Emerging Trends Transforming the Logistics Industry in 2025

You see the logistics industry changing fast in 2025. The global logistics market is projected to reach $11.23 trillion, rising from $8.96 trillion in 2023, with a steady growth rate of 6.3% through 2028.

The most impactful trends include:

Supply chain visibility

Agility

Automation

Sustainability

Micro-fulfillment

AI

Resilience

Globalization

Customer transparency

Industry analysts highlight these areas:

Global labor shortages

Automation complexity

Demands for real-time data

Supply chain transparency for critical collaborations

You must understand these trends because they shape logistics industry analysis and insights. You need practical strategies to stay competitive and resilient. This blog will give you clear actions to help you succeed.

Key Takeaways

Supply chain visibility is crucial. Use real-time tracking to keep customers informed and build trust.

Embrace automation to address labor shortages. Invest in AI and robotics to enhance efficiency and reduce costs.

Focus on sustainability. Implement green practices like electric vehicles and optimized routes to meet customer demands for eco-friendly logistics.

Agility is key. Develop flexible logistics models and strong supplier relationships to quickly adapt to market changes.

Leverage predictive analytics. Use data-driven insights to forecast demand and optimize inventory, improving customer satisfaction.

2025 Logistics Industry Analysis and Insights

Key Market Drivers

You see many forces shaping the logistics industry in 2025. E-commerce continues to grow, pushing companies to improve delivery speed and accuracy. Inventory management systems get smarter, helping you track goods and reduce waste. Businesses focus on cost efficiency to stay profitable. Manufacturing sectors expand, creating new opportunities and challenges. Changes in trading regulations force you to adapt quickly. Sustainable and green logistics practices become more important as customers demand ethical choices. Technology drives change with blockchain, real-time tracking, smart infrastructure, and IoT solutions.

Tip: You can stay ahead by watching these market drivers and adjusting your strategies often.

Enhancements to inventory management systems

Drive towards cost efficiency

Expansion of manufacturing sectors

Alterations in trading regulations

Incorporation of sustainable and green logistics practices

Technological advancements like blockchain, real-time tracking, smart infrastructure, and IoT

You must also respond to customer expectations and global economic factors. Customers want more sustainable options and better crisis communication. Companies adapt to trade regulations and focus on regional supply chains to reduce risks. Strategic partnerships with third-party logistics providers help you expand market reach. You need to monitor regulatory changes, invest in resilient supply chains, and use advanced technology for efficiency and security.

Technology’s Role in Transformation

Technology changes how you manage logistics every day. Artificial intelligence and machine learning help you spot patterns and reduce delays. Real-time visibility and predictive analytics let you make better decisions using data. IoT integration connects devices and improves data collection. Autonomous vehicles and drones speed up deliveries. Blockchain builds trust by making supply chains more transparent. Sustainability-focused solutions help you lower your environmental impact. Cloud-based logistics platforms give you flexibility and help you handle market changes.

Technological Advancement | Description |

|---|---|

AI and ML enhance supply chain technology by reducing delays and inefficiencies through pattern recognition in data. | |

Real-Time Visibility and Predictive Analytics | These systems process large data volumes to identify areas needing attention and improve decision-making. |

IoT Integration in Supply Chain Operations | IoT changes how supply chain operations are managed, providing better connectivity and data collection. |

Autonomous Vehicles and Drone Deliveries | Retail companies invest in autonomous fleets for faster fulfillment and reduced wait times. |

Blockchain for Enhanced Supply Chain Transparency | Businesses adopt blockchain to meet customer demands for ethics and transparency in supply chains. |

Sustainability-Focused Logistics Solutions | Companies develop strategies to minimize their environmental impact. |

Cloud-Based Logistics Platforms | The shift to cloud systems is essential for companies to navigate market uncertainties effectively. |

You need to use logistics industry analysis and insights to guide your decisions. Technology, customer needs, and global trends all play a role. If you keep learning and adapting, you will succeed in the changing logistics world.

Supply Chain Visibility and IoT

Real-Time Tracking Solutions

You can see how real-time tracking changes the way you manage deliveries. When you use tracking tools, you get instant updates about where your shipments are. Customers feel more confident because they know exactly when their packages will arrive. You build trust by keeping them informed at every step. This connection helps customers plan their day and reduces worries about missed deliveries.

Real-time tracking gives you accurate updates on shipment status.

Customers trust your service more when they see clear information.

You stand out from competitors by offering better communication.

You can monitor goods from supplier to customer, making your supply chain more efficient.

If a problem happens, you can fix it before it gets worse.

Tip: You can use logistics industry analysis and insights to choose the best tracking solutions for your business.

Enhancing Transparency

You improve your supply chain when you focus on transparency. You collect better data, which helps you lower costs and make smarter decisions. You can see how your suppliers perform and spot issues before they become big problems. Customers want to know where products come from and if brands follow ethical practices. When you share this information, you build loyalty and trust.

Benefit Type | Description |

|---|---|

Cost Reduction | You lower operational costs by collecting better data and improving accuracy. |

Revenue Increase | You boost revenue by making your supply chain more efficient and digital. |

You manage inventory better by watching supplier performance.

You find bottlenecks and regulatory issues early.

You show customers that you care about ethical sourcing.

You make your business stronger and more reliable when you use transparency and IoT tools. You can keep up with changes in the logistics industry analysis and insights and stay ahead of your competitors.

Agility and Adaptability

You need agility and adaptability to succeed in the logistics industry in 2025. Fast changes in demand, supply chain disruptions, and new technology challenge your business every day. You must respond quickly and adjust your operations to stay ahead.

Rapid Response Strategies

You can use several strategies to respond quickly when problems arise. Building strong relationships with different suppliers helps you avoid delays. Real-time data lets you see inventory and shipments, so you can make fast decisions. You can change transportation plans when delays happen. Buffer stocks help you keep orders moving even during disruptions. Working with third-party logistics partners gives you more flexibility. Contingency plans prepare your team for emergencies.

Strategy | Description |

|---|---|

Diversify suppliers and keep strong communication to reduce risks. | |

Leveraging Real-Time Data for Decision Making | Use real-time data to monitor inventory and shipments for quick decisions. |

Agile Transportation Management | Adapt logistics plans quickly when transportation delays occur. |

Inventory Management and Buffer Stocks | Keep buffer stocks to prevent stockouts and continue fulfilling orders. |

Collaborating with Third-Party Logistics (3PLs) | Partner with 3PLs for flexibility and scalability during disruptions. |

Implementing Contingency Plans | Develop crisis management protocols for a coordinated response to disruptions. |

Tip: You can train cross-functional teams to solve problems faster and use exception management systems to stop small issues from becoming big ones.

Flexible Logistics Models

You can build flexible logistics models to handle market changes. Combining owned assets with brokered capacity helps you avoid sudden rate increases and shortages. Dedicated assets work well for stable routes, while brokerage helps with changing demands. Advanced tracking technology gives you real-time insights, so you can make quick decisions during disruptions.

Self-service onboarding platforms help you add new customers and suppliers quickly.

Decentralized authority lets your front-line team make fast decisions.

Change management tools allow you to adjust operations without major reconfigurations.

Continuous improvement cultures help your team learn from challenges and adapt quickly.

You can use logistics industry analysis and insights to choose the best models for your business. Flexible models help you reduce risk, control costs, and improve service. You stay resilient and ready for anything the market brings.

Labor Shortages and Automation

Workforce Challenges

You face big challenges with finding enough workers in the logistics industry in 2025. Many companies struggle to fill open jobs. The U.S. logistics sector expects a shortfall of over 2 million workers this year. One in four freight firms says labor shortage is their main concern. Several reasons cause this problem:

The workforce is aging, and fewer young people join the field.

High turnover rates make it hard to keep skilled employees.

E-commerce grows fast, so you need more workers than ever.

You must find ways to keep your business running smoothly. Upskilling programs help your team learn new skills. Companies like Amazon have reskilled over 700,000 employees through special training. You can also use technology to fill gaps and make work easier for your staff.

Tip: You can offer flexible schedules and better benefits to attract and keep workers.

Warehouse Automation

You see more companies using automation to solve labor shortages. Robots and AI-powered machines help you process orders faster and lower costs. AI robots can cut warehouse processing time by up to 50% and reduce fulfillment costs by about 25%. Automation also helps cover the shortage of truck drivers, which is expected to reach 160,000 in the U.S. by 2030.

Evidence Type | Description |

|---|---|

AI Automation Benefits | AI-powered robots can reduce warehouse processing time by up to 50% and fulfillment costs by approximately 25%. |

Workforce Reskilling | Amazon has reskilled over 700,000 employees globally through its Upskilling 2025 program. |

Labor Gap Coverage | AI helps address the projected shortage of 160,000 truck drivers in the U.S. by 2030. |

You notice that 41% of supply chain leaders use robotics and automation now. Experts predict this number will jump to 83% in five years. Inventory and network optimization technologies have a current adoption rate of 58%, and this is expected to reach 92% soon.

Automation helps you keep up with demand and reduce mistakes.

You can use logistics industry analysis and insights to choose the best automation tools for your business.

Training your team to work with new technology makes your operations stronger.

You prepare your business for the future when you invest in automation and upskilling. This helps you stay competitive and meet customer needs.

Sustainability in Logistics

Green Transportation

You play a key role in making logistics greener. Many companies now use electric and hybrid vehicles to lower greenhouse gas emissions. Electric trucks work well for short trips, while hybrid vehicles help with longer routes. This shift reduces your reliance on fossil fuels and helps the environment. You also save money because electric vehicles have fewer moving parts and need less maintenance.

Logistics companies use new technology to make transportation even cleaner. Real-time tracking helps drivers find better routes, which cuts emissions by up to 30%. Trucks get alerts if they idle too long, so you waste less fuel. Sensors monitor the condition of goods, which prevents spoilage and stops extra emissions from wasted products.

Initiative | Description | Impact on Emissions |

|---|---|---|

Optimized Routes | Real-time tracking suggests better routes for drivers. | Cuts transportation emissions by 20-30%. |

Idle Time Management | Alerts for trucks idling too long to reduce fuel waste. | Reduces fuel waste significantly. |

Condition Monitoring | Sensors prevent spoilage and waste of products. | Prevents food waste emissions. |

You see big brands making changes too. IKEA’s Sydney warehouse now uses solar energy for 70% of its operations. Uber Freight works with Tesla to make electric trucks more affordable and gives fleets access to charging networks. The International Maritime Organization has set rules to cut ship emissions to net zero by 2050, so you must follow new standards and invest in green solutions.

Sustainable Supply Chains

You can build a sustainable supply chain by tracking key metrics. These include your carbon footprint, energy use, water usage, waste generation, recycling rates, and how your suppliers perform on sustainability.

Metric | Description |

|---|---|

Carbon Footprint | Total greenhouse gas emissions from your supply chain. |

Energy Consumption | Total energy used in your operations. |

Water Usage | Total water consumed in your processes. |

Waste Generation | Total waste produced by your activities. |

Recycling Rates | Percentage of waste recycled or diverted from landfills. |

Supplier Sustainability Performance | How well your suppliers follow sustainable practices. |

You can save money by using recycled packaging and optimizing routes. Customers want brands that care about the planet, so you meet their demands by making your operations greener. When you focus on sustainability, you improve your logistics and help protect the environment for the future.

Tip: Start small by measuring your carbon footprint and recycling rates. You will see progress and inspire others in your industry.

Micro-Fulfillment and Last-Mile Delivery

Urban Logistics

You see cities changing fast because of e-commerce growth. Companies now use micro-fulfillment centers to store goods closer to customers. This helps you deliver packages faster and reduces travel distance. The micro-fulfillment market is expected to reach $9.3 billion in 2025, growing quickly each year. The last-mile delivery market will reach $170.6 billion in 2025, showing how important fast delivery has become.

Micro-fulfillment centers bring products closer to urban customers.

Last-mile delivery services grow as more people shop online.

You use new tools to make urban logistics better. Route optimization software helps you find the best path for each delivery. Drones and delivery robots move packages quickly and avoid traffic jams. Autonomous vehicles help you deliver more packages with fewer workers. Electric vehicles and bike couriers lower pollution and make deliveries greener. Companies also use smart packaging to reduce waste.

Note: You can switch to cargo bikes for last-mile delivery. This lowers emissions and helps you reach places regular trucks cannot.

Customer Experience

You improve customer experience by making deliveries faster and more reliable. People want their packages quickly and expect accurate updates. Real-time tracking lets customers see where their package is at any moment. Proactive communication reduces worry and builds trust.

Speed and reliability make customers happy.

Transparency helps customers feel confident.

Smart lockers and mobile apps give customers more control over their deliveries.

Eco-friendly delivery options attract people who care about the environment.

Customer Experience Factor | How It Helps You Succeed |

|---|---|

Timeliness & Reliability | Builds trust and meets delivery expectations |

Flexibility & Convenience | Increases satisfaction with more delivery choices |

Transparency & Updates | Reduces anxiety and improves communication |

Quality of Service | Creates positive impressions with courteous staff |

You see that better last-mile delivery leads to loyal customers. When you offer flexible options and keep people informed, you stand out in the crowded logistics market. 🚚

AI and Data-Driven Decisions

Predictive Analytics

You see AI and predictive analytics changing logistics in 2025. These tools help you forecast demand and optimize inventory. You use historical data and machine learning to spot patterns. This lets you plan ahead and avoid surprises. Predictive analytics helps you reduce costs by preventing overstock and shortages. You can also improve customer service because you know what your customers need before they ask.

You move from reacting to problems to stopping them before they happen. Predictive analytics gives you real-time insights. You can adjust your supply chain quickly when you see trends. This proactive approach makes your business stronger and more reliable. You save money and keep customers happy.

Tip: You can use predictive analytics to streamline your supply chain and make smarter decisions every day.

Operational Efficiency

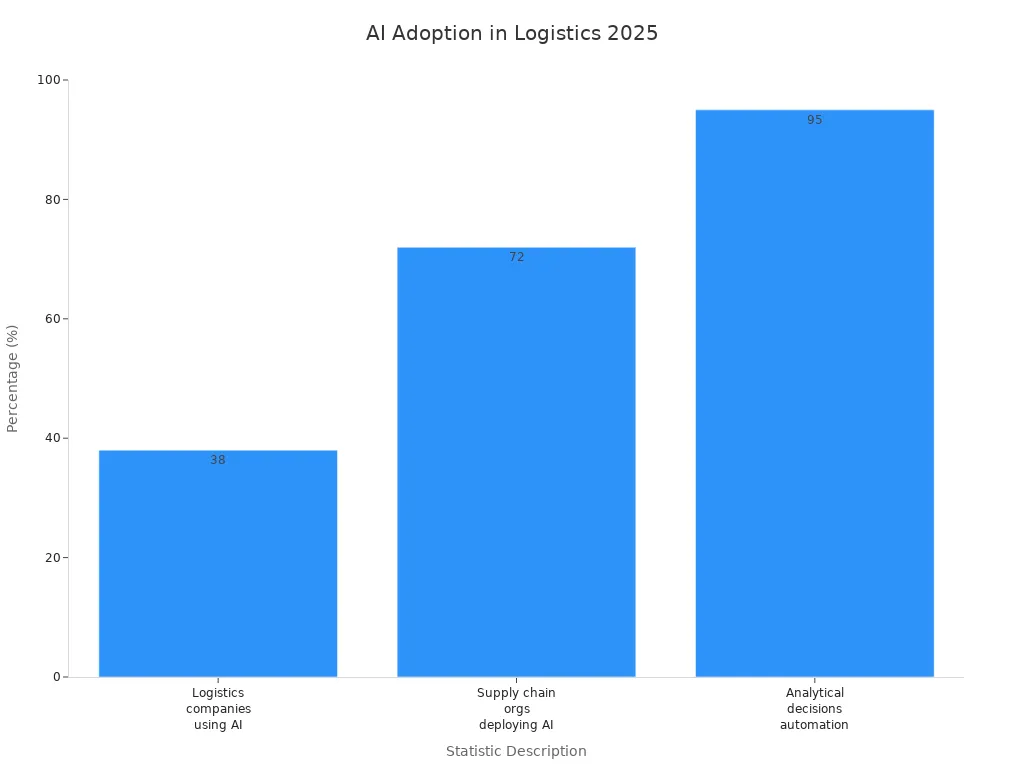

You boost operational efficiency when you use AI and data-driven decisions. More logistics companies now rely on these technologies. The numbers show how fast adoption is growing:

Statistic Description | Percentage |

|---|---|

38% | |

Supply chain organizations deploying AI | 72% |

Expected analytical decisions involving automation | 95% |

38% of logistics companies use AI solutions.

72% of supply chain organizations deploy AI in at least one business function.

By 2025, 95% of analytical decisions will involve automation.

You use AI to automate routine tasks and speed up operations. Machine learning helps you find the fastest routes and best delivery times. You can track shipments and spot delays before they affect customers. AI also helps you manage inventory and reduce waste. You make better decisions with data, which leads to lower costs and higher profits.

Note: You stay ahead in logistics when you use AI and data-driven tools to improve efficiency and customer satisfaction.

Resilience and Risk Management

You face many risks in the logistics world. Disruptions can come from natural disasters, political changes, or sudden demand spikes. Building resilience helps you keep your supply chain strong, even when problems arise. You need to plan ahead and use smart tools to protect your business.

Disruption Mitigation

You can take steps to reduce the impact of disruptions. Start by working with reliable partners. Strategic partnerships give you more options when things go wrong. Train your employees often so they know how to handle emergencies. Look at your supply chain as a whole. This helps you spot weak points before they cause trouble. Use IoT devices to get real-time data and respond quickly.

Strategy | Description |

|---|---|

Build strategic partnerships | Collaborating with reliable partners ensures a more robust supply chain, providing alternative resources in crises. |

Invest in employee training | Regular training programs empower employees to handle disruptions proactively. |

Adopt a holistic view of the chain | Viewing the supply chain as a whole helps identify potential risks and vulnerabilities across the network. |

Enhance visibility with IoT | Integrating IoT devices provides real-time data, improving transparency and enabling quicker responses. |

You can also diversify your supply chain. Work with different suppliers so you do not depend on just one. Map out your supply chain to understand every link. This makes it easier to find and fix problems.

Tip: Digital tools like predictive analytics help you spot risks early. Real-time data visualization lets you track shipments and inventory, so you can act fast if something goes wrong.

Building Robust Operations

You need strong operations to survive in a changing world. Companies with diverse supplier networks recover from disruptions 30% faster than those with only one source. Build a flexible supply chain that can adapt to new challenges. Use different suppliers and transport routes to lower your risk. Always have a backup plan ready.

Build a flexible and resilient supply chain.

Diversify suppliers and transport routes.

Prepare contingency plans for emergencies.

Use technology for real-time visibility and quick action.

You can follow these steps to make your logistics operations stronger. When you plan ahead and use digital tools, you protect your business from surprises. This approach keeps your supply chain running smoothly, even in tough times.

Customer-Centric Logistics

Personalization Trends

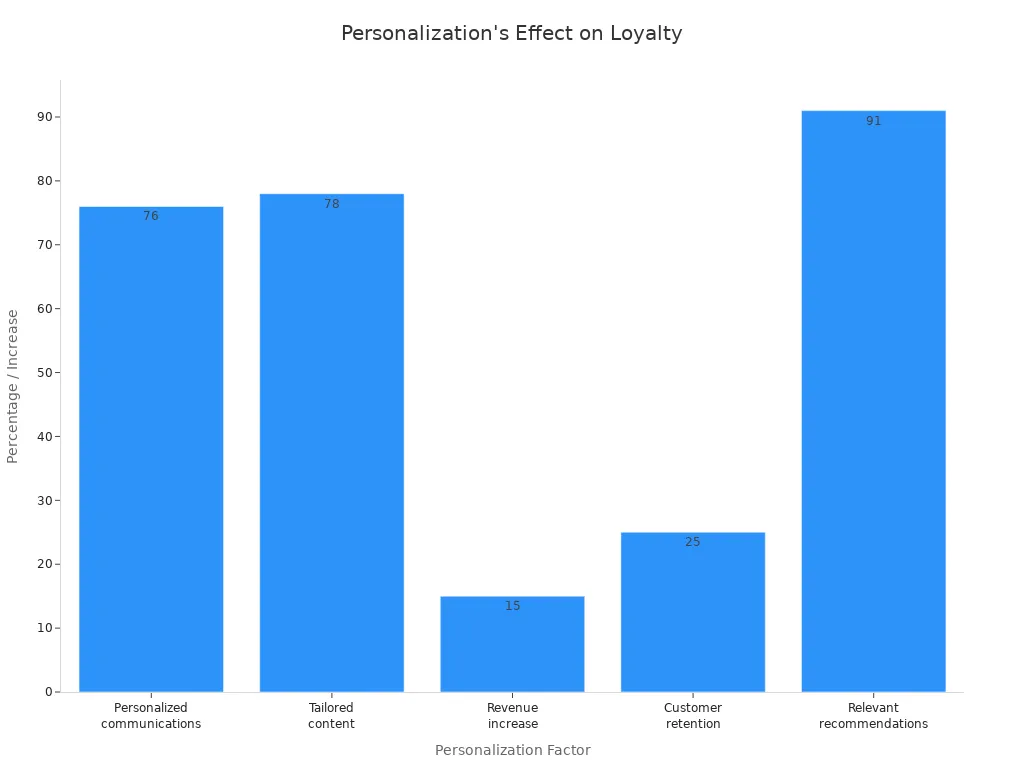

You see personalization changing how you serve your customers in logistics. When you tailor your services, you make each customer feel special. People want brands to understand their needs and give them relevant choices. You can use data to learn what your customers like and offer them better delivery options. Personalized messages and recommendations help you build strong relationships.

Statistic | Implication |

|---|---|

76% of consumers say personalized communications influence their decision to consider a brand | Personalization attracts new customers. |

78% are more likely to repurchase when receiving tailored content | Personalized services encourage repeat purchases. |

Personalization can increase revenue by 10–15% | You can grow your business with tailored experiences. |

Improve customer retention by 25% | Customers stay loyal when you meet their needs. |

91% of consumers are more likely to shop with brands offering relevant recommendations | Relevant suggestions build trust and connection. |

You notice that personalization leads to a 25% increase in retention rates. Over half of consumers stay loyal to brands that offer personalized experiences. Most people say understanding their needs makes them want to return.

Tip: You can use customer feedback and order history to create personalized delivery options and messages.

Real-Time Communication

You improve customer satisfaction when you provide real-time updates. Customers want to know where their packages are and when they will arrive. You can use technology to keep them informed every step of the way. Real-time communication builds trust and helps you solve problems quickly.

Real-time visibility and communication make customers feel secure.

You stand out in the market by focusing on customer needs.

Better planning and resource allocation reduce delays.

Technology | Description |

|---|---|

Cloud-based platforms | Centralize data and give instant access to shipment information. |

IoT sensors | Track goods and send continuous updates to customers. |

Artificial Intelligence (AI) | Analyze data to improve forecasting and efficiency. |

Blockchain technology | Secure transactions and verify data in real time. |

Show end-to-end shipment status. | |

Advanced analytics | Process data quickly for smart decisions. |

Augmented connected workforce (ACWF) | Digital tools help teams make accurate decisions and boost productivity. |

You see that companies who exceed customer expectations gain loyalty and recommendations. Real-time communication helps you plan better and use resources wisely. You can use these technologies to make your logistics operations more efficient and customer-friendly.

Note: When you focus on customer-centric logistics, you gain a competitive advantage and improve your brand reputation. 😊

You see major trends like supply chain visibility, automation, and sustainability shaping logistics in 2025. Agility and technology adoption help you stay ahead. You can map supply chains to Tier 4, use predictive analytics, and integrate global systems. You improve flexibility by highlighting alternative product flows. You protect your business by addressing cybersecurity threats. You boost performance by collaborating with partners and using digital freight platforms. Regular industry analysis keeps your strategies strong.

FAQ

What is supply chain visibility and why does it matter?

Supply chain visibility lets you track goods in real time. You see where shipments are and spot problems early. This helps you make quick decisions and keeps customers informed.

How does automation help with labor shortages?

Automation uses robots and smart machines to handle tasks. You fill gaps when you cannot find enough workers. You also speed up operations and reduce mistakes.

What are micro-fulfillment centers?

Micro-fulfillment centers store products close to customers in cities. You deliver packages faster and lower transportation costs. These centers help you meet rising demand for quick delivery.

How can you make logistics more sustainable?

You switch to electric vehicles and use recycled packaging. You optimize delivery routes to cut emissions. You track your carbon footprint and choose suppliers who follow green practices.

Why is customer transparency important in logistics?

Customers want to know where their orders are. You build trust by sharing updates and delivery times. Clear communication leads to happier customers and repeat business.

See Also

Enhancing Global Operations Through Innovative Logistics Strategies

Key Strategies for Effective Global Logistics Administration

Prepare for Holiday Demand with PGL’s Logistics Services

Optimizing East Coast Imports with Premier Logistics Solutions

Boosting Global Efficiency with Point-to-Point Logistics Systems