Emerging Logistics Industry Trends Transforming Operations in 2025

The logistics industry update may 2025 highlights major changes in operational practices. Companies invest heavily in technology to boost supply chain visibility and agility. Only 43% of organizations see beyond tier 1 suppliers, while 55% plan to upgrade systems. Sustainability drives strategic decisions, with 45% prioritizing green initiatives. The table below shows the most influential trends shaping logistics this year:

Trend | Description |

|---|---|

Supply Chain Visibility | Improves transparency and tracking across operations. |

Internet of Things | Enables real-time data collection with smart devices. |

Artificial Intelligence | Powers predictive analytics and process improvements. |

Circular Economy | Advances sustainability in logistics practices. |

Key Takeaways

Invest in technology like AI and IoT to improve supply chain visibility and efficiency.

Focus on sustainability by adopting green practices and using electric vehicles to reduce emissions.

Enhance agility in operations by optimizing inventory and building strong supplier relationships.

Prepare for disruptions with scenario planning and strong risk management strategies.

Upskill your workforce to adapt to new technologies and improve job satisfaction.

Logistics Industry Update May 2025: Key Trends

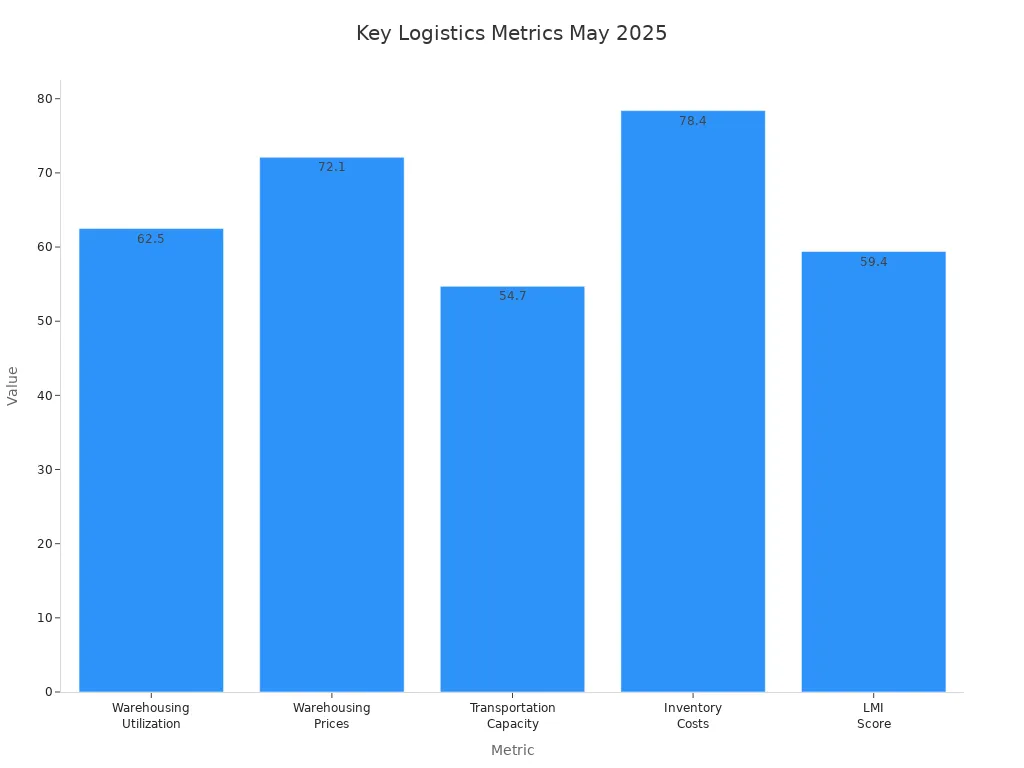

The logistics industry update may 2025 reveals several important shifts in operational performance. Warehousing utilization increased to 62.5, showing a positive trend. Warehousing prices remain elevated at 72.1, while transportation capacity tightened to 54.7. Inventory costs rose, and the Logistics Managers' Index (LMI) score reached 59.4, signaling stabilization across logistics activities.

Metric | May 2025 Value | Change from April 2025 | Change from May 2024 |

|---|---|---|---|

Warehousing Utilization | 62.5 | +2.4 | -1.5 |

Warehousing Prices | 72.1 | -0.2 | +7.6 |

Transportation Capacity | 54.7 | -0.5 | -2.6 |

Inventory Costs | 78.4 | +2.8 | N/A |

LMI Score | 59.4 | +0.6 | N/A |

Supply Chain Visibility & IoT

The logistics industry update may 2025 highlights rapid adoption of IoT and visibility platforms. Companies use smart sensors to monitor temperature and humidity, track fleet locations, and predict maintenance needs. IoT-powered sensors in fleet management detect vehicle health issues, preventing breakdowns and ensuring safe delivery of perishable goods.

In fleet management, IoT-powered sensors monitor vehicle health, detecting maintenance needs, and preventing unexpected breakdowns. Temperature-controlled IoT solutions ensure the safe transportation of perishable goods, preventing spoilage and maintaining quality throughout their journey.

Advancement Type | Description | Impact on Logistics |

|---|---|---|

Visibility Platforms | Consolidate data from carriers, suppliers, and distribution centers. | Creates a single source of truth. |

IoT Sensors | Includes RFID tags and AI-powered sensors for real-time visibility. | Potential to cut warehouse costs by 20%. |

Fleet Management IoT | Monitors vehicle health and detects maintenance needs. | Prevents unexpected breakdowns. |

Temperature-Controlled IoT | Ensures safe transportation of perishable goods. | Maintains quality throughout the journey. |

Data Analytics & Real-Time Tracking

Data analytics and real-time tracking drive smarter decision-making in the logistics industry update may 2025. Companies use platforms like Overhaul, Fourkites, Shippeo, Shipsy, and Tive for predictive analytics, shipment alerts, and condition monitoring. Real-time analytics help businesses respond instantly to market changes, adjust delivery routes, and prevent equipment breakdowns.

Real-time analytics allows businesses to respond instantly to market changes, enhancing speed and efficiency.

A logistics company can adjust delivery routes based on current traffic data, improving accuracy and customer satisfaction.

Proactive problem-solving is exemplified by a manufacturing plant that monitors equipment performance in real-time to prevent breakdowns.

Platform | Key Features |

|---|---|

Overhaul | User-friendly interface, compliance tools, performance benchmarking. |

Fourkites | Predictive analytics, comprehensive tracking, collaboration tools, shipment alerts. |

Shippeo | Advanced technology for real-time insights, predictive analytics, detailed reporting, sustainability focus. |

Shipsy | AI and automation for supply chain visibility, real-time tracking, personalized delivery options. |

Tive | IoT devices for tracking sensitive goods, real-time condition monitoring, intuitive interface. |

Agility in Operations

Agility remains a top priority in the logistics industry update may 2025. Companies streamline warehouse management, optimize inventory, and build strong supplier relationships. These strategies enable faster delivery times, improved customer trust, and greater resilience during disruptions.

Benefit | Description |

|---|---|

Faster delivery times | Accelerated response to shifting demands. |

Improved customer trust | Reliability in challenging conditions. |

Operational efficiency | Maximizing truck utilization and yard space. |

Crisis resilience | Staying ahead despite global disruptions. |

Flexibility in capacity based on fluid forecasts.

Better positioning and adaptability.

Enhanced resilience in the face of disruptions.

The logistics industry update may 2025 sets the stage for deeper exploration of these trends, guiding companies toward smarter, more resilient operations.

Tech Innovations in Logistics

Generative AI & Orchestration

Generative AI is transforming logistics operations in 2025. Companies use AI to connect data, streamline decision-making, and optimize supply chain performance. AI platforms now move beyond pilot projects, delivering measurable returns and supporting innovation priorities for the coming year.

AI absorbs real-time variables, such as weather and port congestion, and recommends optimal actions faster than human planners. This technology automates repetitive cognitive tasks, boosting workforce productivity and reducing logistics costs.

Application Area | Description |

|---|---|

System-of-systems integration | AI brings data, operations, and decision-making onto a common platform for supply chain optimization. |

Fleet performance analysis | AI analyzes fleet performance and simulates fuel consumption. |

Real-time variable absorption | AI absorbs variables like weather and port congestion to recommend optimal actions. |

Generative AI automates over 90% of logistics managers' tasks, improving operational efficiency and reducing labor costs per interaction.

Companies report that generative AI improves customer satisfaction by providing timely updates and answers to inquiries. It also suggests cost-effective routes, minimizing waste and enhancing daily operations.

Automation & Robotics

Automation and robotics drive productivity and cost efficiency in logistics. Facilities equipped with automated systems process thousands of orders per hour with minimal human input. Robotics lower labor costs and minimize costly human errors.

AI-driven quality checks ensure precise picking and packing, leading to fewer returns. Automated systems scale easily during peak times, supporting business growth without extensive hiring.

Evidence Type | Description |

|---|---|

Faster Order Processing | Automation enables facilities to handle thousands of orders per hour with minimal human input. |

Reduced Operational Costs | Robotics can significantly lower labor costs and minimize costly human errors. |

Scalability | Automated systems can easily increase capacity during peak times without extensive hiring. |

Enhanced Accuracy | AI-driven quality checks ensure precise picking and packing, leading to fewer returns. |

Productivity Improvement | Businesses implementing automation can achieve up to a 48% increase in productivity. |

Cost Reduction | Companies can see a 42% decrease in operating costs through automation. |

Human-Machine Collaboration | Projected to enhance productivity by up to 30%. |

Digital Twins

Digital twins offer real-time visibility and predictive insights for logistics networks. Companies use digital twins to model warehouse layouts and transportation routes, enabling smarter planning and proactive maintenance scheduling.

A European logistics company reduced delivery delays by 22% and fuel consumption by 18% by modeling distribution routes with digital twins. Large corporations manage global supply chains more effectively, identifying inefficiencies and optimizing delivery times.

Digital twins improve picking productivity and transportation cost savings.

Real-time insights help optimize routes, reduce fuel consumption, and enhance uptime.

When the weighted effectiveness of a digital twin model exceeds 90%, logistics operations see fewer delays and lower costs.

Digital twins allow logistics networks to adapt quickly to disruptions, such as power outages, by simulating alternate delivery scenarios. The logistics industry update may 2025 highlights these innovations as essential for future-ready operations.

Workforce & Labor Trends

Labor Shortages & Automation Response

Logistics companies in 2025 face a persistent talent gap. Many workers retire, and job expectations change quickly. Companies respond by investing in automation and outsourcing. Automated systems handle repetitive tasks, such as sorting and picking, which reduces the need for manual labor. Outsourcing fills critical staffing gaps quickly and cost-effectively.

Companies adopt automation to improve efficiency and lessen dependence on human labor.

Outsourcing helps organizations maintain operations during peak demand.

The industry sees a shift toward technology-driven roles.

A recent survey highlights several workforce challenges:

Trend | Description |

|---|---|

Employees experience lower morale, which impacts productivity and retention. | |

Skepticism Toward AI | Distrust in AI technologies grows, affecting employee acceptance. |

Increase in Employee Attrition | Higher turnover rates create staffing challenges. |

Tension Around Returning to Office | Debates about returning to the office cause uncertainty and stress among workers. |

Companies that prioritize automation and flexible staffing models adapt faster to labor shortages.

Workforce Upskilling

Leading logistics firms invest in upskilling programs to prepare employees for new technology. Amazon, Walmart, and DHL offer training and education to help workers advance their careers. These programs focus on technical skills, logistics management, and continuous learning.

Company | Program Description | Investment/Details |

|---|---|---|

Amazon | Technical academy and Career Choice for tuition assistance | $700 million to upskill 100,000 employees by 2025 |

Walmart | Education program for associates to earn degrees | Over 100,000 associates enrolled, costs $1 per day |

DHL | Global training initiative for international logistics | Continuous learning to meet customer demands |

Employees who participate in upskilling programs gain new skills and improve job satisfaction. Companies benefit from a more capable workforce and higher retention rates.

Remote Operations

Remote operations become more common in logistics. Advanced technologies enable teams to manage supply chains from anywhere. Robotics and automation handle warehouse tasks, while blockchain provides transparency and traceability. Artificial intelligence analyzes data for better forecasting, and IoT sensors deliver real-time updates. Transportation Management Systems optimize routes and track shipments.

Technology | Description | Benefits |

|---|---|---|

Robotics and Automation | Automates tasks like picking, sorting, and delivery. | Increases efficiency, reduces human error, lowers labor costs. |

Blockchain | Provides transparency and traceability in the supply chain. | Enhances trust, simplifies customs, allows real-time tracking of goods. |

Artificial Intelligence (AI) | Analyzes data for better demand forecasting and supply chain management. | Optimizes routes, improves customer service, enables predictive maintenance. |

Internet of Things (IoT) | Uses sensors for real-time data on logistics variables. | Improves visibility, ensures safe transport of goods, enhances warehouse efficiency. |

Transportation Management System (TMS) | Manages transportation activities like route planning and shipment tracking. | Reduces costs, improves delivery times, optimizes routes. |

Logistics teams that embrace remote operations and digital tools achieve greater flexibility and resilience in 2025.

Sustainability & Green Logistics

Autonomous & Electric Vehicles

Logistics companies in 2025 focus on reducing emissions by adopting autonomous and electric vehicles. Electric trucks now handle many short-haul routes, driven by both environmental and economic benefits. Autonomous vehicles expand their reach, with driverless runs on major freeways becoming more common. New regulations, such as the EPA Phase-3 Heavy-Duty Vehicle rules, require up to 60% CO₂ reduction by 2032. Many cities introduce zero-emission zones and green freight corridors to support cleaner transport.

In Europe, DPDHL aims to operate 70% of its first and last-mile services with clean pick-up and delivery solutions by 2025.

Initiative | Description |

|---|---|

Electric Vehicles (EVs) | Adoption of EVs in logistics, supported by programs like Uber Freight's EV Fleet Accelerator. |

Sustainable Aviation Fuel (SAF) | SAF can reduce life cycle carbon emissions by up to 80%, with companies like DHL committing to its use. |

Compliance with Environmental Regulations | New regulations driving companies to adopt greener practices in logistics. |

Micro-Fulfillment Centers

Micro-fulfillment centers help companies lower emissions and speed up deliveries. These small, automated warehouses sit close to urban customers. They use robotics and smart warehousing to process orders quickly and reduce energy use. Companies benefit from lower transportation costs and less traffic congestion. Smart warehousing also supports sustainability by using less energy and optimizing space.

Micro-fulfillment centers use automation and robotics to boost efficiency.

Companies reduce delivery distances, which cuts fuel use and emissions.

Smart warehousing lowers energy consumption and supports green goals.

Circular Supply Chains

Many logistics firms move from linear to circular supply chains to improve sustainability. Circular logistics keeps resources in use longer and reduces waste. Companies use reusable packaging and multi-use containers to minimize environmental impact. Technology helps track and optimize these supply chains, making them more efficient.

Companies focus on efficiency and sustainability by adopting circular models.

Reusable packaging and containers become standard in logistics operations.

Regulatory frameworks encourage the shift to circular practices.

Circular supply chains help companies meet new environmental standards and build a greener future for logistics.

Risk Management & Resilience

Scenario Planning

Logistics firms in 2025 rely on scenario planning to prepare for unexpected disruptions. They use digital tools to map out hypothetical situations, which helps them adapt quickly when challenges arise. Anticipating difficulties allows teams to create action plans that minimize impact and speed up recovery. Companies establish specific response procedures, so decision-makers avoid improvisation during a crisis. This approach accelerates action and reduces confusion.

Mapping out possible disruptions helps organizations adapt faster.

Action plans based on scenarios minimize downtime and losses.

Clear procedures support quick, confident decisions in emergencies.

Digital transformation and data availability support these efforts. Many firms now prioritize executive oversight and dedicated risk management teams. They favor incremental strategy adjustments over full overhauls, building long-term resilience step by step.

Cybersecurity

Cybersecurity remains a top concern for logistics companies. In 2025, threats like ransomware, data breaches, denial-of-service attacks, and supply chain attacks target the industry. Ransomware accounts for most cyber incidents in the transport sector, with strains such as Akira and Cl0p causing significant disruptions. These attacks can halt operations and expose sensitive data.

Ransomware and data breaches threaten daily logistics activities.

Denial-of-service attacks disrupt digital platforms and tracking systems.

Supply chain attacks target partners and vendors, spreading risk.

Companies respond by investing in advanced security tools and regular employee training. They monitor systems for unusual activity and update defenses often. Leadership teams oversee cybersecurity strategies, ensuring alignment with business goals.

Supply Chain Disruption Response

Logistics firms build resilience by strengthening relationships with suppliers and customers. Mutual trust enables open communication about potential disruptions. High-trust partnerships support joint scenario planning and faster responses. Proactive decision-making, supported by predictive analytics, helps organizations stay ahead of risks.

Digital tools monitor disruption indicators and enable early risk anticipation.

Integrating risk insights with financial models supports informed choices.

Automation reduces errors in trade document management and ensures compliance.

Using multiple suppliers lowers dependency and increases flexibility.

Real-time monitoring and data analytics identify risks before they escalate.

By combining technology, strong partnerships, and clear procedures, logistics companies in 2025 create robust systems that withstand disruptions and maintain smooth operations.

Market & Regulatory Shifts

Trade Policy Changes

Logistics companies in 2025 face new challenges from shifting trade policies. Many leaders identify rising tariffs and trade barriers as their top concern. Brands see global container volumes decline because of geopolitical tensions and US tariffs. These changes force companies to rethink their logistics strategies. Nearshoring gains popularity as organizations move manufacturing closer to the US to reduce tariff impacts. The demand for waterway transportation grows, offering cost efficiency and helping firms adapt to changing trade routes.

The e-commerce logistics market is projected to exceed $535 billion in 2025, driven by higher fuel prices and a shortage of drivers.

Geopolitical tensions and tariffs cause brands to reconsider their logistics strategies.

Nearshoring helps companies mitigate tariff impacts.

Waterway transportation becomes more attractive for cost savings.

Logistics firms respond to increased online shopping with advanced technologies and smarter workforce strategies.

Evidence Type | Description |

|---|---|

Trade Policy Challenges | 48% of logistics leaders cite rising tariffs and trade barriers as their top challenge. |

Impact of Tariff Changes | Businesses face greater volatility as tariff changes disrupt supply chains and operational costs. |

ESG Compliance

Environmental, Social, and Governance (ESG) compliance shapes logistics operations in 2025. Many organizations rank ESG as their number one international trade challenge. Companies must meet stricter regulations and report on sustainability efforts. This shift encourages investment in green technologies and transparent supply chains. Firms that prioritize ESG compliance gain trust from customers and partners. They also reduce risks related to environmental penalties and reputational damage.

Evidence Type | Description |

|---|---|

ESG Compliance Concerns | 44%-47% of mid-size to large organizations view ESG compliance as their number one international trade challenge. |

Companies that invest in ESG compliance build stronger relationships with stakeholders and improve long-term resilience.

Freight Rate Volatility

Freight rate volatility remains a major issue for logistics firms. Tariff changes and fuel price fluctuations create uncertainty in shipping costs. Businesses must monitor market trends and adjust budgets quickly. Advanced analytics help companies forecast rate changes and plan for unexpected expenses. Many organizations diversify transportation modes to manage risks and maintain service levels.

Evidence Type | Description |

|---|---|

Impact of Tariff Changes | Businesses face greater volatility as tariff changes disrupt supply chains and operational costs. |

Logistics leaders use technology and flexible strategies to navigate freight rate volatility and protect profit margins.

Logistics leaders see technology, sustainability, and resilience as key drivers of change in 2025. These trends reshape daily operations and create new opportunities for growth. Companies must act quickly and embrace innovation to stay competitive.

Proactive adaptation ensures long-term success in a fast-changing market.

Practical Recommendations:

Invest in AI, automation, and IoT for better visibility and efficiency.

Build strong risk management strategies to handle disruptions.

Adopt green logistics practices to meet regulatory demands and customer expectations.

FAQ

What is supply chain visibility and why does it matter in 2025?

Supply chain visibility means tracking goods and data at every step. Companies use sensors and software to see shipments in real time. This helps them avoid delays and improve customer trust.

How do logistics firms use generative AI?

Generative AI helps logistics teams analyze data, predict problems, and automate tasks. AI suggests better routes and speeds up decision-making. Companies save time and reduce costs.

Why are micro-fulfillment centers important for green logistics?

Micro-fulfillment centers sit close to customers. They use robots and smart systems to process orders quickly. Companies lower emissions and reduce delivery times.

What steps do companies take to manage supply chain risks?

Strategy | Benefit |

|---|---|

Scenario planning | Faster response |

Cybersecurity training | Fewer data breaches |

Multiple suppliers | More flexibility |

How do trade policy changes affect logistics operations?

Trade policy changes can raise costs and slow shipments. Companies adapt by moving production closer to customers and using new transport routes.

See Also

Enhancing Global Operations Through Innovative Logistics Strategies

Key Strategies for Effective Management of Global Logistics

Optimizing East Coast Imports with Premier Logistics Solutions

Prepare for Holiday Demand with PGL’s Logistics Services

Boosting Global Efficiency with Point-to-Point Logistics Systems