How to Improve Efficiency in Chemical Logistics Operations

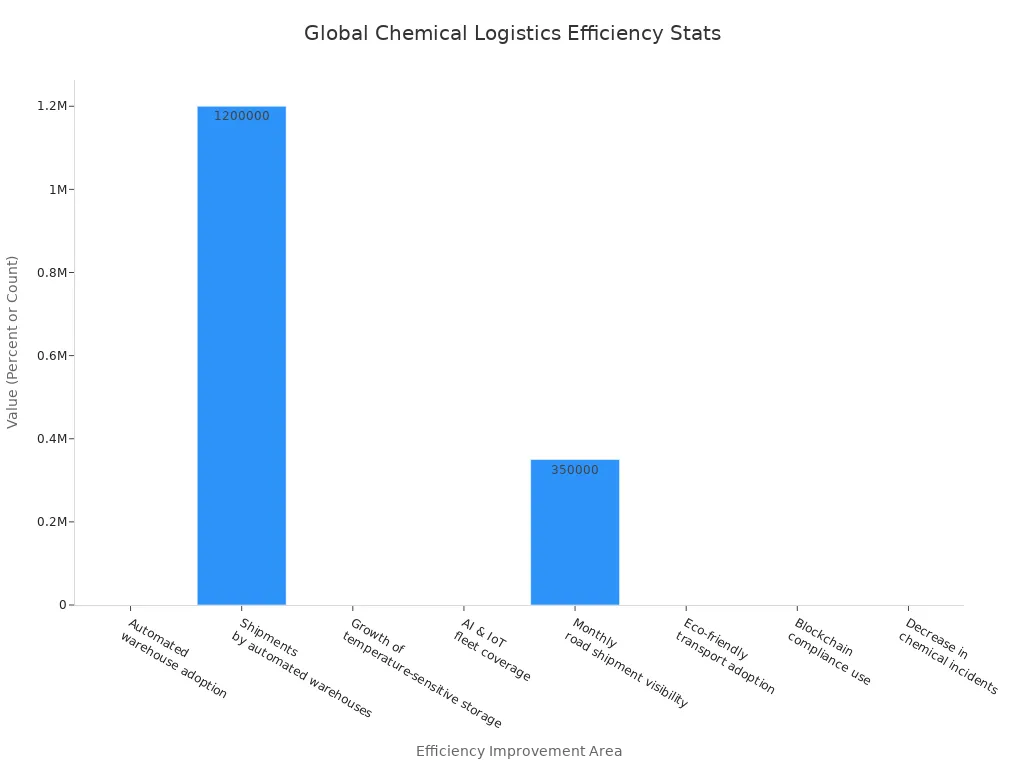

You can achieve chemical logistics efficiency improvement by using integrated solutions and advanced technology. Safety and compliance play a big role. You need strong teamwork and clear communication. Many companies now use automated warehouses, AI tracking, and eco-friendly transport. The table below shows how these changes help the industry:

Statistic Description | Value |

|---|---|

Increase in automated warehouse adoption | 32% |

Total shipments managed by automated warehouses | Over 1.2 million shipments/year |

Growth of temperature-sensitive chemical storage | 22% of total warehouse capacity |

Coverage of AI and IoT tracking in transport fleets | 28% |

Monthly visibility of road shipments | 350,000 shipments |

Adoption of eco-friendly transport methods | 12% of road fleet |

Use of blockchain for compliance verification | 15% of logistics operators |

Decrease in chemical incidents due to risk management | 23% |

You see better results when you use integrated approaches. These methods let you track shipments, lower risks, and improve safety. You also get more control over your supply chain.

Key Takeaways

Use integrated solutions and advanced technology to enhance efficiency in chemical logistics. This approach helps track shipments and improve safety.

Regular safety audits and staff training are essential. They reduce accidents and improve compliance, leading to a safer work environment.

Implement process mapping to identify bottlenecks. This visual tool helps streamline operations and enhances overall efficiency.

Adopt data analytics and tracking systems for better control over shipments. Real-time data improves decision-making and reduces downtime.

Focus on customer satisfaction by optimizing routes and schedules. Efficient logistics lead to faster deliveries and happier customers.

Why Chemical Logistics Efficiency Matters

Safety and Compliance

You face many safety and compliance challenges in chemical logistics. Changing regulations make it hard to keep up. You must handle hazardous materials with care. Trained staff help prevent accidents and mistakes.

Regulatory overload can happen because rules change often.

Hazardous chemicals need special handling and clear declarations.

A shortage of trained workers increases the risk of errors.

You need to keep accurate records and update your data systems. Safety Data Sheets must be easy to find. Regular audits check your storage and paperwork. Following these steps protects your team and your business.

Cost and Waste Reduction

You can lower costs and reduce waste by improving your processes. Good planning helps you avoid unplanned freight costs. You save money when you manage waste well. This also helps your brand and keeps you in line with regulations.

Benefit Type | Description |

|---|---|

Cost Reduction | Waste management cuts costs and boosts efficiency. |

Brand Reputation | Customers trust companies that manage waste responsibly. |

Regulatory Compliance | Meeting rules improves your image and avoids fines. |

You see better results when you use chemical logistics efficiency improvement strategies. Data analytics help you make smart decisions and plan better.

Customer Satisfaction

Your customers want fast and reliable service. Efficient logistics improve booking times and reduce cancellations. You can handle more orders and meet customer needs with accuracy.

Metric Description | Improvement | Timeframe |

|---|---|---|

Improved from 70% to 91% | Last 3 months | |

Booking confirmation for DG cargo within 2 hours | Over 50% of requests | Last 3 months |

Cancellation of bookings | Reduced to zero | N/A |

Automated systems help you fill orders faster and more accurately. You keep customers happy by meeting their expectations and providing full traceability.

Chemical Logistics Efficiency Improvement Strategies

Process Mapping and Workflow Documentation

You can start your chemical logistics efficiency improvement journey by mapping your current processes. Process mapping gives you a clear picture of how tasks, people, and resources connect. When you see the whole workflow, you spot bottlenecks and areas that slow you down. Teams often find hidden problems when they map out the steps from suppliers to customers. Regular updates to these maps help you stay competitive and keep your operations running smoothly.

Tip: Use flowcharts or value stream maps to visualize your logistics process. These tools make it easier to understand and share with your team.

Follow these steps for effective process mapping:

Define the scope and purpose of your mapping project.

Gather data like delivery times and inventory levels.

Choose the right diagram for your needs.

Map the current process and note any inefficiencies.

Analyze the map and look for ways to optimize.

When you document your workflows, you create a reference for training and troubleshooting. This practice supports continuous improvement and helps you respond quickly to changes.

Safety Audits and Staff Training

Safety audits and staff training play a big role in chemical logistics efficiency improvement. You need to check your safety procedures often. Audits help you find risks before they become problems. When you train your staff, you lower the chance of accidents and mistakes. One company saw a 20% drop in incidents and a 15% boost in efficiency after starting a special training program.

Many teams face training gaps. Common issues include:

Lack of digital fluency

Poor understanding of the whole process

Weak communication skills

Limited data analysis abilities

Not enough knowledge of trade rules

Trouble adapting to automation

Little hands-on training for new workers

Need for ongoing learning

You can close these gaps by offering regular training and encouraging your team to learn new skills. Well-trained staff work faster and safer, which helps your business grow.

Integrated Solutions and Collaboration

Integrated solutions and strong collaboration make chemical logistics efficiency improvement possible. When you centralize information, you connect knowledge and data across your company. A unified system lets you track chemical usage, spot risky substances, and manage compliance better.

You should break down silos between departments. Sharing platforms and processes helps everyone access important information. This teamwork speeds up responses and improves sourcing and safety. Control towers give you a full view of your supply chain. With predictive analytics, you can spot disruptions early and adjust your plans.

Note: Working with logistics partners who use extra safety checks and specialized infrastructure can boost your efficiency and safety.

Some companies have seen big gains by using integrated solutions. For example, Rinchem’s 4PL services improved inventory management by 60% for a large company. These results show the power of collaboration and smart systems.

Technology and Automation

Technology and automation drive chemical logistics efficiency improvement. You can use AI and robotic process automation to streamline your workflows. These tools help you collect and use data quickly, reduce errors, and cut down on manual work. Automation can speed up freight processing by up to 50% and save 30-40% on labor costs.

Here are some automation capabilities that help logistics teams:

Capability | Description |

|---|---|

Water Balancing and Accounting | Predicts water inventory and manages scheduling, reporting, and billing. |

Data Collection & Integration | Gives instant visibility and access to data through web and mobile apps. |

Process Control | Automates chemical dosing and water treatment processes. |

Pond Impoundment Mapping | Maps and monitors water infrastructure in real time. |

Water Quality and Automated Blending | Tracks water quality and optimizes composition. |

Leak Detection | Finds leaks to prevent losses and protect the environment. |

Flow Management | Measures water movement for better planning. |

Automated Motor Control | Controls pumps and manifolds for efficient water movement. |

Reporting and Command Center | Provides automatic updates and 24/7 monitoring for operations. |

You also get better scalability with real-time tracking and analytics. These features help you make smart decisions and keep your supply chain running smoothly. When you invest in automation, you see returns in efficiency, cost savings, and customer satisfaction. Smaller projects often show results in 2-3 years, while larger ones may take up to 5 years.

Tip: Start by assessing your current systems and defining your goals. Document both financial and non-financial benefits to measure your progress.

By using these strategies, you build a strong foundation for chemical logistics efficiency improvement. You can handle disruptions, work smarter, and keep your customers happy.

Advanced Practices for Efficiency

Data Analytics and Tracking Systems

You can boost your chemical logistics operations by using data analytics and tracking systems. Real-time tracking with GPS and RFID gives you better control over shipments. IoT sensors collect data on temperature, humidity, and movement. This helps you monitor chemical products and keep them safe. Data analytics lets you study large amounts of information. You can find patterns and improve your transportation routes. Predictive analytics helps you spot maintenance needs before they cause problems. Transportation Management Systems (TMS) show key performance indicators, so you make smarter decisions every day.

Tip: Use predictive analytics to reduce downtime and keep your supply chain running smoothly.

Real-time tracking increases visibility.

Data analytics improves route planning and inventory management.

Predictive analytics lowers unplanned downtime by up to 30%.

Inventory Management (JIT)

Just-in-time (JIT) inventory management helps you save money and reduce waste. You order materials only when you need them. This keeps your inventory low and cuts storage costs. JIT aligns material purchases with production needs. You improve cash flow and streamline operations. However, JIT can bring risks. You depend on suppliers and face possible stockouts if something goes wrong.

Benefits | Challenges |

|---|---|

Cost reductions | |

Improved efficiency | Increased complexity |

Minimized waste | Risks of stockouts |

JIT reduces excess inventory.

You must watch for supply chain disruptions.

Natural disasters or delays can impact your operations.

Routing and Scheduling Optimization

You can make your deliveries faster and cheaper by optimizing routes and schedules. Advanced software uses real-time data and predictive analytics. It checks traffic, delivery windows, and vehicle capacity. Heuristic and metaheuristic methods help you find the best routes. Dynamic routing adapts to changes quickly. Route optimization software can cut transportation costs by 12% and shorten delivery times by 20%. Efficient planning also lowers fuel use and vehicle wear.

Note: Avoid toll roads and restricted routes to save money and time.

Computer-based technologies like GIS and GPS support smart routing.

Real-time decision support systems help you respond to changes.

Optimized scheduling improves customer satisfaction.

You see chemical logistics efficiency improvement when you use these advanced practices. You gain better control, save money, and deliver products safely.

Common Mistakes to Avoid

Mistakes in chemical logistics can slow down your operations and increase risks. You need to watch out for these common errors:

Poor inventory management

Inadequate risk management

Overlooking supplier relationships

Ignoring sustainability

Lack of flexibility

Failure to invest in talent

Ignoring Regulatory Compliance

You must follow all rules when handling chemicals. Ignoring compliance can lead to serious problems. The table below shows what can happen if you do not meet regulations:

Consequence Type | Description |

|---|---|

Legal and Financial Consequences | Non-compliance can lead to heavy fines, unexpected legal costs, or bans, disrupting supply chains. |

Economic Consequences | Disruptions in supply chains and increased oversight can raise costs for businesses handling hazardous materials. |

Environmental and Health Risks | Mishandling hazardous materials can harm the environment and public health, leading to costly clean-ups and lawsuits. |

You need to clean up spills quickly and train your team on spill response. Good procedures and equipment help protect people and the environment.

Inadequate Documentation

Poor documentation can cause shipment delays and fines. You need clear records to meet growing traceability requirements. The table below highlights why documentation matters:

Risk | Impact |

|---|---|

Shipment Delays | Minor paperwork errors can stop shipments and cost you money. |

Lost Market Access | Incomplete records can block you from selling in some markets. |

Compliance Problems | Missing documents can lead to fines and legal trouble. |

Quality Assurance Gaps | Buyers expect full records to prove safety and quality. |

You should check your paperwork often and keep records up to date. Good documentation supports compliance and builds trust with customers.

Insufficient Training

You need to train your team regularly. Without enough training, you face more accidents, fines, and unhappy customers.

Continuous safety training ensures that all employees understand proper procedures and emergency responses. Training programs should be mandatory and regularly refreshed to maintain high safety standards.

Here are some problems that come from poor training:

More workplace accidents and higher costs

Regulatory fines and legal expenses

Product quality issues and recalls

Customer dissatisfaction and lost business

Higher insurance premiums

Increased staff turnover

You should teach your team about chemical hazards, emergency steps, and protective equipment. Regular refreshers help everyone stay safe and efficient.

You can improve chemical logistics efficiency by using process mapping, safety audits, and automation. Integrated solutions and teamwork help you solve problems faster. Technology gives you better control and saves money.

Review your current operations.

Choose tools that fit your needs.

Train your team often.

Keep learning and share ideas with others in your field. Working together helps everyone stay safe and efficient.

FAQ

What is the most important factor for improving chemical logistics efficiency?

You need to focus on safety and compliance first. These areas protect your team and your business. Technology and teamwork also help you reach higher efficiency.

How can technology help you track chemical shipments?

You can use GPS, RFID, and IoT sensors. These tools give you real-time updates. You see where your shipments are and check their condition.

Tip: Choose a tracking system that fits your company size and needs.

Why does staff training matter in chemical logistics?

Staff training keeps your team safe and skilled. You lower accident risks and improve workflow. Regular training helps everyone stay updated on new rules and tools.

What should you do if a chemical spill happens during transport?

You must follow your emergency plan. Alert your team and use spill kits. Report the incident to authorities. Quick action protects people and the environment.

Step | Action |

|---|---|

Alert | Notify your team |

Contain | Use spill kits |

Report | Contact authorities |

See Also

Transforming Global Operations Through Innovative Logistics Solutions

Key Strategies for Effective Global Logistics Management Success

Streamlining Supply Chains with American Global Logistics Solutions

Optimizing Inventory and Distribution Through Global Logistics Warehousing

Enhancing Global Efficiency with Point-to-Point Logistics Systems