How DC Logistics Streamlines Supply Chain Management for Modern Businesses

DC Logistics supply chain management helps you automate daily tasks, speed up operations, and simplify complex processes. You gain extra time and resources for your team. Many businesses have seen a 60% increase in efficiency after switching to these solutions. You can focus on profit margins and build resilience for your company. With smart systems, you stay ahead in a fast-changing market.

Key Takeaways

DC Logistics boosts efficiency by automating tasks, leading to a 60% increase in operational performance.

Effective supply chain management enhances customer satisfaction through timely deliveries and better inventory control.

Automation reduces manual errors and downtime, allowing teams to focus on strategic tasks.

Real-time data integration helps businesses respond quickly to market changes and improve decision-making.

Optimizing distribution centers can lower costs and improve service, driving business growth and customer loyalty.

Supply Chain Management Basics

What Is Supply Chain Management

You manage many moving parts when you run a business. Supply chain management helps you organize these parts so your products reach customers on time. Experts say supply chain management means planning and managing all activities related to sourcing, procurement, conversion, and logistics. You work with suppliers and customers to make sure everything runs smoothly. This coordination helps you deliver value and stay ahead of competitors.

Supply chain management is a strategic way to connect all supply chain activities. You use it to maximize customer value and gain a strong advantage in your market.

When you look at the basics, supply chain management includes several key components:

Planning

Sourcing

Making

Delivery

Returning

Each part plays a role in getting products from the start to the finish line. You plan how much to make, choose where to get materials, create products, deliver them, and handle returns. dc logistics supply chain management uses these steps to help you build a reliable process.

Importance for Modern Businesses

You face tough competition in today’s market. Supply chain management gives you tools to stay ahead. Here are some reasons why it matters:

You boost efficiency and cut costs, which helps you compete.

You keep customers happy with fast delivery and good inventory control. Satisfied customers come back again.

You respond quickly to changes in the market. This agility helps you survive and grow.

You get an edge over others with better product availability and customer service.

If you want your business to grow, you need a strong supply chain. dc logistics supply chain management helps you reach your goals by making every step easier and faster.

Challenges in Supply Chains

Inventory and Demand Fluctuations

You face constant changes in customer demand. Sometimes, you have too much inventory. Other times, you run out of stock. These swings can hurt your business. You need to keep enough products to meet customer needs but avoid extra stock that ties up money. A data-driven approach helps you manage this uncertainty. You can use key metrics like forecast accuracy, stockout levels, and inventory turnover to track how well you handle these changes.

Tip: Accurate forecasting and demand planning help you stay ahead of demand swings and keep your supply chain running smoothly.

Some of the biggest challenges you may face include:

Demand volatility that makes inventory planning difficult

The need for real-time data to adjust quickly

The importance of tracking inventory management metrics

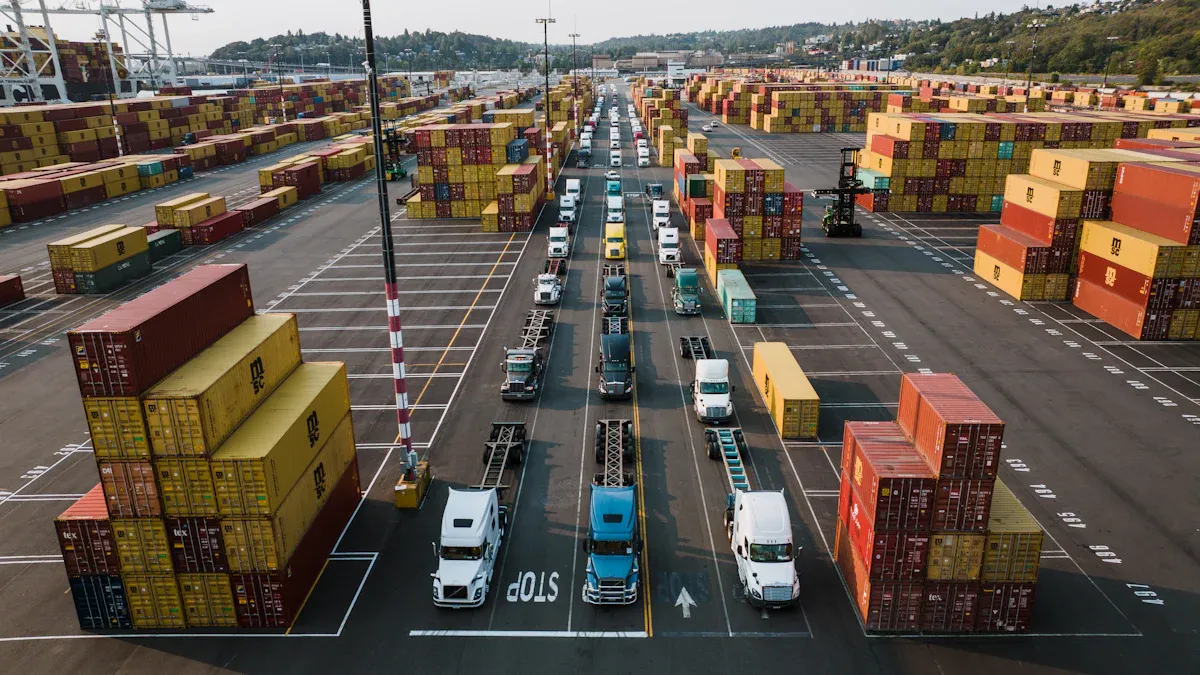

Transportation and Delivery

Getting products to customers on time is not always easy. Many factors can cause delays. You might see problems from bad weather, rising fuel prices, or even customs rules. Worker shortages and supplier issues can also slow things down. The table below shows some main causes of transportation and delivery delays:

Cause of Delay | Description |

|---|---|

Weather-Related Disruptions | Natural events can halt shipments for extended periods, especially affecting land and overseas transport. |

Transportation and Logistics Issues | Rising fuel prices, worker shortages, and increased online sales contribute to significant delays. |

Customs and Regulatory Hurdles | Stricter regulations and customs processes lead to long clearance times for international shipments. |

Supplier and Manufacturing Delays | Disruptions from suppliers and manufacturers, often due to geopolitical issues and pandemics, affect delivery schedules. |

You need strong systems to handle these risks and keep your deliveries on track.

Visibility and Costs

You need to see every part of your supply chain to control costs. Poor visibility can lead to higher expenses. For example, you might carry too much inventory or pay extra for fast shipping. Labor costs can also rise if you do not have clear information. The table below shows how limited visibility can increase costs:

Cost Type | Impact (%) |

|---|---|

Excess Inventory Carrying Costs | 20-30% increase |

Expedited Shipping Expenses | 15% increase |

Labor Inefficiencies | 20-25% of costs |

With dc logistics supply chain management, you gain better visibility and control. This helps you reduce waste and improve your bottom line.

DC Logistics Supply Chain Management Solutions

Automation and Workflow Acceleration

You can transform your supply chain by using automation. Automation speeds up your daily tasks and reduces manual work. You avoid mistakes that often happen with repetitive jobs. Automated systems spot errors quickly and fix them, so your team spends less time on corrections. Real-time data helps you predict demand and manage inventory better.

Some of the most effective automation technologies include:

Physical automation, such as robotics, improves how you move and store products.

Workflow automation streamlines your processes and increases efficiency.

AI and robotics handle complex tasks, making your supply chain faster and more reliable.

Hyper automation combines AI, machine learning, robotic process automation (RPA), and data analytics to boost efficiency in procurement, production, and distribution.

IoT devices and RPA minimize errors and save time in sourcing and customer service.

Automation in dc logistics supply chain management helps you reduce manual mistakes, lower downtime, and keep your warehouse running smoothly.

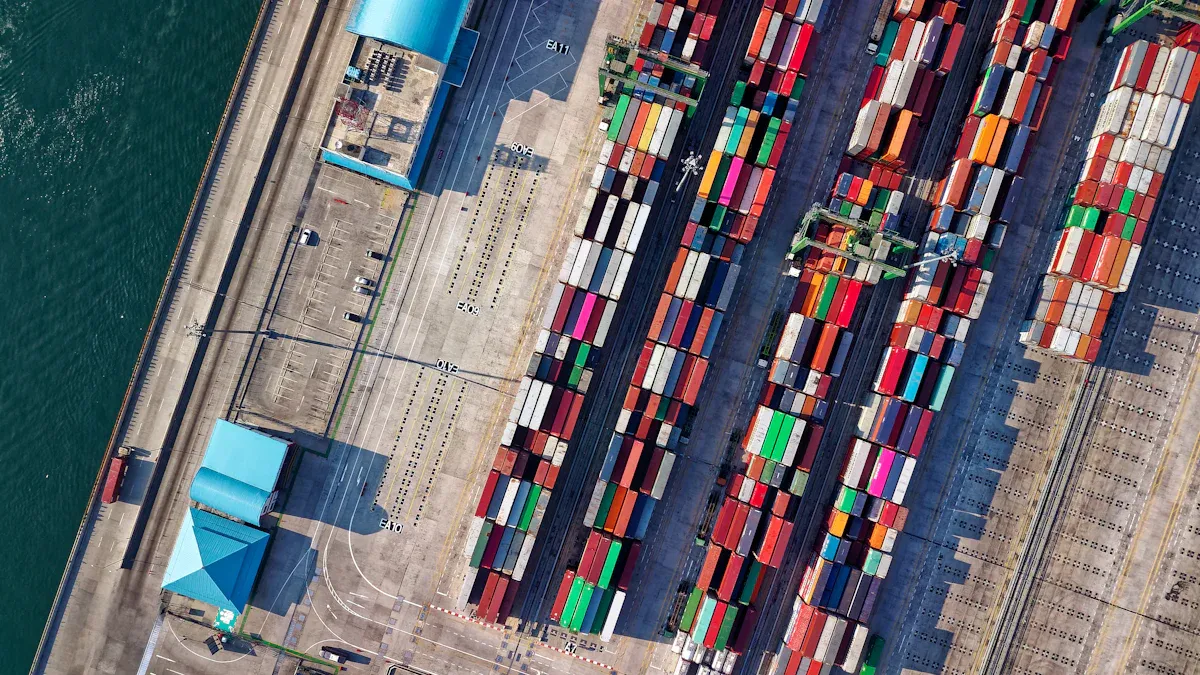

Distribution Center Optimization

You can optimize your distribution centers to improve delivery and consolidate shipments. This strategy saves money and makes your supply chain more efficient. Distribution centers use advanced planning and real-time data to manage inventory and routes. They group shipments together, which is ideal for e-commerce businesses with many small orders. They also adjust delivery schedules for just-in-time manufacturing, so parts arrive exactly when needed.

Strategy | Focus | Implementation Complexity |

|---|---|---|

Reduce costs and improve efficiency | Needs advanced planning, inventory management, and route optimization. | |

Delivery Schedule | Ensure timely and reliable delivery | Uses real-time data and dynamic adjustments for changes. |

Optimizing your distribution centers brings many benefits:

Benefit | Description |

|---|---|

Better planning lowers your expenses. | |

Improved customer satisfaction | Faster, more reliable service keeps customers happy. |

Enhanced operational efficiency | Streamlined processes increase productivity. |

Risk mitigation | Good planning reduces disruptions. |

Increased sales and revenue | Efficient supply chains support business growth. |

Sustainability | Eco-friendly logistics help the environment. |

Technology Integration

You can use advanced technology to make your supply chain smarter. AI-powered transportation management systems (TMS) help you plan and track shipments. Warehouse robotics move products quickly and safely. End-to-end automation connects every part of your supply chain, cutting costs and saving time.

Key technology integrations include:

Blockchain, IoT, and AI & ML streamline your operations.

Digital twins let you simulate your supply chain and manage risks.

Real-time data integration gives you instant insights into demand, so you can forecast accurately and adapt to changes.

Better reporting helps you spot problems right away and make quick decisions.

Real-time data and smart technology in dc logistics supply chain management give you a clear view of your operations and help you stay ahead of disruptions.

Scheduling Solutions

Effective scheduling keeps your supply chain running on time. You need to deliver goods when customers expect them. Poor scheduling can lead to late deliveries and higher costs. Modern scheduling solutions use automation and real-time visibility to track shipments and adjust to changes fast.

Key features of strong scheduling solutions:

Automation reduces manual errors and speeds up planning.

Real-time visibility lets you monitor shipments as they move.

Flexibility helps you respond to changes in demand.

Data-driven decision-making uses analytics to improve efficiency.

You can use strategies like Master Purchasing Receipt Scheduling and dock arrival scheduling. These tools make sure raw materials and parts arrive when you need them, so your production never stops. They also connect your ERP, WMS, TMS, and dock scheduling systems for precise timing. Well-organized dock scheduling reduces wait times and costs, making your supply chain more reliable.

Smart scheduling in dc logistics supply chain management ensures you deliver on time, save money, and keep your customers satisfied.

Business Impact

Efficiency Gains

You can achieve impressive efficiency gains when you use dc logistics supply chain management. Many companies report big improvements after adopting AI solutions. You see better fleet planning, route optimization, and overall operational efficiency.

70% of businesses now use AI, which is a 17% increase from last year.

Fleet planning improved by 36%, route optimization by 35%, and operational efficiency by 34%.

About 40% of companies saved at least 50% on fuel costs, operational expenses, and distance traveled with AI-powered route optimization.

Case studies show real results. A global automated material handling company used predictive analytics to solve problems quickly and keep operations reliable. Sager Electronics improved visibility into shipments, which helped manage inventory and communicate with customers better.

Case Study | Description |

|---|---|

Contract Warehouse Solutions | Optimized supply chain management, reduced costs, and improved visibility. |

Transportation Optimization Strategies | Streamlined operations for clients in many industries. |

Cost Reduction

You can lower your operational expenses by streamlining supply chain processes. Efficient management helps you save money and boost profits.

Optimizing warehouse space and inventory stock creates new efficiencies.

Better order processing leads to more savings.

Improved supply chain processes increase customer satisfaction and overall profitability.

When you use dc logistics supply chain management, you free up resources for other important tasks. You spend less on storage and transportation, which helps your business grow.

Flexibility and Responsiveness

You need flexibility to handle changes in the market. DC Logistics helps you tailor services to meet your unique needs, especially during busy seasons. You can use dynamic truck routing to solve complex logistics challenges. Real-time data exchanges between warehouse and logistics operations make your business more responsive.

You can switch suppliers or routes to reduce risks.

You adjust production levels and distribution channels quickly to meet changing demand.

You seize new opportunities, like entering new markets or launching products.

Improved forecasting of labor needs and collaborative transparency help you respond faster when your business grows. Flexibility makes your supply chain resilient, so you can adapt to disruptions and keep customers happy.

You can transform your business with dc logistics supply chain management. Collaborative logistics and seamless integration help you optimize your network and reduce risks.

Case studies show up to €10 million in annual savings per facility and a 33% drop in logistics costs.

To achieve supply chain excellence, follow these steps:

Automate your processes.

Enhance communication with dispatching tools.

Use inventory management systems to predict trends.

FAQ

How does DC Logistics improve supply chain visibility?

You get real-time tracking for shipments and inventory. This helps you spot problems early and make quick decisions.

Tip: Use dashboards to see updates and alerts for every step in your supply chain.

What automation tools can you use with DC Logistics?

You can use robotics, AI, and IoT devices. These tools help you speed up tasks, reduce errors, and save time.

Robotics move products faster

AI predicts demand

IoT tracks shipments

Can DC Logistics help you lower costs?

Yes. You optimize routes, reduce storage needs, and avoid extra shipping fees. Smart planning and automation help you spend less on labor and transportation.

How does DC Logistics support business growth?

You scale your operations easily. You add new suppliers or enter new markets without slowing down.

Note: Flexible systems let you adjust quickly when your business expands.

See Also

Efficient East Coast Import Warehousing Solutions By PGL

Optimized Inventory Management And Distribution Through PGL Warehousing

PGL Enhances West Coast Trucking For Today's Supply Chains

Connecting Warehouses And Optimizing Supply Chains With PGL

Understanding PGL's East Coast B2B Warehousing And Distribution Services