Top Proven Retail Supply Chain Best Practices for 2025

You can boost your retail supply chain by adopting best practices that drive adaptability, efficiency, and resilience.

Use AI and machine learning to manage inventory and predict disruptions.

Deploy robotics and automation in warehouses for faster operations.

Outsource and build partnerships to expand capabilities and productivity.

Focus on space management and omnichannel services for better customer reach.

Analyze cost-to-serve at a detailed level to manage inflation and set smart pricing.

These retail supply chain best practices help you improve performance and profitability. Reflect on your current strategy and identify immediate changes for stronger results in 2025.

Key Takeaways

Adopt AI and automation to enhance inventory management and streamline operations. This will help predict disruptions and improve efficiency.

Build strong partnerships with suppliers to expand capabilities and improve service. Collaborate regularly to align goals and share resources.

Implement clear success metrics to track supply chain performance. Regularly review these metrics to identify areas for improvement.

Focus on omnichannel management to provide a seamless shopping experience. Keep inventory synchronized across all sales channels to meet customer expectations.

Embrace sustainability by choosing eco-friendly suppliers and reducing waste. This not only benefits the environment but also attracts conscious consumers.

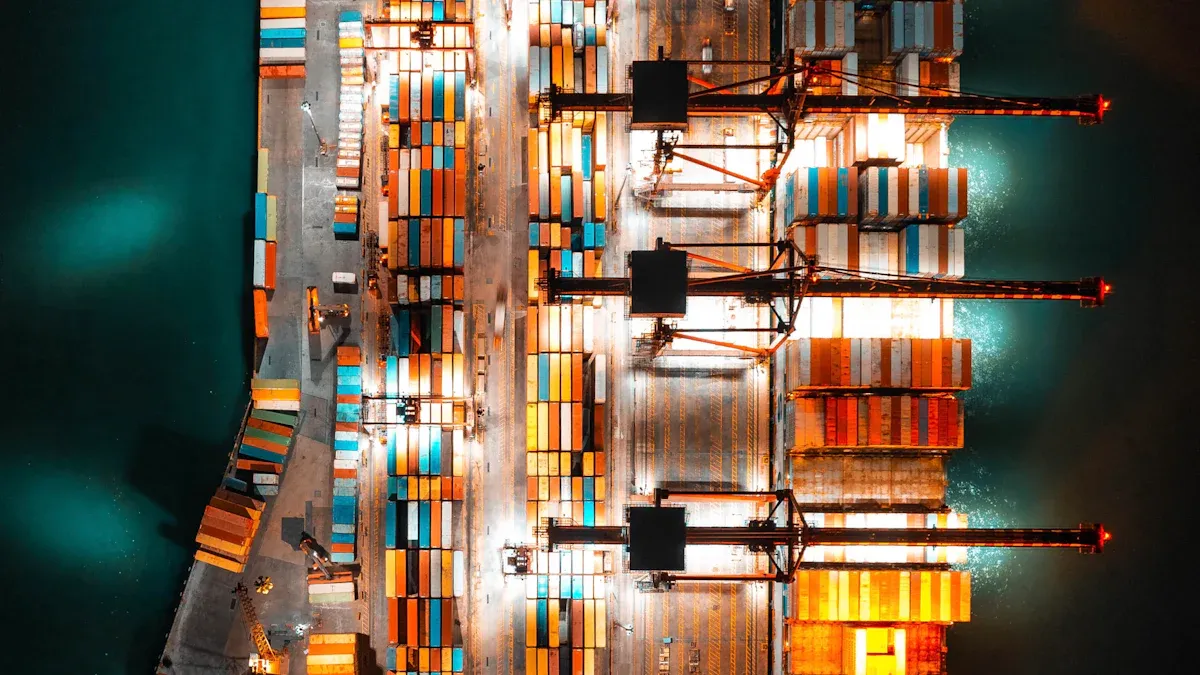

What Is Retail Supply Chain Management?

Key Components

You manage a retail supply chain by connecting many moving parts. Each part plays a role in getting products from suppliers to your customers. Here are the main components you need to focus on:

Procurement: You buy goods from suppliers who meet your quality and price needs.

Inventory Management: You track and control stock levels to match customer demand and avoid extra costs.

Warehousing: You store products safely until you need to ship them out.

Distribution: You move goods through a network to stores or directly to customers.

Supply Chain Sustainability: You use methods that lower your environmental impact and support long-term growth.

Tip: When you understand each component, you can spot weak areas and improve your supply chain step by step.

Impact on Retail Success

A strong supply chain helps you serve customers better and grow your business. Here is how effective management makes a difference:

You use demand data to predict what customers want, so you stock the right products.

You rely on supply data to plan for delivery times and avoid delays.

You monitor inventory data to keep shelves full and prevent overstocking.

You use real-time inventory management tools, like IoT devices, to track products and automate reordering.

You improve customer service by using AI to learn what shoppers like and offer them better choices.

You cut waste and save money by using AI to find extra stock and suggest better delivery routes.

Retail supply chain best practices help you connect these parts for smoother operations and higher profits. When you follow these steps, you build a supply chain that supports your goals and keeps customers happy.

Retail Supply Chain Best Practices for 2025

Strategic Partnerships

You can strengthen your supply chain by forming smart partnerships. These partnerships help you reach more customers, improve delivery speed, and share resources. When you work with the right partners, you can solve problems faster and offer better service.

Here are some real-world examples of successful partnerships:

Partnership | Description |

|---|---|

Target and Shipt | This partnership changed same-day delivery. Target used Shipt’s supply chain skills to fill orders quickly and keep customers happy. |

Walmart and Shopify | Walmart teamed up with Shopify to let more sellers join its marketplace. This move increased product choices and made order fulfillment easier. |

Tip: Choose partners who share your goals and values. Meet often to review progress and solve issues together.

Building the Right Team

Your team is the heart of your supply chain. You need people who can work together, use new technology, and solve problems. Leading companies look for these qualities:

Criteria | Description |

|---|---|

Teams match calendars, budgets, and purchases to keep everyone on the same page. | |

Cross-functional capabilities | Teams share forecasts and vendor plans to make sure products arrive when needed. |

Integration of advanced technologies | Companies like Nike and Target use shared calendars and scorecards to track progress. |

Work well across all parts of your business to meet customer needs.

Build a clear plan for omnichannel skills.

Set clear roles and rules for each team member.

Note: Train your team to use new tools and encourage them to share ideas. This helps you stay ahead in the fast-changing retail world.

Clear Success Metrics

You need to track your progress to know if your supply chain works well. Use clear metrics to measure your results and find areas to improve. Here are the most common metrics for 2025:

Cash-to-Cash Cycle Time

Perfect Order Rate

On-Time Delivery Rate

Inventory Turnover Rate

Supplier On-Time Delivery Rate

Customer Order Cycle Time

Forecast Accuracy

Return Rate

You should also watch:

Supply chain performance metrics

Supplier performance metrics

Supplier onboarding and adoption metrics

Callout: Review these numbers often. Use them to set goals and reward your team for hitting targets.

Tactical Execution

You need to turn your plans into action. Focus on steps that help you move quickly and adjust to changes. Here are proven actions you can take:

Use retail execution software for real-time data and analytics.

Standardize product displays and check for planogram compliance.

Train your staff regularly to keep skills sharp.

Collect and study sales and inventory data to spot trends.

Encourage strong communication between teams.

Put customers first by shaping your strategies around their needs.

Use predictive analytics to manage inventory levels.

Connect your online and offline channels for a smooth shopping experience.

You can also:

Automate supply chain tasks with software.

Use tracking and forecasting tools for better visibility.

Bring all your systems together for a single view of operations.

Adjust your supply chain to match real-time demand.

Use software to see every part of your supply chain clearly.

Tip: Start with small changes and build on your success. Review your actions often and adjust as needed.

By following these retail supply chain best practices, you can build a supply chain that is strong, flexible, and ready for the future. You will serve your customers better and grow your business.

Overcoming Retail Supply Chain Challenges

Disruption & Volatility

You face many disruptions in retail supply chains. Economic shifts and tariff increases over 25% on consumer goods can change your pricing and sourcing plans. Geopolitical tensions often slow shipping and raise costs. You must stay alert and ready to adapt.

Build strong relationships with suppliers for better visibility.

Diversify your supplier base to avoid relying on one source.

Use technology to improve productivity and adaptability.

Leverage AI to predict demand and spot disruptions early.

Automate shipping to streamline your workflow.

Speed up cash conversion to keep your business flexible.

Tip: Review your supply chain often. Seek improvements to stay ahead of market changes.

Customer Expectations

Customers want fast and reliable service. You must meet their needs to keep them coming back. Many shoppers expect same-day or two-day delivery. They also want quick answers to their questions.

Evidence | Description |

|---|---|

87% of online shoppers | Shipping speed is critical for repeat purchases. |

67% of online shoppers | Will pay more for same-day delivery if needed by a deadline. |

Want an immediate response from brands. |

Amazon changed the game with Prime’s free two-day shipping. Now, you must optimize last-mile delivery and use digital networks to connect your supply chain. Partner with logistics providers to offer faster shipping.

Callout: Fast shipping and quick responses build trust and loyalty.

Global Complexity

Global supply chains bring many challenges. You must manage complicated transportation routes and customs controls. Network density and interconnectedness affect how you plan and respond to changes.

Aspect | Description |

|---|---|

Interconnectedness | Collaboration among suppliers can reduce negative effects of complexity. |

Network Density | More connections mean more complexity in your supply base. |

Moderating Impact | High interconnectedness can make spatial complexity harder to manage. |

Many companies now consider near-shoring to simplify their supply chains. You can benefit from closer suppliers and fewer transportation hurdles.

Note: Work closely with your suppliers. Strong networks help you handle global challenges.

Technology in Retail Supply Chains

Automation & Robotics

You can transform your supply chain with automation and robotics. These tools speed up tasks and reduce errors. Automated data capture saves time and improves accuracy. Robots help manage inventory and restock shelves. Drones count inventory, which keeps workers safe. Studies show automation can boost employee productivity by up to 100%. You also cut costs because automation reduces travel time for workers and lets them focus on complex jobs.

Benefit | Description |

|---|---|

Productivity Improvement | Automation can double employee productivity. |

Cost Reduction | Less travel time means more savings. |

Inventory Management | Robots keep stock levels accurate. |

Safety Enhancements | Drones lower the risk of injuries. |

Real-time Visibility | AI tracks inventory across all channels. |

Smart manufacturing uses automation and IoT to give you real-time insights, reduce waste, and improve product quality.

AI & Data Analytics

AI and data analytics help you make better decisions. You can use AI to predict demand and avoid stockouts. AI tools analyze large data sets, so you understand what your customers want. Predictive analytics helps you plan inventory and supply chain operations. You can also use AI to spot disruptions and suggest new routes or suppliers. This keeps your supply chain running smoothly.

Predictive analytics optimizes inventory.

AI-driven automation helps you respond to changes fast.

You gain insights to improve products and customer experiences.

Real-Time Visibility

Real-time visibility lets you see every part of your supply chain. IoT devices track products and give instant updates. This helps you spot problems early and fix them fast. You can reduce stockouts by up to 50% and cut emergency shipping costs by 30%. On-time delivery rates can reach 98% or higher. You also lower inventory costs and improve customer service.

Benefit | Impact Description |

|---|---|

Stockout Reduction | Up to 50% fewer stockouts. |

Emergency Shipping Cost | 30% or more savings. |

Service Level Excellence | 98%+ on-time delivery. |

Inventory Optimization | 15-25% lower carrying costs. |

Market Responsiveness | Adjust strategies in real time. |

Customer Experience | Better communication and service recovery. |

Supplier Collaboration | Share real-time information for better teamwork. |

Risk Management | Spot and fix disruptions quickly. |

Integrated Systems

Integrated systems connect all your supply chain tools. You get a single view of orders, inventory, and deliveries. This makes it easier to plan and react to changes. For example, a 3PL provider cut delivery delays by 15% with an integrated system that used dynamic routing. An online retailer delivered 20% faster during busy times by linking order data with logistics and analytics. When you weave systems together, you create a seamless flow of information and boost your supply chain’s performance.

Tip: Connect your systems for better data, faster decisions, and a stronger supply chain.

Inventory & Logistics Optimization

Demand Forecasting

You need accurate demand forecasting to keep your shelves stocked and your customers happy. Use both numbers and technology to predict what shoppers want. Quantitative techniques like time series analysis, moving averages, and regression analysis help you spot trends in your sales data. Machine learning and AI can dig deeper, finding patterns that humans might miss. You can also work with your suppliers and share data for better forecasts. When you combine these methods, you get a clearer picture of future demand.

Tip: Mix statistical forecasting with collaborative planning to boost accuracy and reduce surprises.

Just-in-Time Inventory

Just-in-time (JIT) inventory helps you cut waste and save money. You only order products when you need them, so you avoid overstocking. Many retailers, including fast fashion brands and grocery stores, use JIT to keep inventory fresh and match customer trends. Over 70% of manufacturers now use JIT strategies. JIT works best when you use advanced analytics and share forecasts with your suppliers. The Theory of Constraints helps you find weak spots in your system and fix them quickly.

JIT reduces waste by delivering products only when needed.

Analytics and collaboration align supply with demand.

You improve efficiency and lower costs.

Impactful Logistics Strategies

Strong logistics keep your supply chain moving. Real-time tracking lets you and your customers see where orders are at any moment. AI and automation speed up deliveries and cut costs. You must also plan for disruptions and fix inventory mismatches fast. Focus on making your logistics scalable and adaptable. This way, you can grow your business and handle changes in the market.

Strategy | Description |

|---|---|

Real-time Tracking | Lets customers monitor orders and improves delivery reliability. |

AI & Automation | Speeds up logistics and lowers costs. |

Scalability & Adaptability | Prepares your supply chain for growth and change. |

Omnichannel Management

You need a unified inventory system to manage sales across stores, online, and mobile. This system keeps stock levels updated in real time, so customers always know what is available. Companies like Walmart and Coles have built strong omnichannel networks. Walmart now gets 14% of its sales from e-commerce. Coles uses special fulfillment centers to fill online orders quickly.

At the heart of an effective omnichannel supply chain is a unified inventory management system, ensuring real-time synchronization of stock levels across all channels.

Step | Description |

|---|---|

1 | Invest in robust technology platforms for seamless integration. |

2 | Keep branding and messaging consistent across all channels. |

When you offer options like online browsing, in-store pickup, and fast delivery, you create a smooth shopping journey for your customers.

Supplier & Vendor Relationships

Collaboration & Communication

You build a strong supply chain by working closely with your suppliers. Open communication helps you solve problems quickly and avoid misunderstandings. You can use supplier relationship management software to automate tasks and share real-time data. This technology makes your workflow smoother and keeps everyone informed. When you set clear expectations and hold regular meetings, you build trust and improve teamwork.

Align product availability across all channels to give customers a better experience.

Share delivery timelines and order updates to prevent stockouts.

Use transparent data sharing to boost accountability and trust.

Partner with suppliers who focus on sustainability to meet customer demands.

Tip: Start every partnership with a thorough onboarding process. Include suppliers in your business planning to make sure everyone works toward the same goals.

Supplier Diversification

You protect your business by working with a variety of suppliers. Diversifying your supplier base helps you avoid big problems when disruptions happen, like natural disasters. A diverse supply chain adapts quickly and keeps your operations running smoothly during crises. Companies that diversify save more money on procurement and gain a competitive edge.

Minority-owned businesses generate over $400 billion in annual revenue.

People of color will drive most of the increase in purchasing power in the coming years.

Diversification supports responsible growth and global responsibility.

Note: When you choose suppliers from different backgrounds, you make your supply chain stronger and more flexible.

Performance Partnerships

You get better results when you treat suppliers as partners. Performance partnerships focus on sharing information, building trust, and managing goals together. These partnerships help you cut costs, speed up order fulfillment, and improve customer service. You also forecast demand more accurately and manage inventory better.

Benefit | Description |

|---|---|

Spend less and stay competitive. | |

Faster Fulfillment | Deliver orders quickly. |

Better Service | Keep customers satisfied. |

Improved Forecasting | Plan inventory with confidence. |

Stronger Strategies | Build a smarter supply chain. |

Callout: Invest in supplier training and process improvement projects. When you help your suppliers grow, you build a supply chain that is ready for the future.

Sustainability & Ethics

Environmental Impact

You play a key role in reducing the environmental impact of your retail supply chain. Manufacturing creates 29% of total retail emissions. Agriculture and forestry add 24%. Power generation makes up 23%. Transportation, while important, only accounts for 15%. If you work in fashion or home goods, Scope 3 emissions can reach up to 98% of your carbon footprint. You can lower these numbers by choosing greener materials, using renewable energy, and improving transportation efficiency.

Use energy-saving equipment in warehouses.

Choose suppliers who follow eco-friendly practices.

Reduce packaging waste with recyclable materials.

🌱 Small changes in your supply chain can lead to big improvements for the planet.

Ethical Sourcing

You must make sure your products come from ethical sources. With 1.8 billion people expected to join the global consumer class by 2025, shoppers want to know where and how products are made. More than 70% of Gen Z consumers say they try to buy from ethical brands. You can meet these expectations by checking your suppliers’ labor standards and making your sourcing process transparent.

Share information about your suppliers with your customers.

Audit factories and farms to ensure fair treatment of workers.

Support suppliers who pay fair wages and provide safe working conditions.

A 2024 survey by PwC shows that consumers will spend almost 10% more on goods that are made or sourced sustainably. You can attract loyal customers by showing your commitment to ethical sourcing.

Circular Models

You can build a circular supply chain by reusing, recycling, and repairing products. This model helps you cut waste and save resources. The global sustainable fashion market is expected to reach $15 billion by 2026, growing 9% each year. You can join this trend by offering recycling programs and designing products that last longer.

Collect used products for recycling or refurbishment.

Design packaging that customers can reuse.

Encourage customers to return items for repair instead of throwing them away.

♻️ Circular models help you protect the environment and meet the growing demand for sustainable products.

Risk & Performance Management

Scenario Planning

You can prepare for the unexpected by using scenario planning. This method helps you think about different risks that might affect your supply chain. You create plans for events like natural disasters, supplier failures, or sudden changes in demand. When you practice these scenarios, you react faster and make better decisions.

List possible risks for your business.

Build simple action plans for each risk.

Test your plans with your team.

Update your plans as new risks appear.

Tip: Scenario planning helps you stay calm and focused when problems happen.

Supply Chain Visibility

You need clear visibility to manage your supply chain well. When you see every step, you spot problems early and fix them before they grow. Use real-time tracking tools and dashboards to watch your inventory, shipments, and supplier performance.

Tool | Benefit |

|---|---|

Real-time dashboards | Track orders and inventory |

IoT sensors | Monitor goods in transit |

Supplier portals | Share updates and alerts |

You build trust with your team and partners when you share information. Visibility also helps you avoid delays and reduce costs.

KPIs & Continuous Improvement

You measure your supply chain’s success with key performance indicators (KPIs). These numbers show you what works and what needs fixing. Common KPIs include on-time delivery, order accuracy, and inventory turnover.

Set clear targets for each KPI.

Review your results every month.

Celebrate wins and learn from mistakes.

Use feedback to improve your process.

🚀 Continuous improvement keeps your supply chain strong and ready for the future.

You can build a stronger supply chain by using proven best practices. Focus on technology, strong partnerships, and clear goals. Keep your team trained and your systems connected. Review your progress often and look for ways to improve.

🚀 Take action now. Start with one change and watch your supply chain grow stronger for 2025.

FAQ

What is the most important retail supply chain trend for 2025?

You should focus on real-time data and automation. These tools help you react quickly to changes. They also improve accuracy and save money.

How can you make your supply chain more resilient?

Build strong partnerships and use multiple suppliers. Invest in technology for better visibility. Test your plans often to prepare for disruptions.

Why does omnichannel management matter?

Omnichannel management lets you serve customers in stores, online, and on mobile. You keep inventory updated everywhere. This approach improves customer satisfaction and boosts sales.

How does AI help with inventory management?

AI predicts what products you need and when. It helps you avoid running out of stock or having too much. You save money and keep customers happy.

What are some quick wins for supply chain improvement?

Train your team on new tools.

Use real-time tracking.

Review supplier performance.

Automate simple tasks.

Tip: Start with one change and measure the results.

See Also

Connecting Warehouses To Enhance Supply Chain Efficiency With PGL

PGL’s Knowledge Ensures Smooth Operation Of U.S. Supply Chains

Simplifying Supply Chain Efficiency With American Global Logistics Services

Key Strategies For Effective Management Of Global Logistics

Optimized Inventory And Distribution Through Premier Global Logistics Solutions