategies by using Transportation Management Systems. TMS helps you plan, execute, and track shipments with ease. Many logistics companies have adopted TMS to boost efficiency. The table below shows how different groups use TMS and their satisfaction levels:

Category | Percentage |

|---|---|

Carriers with >20 trucks | 90% |

Brokers | 68% |

Overall logistics professionals | 61% |

71% | |

Satisfied with TMS | 50% |

Dissatisfied with TMS | 29% |

You see that most large carriers use TMS. About half of users feel satisfied with their system. TMS helps you benchmark freight costs and track shipments in real time. Companies using advanced logistics technology solutions report an average ROI of 7-8%. You gain savings from better procurement and improved operations.

Real-Time Tracking

Real-time tracking gives you continuous visibility of your shipments. You can monitor delivery status and share accurate estimated times of arrival with customers. This transparency builds trust and reduces anxiety about delivery times. You spot delays quickly and send automated alerts. You also monitor sensitive goods and keep customers informed. These features help you improve customer satisfaction and loyalty.

Proactive communication with real-time tracking helps you solve problems before they grow.

Automation and Analytics

Automation and analytics tools make your logistics carrier management strategies more effective. You use AI and IoT to monitor shipments and inventory. Robotics and automated warehousing increase productivity. Cloud-based TMS automates scheduling and routing. Digital freight matching platforms help you match loads with carriers and optimize truck use. Predictive analytics lets you forecast demand and manage inventory.

Some popular tools include:

LogiNext Mile for delivery tracking and route optimization.

Blue Yonder for predictive planning.

Gmail Analyzer by Compare The Carrier for team communication.

Oracle, SAP, and MercuryGate for freight benchmarking.

Infor WMS and Manhattan Associates WMS for warehouse operations.

You see better results when you use these tools. You save time, reduce errors, and make smarter decisions.

Compliance and Risk Management

Regulatory Requirements

You must follow strict rules when you manage logistics carriers. These rules protect your business and keep your supply chain running smoothly. Different countries have their own laws for shipping, safety, and data protection. If you ignore these rules, you risk delays, fines, or even losing your goods. The table below shows some important regulations and what happens if you do not comply:

Regulation | Description | Consequences of Non-compliance |

|---|---|---|

CTPAT | U.S. program for supply chain security | Shipment delays or more inspections |

IMO | Safety and environmental rules for ships | Fines or legal trouble |

GDPR | EU law for personal data | Fines or damage to reputation |

USMCA | North American trade agreement | Criminal charges or loss of tariff benefits |

REACH | EU chemical safety law | Fines or product recalls |

AFR | Japan’s cargo info rule | Cargo delays or denial of entry |

SASO | Saudi standards for imports | Goods rejected or confiscated |

Tip: You protect your business by staying updated on global regulations and training your team.

Carrier Audits

You need to check your carriers often to make sure they follow the rules and meet your standards. Leading companies audit carriers every month or quarter. These audits help you find mistakes, save money, and improve contracts. Common findings include:

Discrepancies in charges

Ways to cut costs

Insights for better contract negotiations

Regular audits keep your supply chain safe and efficient. You spot problems early and fix them before they grow.

Risk Mitigation

You lower risks by using smart strategies. Industry experts recommend several ways to protect your supply chain:

Strategy | Description |

|---|---|

Frequent checks and training keep everyone compliant. | |

Technology for compliance tracking | Software tracks rules and alerts you to issues. |

GPS tracking systems | Real-time tools show cargo location and flag problems. |

Secure documentation and packaging | Complete records and tamper-proof packaging prevent loss. |

Maintenance schedules | Planned repairs reduce breakdowns. |

Driver and employee safety training | Training helps staff avoid accidents and spot hazards. |

Diversifying suppliers | Working with many vendors protects you from shutdowns. |

Third party vendors | Backup contracts keep goods moving if a supplier fails. |

If you fail to manage risks, you face higher costs, delays, and unhappy customers. You keep your supply chain strong by preparing for problems and acting fast when issues arise.

Monitoring Performance and Costs

Key Performance Indicators (KPIs)

You need to track the right KPIs to measure your carrier’s performance. These indicators show how well your logistics partners support your business. When you monitor KPIs, you spot problems early and make better choices. Here are some important KPIs you should watch:

On-time delivery

Transit time

Freight damage and loss

Claims ratio

Cost and pricing

Invoice accuracy

Customer service responsiveness

Communication and visibility

Safety performance

Compliance with service level agreements (SLAs)

Carrier capacity and reliability

Overall customer satisfaction

Onboarding and training efficiency

Environmental impact

Technology integration

You can also track on-time payment, routing guide compliance, and driver performance. These numbers help you compare your results to industry standards and find areas to improve.

Data-Driven Decisions

You make smarter choices when you use data. Data helps you see patterns and spot bottlenecks in your supply chain. You can use analytics to forecast demand and manage inventory. This reduces stockouts and lowers costs. Real-time tracking gives you visibility and helps you respond quickly to problems. When you use data, you improve customer satisfaction and reduce risks. Leading companies compare their performance to industry averages and best-in-class competitors. This benchmarking uncovers gaps and helps you set clear goals.

Tip: Data-driven decisions help you plan for growth and avoid costly mistakes.

Freight Spend Control

You control costs by using proven strategies. Shipment consolidation lets you combine loads and save money. Route optimization software finds the fastest and cheapest delivery paths. Data analytics shows you where you waste money and helps you fix it. Fleet management reduces idle time and improves fuel use. Cross-docking moves goods quickly and cuts storage fees. Automation speeds up operations and lowers errors. Sustainable practices reduce costs and help the environment. Provider analysis and supplier negotiations help you get better rates.

Strategy | Description |

|---|---|

Shipment Consolidation | Combine smaller shipments to maximize load and reduce costs. |

Route Optimization | Use software to find efficient delivery routes. |

Data Analytics | Analyze data to spot inefficiencies and optimize routes. |

Fleet Management | Monitor vehicles to reduce idle time and improve fuel efficiency. |

Cross-docking | Transfer products directly to outbound transport to cut storage time. |

Automation and Technology | Automate tasks to streamline operations and reduce delays. |

Sustainable Practices | Use eco-friendly methods to lower costs and environmental impact. |

Inventory Management | Keep inventory levels balanced to avoid extra costs. |

Provider Analysis | Evaluate carriers to choose the most cost-effective options. |

Supplier Negotiations | Work with suppliers to get better shipping rates. |

You face challenges like high shipping costs, inventory imbalances, and communication breakdowns. By monitoring performance and controlling costs, you keep your supply chain strong and competitive.

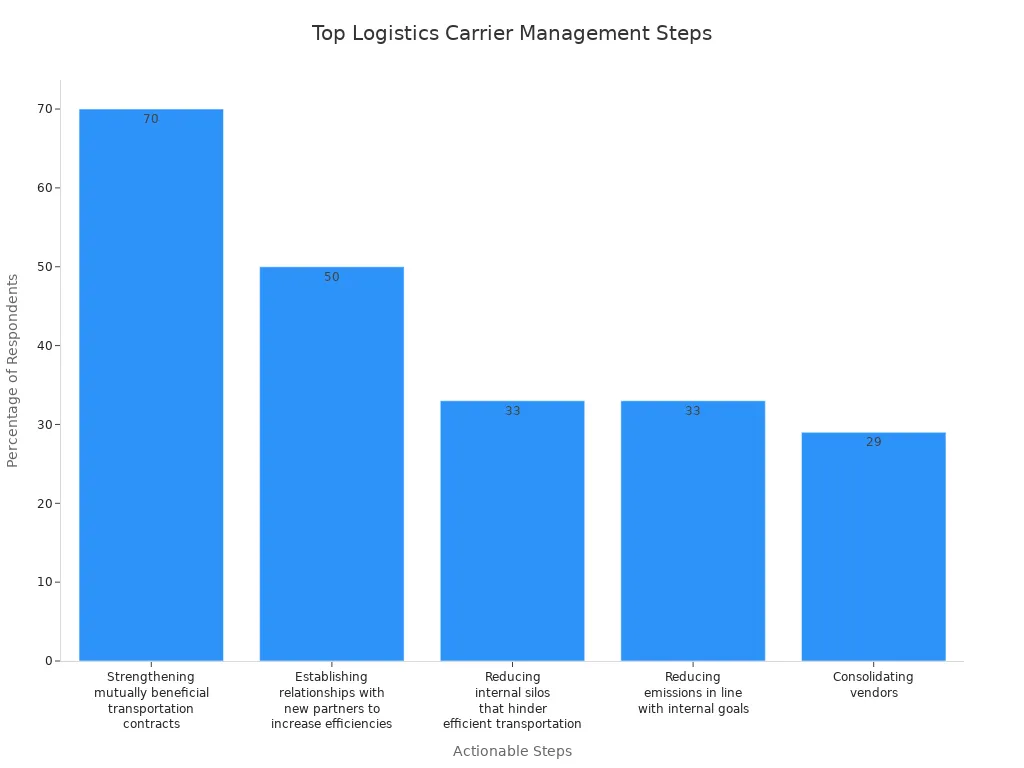

You can boost your supply chain by choosing the right carriers, building strong partnerships, and using smart technology. These steps help you work faster, save money, and avoid risks. Strong carrier relationships give you better service and help you handle market changes. Carrier management systems let you see problems early and make quick decisions. To improve, try these steps:

Actionable Steps | Percentage of Respondents |

|---|---|

Strengthen transportation contracts | 70% |

Build new partnerships | 50% |

Reduce internal silos | 33% |

Cut emissions | 33% |

Consolidate vendors | 29% |

Review your carrier management today. You can start by using a Transportation Management System or scheduling a carrier audit.

FAQ

What is the most important factor when choosing a logistics carrier?

You should focus on reliability. Reliable carriers deliver on time and protect your goods. Use a simple checklist to compare options:

Service quality

Coverage area

How can technology help you manage carriers?

You use technology to track shipments and automate tasks. Transportation Management Systems (TMS) give you real-time updates and help you plan better. Technology reduces errors and saves you time.

How often should you review carrier performance?

You should review carrier performance every quarter. Regular reviews help you spot problems early. Use a table to track key metrics:

Metric | Goal |

|---|---|

On-time rate | 98% |

Damage claims | <2% |

What can you do if a carrier fails to meet expectations?

You can communicate your concerns and review the contract. Try to solve issues together. If problems continue, you may need to switch carriers.

Tip: Keep records of all interactions for future reference.

See Also

Key Strategies For Effective Global Logistics Management Success

Enhancing International Operations With Innovative Logistics Solutions

Boosting Global Efficiency Through Point-to-Point Logistics Systems

Simplifying Supply Chain Optimization With U.S. Logistics Solutions

Top Global Logistics Services For Efficient East Coast Imports