HAZMAT Freight? Trust PGL for Safe, Compliant Delivery

Hazardous materials transportation, including the trucking of flammable liquids and gases, presents significant challenges for companies handling these substances. Strict regulations govern every aspect, from packaging to route planning, and non-compliance can lead to serious consequences. Between 1994 and 2003, trucks were involved in approximately 87% of 157,861 hazardous materials incidents in the U.S., with gasoline and flammable liquids accounting for more than half of the severe cases.

Premier Global Logistics specializes in the trucking of flammable liquids and gases, employing certified hazmat drivers and specialized vehicles while ensuring full compliance with all regulatory requirements. Their expertise in packaging, documentation, and adherence to safety standards guarantees that hazardous materials are transported safely, legally, and efficiently. When it comes to moving flammable liquids and gases by truck, partnering with a company well-versed in hazmat safety and regulations is essential.

Key Takeaways

Moving hazardous materials like flammable liquids and gases needs strict safety rules. Special trucks and trained drivers are required.

Companies must follow federal rules for packaging, labeling, and paperwork. They also need emergency plans to avoid big fines and keep people safe.

PGL uses certified hazmat drivers and special vehicles. They plan smart routes to make sure hazardous shipments are safe, legal, and on time.

Good paperwork, like Safety Data Sheets and shipping papers, helps stop accidents, delays, and fines during hazmat transport.

Picking a trusted company like PGL means expert handling, real-time tracking, and strong safety help for all hazardous shipments.

Trucking of Flammable Liquids and Gases

Hazardous Materials Overview

Hazardous materials are important for many industries, but moving them needs strict rules. Trucks carry flammable liquids and gases that can catch fire or explode if not handled right.

Flammable liquids have a flash point under 100°F (38°C).

These liquids are sorted into three groups:

Class IA: Flash point under 73°F (23°C), boiling point under 100°F (38°C)

Class IB: Flash point under 73°F (23°C), boiling point at or above 100°F (38°C)

Class IC: Flash point at or above 73°F (23°C), but under 100°F (38°C)

Flammable gases are stored under pressure and can turn into liquid. They can catch fire easily.

Other hazardous materials are corrosives, cryogenic fluids, lithium batteries, medical waste, oxidizers, and pyrophoric chemicals.

OSHA, DOT, and other groups make rules for storing, packing, and moving hazardous materials. Companies must keep track of amounts and use the right packaging to stop leaks or bad reactions.

Specialized Vehicles and Drivers

Moving hazardous materials needs more than regular trucks and drivers. Hazmat drivers need a special hazmat endorsement on their CDL. They must pass background checks, health exams, and special training.

Carriers use trucks made for hazmat loads. These trucks have leak-proof tanks, linings that resist corrosion, and temperature controls.

Drivers must follow careful steps for loading, unloading, and what to do in emergencies.

Carriers plan routes to avoid places where hazmat trucks cannot go and to deliver on time.

Training and regular checks help keep trucks and workers ready for anything.

Safety Data Sheets (SDS) and Material Safety Data Sheets (MSDS) help drivers and handlers know how to pack, label, and handle emergencies with hazardous materials.

Common Transport Challenges

Trucking flammable liquids and gases has some big problems:

Challenge | Impact on Hazmat Transportation |

|---|---|

Driver shortages | Not enough trained drivers |

Route restrictions | Some places are off-limits |

Complex documentation | More chances for mistakes |

Transfer risks | Spills or accidents can happen |

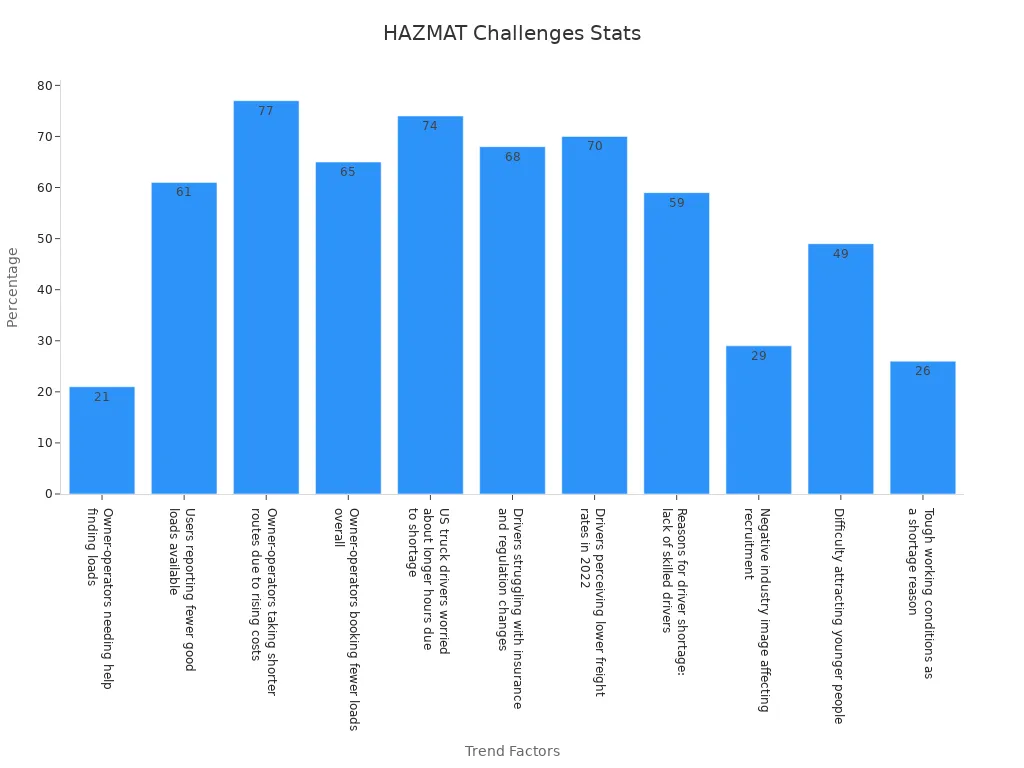

In 2019, there were 61,000 fewer drivers than needed. By 2028, this could rise to 160,000. New rules and checks for hazmat drivers make it harder to find enough people. Route rules and city laws make planning harder. Keeping paperwork right and handling transfer risks need good systems and regular checks.

Hazmat trucking companies must spend money on technology, training, and following rules to move hazardous materials safely and legally.

Hazardous Materials Regulations

Federal Oversight and Agencies

Hazardous materials transportation in the U.S. must follow strict federal rules. Many agencies work together to keep people safe and make sure companies follow the law.

The Department of Transportation (DOT) makes the main rules for hazardous materials. DOT gives jobs to other groups like FMCSA, PHMSA, FAA, FRA, and USCG.

FMCSA checks motor carriers, gives safety permits, and watches over commercial drivers.

PHMSA checks how hazardous materials are moved, does inspections, and makes sure packaging is safe.

The Environmental Protection Agency (EPA) protects the environment, especially if there is a spill.

All these groups work together to make sure rules are followed, help with emergencies, and teach about safety.

Agency | Role in Hazardous Materials Oversight | Key Responsibilities and Enforcement Tools |

|---|---|---|

PHMSA | Watches over hazardous materials transportation and pipeline safety | Inspections, enforcement, packaging checks, accident investigations, outreach, and education |

FMCSA | Checks motor carriers and enforces hazardous materials rules on highways | Safety permits, reviews, public safety ratings, and carrier profiles |

Federal agencies also do research and run safety programs. These programs help lower risks and make emergency response better for hazardous materials transportation.

Key Compliance Requirements

Companies must follow many steps to move hazardous materials safely.

Registration and permitting: Carriers must sign up with DOT and get special permits for some hazardous materials.

Hazardous materials training requirements: Drivers and workers need regular training, every three years or sooner if rules change.

Packaging: Companies must use approved packaging that stops leaks and does not rust.

Labeling: Hazardous materials must have clear labels and symbols for safety and emergencies.

Documentation: Every load needs correct shipping papers and emergency contact information.

Emergency response requirements: Carriers must have plans for spills or accidents and train workers to act fast.

Security: Companies must keep hazardous materials safe and follow security plans to stop theft or misuse.

Incident reporting: Any accident or spill must be reported to the right agencies right away.

If companies do not follow the rules, they can get fines over $70,000. If someone gets hurt or property is damaged, fines can go up to $179,000. These rules help keep people, property, and the environment safe when moving hazardous materials.

Documentation and Safety Data Sheets

Good paperwork is very important for hazardous materials rules.

Safety Data Sheets (SDS) give details about chemicals, dangers, safe handling, emergencies, and following the law.

SDSs must have 16 sections, including information for transport and emergencies.

OSHA’s Hazard Communication Standard says employers must keep SDSs at work, label containers, and train workers about hazardous materials.

Shipping papers must list hazardous materials, emergency contacts, and safe handling steps.

Good paperwork helps shippers, helps emergency workers, and stops delays or fines.

Having correct SDSs and shipping papers helps everyone follow the rules, helps in emergencies, and keeps people safe during hazardous materials transportation.

HAZMAT Compliance with PGL

Certified Drivers and Fleet

Premier Global Logistics has a team of well-trained, HAZMAT-certified drivers. Each driver has the right certification for hazmat work. This means they follow all federal and state rules. The company gives drivers regular training. This helps them learn new safety and packaging rules for hazardous shipments.

PGL’s trucks are made for hazmat shipping. The trucks have special safety systems and emergency gear. They also use GPS tracking to watch every trip. All vehicles get checked and fixed often to make sure they work well. Special trucks carry many types of hazardous materials. These include flammable liquids, corrosives, compressed gases, lithium batteries, and medical waste. The fleet has:

Hazardous waste trucks with tanks that do not leak or rust

Medical waste vehicles that keep things at the right temperature

Collection and support vehicles for different hazardous materials

Engines that are modern and eco-friendly to help the environment

PGL keeps people and equipment safe. Every shipment gets help from a team and trucks made for hazardous materials.

Route Planning and Risk Management

Planning routes is very important for safe hazmat shipping. PGL uses smart technology to pick the best routes. They avoid places where hazmat trucks cannot go. They also stay away from crowded areas and sensitive places. The company checks traffic, weather, and air quality to make each trip safe and fast.

Health-safe routes help lower pollution for drivers and people nearby.

The system changes routes if there is traffic or an accident. This helps deliveries arrive on time and follow local rules.

Eco-friendly routes help cut down on pollution and keep trips safe.

A normal PGL route plan has these steps:

Step | Description |

|---|---|

Route Assessment | Finds places to avoid, like busy areas |

Risk Evaluation | Looks at safety, security, and the environment |

Real-Time Monitoring | Uses GPS and live updates to change routes if needed |

Emergency Protocols | Has clear plans and ways to talk in case of an emergency |

Custom route planning follows the rules and shows PGL works hard to keep risks low when moving hazardous materials.

End-to-End Service Process

PGL makes hazmat shipping easy from start to finish. They pick up the shipment safely at the customer’s site. Then they move it to the final place. Every step follows strict safety and security rules.

At pickup, they check the right hazardous materials are chosen and written down.

They make sure packaging and labels meet all rules.

All paperwork, like shipping papers and MSDS/SDS, goes with the shipment.

GPS tracking lets customers see updates and when the shipment will arrive.

If something goes wrong, there are plans to handle emergencies fast.

Customers get alerts and can watch their shipment at any time.

PGL’s full service covers everything, from packing and labeling to paperwork and delivery. This helps companies like medical device makers, chemical factories, electronics sellers, and supply chain managers who need special hazmat shipping.

Here is a recent example:

A chemical company in Texas sends hazardous materials to New Jersey every week. PGL gives them a special hazmat driver and a custom route. They also provide 24-hour tracking. The company has had no safety problems for 36 months.

PGL’s strengths in hazmat shipping are:

Special workers and trucks for each shipment

Correct safety paperwork and labels

Fast truck dispatch and helpful support

Shipping that follows all rules and can be tracked

When you need safe, careful, and rule-following hazmat shipping, Premier Global Logistics is a company you can trust.

Risks and Why Trust PGL

Penalties for Non-Compliance

Hazmat transportation in the U.S. has very strict rules. Companies must follow these rules or face big fines. FMCSA says drivers need special training and must use the right packaging. Labels must be clear, and there must be emergency plans. If companies break the rules, they can get fined a lot of money. Some mistakes, like using the wrong packaging or missing safety tools, can cost from $1,000 to $16,500 each time. If a company moves hazardous materials without the right papers or uses packaging that is not approved, the fine can be as high as $102,348 for each mistake. If someone gets hurt or property is damaged, the fine can go up to $238,809. If a company keeps breaking the rules, it might lose its license and have to close. These rules help keep people safe and make sure companies move hazardous materials the right way.

Not removing hazardous materials packages: $1,000–$5,000

Explosives not tied down right: $6,500+

Leaving Class 1 explosives alone: $3,000

Packaging not certified: $4,500–$16,500

Tanks not tested: $2,300–$8,700

Strong rules for hazardous materials help keep everyone safe and make sure companies do the right thing.

Safety and Environmental Impact

Moving hazardous materials the wrong way can be very dangerous. The U.S. moves about 35 million tons of hazardous materials every year. If these are not handled safely, there can be spills, fires, or toxic leaks. Only 5% of lithium-ion batteries get recycled, so the rest can pollute soil and water. Old hand sanitizer and other chemicals can get into water or start fires if not thrown away right. In 2022, the UK had 70% more fires from lithium-ion batteries, showing this is a problem everywhere.

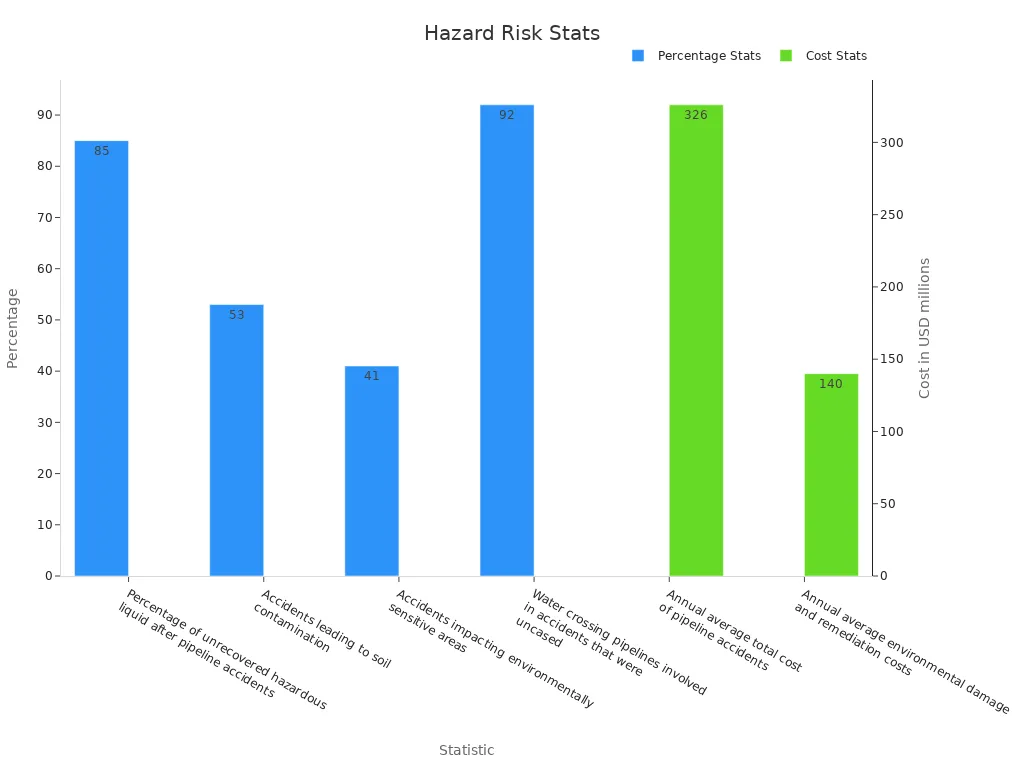

Statistic Description | Value/Percentage |

|---|---|

Percentage of unrecovered hazardous liquid after pipeline accidents | 85% |

Accidents leading to soil contamination | 53% |

Accidents impacting environmentally sensitive areas | 41% |

Water crossing pipelines involved in accidents that were uncased | 92% |

Annual average total cost of pipeline accidents | USD 326 million |

Annual average environmental damage and remediation costs | USD 140 million |

Handling hazardous materials the right way helps stop these problems. Using the right packaging, labels, and emergency plans makes things safer. Training workers and following the rules helps stop accidents and keeps the environment safe.

PGL’s Safety Record and Support

Premier Global Logistics is a leader in hazmat shipping. The company has a perfect safety record and always follows the rules. PGL uses drivers who are HAZMAT-certified and special trucks for these jobs. They use tracking systems to watch every shipment. Every load is packed, labeled, and has the right papers. The team is ready to help if there is an emergency or security problem. Customers get updates all the time and can call for help any hour of the day. PGL works hard to make sure every shipment is safe, follows the rules, and gets there on time.

PGL’s great safety record, skilled team, and strong focus on rules make it the best choice for medical, chemical, electronics, and industrial companies all over the country.

Picking a certified company for hazmat transportation keeps people, property, and nature safe. PGL is different because they have skilled hazmat drivers and special trucks. They always follow the rules for hazardous materials.

Always use certified packaging when moving hazardous materials.

Make sure to follow all hazmat labeling and paperwork rules.

Train workers so they know how to handle and move materials safely.

Keep records for each hazardous shipment you send.

Ask experts for help with hazmat rules and lowering risks.

Hazmat transportation needs careful work. You can count on PGL for safe and rule-following hazardous materials shipping every time.Do you need to move hazardous materials? Reach out to PGL for expert hazmat shipping help.

FAQ

What types of hazardous materials can PGL transport?

PGL moves many kinds of hazardous materials. These include flammable liquids, compressed gases, corrosives, lithium batteries, and medical waste. Their hazmat trucking USA services help medical, chemical, electronics, and industrial companies.

How does PGL ensure compliance with federal HAZMAT regulations?

PGL hires HAZMAT-certified drivers and uses special trucks. The team follows DOT, FMCSA, EPA, and PHMSA rules. Every shipment gets the right labels, paperwork, and live tracking. Drivers get regular training, and the company checks its work often to stay safe and follow the law.

Can PGL provide nationwide HAZMAT trucking solutions?

Yes. PGL offers hazmat trucking all over the USA. They cover every state. The company picks routes that skip restricted places. This helps clients in medical, chemical, and electronics fields get safe and on-time deliveries.

What support does PGL offer for documentation and labeling?

PGL helps with MSDS/SDS, shipping papers, and labels. The team checks each document to make sure it is right and follows the rules. This lowers the chance of delays or fines when moving hazardous materials.

How does PGL manage shipment safety and emergency response?

PGL uses GPS tracking and alarms for every shipment. They have emergency plans ready. Drivers get safety training all the time. The company is ready for problems with fast response teams and clear ways to talk. This keeps hazardous shipments safe.

See Also

PGL Warehouse Services In Miami For Rapid East Coast Shipping

Reliable East Coast Trucking By PGL Ensures Safe Transport

PGL Addresses Fast-Paced Logistics Needs In Los Angeles