How to Implement Best Practices in Pharmaceutical Logistics for Reliable Delivery

Imagine a shipment of life-saving medicine arriving late or spoiled. You know that every step in the supply chain matters. When you use pharmaceutical logistics best practices, you focus on temperature control, real-time tracking, inventory accuracy, and strict compliance. Industry studies show that these actions reduce risks and help ensure safe, effective delivery. Reliable logistics protect patient health and support trust in the healthcare system.

Key Takeaways

Implement temperature-controlled packaging to protect medicines during transport. This reduces spoilage and ensures product effectiveness.

Utilize real-time visibility tools to track shipments. These tools help you respond quickly to issues and maintain compliance.

Adopt inventory management methods like FIFO and JIT. FIFO keeps medicines fresh, while JIT reduces costs and waste.

Follow strict regulatory compliance and security measures. This builds trust and protects patient safety in the supply chain.

Leverage technology and automation to improve efficiency. These tools help streamline processes and minimize errors.

Pharmaceutical Logistics Overview

What Is Pharmaceutical Logistics?

You manage many steps when you move medicine from the manufacturer to the patient. Pharmaceutical logistics covers every part of this journey. You must follow strict rules to keep products safe and effective. These rules include Good Distribution Practice (GDP) and temperature control. You also need to track products and keep them secure.

Here are the main components and processes you handle in pharmaceutical logistics:

Warehousing and Storage: You keep medicine in secure places with the right temperature.

Transportation: You use trucks, ships, or planes to move products quickly and safely.

Inventory Management: You check expiration dates and make sure you have enough stock.

Packaging and Labeling: You use special packaging and clear labels for safety.

Reverse Logistics: You manage returns and dispose of products the right way.

Pharmaceutical logistics is different from general logistics. You must follow more rules and keep products at the right temperature. The table below shows some key differences:

Aspect | Pharmaceutical Logistics | General Logistics |

|---|---|---|

Regulatory Compliance | Operates under national frameworks like the FDA's DSCSA | Follows general logistics regulations |

Temperature Control | Requires strict cold chain management | Less stringent temperature requirements |

Documentation | Extensive documentation for cross-border shipments | Simpler documentation for domestic shipments |

Security Measures | Higher security risks with multiple handling points | Standard security protocols |

Infrastructure Standards | Varies significantly across countries | More uniform within a single country |

Why Reliability Is Critical

You protect patient health when you deliver medicine on time and in good condition. If you do not follow pharmaceutical logistics best practices, you risk errors and delays. These mistakes can harm patients and cause serious problems in hospitals.

Tip: Reliable delivery helps you avoid medication errors and keeps patients safe.

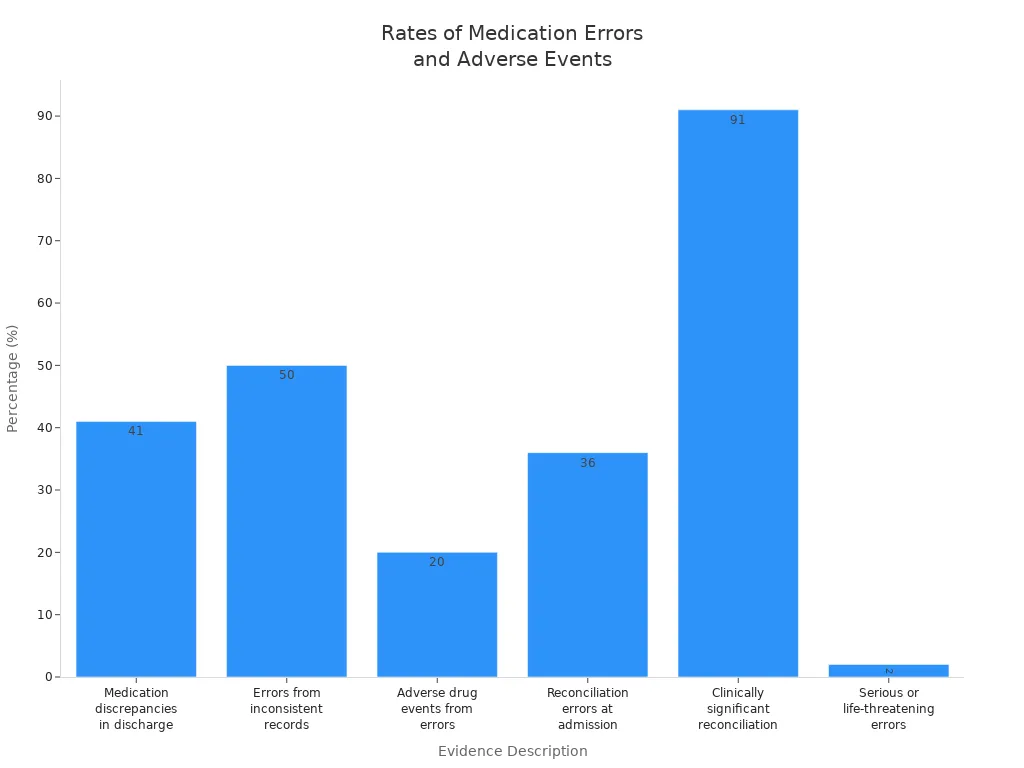

The chart below shows how unreliable delivery can lead to medication errors and adverse events:

You see that up to 91% of medication reconciliation errors can be clinically significant. Even small mistakes can lead to life-threatening situations. You must use strong processes and technology to reduce these risks. When you follow best practices, you help hospitals, pharmacies, and patients trust the supply chain.

Key Challenges in Pharmaceutical Logistics

Pharmaceutical logistics faces many obstacles that can affect reliable delivery. You must understand these challenges to apply pharmaceutical logistics best practices and protect patient safety.

Cold Chain and Temperature Control

Temperature control is vital for many medicines. In 2022, 35% of medicines needed cold storage, and experts expect this number to reach 50% for new products in the next five years. If you do not keep the right temperature, medicines can spoil or lose effectiveness. Common causes of temperature excursions include equipment malfunctions, human errors, and customs delays.

Cause | Description |

|---|---|

Equipment malfunctions | Failures in refrigeration units or HVAC systems. |

Human errors | Mistakes in setting or managing temperature controls. |

Environmental conditions | Transit delays or extreme weather causing temperature changes. |

Inadequate packaging | Poor insulation that does not protect against temperature shifts. |

Power outages | Interruptions in temperature-controlled systems. |

Customs delays | Border delays affecting timely delivery of sensitive products. |

Inventory and Stock Management

You must track inventory closely to avoid shortages and waste. Poor stock control leads to expired medicines and lost products. Overstocking causes excess inventory that may expire before use. Inadequate tracking makes it hard to know what you have and what you need.

Poor stock control systems lead to inefficient inventory management.

Overstocking results in excess inventory that may expire before use.

Inadequate tracking of medications contributes to mismanagement and wastage.

Regulatory and Security Concerns

You must follow strict rules in the US, EU, and other regions. Regulations like the Drug Supply Chain Security Act and Good Distribution Practice set standards for temperature control, traceability, and safe handling. Security is also a major concern. Cargo thefts increased by 27% in 2024, with criminals using deception tactics. Losses from theft reach $35 billion each year in the US.

Regulatory Body | Key Regulations | Description |

|---|---|---|

U.S. Pharmacopeia (USP) | Chapter <1079> | Standards for temperature control and monitoring. |

EU | Good Distribution Practice (GDP) | Regulations for temperature control during transport and storage. |

U.S. FDA | Drug Supply Chain Security Act | Ensures traceability and verification of prescription drugs. |

Technology and Visibility

You need real-time visibility to track shipments and respond to problems quickly. Lack of visibility can lead to delivery failures, product tampering, and cold chain breakdowns. Technologies like track-and-trace systems, IoT devices, and real-time location monitoring help you keep shipments safe and on time.

Tip: Use technology to minimize risks and improve delivery reliability.

Applying these solutions helps you overcome challenges and supports reliable delivery in pharmaceutical logistics.

Pharmaceutical Logistics Best Practices

Temperature-Controlled Packaging

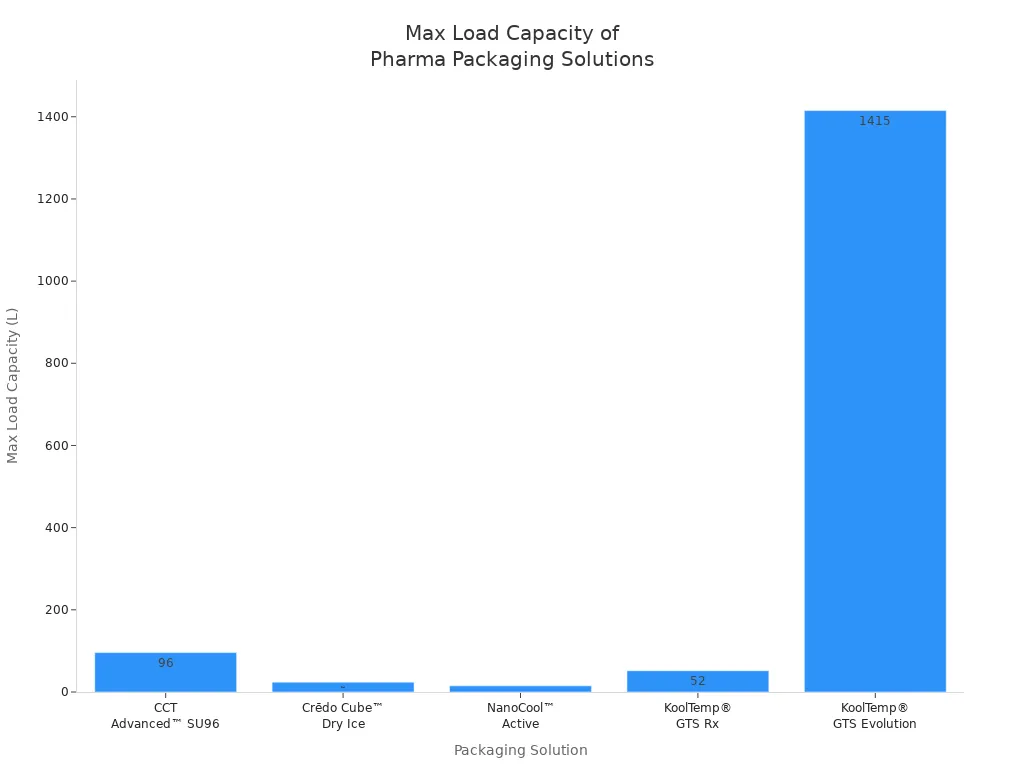

You must use the right packaging to keep medicine safe. Temperature-controlled packaging protects products from heat and cold during transport. Many solutions exist for different needs. The table below shows some of the most effective options:

Solution | Temperature Range | Duration | Reuse Options | Max Load Capacity |

|---|---|---|---|---|

CCT Advanced™ SU96 VIP | -70°C to 50°C | Up to 144 hrs | Reusable (50 cycles) | 96L |

Crēdo Cube™ Dry Ice | Below -60°C | 96–156 hrs | Reusable (5 years) | 24L |

NanoCool™ Active | 2°C to 8°C | 48–92 hrs | Single-use | 15L |

KoolTemp® GTS Rx | -20°C to 25°C | Up to 72 hrs | Single-use | 52L |

KoolTemp® GTS Evolution | -20°C to 30°C | 120 hrs | Reusable | 1415L |

You see that some packaging can keep medicine cold for days. The CCT Advanced™ SU96 VIP uses vacuum-insulated panels and phase change material. This system keeps medicine at the right temperature for up to 144 hours and can be reused 50 times. Crēdo Cube™ Dry Ice works well for very cold shipments. NanoCool™ Active uses evaporative cooling for short trips. KoolTemp® GTS solutions offer reliable control for many types of medicine.

Temperature-controlled packaging helps you lower spoilage rates. AI-enabled sensors track temperature, humidity, and light. These sensors send alerts if something goes wrong. A leading company saw spoilage drop by 30% after using advanced packaging and real-time monitoring. You need strong packaging to protect medicine as it moves across different climates and countries.

Tip: Always choose packaging that matches your product’s temperature needs and shipping time.

Real-Time Visibility Tools

You need to see where your medicine is at all times. Real-time visibility tools help you track shipments and respond to problems fast. These tools use sensors and software to monitor temperature, location, and other conditions.

Feature | Description |

|---|---|

Visibility | High-contrast display for instant shipment status |

Monitoring | Tracks temperature with ±0.5°C accuracy |

Location Intelligence | Triple-redundant technology for precise tracking |

Environmental Monitoring | Alerts for temperature, humidity, light, shock, motion, and tilt |

Regulatory Compliance | Meets GxP and other regulatory standards |

Real-time monitoring lets you track medicine from start to finish.

Data generation helps you spot problems and fix them quickly.

Proactive monitoring prevents delays and damage.

The industry uses real-time location monitoring to keep shipments safe. You can track every step and get alerts if something changes. These tools help you follow rules and keep medicine safe. IoT devices check temperature and humidity. AI analytics predict problems before they happen.

Note: Real-time visibility tools help you meet regulations and lower risks. You can make better decisions and keep medicine safe.

Inventory Management (FIFO & JIT)

You must manage inventory to avoid waste and shortages. Two main methods help you do this: FIFO (First-In, First-Out) and JIT (Just-In-Time).

FIFO means you sell older stock first. This keeps medicine fresh and safe. You lower the risk of spoilage and make sure patients get effective products. JIT means you order medicine only when you need it. This saves money and reduces storage costs. You must have a strong supply chain for JIT to work well. Delays can cause shortages.

You can measure how well your inventory system works by:

Accurate demand forecasting using past data and market trends.

Batch control and expiry management to reduce waste.

ABC analysis to focus on high-value items.

Using technology to automate tracking and improve accuracy.

Working with suppliers to share forecasts and improve delivery times.

Tip: Use FIFO for safety and JIT for efficiency. Combine both for the best results in pharmaceutical logistics best practices.

Regulatory Compliance and Security

You must follow strict rules to keep medicine safe. Regulatory compliance means you meet standards for temperature, traceability, and handling. Security stops theft and counterfeiting.

Keep organized records of dates, people, inventory, and shipping.

Audit business partners to check compliance.

Write standard operating procedures for every step.

Train employees on rules and safety.

Use technology like temperature monitors and GPS tracking.

Set up a compliance management system to document policies.

Use technology controls for security and monitoring.

Follow facility and quality controls that meet CGMPs.

Audit supply chain partners with questionnaires.

Screen and train employees on safety and regulations.

Security protocols help you stop product diversion and counterfeiting. Serialization gives each product a unique code. You can trace every item. Checkpoints catch fake products before they reach patients. Work with logistics partners and regulators to improve security.

Alert: Strong compliance and security protect patients and build trust in your supply chain.

Process Standardization and Automation

You need standard processes and automation to work faster and safer. Standardization means you do things the same way every time. Automation uses machines and software to help you.

Benefit | Description |

|---|---|

Improved Efficiency | Automation speeds up production and cuts downtime. |

Enhanced Accuracy and Quality | Machines reduce mistakes and improve product quality. |

Cost Reduction | Automation lowers labor costs and waste. |

Faster Drug Discovery | Automated tasks help develop new drugs quickly. |

Enhanced Worker Safety | Machines keep workers away from dangerous materials. |

Automation improves efficiency and accuracy.

You save money and reduce errors.

Automated systems like the Ocado Storage and Retrieval System pick and pack orders in minutes.

Sensors track temperature and prevent spoilage.

Algorithms optimize warehouse operations for better performance.

Tip: Use automation and standard processes to follow pharmaceutical logistics best practices. You will work faster, safer, and with fewer mistakes.

Technology’s Role in Reliable Delivery

Advanced Tracking and Monitoring

You rely on technology to keep your pharmaceutical deliveries safe and on time. Technology gives you better visibility and transparency at every step. Advanced tracking systems and automated tools help you prevent delays and errors. You can respond quickly when something goes wrong.

Today, you use several advanced tracking and monitoring technologies in your supply chain:

GPS tracking lets you see exactly where your shipments are at any moment.

Temperature monitoring keeps your medicines at the right temperature, protecting their strength.

Track-and-trace technology uses GPS and RFID devices to show the location and condition of your products in real time.

Cold chain monitoring records temperature data throughout the journey, making sure your products stay safe.

IoT-enabled systems give you continuous data on temperature, humidity, and location. These systems send alerts if something changes, so you can act fast. You move from reacting to problems to predicting and stopping them before they happen. Real-time GPS updates help you solve transit challenges and avoid delays. You keep your products safe and effective by monitoring them every step of the way.

Tip: Advanced tracking and monitoring systems help you catch problems early and protect your shipments from loss or damage.

Digital Platforms and Data Analytics

Digital platforms and data analytics change how you make decisions in pharmaceutical logistics. You use these tools to analyze large amounts of data and find patterns. This helps you plan better and avoid mistakes.

The Nerve Live program at Novartis shows how digital transformation can improve decision-making. By combining operational data with machine learning, you get insights that lower costs and improve quality.

You benefit from:

AI that speeds up decision-making and improves supply chain efficiency.

Better demand forecasting and inventory management, which reduces shortages and waste.

Big data analytics that turns information into actions for smarter planning.

You gain more transparency and efficiency.

AI helps you plan for market changes and disruptions.

Description | |

|---|---|

Increased reliability and accuracy | You reduce errors and make sure orders are right the first time. |

Faster response times | You can send out urgent medications quickly. |

Real-time tracking | You and your patients always know where deliveries are. |

Route flexibility | Drivers can change routes to avoid delays. |

Cost-effective delivery | You save money by optimizing routes and grouping orders. |

Simple scalability | You can handle busy times without extra resources. |

You see that digital platforms make your deliveries more reliable, faster, and cost-effective. You build trust with pharmacies and patients by keeping them informed every step of the way.

You can achieve reliable pharmaceutical delivery by following key steps.

Use insulated packaging and advanced temperature monitoring to protect sensitive medicines.

Invest in compliance software and train your team regularly.

Enhance security with tamper-evident seals and GPS tracking.

Automate route planning and use real-time dashboards for visibility.

Continuous improvement and technology help you stay ahead. Evaluate your logistics process often and upgrade your systems to keep patients safe.

FAQ

How do you keep medicines at the right temperature during shipping?

You use insulated packaging and temperature sensors. These tools help you monitor conditions. If the temperature changes, you get alerts.

Tip: Always check sensors before shipping to avoid spoilage.

What technology helps you track pharmaceutical shipments?

You use GPS and IoT devices. These tools show you the location and condition of your products.

Real-time tracking helps you prevent delays.

Alerts warn you about problems.

Why is regulatory compliance important in pharmaceutical logistics?

You must follow rules to keep medicines safe. Compliance protects patients and builds trust.

⚠️ Failing to meet standards can lead to fines and product recalls.

What is the best way to manage pharmaceutical inventory?

You use FIFO to sell older stock first. JIT helps you order only what you need.

FIFO reduces waste.

JIT saves money.

See Also

Key Strategies for Effective Management of Global Logistics

Enhancing International Operations Through Innovative Logistics Solutions

Optimizing East Coast Import Warehousing and Delivery Services

Boosting Global Efficiency with Point-to-Point Logistics Systems

Safeguarding Essentials with Temperature-Controlled Freight Solutions