Top Tips to Avoid Pitfalls in Logistics Contract Management

You can avoid common mistakes in logistics contract management by focusing on clear agreements and open communication. Strong provider relationships help you solve problems quickly. Regular contract reviews keep your operations running smoothly. Organized documentation and expert advice give you confidence in every decision. When you use logistics contract management best practices, you build a solid foundation for success.

Key Takeaways

Ensure clarity in contract terms to prevent misunderstandings and costly disputes.

Choose logistics partners based on reliability and technology, not just cost, to avoid inefficiencies.

Regularly review contracts to catch issues early and keep agreements aligned with business needs.

Communicate consistently with partners to strengthen relationships and improve supply chain efficiency.

Utilize technology and automation to streamline processes and enhance accuracy in logistics management.

Common Pitfalls

Unclear Terms

You face problems when contract terms are not clear. Most disputes in logistics contracts happen because people misunderstand what each side expects. If you rush a contract or use vague language, you leave room for costly mistakes. Ambiguous service descriptions and unexpected charges often cause confusion. You can prevent legal issues by making sure every term is clear and specific.

Ambiguous service descriptions lead to confusion.

Unexpected charges create disputes.

Poor project communication increases risk.

Inadequate documentation causes misunderstandings.

Poor Partner Choice

Choosing the wrong logistics partner can hurt your business. If you pick a supplier based only on cost, you may miss important factors like technology and reliability. Poor communication leads to unmet expectations. Lack of technology causes inefficiencies and higher costs. International shipping problems can delay deliveries and increase losses. Improper handling of shipments risks damage and unhappy customers.

Suppliers chosen for cost alone may not meet your needs.

Technology gaps slow down operations.

Mishandled shipments damage goods and trust.

Weak Metrics

Weak performance metrics make it hard to measure success. If your contract does not include accurate metrics, you may not get the results you want. Misalignment between contractor actions and your goals can cause contracts to fail. Tensions grow when metrics do not match daily operations. You need strong metrics that adapt to changes.

Metrics that do not reflect real work cause problems.

Poor tracking leads to contract failure.

Outdated targets create confusion.

Communication Gaps

Communication gaps can cause missed obligations and revenue loss. If you do not share updates, people may not know about important clauses. Inconsistent terms lead to cost overruns. Contracts that renew automatically without review can waste money. Compliance gaps happen when contract versions drift across departments.

Missed obligations due to lack of awareness.

Revenue leakage from outdated terms.

Cost overruns from auto-renewals.

Compliance gaps from poor communication.

Compliance Risks

You must follow rules and regulations in logistics contracts. Failing to comply can lead to fines, lawsuits, and loss of business licenses. Non-compliance damages your reputation and relationships with partners. Unsafe working conditions lower employee morale and productivity.

Compliance Risk | Consequence |

|---|---|

Regulatory non-compliance | Fines and penalties ranging from hundreds to thousands of dollars depending on severity. |

Legal action | Civil lawsuits and potential criminal charges leading to financial strain and reputational damage. |

Loss of license or certification | Suspension or revocation halting business operations and damaging trust with customers. |

Reputation damage | Negative publicity and loss of customer trust due to non-compliance issues. |

Damage to business relationships | Hesitance from partners to work with companies with a history of violations. |

Reduced employee morale and productivity | High turnover rates and decreased efficiency due to unsafe working conditions. |

Missed Reviews

Missing contract reviews can cost you money and slow down your operations. If you do not check contracts regularly, you risk non-performance and breaches. This can lead to penalties and lost revenue. Poor contract management causes delays and lowers productivity. Legal risks increase when you overlook contract details.

Financial losses from missed reviews.

Operational bottlenecks and delays.

Higher risk of legal problems.

Partner Selection

Due Diligence

You need to choose logistics partners carefully. Good partner selection starts with strong due diligence. You look at legal records, financial health, and technology systems. You check if the company follows environmental rules and pays taxes correctly. Each step helps you avoid risks and build trust.

Here is a table that shows important types of due diligence and their benefits:

Due Diligence Type | Description | Benefits |

|---|---|---|

Legal Due Diligence | Review of lawsuits, permits, licenses, agreements | Ensures compliance with legal standards |

Commercial Due Diligence | Assessment of market appeal and competition | Identifies commercial viability |

Financial Due Diligence | Analysis of financial stability and performance | Mitigates financial risks |

IT Due Diligence | Audit of IT policies and security | Reveals potential security threats |

Environmental Due Diligence | Evaluation of environmental risks | Ensures environmental compliance |

Tax Due Diligence | Review of tax compliance | Prevents legal issues related to taxation |

You protect your business when you check these areas. Legal checks help you avoid lawsuits. Financial reviews show if a partner can handle your shipments. IT audits keep your data safe. Environmental and tax checks help you follow the law. You lower your risk and make better choices.

Aligning Goals

You get better results when your goals match your partner’s goals. You work together to solve problems and reach targets. You set clear performance measures and track progress. You build trust and improve communication.

Aligning business goals fosters collaboration between companies and logistics partners.

Enhanced performance measurement through jointly defined KPIs ensures accountability.

Better communication and cultural compatibility lead to a unified approach in addressing logistical challenges.

You should talk about your needs and expectations early. You share your plans and listen to your partner’s ideas. You create a strong team that works toward the same outcome. When you align goals, you avoid confusion and reach success faster.

Clear Agreements

Roles and Responsibilities

You set the stage for success when you define roles and responsibilities in your logistics contracts. Clear agreements help you avoid confusion and keep everyone accountable. You know who handles customs clearance, packaging, and documentation. You also understand how often you need to report and which channels to use for communication. When you outline these details, you prevent disputes and solve problems faster.

Aspect | Explanation |

|---|---|

Outlines service expectations and responsibilities, reducing misunderstandings. | |

Dispute prevention | Minimizes conflicts and provides a reference for quick issue resolution. |

Responsibilities of parties | Specifies obligations of both service provider and client, including customs clearance, packaging, and documentation. |

Communication and Reporting | Details reporting structure, performance review frequency, and communication channels for transparency. |

Tip: Always review your contract to make sure every party knows their duties. This step keeps your logistics process smooth and reliable.

Payment Terms

You protect your business by setting clear payment terms. You should document all costs, payment deadlines, and schedules. Regular reviews help you keep terms fair and up to date. You need to assess your needs and risks before finalizing payment terms. Cash flow and supplier stability matter. You also define Incoterms to clarify responsibilities and avoid disputes.

Communicate and document payment terms clearly.

Review and update terms regularly.

Assess risks and needs before setting terms.

Define Incoterms for clarity.

Negotiate and formalize agreements in writing.

Note: Transparent payment terms build trust and prevent financial surprises.

Dispute Resolution

You lower your risk of conflict by planning for dispute resolution. You set up clear communication lines and draft detailed contracts. Technology like GPS tracking and supply chain software helps you track shipments and prevent issues. Mediation and alternative dispute resolution (ADR) methods solve problems faster than court cases. You monitor logistics processes and use escalation protocols to resolve issues quickly.

Integrate technology solutions for transparency.

Maintain detailed records of all transactions.

Use ADR methods to resolve disputes efficiently.

Proactive planning and continuous improvement help you avoid future disputes and keep your logistics contracts strong.

Performance Metrics

KPIs

You need strong key performance indicators (KPIs) to measure your logistics contract success. KPIs help you see if your logistics provider meets your expectations. When you track the right KPIs, you spot problems early and make better decisions. You should focus on KPIs that show delivery accuracy, delivery time, and supplier compliance.

Here is a table that shows the most common KPIs in logistics contract management:

KPI | Description |

|---|---|

Delivery Accuracy | Percentage of delivery orders handled without incidents, calculated as: (orders without incidents / total orders) x 100. |

Delivery Time | Measures punctuality of shipments, focusing on whether goods were dispatched and delivered on schedule. |

Supplier Compliance | Ratio indicating how efficiently and reliably a service provider works, calculated as: (complained orders / total orders) x 100. |

You should review these KPIs often. Delivery accuracy tells you if your goods arrive safely. Delivery time shows if your shipments reach customers on schedule. Supplier compliance helps you see if your provider follows your rules and meets your standards. When you use these KPIs, you keep your logistics contracts strong and reliable.

Tip: Set clear targets for each KPI. Share these targets with your logistics partner so everyone knows what success looks like.

Monitoring

You must monitor your logistics contracts to keep performance high. Regular monitoring helps you catch issues before they grow. You can use technology to track shipments, inventory, and supplier actions in real time. Many companies use special systems and tools to make monitoring easy.

Here is a table with popular tools and methods for ongoing monitoring:

Tool/Method | Description |

|---|---|

Enables real-time tracking of shipments, route optimization, and carrier management. | |

Warehouse Management Systems | Assists in real-time inventory tracking and streamlining order fulfillment processes. |

IoT and Sensors | Provides real-time data on vehicle locations and conditions of goods during transit. |

Analytics Platforms | Analyzes KPIs and generates reports to identify inefficiencies and optimize operations. |

You can use transportation management systems to watch your shipments and plan better routes. Warehouse management systems help you track inventory and fill orders quickly. IoT sensors give you updates on your goods while they travel. Analytics platforms help you study your KPIs and find ways to improve. When you use these tools, you keep your logistics contracts on track and avoid surprises.

Note: Review your monitoring tools often. Update your systems as your business grows to keep your logistics process efficient.

Communication

Regular Updates

You keep your logistics contracts strong when you communicate regularly with your partners. Ongoing updates help everyone stay on the same page. You share important information and solve problems before they grow. Regular communication boosts supply chain efficiency and prevents misunderstandings that can lead to costly mistakes. You make decisions faster and reduce errors. You also build trust and strengthen relationships with your providers.

Regular updates improve supply chain efficiency.

Clear communication helps you avoid misunderstandings and costly errors.

Fast decision-making keeps your operations agile.

Strong relationships lead to better contract outcomes.

Missed updates can cause delays and increase costs.

You should set a schedule for sharing updates. You can use emails, meetings, or digital platforms. When you keep everyone informed, you make your logistics process smoother and more reliable.

Tip: Use simple language and clear channels for all updates. This keeps your team and partners aligned.

Documentation

You need strong documentation practices to keep your logistics contracts transparent. Good records help you track changes and avoid confusion. You can use templates and automation to save time and reduce mistakes. Centralized storage makes it easy to find documents when you need them. Tracking important dates helps you avoid missed deadlines. You also create opportunities for collaboration and clear communication.

Practice | Description |

|---|---|

Standardize Contract Templates | Customizable templates save time and reduce errors in paperwork. |

Automate Manual Contract Management Processes | Automation removes bottlenecks and speeds up approvals. |

Centralize Contract Storage | A central system ensures easy access and prevents lost documents. |

Track Important Contract Dates and Deadlines | Tools help monitor status and remind users of key dates. |

Establish Effective Communication and Collaboration Opportunities | Keeps all parties informed and aligned. |

You should review your documentation often. You update records when changes happen. You store contracts in a secure place. You use reminders for important dates. These steps help you stay organized and avoid problems.

Note: Good documentation protects your business and supports strong contract management.

Organization & Planning

Documentation

You keep your logistics contracts strong when you organize your files. Well-managed documentation helps you find information quickly and avoid mistakes. You save money by negotiating better rates and combining shipments. Clear contracts set expectations and improve service quality. You lower risks by following safety rules and regulations. Strong documentation also builds trust with your suppliers.

Benefit | Description |

|---|---|

You reduce transportation costs by negotiating rates and combining shipments. | |

Clear expectations lead to reliable service and accountability. | |

Risk Mitigation | Detailed contracts help you follow safety and regulatory standards. |

Enhanced Supplier Relationships | Organized files foster trust and better collaboration with suppliers. |

Tip: Store all contracts in one secure place. Use digital tools to keep records updated and easy to access.

Tracking Deadlines

You avoid problems when you track contract deadlines. Missing a renewal or expiration date can lead to penalties or service gaps. Automated alerts remind you about important dates so you never miss a deadline. Proactive management of contract expirations helps you prevent delays and extra costs.

Automated alerts help you remember key dates.

Proactive tracking avoids penalties and service interruptions.

Staying ahead of deadlines keeps your logistics running smoothly.

Note: Set calendar reminders for renewals and expirations. Review your contracts often to catch upcoming deadlines.

Inventory Planning

You keep your supply chain efficient by planning your inventory carefully. Good planning helps you avoid having too much or too little stock. You use strategies like just-in-time inventory to get supplies only when you need them. Material requirements planning (MRP) systems help you schedule deliveries based on demand. Safety stock optimization lets you balance service levels with costs. Warehouse management systems give you real-time visibility of your inventory.

Strategy | Description |

|---|---|

Just-in-Time Inventory | You receive goods only when needed, reducing excess stock. |

MRP Systems | You plan deliveries based on demand forecasts and lead times. |

Safety Stock Optimization | You keep a buffer to avoid running out of stock. |

Inventory Replenishment Triggers | You set reorder points to know when to order more. |

Warehouse Management Systems | You track inventory in real time for better planning. |

Tip: Review your inventory levels often. Work with suppliers to adjust orders based on changing needs.

Compliance & Risk

Regulatory Updates

You need to stay aware of new rules in logistics. Changes in regulations can affect your contracts and daily operations. If you ignore updates, you risk fines and delays. You should check for new laws often and adjust your processes quickly.

Here are some recent updates that impact logistics contract compliance:

De Minimis Rule: Starting May 2, 2025, you will lose duty-free treatment for some imports from China and Hong Kong. This change means you must pay more attention to customs paperwork and fees.

Cyber Incident Reporting for Critical Infrastructure Act of 2022 (CIRCIA): You must report cyber incidents if you run a logistics firm. This rule helps protect your data and keeps your business safe.

Customs and Environmental Regulations: You face stricter enforcement of customs duties. You also see more rules about environmental protection. These changes require you to follow new procedures and keep better records.

Tip: Review your contracts and update your compliance checklist every quarter. This habit helps you avoid surprises and keeps your business running smoothly.

Risk Assessment

You protect your business when you assess risks in logistics contracts. Risk assessment helps you spot problems before they happen. You look at areas like financial stability, legal issues, and supply chain disruptions. You also check for cyber threats and environmental risks.

Here is a simple table to help you organize your risk assessment:

Risk Type | What to Check | How to Manage |

|---|---|---|

Financial | Payment terms, partner stability | Set clear terms, monitor cash |

Legal | Contract clauses, local laws | Review with legal experts |

Operational | Delivery delays, inventory issues | Use tracking tools |

Cybersecurity | Data protection, incident response | Update security protocols |

Environmental | Waste management, emissions | Follow new regulations |

You should review risks before signing any contract. You also need to check risks during the contract period. Regular reviews help you fix problems early and keep your logistics process strong.

Note: Use a checklist for each contract. This step makes risk assessment easier and helps you stay compliant with new rules.

Reviews & Updates

Scheduled Reviews

You keep your logistics contracts strong when you schedule regular reviews. These reviews help you catch problems early and make sure your agreements stay up to date. You check if your partners meet their promises and if your contract terms still fit your needs. You look for changes in your business, new rules, or better ways to work. You also spot risks before they grow.

Set a review calendar for each contract. You can use reminders or digital tools to track review dates. During each review, ask these questions:

Are all parties meeting their responsibilities?

Do performance metrics show improvement?

Have any laws or regulations changed?

Is the contract still helping your business goals?

A simple review checklist helps you stay organized:

Review Item | Action Step |

|---|---|

Roles & Duties | Confirm responsibilities |

KPIs | Check performance numbers |

Compliance | Update for new rules |

Payment Terms | Verify accuracy |

Renewal Dates | Plan ahead |

Tip: Schedule reviews at least once a year. You can do more frequent checks for high-value or complex contracts.

Expert Involvement

You improve your contract management when you involve experts. Specialists bring deep knowledge and fresh ideas. They help you understand complex terms and spot hidden risks. Experts also guide you in using data to make better decisions. You get advice on new technology and best practices.

The involvement of experts in logistics contract management is crucial for improving outcomes by providing specialized knowledge, facilitating data-driven assessments, and enhancing collaboration among stakeholders.

You can hire a consultant or bring in a fractional expert for a short time. These professionals review your contracts and point out areas for improvement.

I brought in a fractional expert... I can be pretty effective looking at a contract and saying, hey, we’re doing good here, we have opportunity here.

You learn from their experience and avoid costly mistakes. Experts help you negotiate better terms and solve disputes quickly. You build stronger contracts and protect your business from future risks.

Note: Ask for expert help when you face new challenges or want to upgrade your contract process. Their support makes your logistics management more reliable.

Logistics Contract Management Best Practices

Building Relationships

You build strong logistics partnerships by treating your providers as part of your team. When you see your logistics provider as a partner, you create trust and open communication. You share your goals and let them understand your business needs. This approach helps your provider deliver better service and meet your expectations.

You can use these strategies to strengthen your relationships:

Maintain regular communication. Set up weekly or monthly meetings to discuss progress and solve problems early.

Treat your third-party logistics provider (3PL) as an extension of your brand. Let them know your standards and values.

Embrace technology together. Use real-time tracking and data analytics to improve efficiency.

Collaborate on process improvements. Review your logistics processes with your provider and find ways to make them better.

Foster a culture of innovation. Encourage your provider to try new methods and tools.

Build trust through transparency. Share important data and talk openly about challenges.

Viewing your logistics provider as a partner helps you work together to solve problems. You get better results when you communicate openly and support each other. Your provider can tailor their services to fit your needs, which leads to faster and more accurate deliveries.

Tip: Strong relationships with your logistics partners make your supply chain more reliable and flexible.

Leveraging Technology

You improve logistics contract management best practices by using technology. Automation and digital tools help you work faster and avoid mistakes. You can track shipments, manage documents, and process orders with less effort. Technology also helps you make better decisions using real-time data.

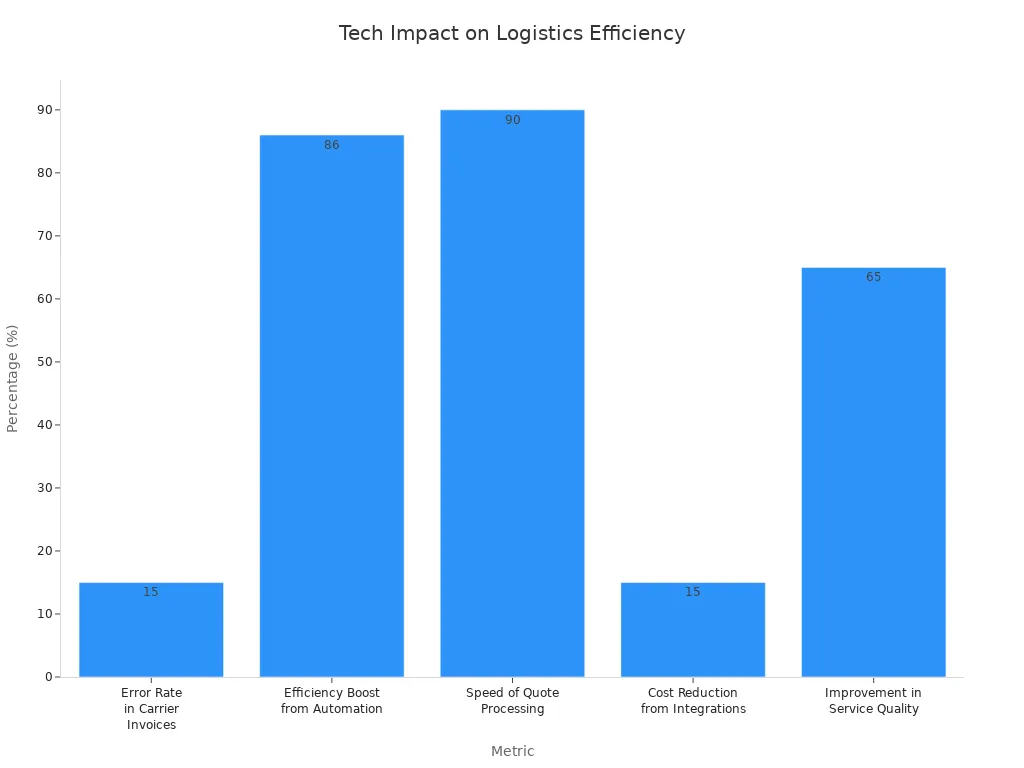

Here is a table that shows how technology boosts efficiency and accuracy in logistics contract management:

Evidence Type | Details |

|---|---|

Error Rate in Carrier Invoices | 15% of all carrier invoices contain errors, costing the industry about $700 million each year. |

Efficiency Boost from Automation | Digital rate management systems can increase team efficiency by up to 86%. |

Speed of Quote Processing | Companies using digital tools process quotes up to 90% faster than traditional methods. |

Cost Reduction from Integrations | ERP and TMS integrations can lower logistics costs by 15%. |

Improvement in Service Quality | These integrations can improve service quality by 65%. |

“The automation of rates allows us to process and compare multiple freight rates quickly and accurately, saving considerable time in quoting and selecting the best offer from a carrier!” – Elizabeth Piña, Digital Transformation Executive

You can follow these logistics contract management best practices to get the most from technology:

Automate order processing. Use software to confirm orders and create invoices quickly.

Track shipments and generate documents automatically. This helps you avoid delays and errors.

Use warehouse automation. Robots can pick, pack, and sort goods faster and cheaper.

Select vendors carefully. Check their experience, financial health, and compliance.

Negotiate contracts that match your goals. Make sure your provider understands your needs.

Manage relationships with open communication and regular reviews.

Focus on continuous improvement. Review your performance and contracts often.

Make decisions based on data. Use analytics to guide your logistics operations.

Customize services to fit your business. Stay flexible to meet changing demands.

You should involve experts when you want to improve your logistics contract management best practices. Specialists help you understand complex terms and spot risks. They guide you in using new technology and finding better ways to work. Regular reviews and expert advice keep your contracts strong and up to date.

Note: Continuous improvement and expert involvement help you stay ahead in logistics contract management. You build a supply chain that adapts to changes and delivers great results.

You can build stronger logistics contracts by following clear agreements, tracking deadlines, and using technology. Regular reviews help you spot problems early and keep your contracts up to date. When you use logistics contract management best practices, you make your supply chain more reliable.

The principle of continuous improvement, shown by the Toyota Production System, highlights how small changes can lead to cost savings and better customer experiences.

Start by monitoring KPIs and tracking progress each month. Develop daily processes and encourage your team to improve every day. Take action now to create a culture of growth and accountability.

FAQ

What is the most important part of a logistics contract?

You need clear terms. Make sure every responsibility, deadline, and cost appears in writing. This step helps you avoid confusion and keeps everyone accountable.

How often should you review your logistics contracts?

You should review your contracts at least once a year. Regular reviews help you catch problems early and keep your agreements up to date.

Why do you need performance metrics in logistics contracts?

Performance metrics show if your provider meets your standards. You can track delivery times, accuracy, and service quality. This helps you spot issues and improve results.

What should you do if a dispute happens with your logistics partner?

Stay calm and follow your contract’s dispute resolution process. Use clear records and communication. Try mediation or alternative dispute resolution before going to court.

See Also

Key Strategies for Effective Global Logistics Operations

Understanding Core Elements of Global Logistics Best Practices

New Trends in Logistics That Will Define Tomorrow

Simplifying Supply Chain Optimization with U.S. Logistics Solutions