What Is a Logistics Company and How Does It Work

A logistics company helps you move goods efficiently from one place to another. You rely on these companies to plan, store, and deliver products safely and on time. Logistics company definition and examples show that these businesses handle transportation, warehousing, and order processing. When you use their services, you see faster loading times and fewer delivery errors. The table below highlights how logistics companies boost business efficiency:

Process Improvement | Impact on Your Business |

|---|---|

Streamlines how you manage operations | |

Automated warehouse management and route planning | Lowers costs and reduces manual errors |

Real-time tracking and precise inventory management | Improves delivery speed and accuracy |

Key Takeaways

Logistics companies streamline the movement of goods, ensuring faster deliveries and fewer errors. This efficiency helps businesses operate smoothly.

Choosing the right logistics partner is crucial. Look for experience, technology use, and good customer service to support your business needs.

Technology integration in logistics enhances tracking, inventory management, and order processing. This leads to improved accuracy and customer satisfaction.

Effective inventory management prevents shortages and excess stock. Logistics companies use advanced systems to keep your inventory accurate.

Understanding different logistics models helps you select the best option for your needs. Each model offers unique advantages for transporting goods.

Logistics Company Definition and Examples

Definition

You need to understand what a logistics company does before you choose one for your business. A logistics company manages and optimizes the movement of goods and services. You rely on these companies to oversee warehousing and transportation from the starting point to the final destination. They tailor their services to meet your needs, making sure your products arrive safely and on time.

Logistics covers the management of resources. You see this in how companies handle transportation, storage, and receiving goods. These steps help you keep customers happy by planning for demand and fulfilling orders quickly. When you look at logistics company definition and examples, you notice that these businesses play a key role in every part of the supply chain.

You might wonder how logistics companies differ from freight forwarding companies. Here are some main differences:

Logistics companies handle a wide range of supply chain functions. You get help with storage, packaging, and transportation. They manage goods before shipping to ensure everything arrives on time.

Freight forwarding companies focus on moving products from one place to another. They act as brokers between you and the shipping service. You use them to coordinate the transportation process.

When you compare logistics company definition and examples, you see that logistics companies offer more complete solutions for your business needs.

Examples

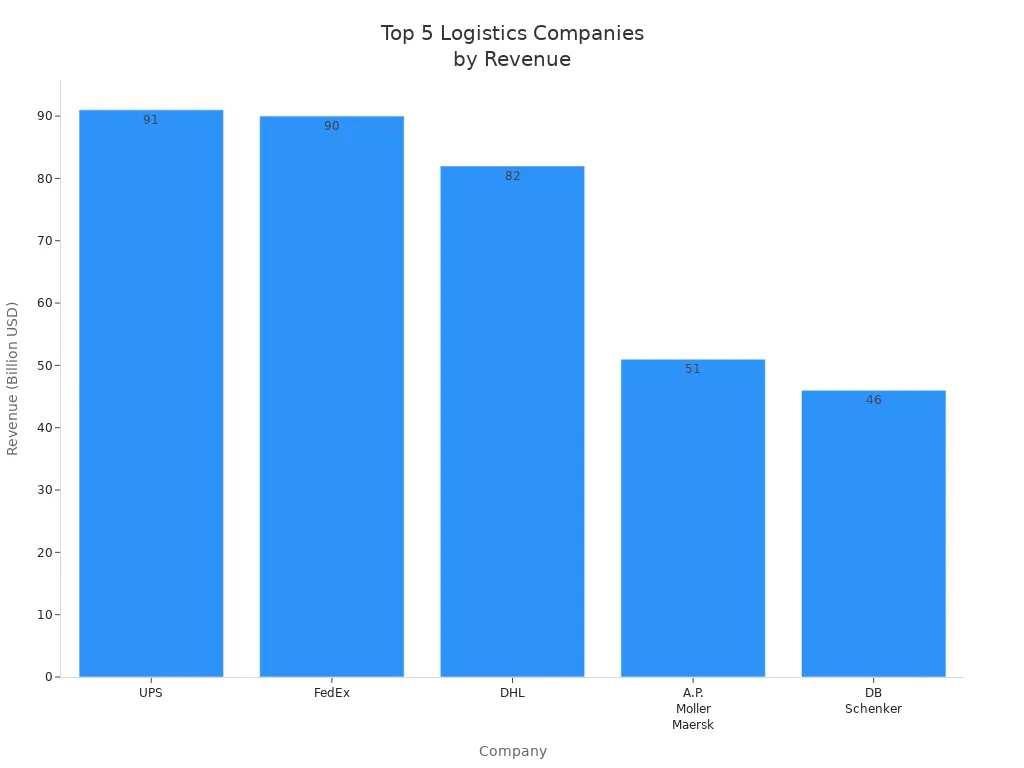

You find many logistics companies around the world. Some of them lead the industry and set standards for others. Here is a table showing the top five logistics companies by revenue:

Rank | Company | Revenue (in Billion USD) |

|---|---|---|

1 | UPS | 91 |

2 | FedEx | 90 |

3 | DHL | 82 |

4 | A.P. Moller – Maersk | 51 |

5 | DB Schenker | 46 |

You see these companies in action every day. UPS and FedEx deliver packages to your home and business. DHL ships products across continents. Maersk moves containers by sea, and DB Schenker handles freight and logistics for large corporations.

Logistics companies play important roles in the supply chains of multinational corporations. You benefit from their expertise in several ways:

Logistics companies help you run your operations more efficiently. You gain a competitive advantage when your supply chain works smoothly.

The job market for logisticians grows quickly. The U.S. Bureau of Labor Statistics expects a 19% increase in jobs from 2023 to 2033.

You see new roles in technology, risk management, and sustainability. These changes help you meet industry needs and stay ahead.

A responsive supply chain lets you meet local consumer expectations. You optimize resources and reduce delays.

Efficient supply chain management helps you control costs and deliver products on time. You build customer loyalty and increase your market share.

Companies use AI and data analytics to reduce inefficiencies. You strengthen your position in the market by embracing new technologies.

When you look at logistics company definition and examples, you see how these businesses help you operate leaner and respond quickly to changes. You gain more control over your supply chain and improve your customer satisfaction.

Core Functions

Transportation

You depend on logistics companies to move goods from one place to another. Transportation is one of the most important services they offer. You can choose from many modes of transportation to fit your needs. Here are some of the most common options:

Full Truckload

Standard LTL (Less Than Truckload)

Volume LTL

Shared Truckload

Intermodal

Box Trucks & Sprinter Vans

Small Pack/Parcel

Other Modes

You also see logistics companies use these main types of transport:

Ocean transport

Road transport

Air transport

Rail transport

Each mode has its own benefits. For example, ocean transport works best for large shipments that are not urgent. Air transport is faster but costs more. Road and rail transport help you move goods across land quickly and safely. By choosing the right mode, you save money and deliver products on time.

Warehousing

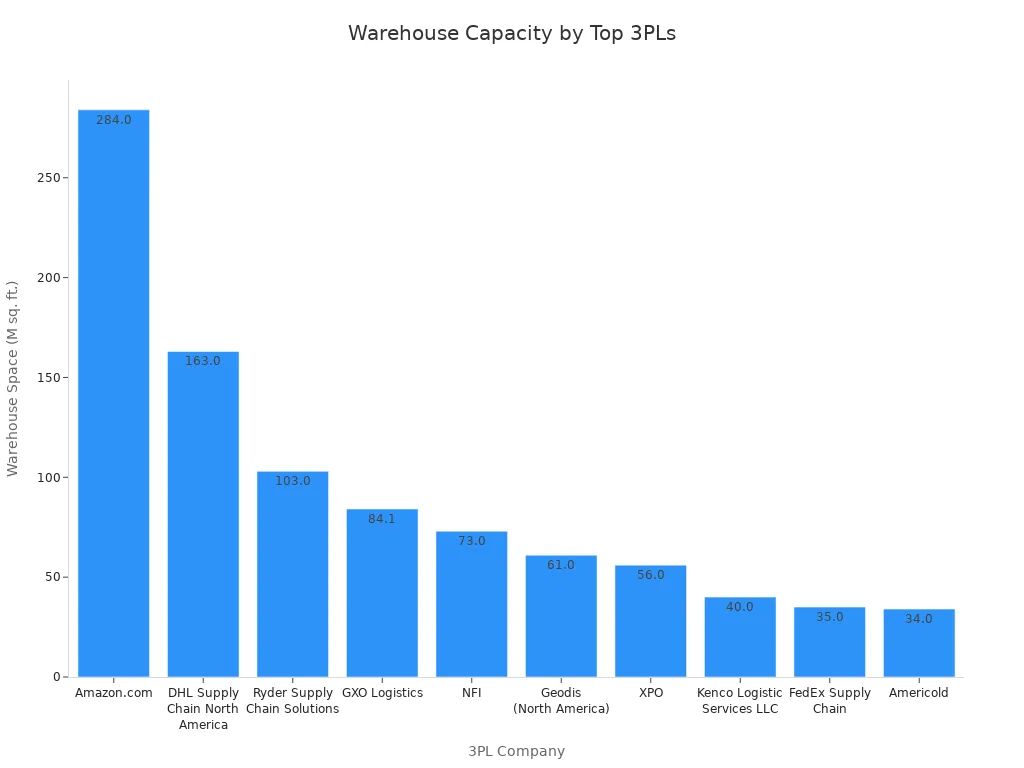

Warehousing gives you a safe place to store your goods before they reach customers. Logistics companies manage large warehouses to keep your products secure and organized. They work hard to reduce costs by fixing old systems and clearing out cluttered spaces. When they move inventory closer to where it is needed, you spend less on storage and labor.

3PL Company | |

|---|---|

Amazon.com | 284.0 |

DHL Supply Chain North America | 163.0 |

Ryder Supply Chain Solutions | 103.0 |

GXO Logistics | 84.1 |

NFI | 73.0 |

Geodis (North America) | 61.0 |

XPO | 56.0 |

Kenco Logistic Services LLC | 40.0 |

FedEx Supply Chain | 35.0 |

Americold | 34.0 |

You benefit when logistics companies optimize warehouse operations. They use these strategies:

Decentralize inventory to move products closer to high-demand areas.

Improve inventory accuracy and use leaner stock models.

Plan inventory based on real demand.

Note: When you use a logistics company with strong warehousing, you get faster deliveries and lower costs.

Inventory Management

Inventory management helps you keep the right amount of stock on hand. Logistics companies use advanced systems to track your products and avoid shortages or excess. They often use these technologies:

Warehouse Management Systems (WMS)

Transportation Management Systems (TMS)

Integrated software with real-time updates and automation

Wireless barcode scanning and labeling

Customizable dashboards for real-time reporting

AI and robotics for faster and more accurate handling

You can trust logistics companies to keep your inventory accurate. They follow these steps:

Use inventory management systems to track stock movements.

Count inventory regularly to check for errors.

Monitor stock to spot problems early.

Update records often to keep information correct.

Train staff on best practices.

Keep safety stock to prevent running out.

Use data and analytics to spot trends.

Techniques to hone inventory accuracy include regular cycle counting, adopting barcode and RFID technology, staff training, streamlining receiving and shipping processes, and leveraging inventory management software for real-time tracking.

Order Processing

Order processing is the step-by-step system that gets your products from the warehouse to your customer. Logistics companies follow a clear process to make sure every order is correct and on time.

Step Number | Step Name | Description |

|---|---|---|

1 | Order Placement | Customers place orders through various channels, capturing order details like products and quantities. |

2 | Order Entry | Verifying order details, checking product availability, and confirming payment terms. |

3 | Order Picking | Warehouse staff locate and pick items listed in the order using efficient methods. |

4 | Order Packing | Items are packed securely for shipment to ensure they arrive in good condition. |

5 | Order Shipping | Shipping the order to the customer’s address, providing tracking information and delivery dates. |

During busy seasons, logistics companies scale up their operations. They add more staff, use bigger warehouses, and rely on advanced technology to handle more orders. They also use data to predict demand and prepare for spikes in sales.

Effective communication among teams helps avoid mistakes.

Past sales trends guide planning for busy times.

Flexible strategies help adapt to sudden changes.

Packaging and Labeling

Packaging protects your products during shipping. Logistics companies follow strict standards to keep items safe and meet regulations. Here are some common packaging rules:

Fragile items need bubble wrap and sturdy boxes.

Hazardous items must have special packaging and labels.

Temperature-sensitive items require insulation and cooling.

Perishable items need waterproof, insulated containers.

Oversized items need extra cushioning and secure packaging.

Labeling is just as important as packaging. Accurate labels help you track products and make sure they reach the right place. Logistics companies use barcodes and RFID tags to update inventory in real time. This reduces mistakes and keeps customers happy.

Evidence | Explanation |

|---|---|

Accurate labeling ensures products are correctly identified and sorted | This leads to improved inventory management and reduced errors in order fulfillment. |

Reliable labels enhance customer satisfaction | When orders are fulfilled accurately, customers are more likely to be satisfied with the service. |

Real-time tracking is facilitated by accurate labeling | Technologies like barcodes and RFID allow for instant updates in inventory management, preventing shortages and excess stock. |

Technology Integration

Technology helps logistics companies work faster and smarter. You see many types of technology in action:

Description | |

|---|---|

Inventory & Order Management Systems | Optimize inventory with real-time synchronization, automate order fulfillment, and reduce shipping costs. |

Predictive Analytics and AI | Use data-driven solutions to forecast demand, optimize inventory, and improve customer satisfaction. |

Cloud-Based Systems | Enable seamless communication across platforms, providing real-time data access for better decision-making. |

Robotics | Automate repetitive tasks to improve efficiency, reduce labor costs, and enhance accuracy in fulfillment processes. |

Automation brings many benefits to your business:

Benefit | Description |

|---|---|

Optimizes Transportation and Routing | AI tools analyze delivery paths, and autonomous vehicles reduce human error. |

Reduces Manual Errors | Automation minimizes mistakes in labeling and order entry, using barcode scanners and RFID tags for accuracy. |

Accelerates End-to-end Order Processing | Automation connects ordering, fulfillment, and shipping into a continuous process, improving delivery timelines and customer updates. |

Supports Scalable Operations | Automated systems can expand output without a proportional increase in staff, ensuring stable performance during demand fluctuations. |

Improves Forecasting and Planning | Predictive analytics tools help logistics managers make informed decisions by processing historical and real-time data, reducing waste and ensuring smoother coordination. |

Strengthens Security and Compliance | Automated systems enforce customs checks and regulations, creating a complete audit trail for compliance reviews. |

Repositions Staff Toward Strategic Tasks | Automation allows staff to focus on supervision and performance improvement rather than repetitive tasks, enhancing operational resilience. |

When you look at logistics company definition and examples, you see how technology integration makes every part of the supply chain more efficient. You get faster deliveries, fewer mistakes, and better customer service.

Operations

Models (Freight Brokers, Forwarders, Carriers, 3PLs)

You can choose from several logistics models to move your goods. Each model has a unique role in the supply chain. Here is a table that shows some of the main models and their features:

Model Name | Description | Best For | Advantages | Challenges | Example |

|---|---|---|---|---|---|

Reverse Logistics Model | Manages returns, recycling, or disposal from customers to origin. | E-commerce, warranty services | Builds trust, supports sustainability | Complex tracking, higher costs | Amazon’s return policies |

Multi-Modal Model | Combines two or more transport modes for seamless movement. | Long-distance, international | Flexible, cost-effective | Needs strong coordination | Export-import operations |

Hub-and-Spoke Model | Routes goods through central hubs for sorting and redistribution. | Large-scale operations | Cost-effective for bulk transport | Hubs may face delays | FedEx, Amazon |

Last-Mile Delivery Model | Focuses on delivering goods from local hubs to the customer’s doorstep. | E-commerce, urban deliveries | Improves customer satisfaction | Expensive, hard in remote areas | Amazon Logistics |

Just-in-Time (JIT) Model | Delivers goods exactly when needed, reducing storage. | Manufacturing | Lowers holding costs, streamlines work | Needs prompt transport | Toyota’s supply chain |

You may also work with different service providers. Third-party logistics (3PL) companies offer a wide range of services and own their equipment. Freight brokers only connect shippers and carriers and do not own assets. 3PLs handle all logistics activities and build long-term partnerships, while brokers focus on single shipments.

Process Flow

You see a clear process when logistics companies manage your goods. The steps usually follow this order:

Demand Planning: Forecast what customers will need.

Order Processing: Enter and check customer orders.

Inventory Management: Track and control stock levels.

Warehouse Operations: Receive, inspect, and store goods.

Transportation: Move goods using the best transport mode.

Order Fulfillment: Deliver goods to the customer.

Good process flow helps you avoid delays and keeps your customers happy.

Coordination

You need strong coordination to ensure timely delivery. Logistics companies use several strategies:

Organize and manage the movement of goods, services, and information.

Plan, execute, and monitor transportation, warehousing, and inventory.

Communicate clearly with teams, suppliers, and customers about expectations and timelines.

You benefit when companies optimize transportation planning with mapping software, use real-time tracking for vehicles, and set up alerts for delays. They also work closely with suppliers and carriers, setting clear agreements for order volumes and communication. This teamwork helps you get your products on time and keeps your supply chain running smoothly.

Benefits

Efficiency

You gain efficiency when you work with a logistics company. Setting clear goals and tracking progress helps you spot bottlenecks and improve productivity. You see better organization, which leads to less chaos and more confidence in your daily operations. Optimized inventory management reduces errors and speeds up order fulfillment. Technology integration streamlines your logistics and enhances order management. You also benefit from streamlined returns, which improve both customer experience and operational efficiency.

Tip: Batch shipping and automatic order syncing from platforms like Shopify make your shipping process faster and more reliable.

You can print discounted shipping labels, access multiple carriers, and track shipments from pickup to delivery. These steps help you save time and avoid mistakes.

Cost Savings

Logistics companies help you control costs. You avoid large expenses for warehouse space and logistics staff by partnering with a third-party provider. You gain flexibility because you can use multiple warehouses without owning them. A strong logistics partner gives you valuable supply chain data, helping you track inventory and find ways to cut costs.

Benefit | Explanation |

|---|---|

Cost Limitation | You avoid big expenses for warehouses and staff. |

Increased Flexibility | You expand operations without owning more locations. |

Better Supply Chain Data | You track inventory and spot areas for savings. |

Access to Logistics Expertise | You get advice from experts on how to improve efficiency and reduce costs. |

Customer Satisfaction

You keep your customers happy when you deliver orders on time and in good condition. Logistics companies help you meet these goals by focusing on key metrics.

Metric | Description |

|---|---|

Customers expect orders to arrive on time. | |

Accuracy of Orders | Correct products and quantities matter for satisfaction. |

Transparency and Communication | Keeping customers informed builds trust. |

Condition of Goods | Safe delivery improves your reputation. |

Cost-Efficiency | Affordable shipping encourages repeat business. |

You can use customer feedback surveys and delivery performance metrics to measure satisfaction. Monitoring social media and online reviews also gives you valuable insights.

Risk Management

You protect your business from delays and damages by working with logistics companies that manage risks well. Supplier diversification helps you avoid major disruptions. Contingency planning prepares you for unexpected problems. Technology solutions track compliance and improve transparency.

Note: Careful vendor selection and regular risk assessments help you minimize supply chain disruptions.

You can use both qualitative and quantitative assessments to measure risks. Building strong vendor relationships and monitoring performance keeps your supply chain resilient.

Choosing a Logistics Partner

Key Factors

You want a logistics partner who fits your business goals and values. The right choice can help you grow and avoid costly mistakes. Use the table below to compare the most important factors:

Factor | Description |

|---|---|

Cultural Alignment | The partner values reliability and solves problems quickly. |

Strategic Fit | The partner matches your needs, such as cost savings or on-time delivery. |

Experience & Expertise | The partner has a strong track record in your industry. |

Technology | The partner uses real-time tracking and data analytics. |

Geographic Coverage | The partner serves all your locations, local or global. |

Data Security | The partner protects your sensitive information. |

Customer Service | The partner responds quickly and helps solve issues. |

Pricing | The partner offers value, not just low prices. |

Tip: A partner with strong technology and customer service can help you avoid delays and keep your customers happy.

Types

You can choose from several types of logistics partners. Each type serves different industries and needs:

Freight Brokers connect you with carriers but do not own trucks or warehouses.

Freight Forwarders arrange shipments and handle paperwork for international trade.

Carriers own the vehicles and move your goods directly.

Third-Party Logistics (3PL) Providers manage warehousing, shipping, and sometimes returns.

Manufacturers often use 3PLs to focus on production. Retailers rely on logistics partners to manage inventory and deliver products on time. Restaurants use logistics companies to keep ingredients fresh and reduce waste.

Questions to Ask

Before you sign a contract, ask these questions to make sure the logistics partner fits your needs:

Does the partner understand your business model?

What experience do they have with your type of shipments?

Which regions do they serve? Can they support your growth?

What technology and tracking systems do they use?

Are their warehouses in the right locations, and do they have enough space?

Asking the right questions helps you find a reliable partner who supports your business goals.

Logistics companies help you keep your supply chain strong and efficient. When you understand their roles and benefits, you make better choices for your business. You can:

Use performance data to solve problems early.

Listen to customer feedback for better service.

Work closely with your team to reach your goals.

Use these tips to choose the right logistics partner and build a supply chain that supports your success.

FAQ

What does a logistics company do?

A logistics company helps you move products from one place to another. You get help with storage, transportation, and tracking. They make sure your goods arrive safely and on time.

How do you choose the right logistics partner?

You should look for experience, technology, and good customer service. Ask about their coverage area and how they handle problems. A strong partner supports your business growth.

Can a logistics company handle international shipping?

Yes, many logistics companies manage international shipping. You get help with customs, paperwork, and tracking. They make sure your products reach customers in other countries.

Why is technology important in logistics?

Technology helps you track shipments, manage inventory, and plan routes. You see fewer mistakes and faster deliveries. Modern systems give you real-time updates and better control.

What is the difference between a 3PL and a freight broker?

A 3PL manages your whole supply chain, including storage and shipping. A freight broker connects you with carriers but does not handle storage. You choose based on your needs.

See Also

Understanding East Coast B2B Warehousing And Distribution Solutions

Essential Elements Of Best Practices In Global Logistics

Key Strategies For Effective Management Of Global Logistics

PGL's Miami Warehouse Solutions For Quick East Coast Shipping

Streamlined Inventory Management And Distribution With PGL Warehousing