Premier Global Logistics – Trusted Cold Chain Warehousing Across the East Coast

Not all warehouses can keep temperature-sensitive goods safe. Premier Global Logistics is a 3pl cold storage partner. They provide trusted cold chain logistics for pharmaceuticals and other important products. Many companies need Cold chain logistics for pharmaceuticals East Coast now. This is because there are strict safety and quality rules. PGL uses advanced systems with different temperature zones. They also use real-time monitoring. Their teams follow all rules. They keep products safe in important East Coast places.

Key Takeaways

Premier Global Logistics gives safe cold chain warehousing. They use advanced temperature control and real-time checks. This keeps medicines and other sensitive items safe.

More people need cold chain logistics on the East Coast. This is growing fast. Medicines like vaccines and biologics need strict temperature control.

PGL follows strict FDA, GMP, and GDP rules. They have important quality certificates. This makes storage and shipping safe and reliable.

Their warehouses are in Miami, New York, and Atlanta. They give fast, safe, and eco-friendly services. These places connect to big ports and transport centers.

PGL uses new technology like IoT, AI, and automated systems. This helps them work better and lowers risks. They also offer extra help like custom packaging and co-packing.

Cold Chain Logistics for Pharmaceuticals East Coast

Market Demand

More companies need cold chain logistics for pharmaceuticals east coast. They want safe ways to store and move medicines that need cold temperatures. In 2024, the U.S. cold chain logistics market was worth $109.5 billion. Experts think it will grow by 14.9% each year for ten years. North America, including the East Coast, will keep growing. The pharmaceutical logistics market was $94.6 billion in 2023. This growth is because more medicines and vaccines need cold storage. Now, about 35% of new medicines need cold chain management. In 2017, it was only 26%. In five years, half of all new medicines may need cold chain logistics for pharmaceuticals east coast.

East Coast ports are very important in this supply chain. But, labor problems and strikes could stop about half of the country’s ocean imports. These problems might cause delays and make shipping cost more. Companies should pick partners with strong cold chain logistics for pharmaceuticals east coast. This helps avoid risks and keeps products safe.

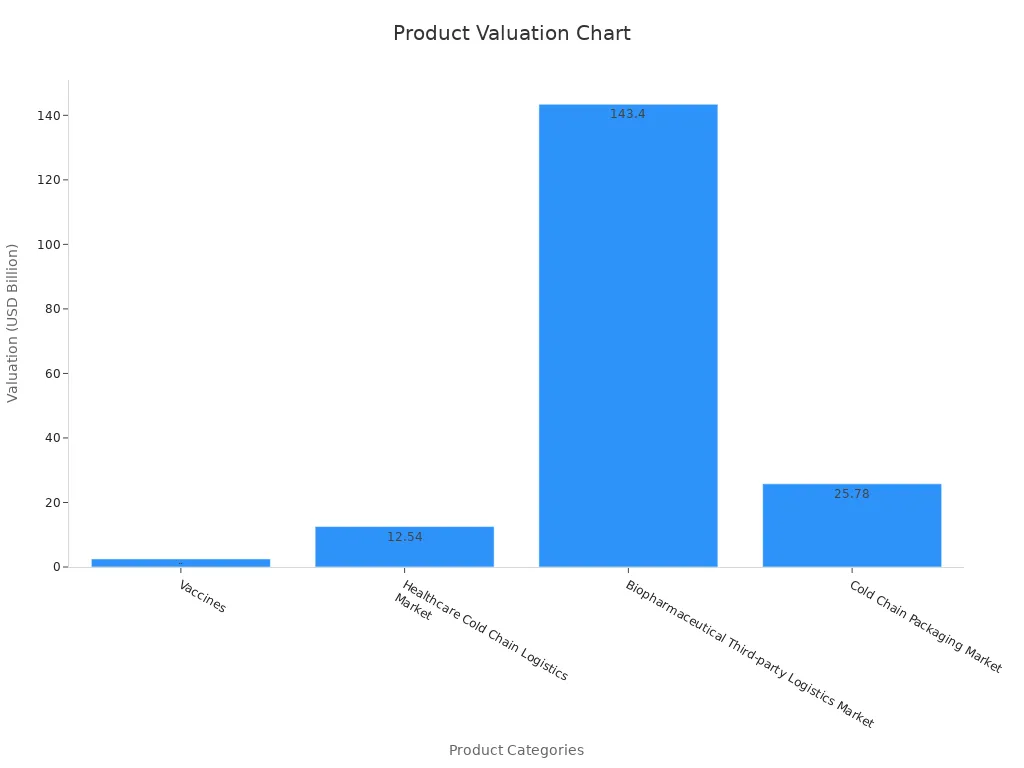

Product Categories

Cold chain logistics for pharmaceuticals east coast includes many products. The main ones are temperature-sensitive pharmaceuticals like vaccines, biologics, and special medicines. These need strict temperature control to stay safe and work well. The market also has other goods like frozen foods, dairy, seafood, cosmetics, and special chemicals.

Product Category / Market Segment | Valuation (USD Billion) | Year | Projected Valuation (USD Billion) | Projected Year | CAGR (%) | Additional Notes |

|---|---|---|---|---|---|---|

Vaccines | 2.5 | 2024 | 3.69 | 2032 | N/A | Growing focus on vaccine distribution |

Healthcare Cold Chain Logistics Market | 12.54 | 2024 | 20.29 | 2032 | 6.19 | Includes medications, vaccines, and biologics |

143.4 | 2024 | N/A | 2030 | 6.58 | Driven by demand for biologics and temperature-sensitive pharmaceuticals | |

25.78 | 2023 | 57 | 2030 | 12 | Packaging for temperature-sensitive products |

Note: Cold chain logistics for pharmaceuticals east coast helps not just medicines. It also helps food, cosmetics, and chemicals. This wide coverage keeps many products safe and follows the rules.

PGL’s Pharmaceutical Cold Storage Solutions

Storage Capabilities

Premier Global Logistics has advanced cold storage for many products. Their buildings have different storage types for different needs. The table below lists the main storage options and what they do:

Storage Type | Temperature Range | Examples | Typical Hold Time |

|---|---|---|---|

Refrigerated Storage | 2°C to 8°C (36°F to 46°F) | Vaccines, some biologics, certain drugs | Medium to long-term |

Frozen Storage | Below -18°C (0°F) | Biological products, tissue samples | Extended |

Controlled Environment | Specific temperature & humidity | Advanced therapies, specialty pharmaceuticals | Varies, typically long-term |

Cryogenic Storage | As low as -200°C (-352°F) | Cell and gene therapies (e.g., Kymirah, Yescarta) | Long-term, unbroken cold chain |

PGL uses cold chain packaging and special containers to keep medicines safe. Their warehouses can hold over 8,000 SKUs and have 99.97% inventory accuracy. Each storage area has strong cooling systems and tight security. These things help PGL serve clients who need safe cold chain packaging and storage for medicine, food, and cosmetics.

Note: PGL’s storage meets cGMP and ISO 9001:2015 standards. This means all pharmaceutical cold storage is handled safely and by the rules.

Temperature Control

PGL builds its cold storage with careful temperature control. Each warehouse has different zones: cold, frozen, and regular. This lets PGL store medicines and vaccines at the right temperature. Cold chain packaging and special containers keep products safe in storage and when moving.

Key features include:

24/7 temperature checks with sensors in every zone

Backup power so temperatures stay steady

Alarms that warn staff if temperatures change

Quick teams ready to fix problems fast

PGL’s systems use FIFO and batch tracking. This keeps medicines and other items at safe temperatures. Cold chain packaging and careful steps help keep products good from start to finish.

Real-Time Monitoring

PGL uses real-time monitoring to protect every shipment and storage batch. Their cold storage uses new technology to watch and report conditions all the time.

Key monitoring features include:

Real-time temperature checks with alerts for changes

GPS tracking for time and temperature rules

Data logs for audits and checks

Early warnings to stop product loss

IoT and AI tools for planning and fixing problems

Special trailers with more than one temperature zone

Blockchain tracking for safety and clear records

Automated warehouse tools to help with cold chain packaging and moving goods

Cryoport’s SmartPak II™ system shows how real-time monitoring works. It checks temperature, humidity, pressure, and even shock or movement. GPS and cell tech keep it connected, even in weak signal areas. This helps PGL keep high standards for cold storage and cold chain packaging.

Tip: Real-time monitoring and special containers help PGL follow FDA and GDP rules. This keeps medicines safe and makes sure they get to customers across the East Coast.

Regulatory Compliance

FDA, GMP, GDP Standards

Premier Global Logistics always follows the rules. They listen to the Food and Drug Administration, Good Manufacturing Practice, and Good Distribution Practice. These rules help keep products safe and working right. PGL trains their team often about these rules. They check each shipment for the right labels and papers. Workers use temperature logs and records to follow all the rules.

PGL’s warehouses have smart systems to watch temperature and humidity. These systems help keep vaccines and medicines safe. The company uses locked doors and tracking to stop tampering. These actions help keep every product safe in the supply chain.

Note: By following FDA, GMP, and GDP rules, PGL gives safe cold chain help for food, medicine, and cosmetics.

Quality Assurance

Quality assurance is very important to PGL. The company uses many steps to keep things safe and high quality. PGL has important certificates that show they care about quality:

ISO 14001 certificate for caring for the environment

ISO 45001 certificate for health and safety at work

These certificates show PGL’s ways meet world standards. Workers do checks and look for problems often. They use real-time tools to find issues fast. This focus on quality helps stop product loss and keeps goods safe for customers.

Certification | Focus Area | Benefit to Clients |

|---|---|---|

ISO 9001 | Quality Management | Consistent, reliable service |

ISO 14001 | Environmental Management | Eco-friendly operations |

ISO 45001 | Health and Safety | Safer work environment |

Strategic East Coast Locations

Miami

Miami is an important city for cold chain logistics on the East Coast. It connects North America with Latin America and the Caribbean. PGL’s Miami warehouse helps move medicines, vaccines, and other goods that need cold storage. The building has special temperature zones and real-time checks. Security is very strong. Miami’s spot lets companies ship products fast by air or sea. Many medicine importers pick Miami because of its customs skills and FDA rules. Food and cosmetic brands also use Miami’s good logistics system. The PGL team in Miami handles urgent shipments and keeps products safe from start to finish.

New York

New York is a big part of moving medicines on the East Coast. PGL’s warehouse is close to the busy Port of New York/New Jersey. This spot gives clients easy access to highways, airports, and trains. The New York warehouse uses RFID systems to track things better. It has the biggest solar power setup in the area. This shows PGL cares about the environment. The warehouse won the World Trade Week NYC Global Logistics Award. Food Logistics put it on the Top 3PL & Cold Storage Providers List many times. These things help PGL give safe and trusted cold chain services for medicines, food, and cosmetics. Companies trust New York for quick, safe, and green shipping.

Atlanta

Atlanta is a main place for logistics in the Southeast. PGL’s Atlanta warehouse helps deliver medicines with high standards. The building has the CEIV Pharma certification. This means it follows strict world rules for handling sensitive medicines. The team uses special containers to keep products cold during travel. They have strong quality checks, good training, and clear steps to follow. Atlanta’s location connects to big airports and highways. This makes it easy to reach customers all over the East Coast. Medicine and healthcare companies count on Atlanta for safe and on-time deliveries.

PGL’s locations in Miami, New York, and Atlanta give clients fast, safe, and trusted cold chain warehousing. These key places help brands meet demand and keep products safe at every step.

Overcoming Challenges & Innovations

Risk Management

Premier Global Logistics faces many problems in cold storage for medicine. Keeping the right temperature is hard. Moving temperature-sensitive pharmaceuticals is also tricky. These things can make products unsafe. PGL uses different ways to lower these risks:

They talk often with suppliers and get ready for emergencies.

Their team checks important product groups every week using data.

PGL spreads out where they get products and makes more in the U.S. to stop shipping delays.

They use tested shipping containers and good cold chain packaging to keep products safe while moving.

Real-time monitoring, GPS, and temperature loggers help them see problems early and stop them.

Working with third-party logistics early helps make supply chains that can change fast.

PGL works with all partners to keep products safe at every step.

These actions help PGL save money, follow the rules, and deliver medicine safely.

Technology Integration

PGL uses new technology to make cold chain packaging and storage safer and better. Their warehouses have IoT devices like smart temperature sensors, GPS trackers, and humidity monitors. These tools give real-time data to keep storage just right. AI-powered analytics help spot equipment problems and find the best delivery routes. This means less downtime and less waste.

Robots and AS/RS in cold storage help pick orders right.

Cloud-based Warehouse Management Systems let people see data and work from anywhere.

AI-driven energy management cuts power use and helps the planet.

Autonomous Mobile Robots lower mistakes and keep warehouses clean.

These new ideas help PGL keep high standards for storing and moving temperature-sensitive pharmaceuticals.

Value-Added Services

PGL gives extra services that make customers happy and help the supply chain work better. Services like kitting, co-packing, and custom cold chain packaging help clients meet what the market wants. These services make things faster and cut wait times.

Co-production and repacking help customers spend less on workers.

Customization fits special needs and helps sell more.

Using inventory management software and performance checks gives steady service.

Studies show value-added services make orders more reliable, fill orders better, and keep things safer. Customers want special solutions, and PGL gives them by focusing on accuracy, speed, and clear data. These services help clients save money, follow the rules, and do better when moving pharmaceuticals.

Premier Global Logistics is a top company for cold chain logistics for pharmaceuticals on the East Coast. The company uses new technology and follows all the rules. Their teams know how to keep sensitive products safe. Many brands pick PGL as their 3pl cold storage partner. PGL has a strong network and good systems. These help clients follow safety rules and deliver products on time. Companies that want safe and smart cold chain solutions choose PGL.

FAQ

What temperature zones does Premier Global Logistics offer?

PGL has three main temperature zones. These are frozen (-20°C), refrigerated (2–8°C), and controlled ambient (15–25°C). These zones help keep pharmaceuticals, food, and cosmetics safe. Each area has special sensors. The sensors check temperatures all day and night. This helps keep the right temperature.

How does PGL ensure regulatory compliance for pharmaceuticals?

PGL follows FDA, GMP, and GDP rules. The team checks who enters the warehouse. They track each batch and write down temperatures. Workers get training often. Audits happen to make sure rules are followed. Clients get reports for every shipment.

Can PGL handle urgent or high-frequency shipments?

Yes. PGL’s warehouses in Miami, New York, and Atlanta can handle fast orders. The team uses machines to sort and pack items. They update inventory in real time. This helps with urgent deliveries.

What value-added services does PGL provide for B2B clients?

PGL offers kitting, co-packing, relabeling, and custom cold chain packaging. These services help brands do better in the market. They also make the supply chain work better. Clients can ask for special solutions for food, pharmaceuticals, or cosmetics.

Who should consider PGL’s cold chain warehousing solutions?

Food brands, pharmaceutical importers, cosmetics companies, and international freight forwarders can use PGL’s safe and flexible cold chain warehousing on the East Coast.

See Also

Comprehensive Guide To Premier Global Logistics East Coast Services

Fast Order Fulfillment With Premier Logistics Warehousing In NJ And FL

Enhancing West Coast Operations Through Premier Logistics LA Warehousing

Trusted East Coast Warehousing And Distribution Across Multiple States

Top Reasons To Select Premier Global Logistics For Export Needs