How to Optimize Logistics Warehouse Operations for Maximum Efficiency

You can optimize logistics warehouse operations by focusing on efficiency, accuracy, and productivity. Logistics warehouse optimization means using smart systems, better layouts, and technology to make every step faster and more reliable. Recent studies show that when you improve efficiency, you boost supply chain performance. For example:

Strategy Used | Benefit for Supply Chain |

|---|---|

Robotic solutions | Faster, more accurate, lower cost |

Predictive analytics | |

End-to-end visibility | Quicker response, happier customers |

Slotting optimization tools | Faster restocking, more output |

Assess your current processes and stay open to new best practices for stronger results.

Key Takeaways

Focus on efficiency to save time and money. Streamlined processes lead to happier customers and lower operational costs.

Utilize smart technology like warehouse management systems and robotics. These tools enhance accuracy and speed in order fulfillment.

Optimize your warehouse layout by placing high-demand items in accessible areas. This reduces travel time and increases productivity.

Regularly track key performance indicators (KPIs) to measure progress. Monitoring helps identify issues and improve warehouse operations.

Stay updated on industry trends like automation and sustainability. Adapting to new practices keeps your warehouse competitive and efficient.

Logistics Warehouse Optimization Essentials

Defining Warehouse Optimization

You can think of logistics warehouse optimization as a way to make your warehouse work smarter, not harder. Leading companies define it as reviewing and improving every part of your warehouse operations. This means you look at how you use space, how you pick and pack items, and how you restock shelves. The goal is to boost productivity and lower costs. When you focus on logistics warehouse optimization, you also try to speed up every process and cut out waste. Many companies use advanced systems like warehouse management systems (WMS) and robotics to help with this.

Industry experts say you should pay attention to these core components:

Supply chain optimization

Transportation management

Inventory management

Performance metrics and monitoring

Key performance indicators (KPIs)

Data analysis and reporting

Role of technology

Warehouse layout and design

Warehouse storage and inventory management

Material handling equipment and systems

When you work on these areas, you set up your warehouse for better results and smoother operations.

Why Efficiency Matters

Efficiency is the key to success in logistics warehouse optimization. When you make your warehouse more efficient, you save money and time. You also make your customers happier because you can get products to them faster and with fewer mistakes. Companies that focus on efficiency often see big benefits:

Benefit | Description |

|---|---|

You cut waste, reduce errors, and use your team better, which saves money over time. | |

Improved Order Fulfillment | You pick, pack, and ship the right products, so you have fewer returns and mistakes. |

Better Space Utilization | You store more products without needing a bigger building. |

Enhanced Inventory Accuracy | You keep better records, so you avoid running out of stock or having too much. |

Scalability | You can handle more orders as your business grows, without starting over. |

Sustainability | You use less energy and create less waste, which is better for the environment. |

You also boost customer satisfaction by making sure products are available and delivered on time. Streamlined processes help you avoid shipping delays. When you optimize your resources, you lower labor costs and speed up order fulfillment. This leads to higher profits and a stronger reputation for your business.

Warehouse Space Optimization

Layout and Slotting Strategies

You can make your warehouse more efficient by focusing on how you arrange products and design your layout. A well-organized warehouse layout helps you reduce picking errors and use space better. This approach lets you manage resources wisely and delay expensive expansions. Place heavy or large items on lower shelves to keep workers safe and reduce accidents. Adjust item placement based on demand patterns to keep your warehouse running smoothly all year.

Place high-velocity items in the 'golden zone' for easy access.

Group items that are often picked together to cut down on travel time.

Use data-driven slotting, like ABC classification, to put fast-moving products in prime spots.

These strategies can cut travel time by up to 55%. You will see faster picking and fewer mistakes.

Balancing Capacity and Flow

You need to balance storage space with smooth workflow. If you do not use space well, you may face cluttered aisles and slowdowns. Seasonal demand changes can also make inventory levels unpredictable. Here are some common challenges:

Challenge | Description |

|---|---|

Can lead to underutilized storage areas and cluttered aisles, resulting in workflow bottlenecks. | |

Adapting to Seasonal Demand | Changing customer demands can lead to volatile inventory, increasing costs and lowering customer satisfaction. |

Managing Inventory Effectively | Poor inventory management can result in misplaced items and underutilized vertical space. |

Many companies use space utilization strategies and dynamic inventory management to improve throughput. Automation and robotics, like the Exotec Skypod system, help you use vertical space and keep operations moving.

Technology for Space Efficiency

Smart technology plays a big role in logistics warehouse optimization. Warehouse management systems (WMS) use real-time data to help you position products for maximum storage and minimum wasted space.

Technology | Impact on Space Utilization |

|---|---|

WMS | Leverages real-time inventory data for strategic product positioning, maximizing storage capacity and minimizing wasted space. |

Reclaims vertical space, boosts storage density, streamlines operations, reduces labor costs, enhances efficiency. |

Automated storage and retrieval systems (AS/RS) use robots to store items in high-density racks. This approach increases cubic capacity and improves order accuracy. When you combine smart systems with good layout strategies, you get the best results for your warehouse.

Streamlining Warehouse Processes

Reducing Touches in Order Fulfillment

You can make your warehouse faster and safer by reducing the number of times workers handle each item. Fewer touches mean less chance for mistakes, damage, or theft. You should track the average number of touches to spot problems in your process. Many companies use automation and warehouse management software to plan the best routes and sequences for picking and putting away items. When you focus on continuous improvement and data-driven decisions, you help your team work smarter and save money. Here are some ways to cut down on touches:

Use automation to move products quickly.

Monitor touches to find and fix slow steps.

Optimize receiving and putaway to speed up picking.

Engage employees and listen to customer feedback for better results.

Tip: Fewer touches lead to faster order fulfillment and happier customers.

Eliminating Redundant Steps

You can boost efficiency by removing steps that do not add value. Start by looking at each part of your workflow and ask if it helps deliver products to customers. Simplify your processes and focus only on what matters. Standardized work procedures make tasks clear and easy to follow. You should design your warehouse with the customer in mind, keeping only features that help meet their needs. Try these methods to remove unnecessary steps:

Simplify processes and focus on value-adding activities.

Standardize work to keep tasks consistent.

Use value stream mapping to spot bottlenecks.

Automate repetitive tasks to save time.

Walk through your warehouse to see where you can improve.

Standardizing Workflows

Standardized workflows help you measure performance and spot problems quickly. When you use clear processes, you make it easier to track packages and orders. This transparency helps you find issues and fix them before they grow. Enforcing standard procedures lowers human error and keeps your warehouse running smoothly. Automation also boosts productivity and helps you reach your logistics warehouse optimization goals. You can:

Set benchmarks for each task.

Make package movement and order fulfillment transparent.

Use automation to keep workflows efficient.

Identify and fix bottlenecks fast.

Note: Standardized workflows lead to fewer errors and higher productivity.

Technology and Automation in Logistics Warehouse Optimization

Robotics and Automation Benefits

You can transform your warehouse by using robotics and automation. These tools speed up order fulfillment and make every process more reliable. Robots help you pick, pack, and ship items faster than manual methods. This means you can handle more orders at once, which is important when customers want quick delivery.

Robots also make your warehouse safer. They take care of heavy lifting and dangerous tasks, so your team can focus on jobs that need problem-solving skills. Automation reduces mistakes, so you lose less inventory and waste fewer resources. You also save money because robots work quickly and do not get tired.

Here is a table that shows the main benefits of using robotics and automation:

Benefit | Description |

|---|---|

Operational Efficiency | You move products faster and restock shelves right away, which helps you offer same-day delivery. |

Labor Management | Robots handle boring or risky tasks, so your team can do more important work. |

Safety | Automation lowers the risk of injuries from lifting heavy items or working with dangerous materials. |

Error Reduction | Automated systems keep inventory records accurate and reduce costly mistakes. |

Cost Optimization | You spend less on labor and avoid losses from errors, so you see a fast return on your investment. |

Customer Satisfaction | Faster and more accurate orders make your customers happy and encourage them to buy again. |

You can also enjoy other advantages:

Flexible automation tools adjust to changes in your workflow or order volume.

Energy-efficient robots help you save power and support sustainability.

Real-time data from automated systems helps you make better decisions and track your progress.

When you use robotics and automation, you see faster order processing, fewer errors, and shorter lead times. These improvements help you reach your logistics warehouse optimization goals.

Smart Warehouse Management Systems

Smart warehouse management systems (WMS) give you control over every part of your warehouse. These systems process orders as soon as they arrive, so you can confirm and ship them quickly. Automation and robotics work together with WMS to speed up picking and packing, which means you can fill more orders in less time.

A WMS helps you use your resources wisely. It assigns tasks based on demand, so you always have the right people and machines working where they are needed most. The system also uses data to help you spot problems and improve your processes. Predictive analytics in a WMS can tell you when to restock, so you never run out of popular items.

Here is a table that shows how smart warehouse management systems improve your operations:

Feature | Impact on Inventory Accuracy and Order Processing Speed |

|---|---|

Orders get processed right away, so you can ship them faster and with fewer mistakes. | |

Automation and Robotics | Automated systems reduce manual work and speed up every step, from picking to shipping. |

Efficient Resource Allocation | The system assigns tasks based on real-time needs, which keeps your team productive and accurate. |

Data-Driven Decision Making | You get insights that help you fix problems and improve speed and accuracy. |

Predictive Analytics | The system predicts what you need to restock, so you avoid delays and keep customers happy. |

Enhanced Customer Experience | Fast and accurate deliveries make your customers trust your business and come back for more. |

When you use a smart WMS, you improve inventory accuracy and order speed. This leads to better customer service and helps your business grow.

Integrating Scalable Solutions

You need scalable technology to keep up with business growth. Scalable solutions let you add new features or handle more orders without starting over. Cloud-based systems help you expand your warehouse operations without buying expensive hardware. Automation tools reduce manual errors and save time, so your team can focus on important tasks.

Scalable solutions also connect with other systems, like e-commerce platforms and shipping services. This makes your operations smoother and helps you manage orders from many channels. You can support multiple users and locations, so your business can grow without limits.

Here are some key features of scalable technology for logistics warehouse optimization:

Cloud-based access lets you grow without big hardware costs.

Process automation cuts down on mistakes and speeds up work.

Integration with other systems keeps your operations connected and efficient.

Support for many users and locations helps you expand easily.

Warehouse optimization software brings everything together. It gives you real-time visibility, reduces picking errors, and improves order fulfillment times. The software can plan the best picking routes, which increases how many orders you can handle each day. You save money on labor and inventory, and you deliver better service to your customers.

Tip: Choose scalable solutions that fit your current needs and can grow with your business. This will help you stay ahead in logistics warehouse optimization and keep your operations running smoothly.

Inventory Efficiency

Inventory Tracking Systems

You need strong inventory tracking systems to keep your warehouse running smoothly. These systems help you know exactly where each item is at any time. You can use barcode scanners, RFID tags, or automated software to track products as they move through your warehouse. Real-time tracking lets you spot missing items fast and helps you avoid costly mistakes. When you use inventory management software, you get instant updates on stock levels. This makes it easier to plan restocking and prevents errors. You also improve order accuracy and customer satisfaction.

Tip: Real-time tracking helps you find problems before they grow and keeps your warehouse organized.

Demand Forecasting

Demand forecasting helps you predict how much stock you need for each season. You use historical sales data and market trends to make smart decisions. This technology keeps your stock levels balanced and matches them to customer demand. You avoid having too much or too little inventory. Demand forecasting supports a resilient supply chain and helps you plan for busy times. You can use predictive analytics to see demand changes before they happen. This reduces risks and keeps your warehouse efficient.

Demand forecasting balances stock levels with market demand.

You avoid revenue loss and protect your reputation.

Accurate forecasting helps you keep the right stock at the right time.

Predictive analytics let you plan for demand changes and avoid costly delays.

Preventing Stockouts and Overstocks

You can prevent stockouts and overstocks by using smart strategies. Start by analyzing historical data and market trends to forecast demand. Review your replenishment policies and adjust thresholds to avoid over-ordering. Use inventory management systems for real-time monitoring. Train your staff in best practices for inventory management. Keep safety stock to prevent running out, but calculate ideal levels to avoid excess. Automated software updates inventory levels instantly and reduces risks. Set up automated reorder points to trigger purchases when stock gets low. Work closely with your sales and marketing teams to understand demand.

Strategy | Benefit |

|---|---|

Data-driven forecasting | Accurate demand predictions |

Real-time inventory management | Timely stock adjustments |

Just-in-Time inventory | Lower holding costs |

Automated reorder points | No guesswork in ordering |

You improve logistics warehouse optimization when you use these strategies. You keep your warehouse efficient and ready for any challenge.

Implementation and Measurement

Step-by-Step Optimization Plan

You can improve your warehouse by following a clear plan. Start by evaluating your current layout and arrangement. Look at how products move through your space. Set goals for how you want your warehouse to work. Make changes that help your team organize better and work faster. Use these steps to guide your process:

Evaluate your existing warehouse layout and arrangement.

Establish clear objectives for your warehouse structure and operation.

Implement changes to enhance your organizational strategy.

You should also set benchmarks for inventory receiving and handling times. Monitor how products flow through your warehouse. Think about how each process affects order fulfillment and delivery speed. These actions help you build a strong foundation for logistics warehouse optimization.

Tip: Review your plan often and adjust as your business grows.

Key Performance Indicators (KPIs)

You need to measure your progress to know if your warehouse is getting better. Key performance indicators show how well your team works and how fast products move. Track these important KPIs:

Receiving Efficiency: Measures how much material you process compared to work hours.

Put-Away Efficiency: Assesses how much stock you move with the effort given.

Put-Away Cycle Time: Tracks how long it takes to finish put-away tasks.

Inventory Accuracy: Compares actual stock with recorded counts.

Inventory Turnover: Shows how quickly items leave your warehouse.

Cost Per Order: Evaluates the total cost to fulfill each order.

Labor Efficiency: Measures employee hours needed for inventory tasks.

Time to Receive: Records how long it takes for inventory to be ready for shipment.

Note: Regularly checking these KPIs helps you spot problems and make smart changes.

Recent Trends in Logistics Warehouse Optimization

You see new trends shaping the future of warehouse operations. Automation brings robots and autonomous vehicles to speed up tasks. Companies use eco-friendly solutions to save energy and reduce waste. Employee wellbeing matters, so ergonomic workstations and career growth get more attention. Space optimization tools like AutoStore help you store more in less space. Advanced technologies, such as AI, improve demand forecasting and real-time inventory management.

Trend | Description |

|---|---|

Automation | Autonomous vehicles and robotics streamline operations and boost efficiency. |

Sustainability | Eco-friendly practices and energy-saving solutions reduce waste. |

Employee Wellbeing | Ergonomic workstations and career development support your workforce. |

Space Optimization | Technologies maximize storage density and minimize aisle space. |

Advanced Technologies | AI improves forecasting and inventory management in real time. |

Companies now balance between large centralized warehouses and smaller facilities closer to customers. The green logistics market grows quickly, showing a shift toward environmental responsibility. Modern Warehouse Execution Systems help you coordinate operations in real time.

Stay updated on these trends to keep your warehouse competitive and efficient.

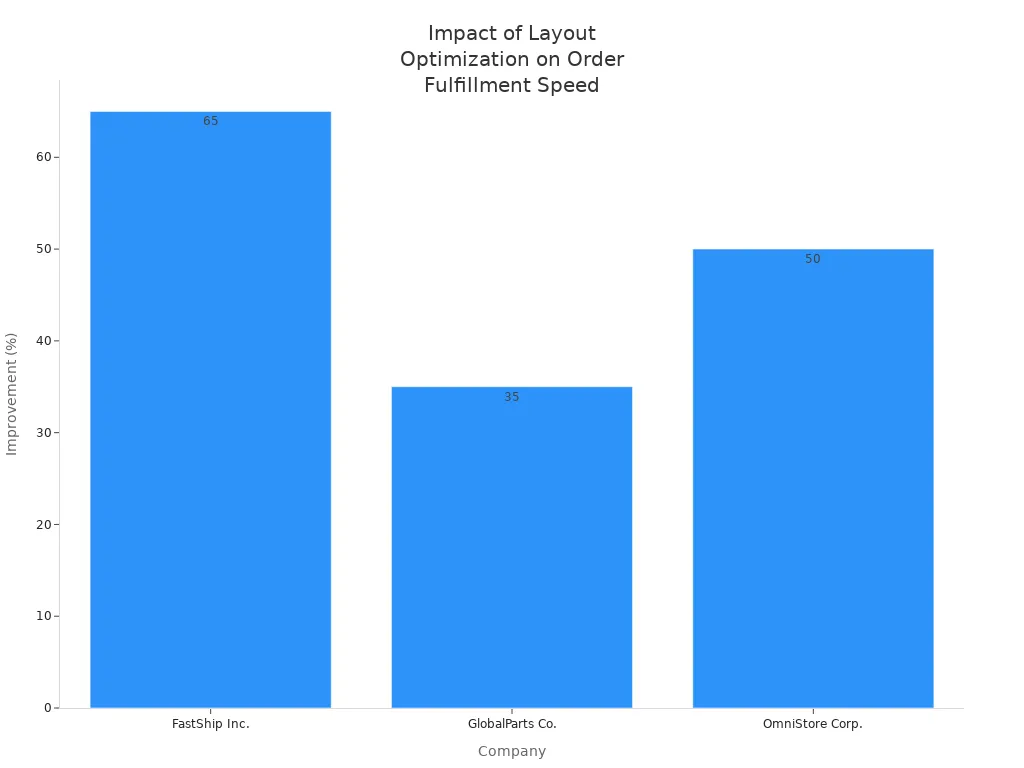

You can achieve logistics warehouse optimization by using smart layouts, automation, and real-time data. When you reduce aisle visits and balance workloads, you process more orders and save money. The table below shows how companies benefit:

Benefit Type | Measurable Improvement |

|---|---|

Labor Cost Reduction | |

Order Accuracy Improvement | Up to 99.5% accuracy |

Energy Efficiency | 20-30% less utility cost |

"You can't manage what you can't measure. Real-time data takes the guesswork out of warehouse operations and puts you in control."

Use checklists and KPIs to track progress. Stay updated on new technologies for ongoing improvement.

FAQ

What is the fastest way to improve warehouse efficiency?

You can start by reorganizing your layout and using a warehouse management system. Focus on high-traffic areas and remove clutter. Train your team on best practices. Small changes often lead to big improvements.

How does automation help reduce warehouse costs?

Automation speeds up picking and packing. You use fewer labor hours and make fewer mistakes. Robots and smart systems handle repetitive tasks. This saves money and boosts accuracy.

Why should you track warehouse KPIs?

Tracking KPIs helps you see what works and what needs fixing. You can measure order speed, accuracy, and costs. Use this data to make better decisions and improve your warehouse every day.

Can small warehouses benefit from optimization?

Yes! Even small warehouses gain from better layouts, clear workflows, and simple technology. You can save space, reduce errors, and serve customers faster. Start with easy changes and build from there.

See Also

Enhancing Global Operations Through Innovative Logistics Strategies

Key Strategies for Effective Management of Global Logistics

Streamlined Inventory Management Through Top Global Logistics Warehousing

Simplifying Supply Chain Optimization With American Logistics Solutions

PGL's Miami Warehouse Solutions Ensure Quick East Coast Deliveries