How Project Cargo Shipping Handles Automotive Parts

You face unique challenges when you move automotive parts project cargo shipping. These parts often come oversized or carry high value, which means you need specialized packaging and careful handling. You cannot treat them like standard freight because insurance becomes more complex and costly. Most large items, such as transmissions or engines, ship on standard pallets, but some require custom solutions. Planning and coordination help you keep everything safe and efficient during transport.

Specialized packaging protects oversized or high-value parts.

Handling differs greatly from standard freight.

Insurance needs more attention and can cost more.

Key Takeaways

Specialized packaging is essential for protecting oversized or high-value automotive parts during transport.

Proper planning and coordination are crucial to avoid delays and ensure safe delivery of automotive parts.

Real-time tracking technology enhances visibility and allows for quick adjustments to shipping routes.

Working with specialized logistics providers streamlines the shipping process and helps navigate complex regulations.

Understanding the unique handling needs of automotive parts can prevent costly mistakes and improve supply chain efficiency.

Automotive Parts Project Cargo Shipping Overview

What Is Project Cargo Shipping

You may wonder what makes project cargo shipping different from regular freight. Project cargo shipping involves moving large, heavy, or complex items that need special handling and planning. You often see this type of shipping in industries like construction, mining, and energy. The process uses different transport modes, such as ocean, air, rail, or road. You need to coordinate every step and follow strict rules. The table below shows the main features of project cargo shipping:

Characteristic/Type | Description |

|---|---|

Definition | Project cargo shipping moves large, heavy, or complex items with special care. |

Planning | You must plan every detail and follow all regulations. |

Examples | Turbines, generators, military equipment, and automotive parts. |

Transportation Modes | Ocean, air, rail, and road—sometimes all in one shipment. |

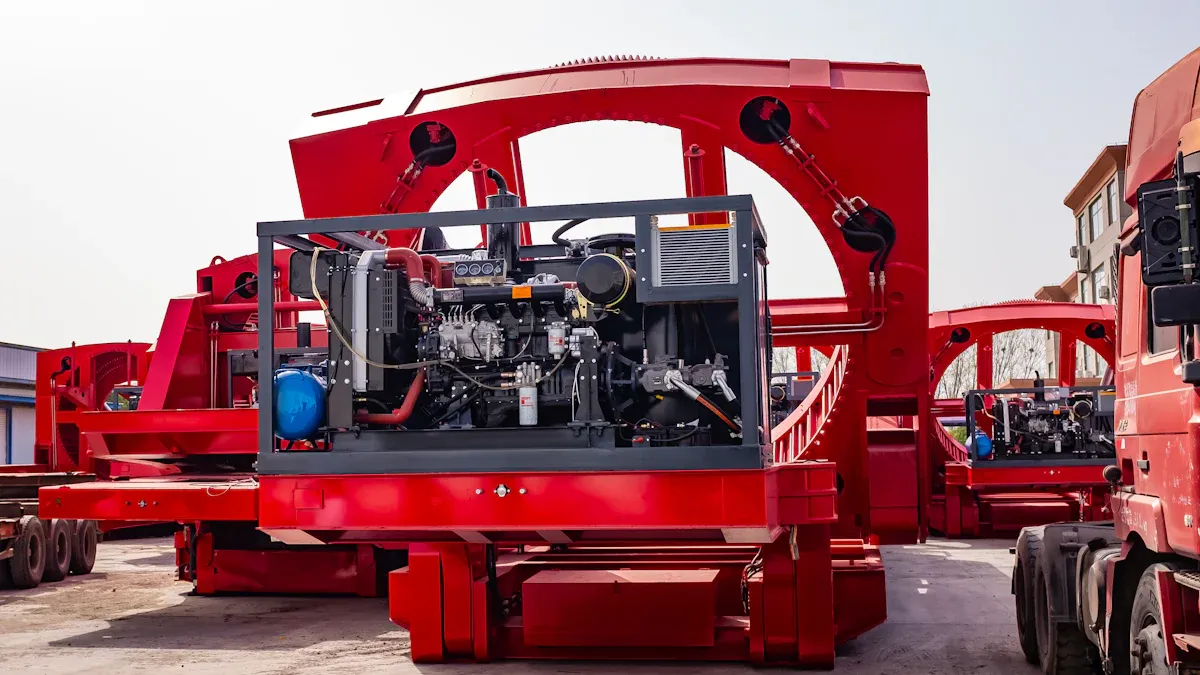

Why Automotive Parts Need Special Handling

You cannot treat automotive parts like regular packages. These parts come in many shapes, sizes, and weights. Some contain fluids or hazardous materials, so you must follow safety rules. If you ship batteries, you need fire-proof packaging. Missing paperwork can cause fines or delays. Here are some reasons why you need special handling for automotive parts project cargo shipping:

Different parts have unique shipping needs based on size and shape.

Some parts contain dangerous materials and need special safety steps.

You must use the right packaging, like aluminum cases with fire-proof inserts.

Proper documents help you avoid legal problems.

Importance for the Automotive Industry

You play a key role in keeping the automotive industry running smoothly when you use project cargo shipping for automotive parts. Careful planning and digital tools help you avoid delays. Real-time tracking lets you see where your shipment is at any time. This makes your supply chain more reliable and efficient. Strong partnerships with logistics providers help you deliver parts on time. When you handle automotive parts project cargo shipping well, you keep factories moving and customers happy.

Shipping Process Steps

Pre-Planning and Assessment

You start every automotive parts project cargo shipping journey with careful pre-planning. This step helps you avoid surprises and keeps your shipment safe and on time. Organized planning saves you money and reduces risks. Here are the main actions you take:

Obtain exact load and equipment details.

Use digital mapping tools to find possible transport corridors.

Check for physical, regulatory, and environmental limits.

Physical route surveys are indispensable to validate assumptions and uncover potential challenges that cannot be identified remotely.

You also review all collected data, verify risk assessments, and confirm the route before you move forward. Advanced logistics software, risk assessment protocols, and real-time data analytics help you spot problems early. Project management tools like digital twins and digital permit management make your job easier. You must also evaluate road conditions, bridge limits, port capacities, and loading facilities. Getting the right permits and understanding transport rules is key.

Packaging and Safety

You need strong packaging to protect oversized or sensitive automotive parts. Foam padding absorbs shocks and keeps parts from moving. Rubber mounts isolate parts from vibrations. Spring-based suspension systems give extra protection for delicate items. You often use foam, plastic, and cardboard for their protective qualities. For electronic parts, anti-static packaging stops static damage. Heavy parts travel safely in reinforced boxes or wooden crates. Thermoformed packaging fits custom shapes and sizes.

Common safety incidents during packaging include:

Unsecured loads that shift or fall.

Mishandling hazardous materials, which can cause spills or explosions.

Cargo overturns from unstable packaging.

Loads projecting outside vehicles due to sudden stops.

Damaged goods from shifting during transit.

Workplace accidents when opening unstable loads.

You must secure every load and follow safety rules to prevent these problems.

Transport Modes and Route Optimization

You choose the best transport mode based on the size and weight of your cargo. For automotive parts project cargo shipping, you often use road, rail, and ocean containers. Roll-on/roll-off vessels and specialized trailers help move heavy loads safely.

Route optimization software helps you deliver faster and save money. It shortens delivery times and gives you real-time traffic updates to avoid delays. You reduce wear and tear on vehicles, lower maintenance costs, and use vehicle space better. The software also helps you avoid toll roads and truck-restricted routes, cutting transportation costs and fuel use.

Execution and Monitoring

During the shipping process, you need to track your cargo in real time. You use web and Android applications that combine wireless, software, and hardware technologies. These tools give you end-to-end visibility and analytics on shipments and workforce activities. You can access this information through secure, cloud-hosted platforms.

Feature | Description |

|---|---|

Application Type | |

Technology | Wireless, software, and hardware integration |

Visibility | End-to-end shipment and workforce analytics |

Access | Cloud-hosted, secure web or client-owned servers |

You use IoT-enabled GPS trackers to monitor vehicle locations. Data goes to a central system for real-time updates. This lets you adjust routes quickly if you see delays. Predictive ETAs and proactive alerts help you plan dock labor and manage schedules. You can combine different systems for smooth transportation management. Instant data updates and dynamic optimization let you change routes and tasks on the fly, reducing idle time.

If you face disruptions or delays, you use AI-powered freight scheduling and predictive analytics. These tools help you spot problems like port congestion or weather issues. You can alert assembly plants and adjust production plans or trigger emergency orders. This keeps your supply chain moving, even when things go wrong.

Delivery and Final Handling

You finish the automotive parts project cargo shipping process with careful delivery and handling. Strategic planning helps you cut costs and meet safety standards. You must follow all regulations to avoid penalties. Optimizing the final mile makes your delivery more efficient.

You may need special equipment like cranes or flatbed trucks for oversized items. Working with experienced logistics providers ensures safe and timely delivery. You must secure the cargo, balance the weight, and use space wisely to reduce trips.

Common challenges during final delivery include:

High costs from fuel, labor, and vehicle maintenance.

Traffic and delays in busy urban areas.

Failed deliveries from wrong addresses or missed appointments.

High customer expectations for fast and accurate delivery.

Complex route planning with many stops and unpredictable factors.

Concerns about the environmental impact of last-mile delivery.

Difficulty integrating new technology for tracking and management.

You can overcome these challenges with good planning, the right tools, and strong partnerships.

Challenges and Solutions

Multi-Modal Coordination

You face many challenges when you move automotive parts using different transport modes. Each mode—road, rail, sea, or air—has its own rules and risks. You must plan routes carefully to avoid obstacles and follow all regulations. Packing and securing cargo is important to prevent damage. Customs clearance can cause delays if you do not prepare the right documents. You need strong project management skills to keep everything on track.

Route planning for oversized cargo is complex.

Packing and securing methods must protect your cargo.

Customs clearance requires expertise in international logistics.

Risk management and insurance are essential for high-value shipments.

You can use integrated logistics solutions and advanced tracking systems to make coordination easier. The table below shows how these strategies help:

Strategy | Impact on Shipping Efficiency |

|---|---|

Just-in-sequence (JIS) delivery | |

Integrated logistics solutions | Streamlines coordination of multiple transport modes |

Advanced tracking systems | Reduces transit times and improves delivery accuracy |

Timing and Scheduling

You must keep shipments on time to avoid costly delays. Many factors can disrupt your schedule, such as mechanical problems, strikes, or issues at ports. Using more than one transport mode increases the risk of delays.

Factor | Description |

|---|---|

Shipping vessels can break down and cause delays. | |

Intermodal issues | Switching between transport modes can create timing problems. |

Unexpected delays | Strikes or port issues can stop shipments. |

To solve these problems, you can use GPS tracking, automate order processing, and build strong relationships with carriers. These steps help you spot delays early and keep your shipments moving.

Tip: Strengthen your communication tools and set up automated alerts to reduce delays and keep everyone informed.

Risk and Safety Management

You must manage many risks when shipping automotive project cargo. High-value shipments need careful insurance checks. Contract language can be complex, and insurance gaps may exist if subcontractors do not have enough coverage. You should secure hazardous materials with leak-tight packaging, clear markings, and proper documentation.

Secure packaging prevents leaks and damage.

Mark all hazardous materials clearly.

Keep a Safety Data Sheet with your shipment.

You can also use Delivery Start Up (DSU) coverage to protect against losses from project delays.

Regulatory Compliance

You must follow many rules when shipping automotive parts across borders. Customs regulations, commercial invoices, and packing lists are required. You need to classify goods under the correct Harmonized System (HS) code and meet safety standards for hazardous materials.

Track inventory accurately.

Follow duty protocols for cost savings.

Train your team and audit your processes often.

Logistics providers stay updated on changing rules from agencies like the EPA, DOT, and CBP. This helps you avoid fines and keep your shipments moving smoothly.

Role of Specialized Logistics Providers

Expertise and Experience

You gain a major advantage when you work with specialized logistics providers for automotive project cargo. These experts know how to handle oversized and high-value shipments with precision. They manage every step, from booking to delivery and documentation. You benefit from their global logistics network, which covers ocean, air, and ground transport. They plan routes, secure permits, and coordinate inspections. You avoid delays because they use proactive strategies to handle customs and supply chain risks.

Expertise Area | Description |

|---|---|

Specialized Handling | Transporting oversized and high-value shipments with precision. |

Global Logistics Network | Access to a vast carrier network across all transport modes. |

End-to-End Project Management | Handling permits, inspections, and multimodal coordination. |

Risk Mitigation & Compliance | Strategies to avoid customs delays and disruptions. |

Customized Transport Planning | Tailored logistics plans for routing and compliance. |

Advanced Risk Management | Anticipating and solving logistical challenges to reduce delays. |

You see how companies like DHL and IAG Cargo use their experience to keep shipments efficient and reliable. Their teams adapt quickly to disruptions and find new solutions to keep your production moving.

Technology and Tracking

You stay informed about your shipment with advanced tracking technologies. Logistics providers use IoT-enabled sensors to monitor cargo conditions and vehicle health. You receive real-time alerts if temperature changes threaten sensitive goods. GPS tracking shows you the exact location of your shipment. RFID tags help you manage inventory and prevent losses. Geofencing creates virtual boundaries, so you get alerts if assets move outside safe zones. Blockchain technology keeps your tracking data secure and transparent.

IoT sensors give you continuous updates on cargo status.

GPS and RFID improve location tracking and inventory control.

Geofencing and blockchain add extra layers of security.

You optimize delivery routes and reduce the risk of misplaced shipments or theft.

Tip: Real-time tracking helps you prevent delays and respond quickly to any issues.

Benefits for Automotive Companies

You see measurable benefits when you partner with specialized logistics providers. Expert handling reduces the risk of damage to complex shipments. You avoid customs problems because your provider manages paperwork and compliance. Shipping routes get optimized, which lowers your costs. Your cargo arrives on time, so you prevent project delays. Advanced technology gives you real-time updates and better project management. You also receive tailored logistics solutions for each shipment.

Benefit | Description |

|---|---|

Expert Handling | Reduces risk of damage through specialized care. |

Compliance and Smooth Clearance | Navigates regulations and customs efficiently. |

Cost Efficiency | Optimizes routes and consolidates shipments to save money. |

Timely Delivery | Ensures cargo arrives on schedule, preventing delays. |

Advanced Technology | Provides real-time tracking and updates for better visibility. |

Tailored Logistics Solutions | Offers customized plans for each project cargo shipment. |

You keep your supply chain strong and your customers satisfied when you choose the right logistics partner.

You can trust project cargo shipping to move your automotive parts safely and on time. Careful planning and strong packaging protect your valuable items. Specialized logistics providers help you solve tough challenges and keep your supply chain running.

When you choose expert project cargo solutions, you gain peace of mind and reliable service for every shipment.

FAQ

What makes project cargo shipping different from regular shipping?

You handle larger, heavier, or more complex items in project cargo shipping. You need special planning and equipment. Regular shipping uses standard boxes and pallets. Project cargo often requires custom solutions.

How do you keep automotive parts safe during transport?

You use strong packaging, like reinforced crates or foam padding. You secure every part to prevent movement. You also track shipments in real time to spot problems early.

Can you ship hazardous automotive parts?

Yes, you can ship hazardous parts. You must follow strict safety rules. You need special packaging and clear labels. You also prepare all required documents.

Why do you need a specialized logistics provider?

You need experts for complex shipments. They know the best routes and handle all paperwork. They use advanced tracking tools. You save time and avoid costly mistakes.

What happens if your shipment gets delayed?

You get real-time alerts from tracking systems. You can adjust your plans quickly. Logistics providers help you find solutions and keep your supply chain moving.

See Also

Efficient Warehouse Solutions In Miami For Quick East Coast Shipping

Understanding Premier Global Logistics' B2B Services On The East Coast

Seamless Transfers Between Warehouses With Premier Global Logistics

PGL's Port-Side Support Ensures Quick And Easy Shipping

Versatile Trucking Solutions By PGL Enhance West Coast Freight Services