PGL’s Proven Tactics for Streamlined Warehousing in Major U.S. Hubs

Premier Global Logistics is transforming logistics nationwide by leveraging robust U.S. warehousing services in Miami, LA, Chicago, and Houston. These strategic locations provide exceptional access to major ports and airports, making them essential hubs for U.S. warehousing services in Miami, LA, Chicago, and Houston. The advanced infrastructure in these cities enables faster and more efficient logistics operations. With PGL’s comprehensive network, companies can streamline their supply chain logistics, reduce delivery times, and enhance overall reliability. Logistics teams benefit from seamless workflows and strong infrastructure, setting new benchmarks for operational excellence in the industry.

Key Takeaways

PGL has warehouses in big U.S. cities like Miami, Los Angeles, Chicago, and Houston. These places connect to main ports and airports. This helps shipping stay fast and reliable.

PGL uses advanced technology and automation. This helps them be more accurate and quick. It also makes managing inventory and filling orders easier.

Flexible warehousing lets businesses change storage and services fast. This saves money and helps with new needs.

PGL gives extra services like shipment consolidation and last-mile delivery. These make shipping faster and lower costs.

Strong customer support and real-time tracking tools help clients stay updated. They also help fix problems fast. This keeps logistics running smoothly.

U.S. Warehousing Services in Miami, LA, Chicago, and Houston

Strategic Locations

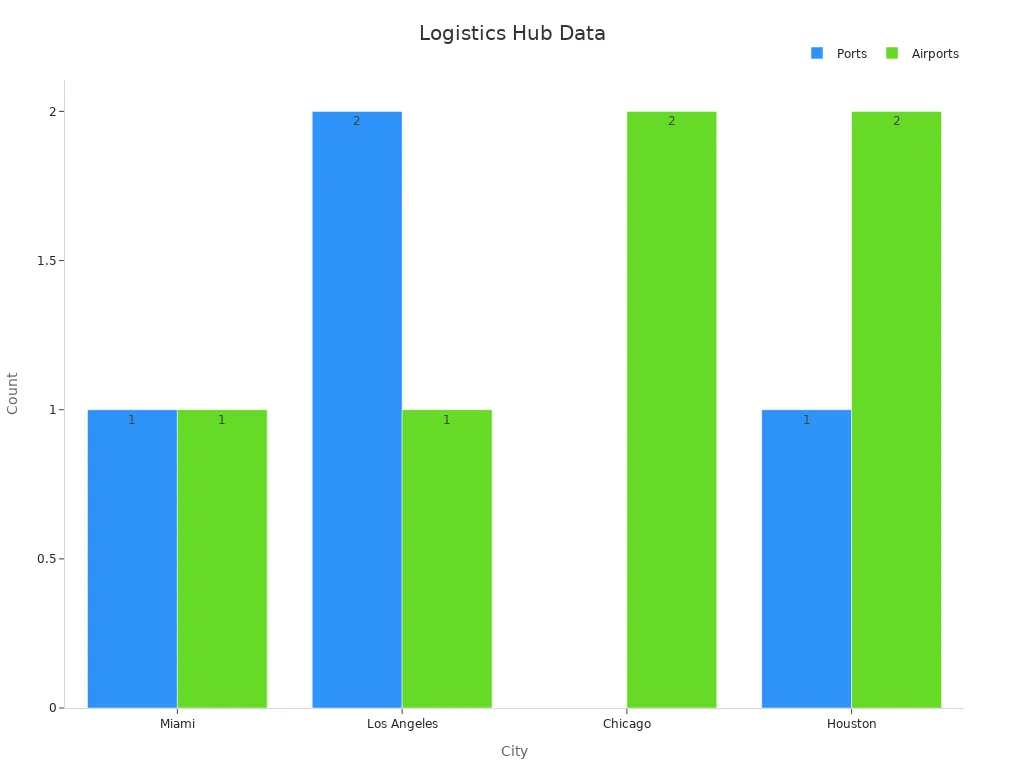

Miami, Los Angeles, Chicago, and Houston are important logistics cities. Each city is in a special spot that helps with warehousing and trade. These cities link big ports, airports, and highways. This makes moving goods easier and faster. The table below shows the main infrastructure in these cities:

City | Ports | Airports | Other Infrastructure |

|---|---|---|---|

Los Angeles | Port of Los Angeles, Port of Long Beach | Los Angeles International Airport (LAX) | Big highway system (I-5, I-10), rail (Union Pacific, BNSF) |

Chicago | N/A | O'Hare International Airport, Midway Airport | Major rail hubs (Union Station, CSX Barr Yard), highways (I-90, I-94) |

Houston | Port of Houston | George Bush Intercontinental, William P. Hobby | Highways (I-10, I-45), rail connections (Union Pacific, BNSF) |

Miami | PortMiami | Miami International Airport | Highways (I-95, Florida’s Turnpike), distribution centers |

These cities have direct access to ports and airports. This helps with international trade. Companies can move goods quickly between centers and customers. Miami connects to Latin America. Los Angeles links to Asia-Pacific. Chicago is a main spot for rail and air. Houston helps with Gulf Coast trade and cross-border shipping.

Distribution Advantages

U.S. warehousing services in Miami, LA, Chicago, and Houston have big benefits. Having warehouses in many cities saves time and money. Companies can keep products closer to customers. This makes shipping faster and more flexible. These cities have good roads with lots of traffic every day. For example, Los Angeles roads see up to 504,000 vehicles daily. Miami’s I-95 has 339,500 vehicles each day.

Houston’s warehouses are near I-10 and I-45. The I-610 loop helps traffic move smoothly. Houston’s airports serve over 50 million people each year. They also handle more than 500,000 metric tons of cargo. The Port of Houston sees over 8,000 ships every year. This helps with trade and shipping. Miami’s warehouses connect to PortMiami and the airport. This makes Miami a key spot for global shipping.

It is easier to manage inventory in these cities. Companies can send stock to the right places. This lowers shipping costs and keeps inventory steady. Each warehouse’s location helps companies react fast to changes. U.S. warehousing services in Miami, LA, Chicago, and Houston give businesses reliable and flexible shipping options.

PGL’s Warehousing Network

Facility Coverage

PGL has many warehouses across the United States. These buildings help store and ship products for many industries. The network includes big cities like Miami, Los Angeles, Chicago, and Houston. Each warehouse is close to highways, airports, or seaports. This helps PGL move goods quickly between places. They can send items from air cargo terminals to ocean ports and distribution centers.

PGL’s services change to fit what customers need. They offer storage for short or long periods. The team handles both palletized goods and special air cargo. Some logistics companies have trouble with space and accuracy. PGL’s network gives steady and reliable results.

PGL’s network can handle lots of products and grow fast. The warehouses store many types of goods, like consumer items and industrial tools. This helps clients react quickly when trade or markets change.

The table below shows important facts about PGL’s network:

Case Study / Partnership | Key Statistical Evidence | Network Reach / Operational Impact |

|---|---|---|

A-Gas Pilot Program | Demonstrates warehouse performance and capacity growth; improved inventory accuracy and visibility | |

AquaRecycle Partnership | 10% to 25% cost savings per shipment; access to DHL Express global network | Extends PGL's global shipping capabilities and competitive pricing |

Texas Rangers Case Study | Reduced equipment move time from all-day to 2 hours via process reengineering and palletization | Shows operational efficiency and logistics management effectiveness supporting large-scale events |

These facts show PGL’s network is accurate and efficient. The network works with partners to help clients reach global trade and air cargo routes.

Integrated Logistics

PGL’s network links warehousing, fulfillment, and transportation together. The company connects its buildings with trucks, ships, and planes. This makes it easy to move goods between warehouses and airports or seaports. Clients get faster shipping and lower costs because the network is well organized.

PGL uses special warehouse management systems to track inventory. The system lets clients see updates and reports in real time. Clients always know where their shipments are, from pickup to delivery. This helps them make better choices and avoid delays.

PGL Connect, made with LogixBoard, gives real-time updates and analytics.

The platform lets clients track shipments worldwide, like using an Airtag.

Clients get alerts at every important step, such as air cargo arrivals.

Live vessel tracking helps with ocean and air cargo planning.

Good communication tools make big warehousing and shipping projects easier.

Many logistics companies have trouble seeing and controlling their shipments. PGL’s network and technology fix these problems. The system gives smart predictions and automates important steps. This makes warehousing, fulfillment, and transportation work better together.

PGL’s network is special because it links buildings, air cargo, and trade routes. Their solutions help clients reach new places and manage tough supply chains. With warehouses near airports and ports, PGL moves goods quickly across the country and the world.

Proven Tactics

Technology & Automation

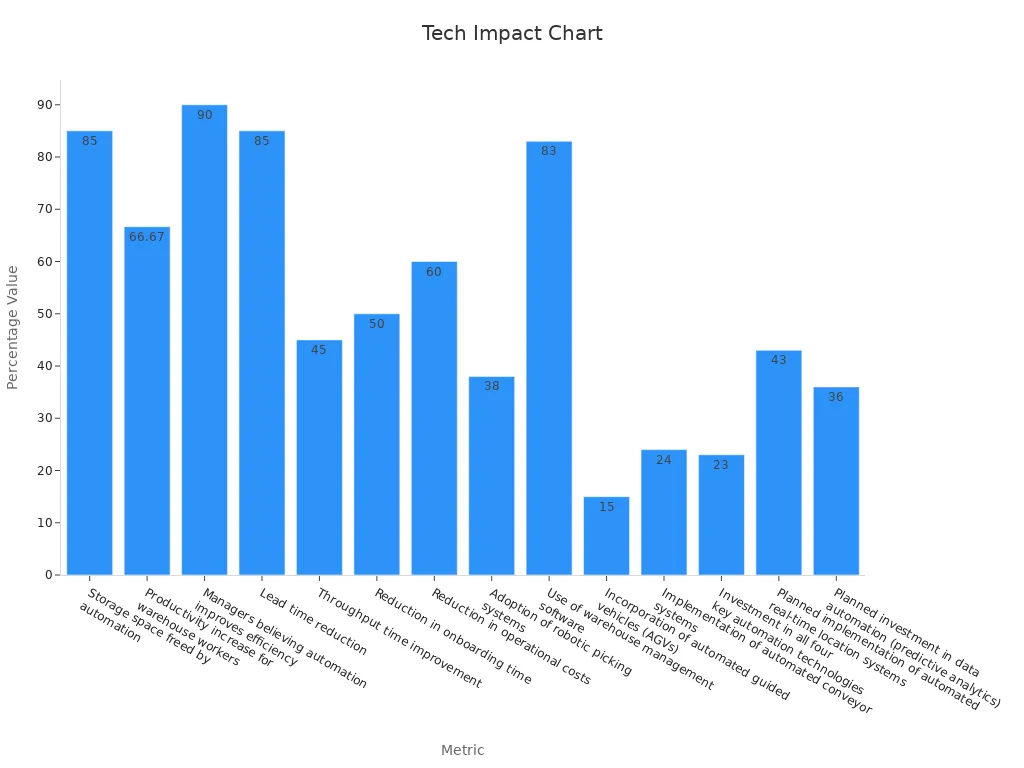

PGL uses advanced technology and automation to make work faster. They have a strong warehouse management system that tracks inventory live. This system links all parts of the network, from when goods arrive to when they are delivered. Automation tools like robotic picking and conveyor belts help process orders quickly and with fewer mistakes. Skilled teams watch over these systems to keep things running well and to react fast when demand changes.

A recent survey says 83% of warehouses use a warehouse management system. Also, 38% use robotic picking systems now. Automation frees up 85% of storage space. It makes workers 66.67% more productive. Pick accuracy goes up to 99.9%. Managers say automation cuts costs by 60%. It also shortens lead times by 85%. These changes help PGL give steady and fast service across its network.

Metric Description | Numerical Value | Impact/Explanation |

|---|---|---|

Storage space freed by automation | 85% | Lets companies keep more inventory without renting extra space, so profits go up. |

Productivity increase for warehouse workers | 66.67% | Automation speeds up tasks like counting and picking, so work gets done faster. |

Pick accuracy improvement | Up to 99.9% | Orders are filled more accurately, which means fewer returns and less wasted time. |

Managers believing automation improves efficiency | 90% | Most managers trust that automation makes warehouse work better. |

Lead time reduction | 85% | Automation helps manage inventory and tasks, so orders ship out much faster. |

Throughput time improvement | 45% | The time from making to delivering products is shorter because of automated checks. |

Reduction in onboarding time | 50% | New workers learn faster with automation, so they start helping sooner. |

Reduction in operational costs | 60% | Automation saves money in warehousing and supply chain work. |

PGL’s use of technology keeps every warehouse working at its best. The setup helps with fast shipping, even when there are lots of orders. Automation lets the team grow operations quickly to help clients in Miami, Los Angeles, Chicago, and Houston.

Flexible Solutions

PGL makes flexible warehousing and fulfillment plans for changing business needs. They offer both short-term and long-term storage. This lets clients change space and resources as needed. Flexibility helps companies handle busy seasons, new products, or sudden market changes.

Flexible warehousing saves money because businesses pay only for what they use. Companies do not need long leases or big upfront costs. Shared space and flexible workers also lower expenses. Studies show 64% of businesses save money and 73% see happier customers with flexible logistics.

Flexible warehousing lets companies put inventory closer to where it is needed. This makes shipping routes better and lowers shipping costs. The network can adjust quickly, so businesses can grow or shrink without waiting.

PGL’s network uses smart technology and data tools. These give real-time updates on inventory and shipping. This helps clients make good choices and react fast. The system links warehousing, fulfillment, and transportation for a smooth experience.

Value-Added Services

PGL adds extra services to warehousing and fulfillment. These include deconsolidation, consolidation, order fulfillment, and last-mile delivery. Each service helps goods move faster and reach customers quickly.

The table below shows how these services help:

Service Feature | Performance Benefit |

|---|---|

Combines shipments to save space and cut shipping costs. | |

Efficient Deconsolidation | Breaks down shipments fast, making inventory more accurate and speeding up delivery. |

Real-time Inventory Visibility | Gives better control and accuracy, so there are fewer stockouts and better order filling. |

Last-mile Delivery Solutions | Gets orders to customers on time and offers flexible delivery choices. |

Automated Reporting & Metrics | Gives useful information to keep making service and operations better. |

PGL’s network lets companies ship more without extra costs. Pooling shipments saves money and makes delivery times more steady. Fewer stops mean less damage and better product quality. Real-time tracking and clear updates help everyone see where goods are and keep customers happy.

Companies can grow without extra costs by using consolidation.

Pooling shipments into full truckloads saves money on shipping.

Fewer stops and less handling mean less risk of damage.

Faster delivery is possible with regional hubs.

Extra services like cross-docking and last-mile delivery make everything work better.

PGL’s setup and skills let them make custom plans for each client. They adjust warehousing and fulfillment for retail, e-commerce, and manufacturing. Clients get a network that fits their needs and helps them run smoothly and save money.

Competitive Edge

Service Control

PGL is different from other logistics companies because it controls its services well and can change quickly. The company gives many types of shipping, like air, ground, ocean, and intermodal. PGL also helps with warehousing, packaging, and special plans for certain industries. Some logistics companies only do one or two things. PGL does all the big logistics jobs, so clients can handle hard supply chains.

PGL uses a control tower to watch shipments and keep quality high. The PGL Connect portal lets clients track shipments live and manage them. Clients can also get custom reports. This tech tool helps PGL make fast changes and fix problems quickly. PGL’s smart technology and many shipping choices make it better than other companies. The company also ships goods that need certain temperatures and knows a lot about aerospace and government work.

PGL’s team works fast to fix problems and meet what clients want. They keep careful records and logs for every step. This close watching makes logistics better and keeps quality strong.

Customer Support

PGL thinks good customer support is very important for logistics. The company trains teams to answer fast and fix problems early. PGL’s staff talks with clients to learn what they need and give the best help. Many logistics companies have trouble keeping up with new needs. PGL’s support helps clients avoid delays and lower risks.

The operations manager leads the team to keep logistics safe and high quality.

Teams use warehouse management systems and compliance software to control things live.

Staff members spot routing problems and check shipments to make sure they arrive.

PGL looks at costs and picks the best way to ship for each client.

PGL’s customer support is better than most logistics companies. The company’s hands-on style and use of technology make its services strong and fast. Clients trust PGL to take care of their logistics from start to finish.

Results in Major Hubs

Miami

Miami is a main entry point for sending goods to Latin America and the Caribbean. Many companies use Miami’s fulfillment centers to reach new places fast. In the last four years, more warehouses in Miami have filled up. The rates went from about 60-65% to over 100%. Because of this, more warehouses were built in 2022. Miami’s distribution centers help businesses save money and reach new areas. They do not need to build their own buildings. Services like warehouse managed solutions and Importer of Record options make logistics and fulfillment easier. Miami is close to big ports and airports. This helps goods move quickly through distribution and fulfillment centers.

Miami’s network helps orders get processed fast.

Companies get flexible fulfillment and deliveries they can trust.

Miami’s logistics market is growing. Global warehousing could reach $1.264 billion by 2030.

Los Angeles

Los Angeles is a key place for sending goods on the West Coast and to Asia-Pacific. The city’s fulfillment centers are close to big ports. This helps with large shipments and quick moves between ocean freight and air cargo. Businesses use these centers for fast fulfillment and last-mile delivery. The logistics network in Los Angeles helps companies ship faster and keep customers happy.

Chicago

Chicago is in the middle of the country, so it is great for shipping everywhere. Fulfillment centers in Chicago help process orders fast and ship them to all regions. Companies use numbers like cycle time and lead time to check how well Chicago’s centers work. These numbers show how fast orders go from start to finish. Chicago’s network connects rail, air, and road. This helps businesses get orders out quickly and easily.

Chicago’s centers help companies set goals, watch progress, and make supply chains better.

Houston

Houston’s centers use new technology and flexible warehousing. The city has over 30 owned and operated facilities. This gives businesses speed and steady service. Houston’s fulfillment centers use real-time inventory management. This helps process orders fast and accurately. Houston is close to highways, railroads, and airports. This makes delivery times better. Houston’s experts handle everything from warehousing to last-mile delivery. Flexible space lets companies grow or shrink as needed. This saves money and helps distribution work better.

Houston’s centers give full fulfillment and logistics solutions.

Businesses get good prices and expert project management.

Real-time tracking helps make sure distribution is on time and reliable.

PGL’s warehousing solutions in Miami, Los Angeles, Chicago, and Houston help businesses do well.

The team uses new technology and smart tools to show what is happening right now and save money.

Flexible service choices and expert help let companies change plans fast.

Connected systems make work easier and give better control.

PGL is ready to make special logistics plans for each business. Companies that want strong and fast supply chain help can contact PGL for expert advice and good results.

FAQ

What makes PGL’s warehousing network unique?

PGL owns warehouses in big U.S. cities. The team uses new technology and skilled workers. This helps clients see their inventory right away and use storage that fits their needs.

How does PGL ensure fast and accurate order fulfillment?

PGL uses machines and a warehouse management system. The team checks each order from start to finish. This cuts down on mistakes and makes shipping faster.

Can PGL customize warehousing solutions for different industries?

Yes. PGL makes special plans for retail, e-commerce, and manufacturing. The team changes storage, order work, and extra services to match what each client needs.

What kind of customer support does PGL provide?

Special support teams answer questions fast.

Clients get updates right away with the PGL Connect portal.

The staff fixes problems and keeps logistics working well.

See Also

Finding The Ideal Warehousing And Fulfillment Solution In The U.S.

How PGL Excels In LTL And FTL Freight Shipping Services