Premier Global Logistics – Optimized Project Trucking Across the West Coast

Dedicated truck routes for West Coast supply chain operations significantly improve efficiency. Companies rely on these specialized routes to transport large project freight across California, Nevada, Arizona, Oregon, and Washington, where regular shipments are essential. Premier Global Logistics designs dedicated truck routes for West Coast supply chain needs, optimizing costs and streamlining operations. Their trucking plans incorporate two-way trips to minimize empty runs, maximizing value on every journey. In today’s logistics landscape, this level of strategic planning is crucial to maintaining steady and reliable supply chains.

Key Takeaways

Special truck routes on the West Coast help companies spend less money. They do this by having fewer empty trucks and using less fuel. Smart planning and two-way trips make deliveries faster and more reliable. This can also lower shipping costs by up to 30%. Using AI and real-time data helps change routes quickly. This helps trucks avoid traffic and bad weather. It keeps shipments on time. When shippers, carriers, and warehouses work together, they share trucks and information. This makes things run better and lowers transport costs. Always trying to get better and using new technology helps companies give better service. It also helps them waste less and grow their business over time.

Dedicated Truck Routes for West Coast Supply Chain

What Are Dedicated Truck Routes?

Dedicated truck routes help move goods on the West Coast. They are very important for companies that ship a lot. These routes are special paths for trucks. They connect big places like California, Nevada, Arizona, Oregon, and Washington. The roads on these routes are wider and can hold heavier trucks. There are also fewer rules, so big trucks can travel safely and quickly.

Companies use these routes to ship goods often and on time. This helps keep products moving without delays. For project freight and full truckload (FTL) shipments, these routes help teams plan better. They can make sure deliveries happen when needed.

Note: Dedicated truck routes for West Coast supply chain projects go both ways. Trucks carry loads out and bring loads back. This helps trucks avoid driving empty. It saves money and makes work more efficient.

Some main things about dedicated truck routes are:

Only commercial trucks use them, so there is less traffic.

They are made for big shipments and special projects.

They work with smart scheduling and dispatch systems.

They can change to fit what customers need or when stores need more products.

Benefits for High-Volume Shipments

Dedicated truck routes give many benefits to companies that ship a lot. They help save time, lower costs, and make deliveries more reliable. This is why they are important for today’s shipping needs.

Key benefits include:

Trucks spend less time traveling and waiting.

Companies save money on fuel and use trucks better.

Deliveries are on time and dependable.

Companies can handle changes in shipment size or timing.

There is less risk of goods getting lost or damaged.

When companies ship a lot, these routes help them save even more. Shipments are grouped together along the West Coast. This means trucks do not have to drive empty as much. Truckload carriers also save money by using fewer empty miles. Programs like the Empty Miles initiative help share space and cut waste.

Real-world examples show these benefits:

Stores get new products every week, so shelves stay full. Computers help order more products when needed. This keeps waste low and saves money. Companies can restock faster and with fewer mistakes.

For big projects, like building or setting up events, these routes help keep everything on schedule. They make sure materials arrive when needed.

Aspect | Statistic / Case Study Detail |

|---|---|

Warehouse Management | 25% productivity increase using WMS (Gartner, 2022) |

Walmart Cross-Docking | 10-15% reduction in inventory holding costs |

Zara Inventory Tracking | Restocks best-sellers within 48 hours, minimizing stockouts |

Boot Barn’s Kansas City center shows how well these routes work. With automation and dedicated lanes, they work 250% faster. Labor costs dropped by half, and picking is always correct.

Companies using dedicated truck routes for West Coast supply chain projects do better than others. They get goods delivered on time, save money, and work more efficiently. This helps them win in today’s busy shipping world.

Regional Logistics Challenges

Congestion and Demand Spikes

West Coast logistics networks have special problems. These problems make it hard to move goods quickly and on time. Big cities like Los Angeles, San Francisco, and Seattle get very crowded. This happens most during busy shipping times. More people and online shopping make the roads even busier. Highways and port roads fill up fast.

Los Angeles highways slow people down by 82 hours each year for each person. This is the most in the country.

Four out of the ten busiest highways in the U.S. are in Los Angeles. Cars wait about 10 minutes longer per trip during rush hour.

I-710 is a main road for ports. It has about five crashes every day. This makes moving freight even slower.

Road freight costs went up by 23.4% in 2021. This means it costs more to move goods.

Warehouse rents went up by 9.5%. Building new warehouses grew by 54% in one year. Online shopping caused this growth.

During holidays, stores need more space to fill orders. This puts extra stress on the system.

West Coast ports took in 57% of Chinese imports in 2024. Now, more cargo goes to other coasts. This causes three big problems: less trade, cargo moving away, and fewer Chinese imports. These changes make traffic and space hard to predict. Problems at the Panama and Suez Canals also change where ships go. This makes West Coast ports even busier.

Route Inefficiencies

Route inefficiencies are still a big problem for project freight and full truckload shipments. Bad connections between ports and cities like Denver and Salt Lake City cause more empty trips and higher costs. Old routes near ports get stuck with traffic jams and not enough roads. Some roads and bridges are old and need fixing.

Aspect | Evidence Summary |

|---|---|

Congestion and Inefficiencies | Long Beach and Los Angeles ports get crowded from more containers and not enough roads. |

Infrastructure Improvements | New projects like bigger terminals and on-dock rail will help move more containers and cut down on traffic. |

On-Dock Rail Impact | Using more on-dock rail will go from 15% to 35%. This will mean fewer trucks and less pollution. |

Stakeholder Coordination | Groups and programs help everyone work together and make things run better. |

Impact on Safety and Emissions | Taking away 200 rail crossings will lower accidents and cut down on pollution. |

Studies show that new ways to plan routes and use different roads can help. They can save money, time, and lower pollution. Good planning for both going out and coming back helps stop empty trips. It also makes delivery times more steady. Premier Global Logistics uses smart planning and two-way trips to fix these problems. They help customers get safe and low-cost shipping across the West Coast and other places.

Dedicated Truck Routes Optimization

Route Planning Strategies

Premier Global Logistics uses smart planning to make special truck routes. These routes help project freight customers get steady results. The team looks at how shipments move, when customers need things, and when deliveries must happen. They use this information to make the best routes. This way, every truckload has a clear job and moves quickly.

PGL’s planners use technology to watch traffic and follow rules. They use tools that plan for many days and check real-time data. This helps them change routes if there is traffic or bad weather. The system also finds ways to fill trucks on the way back. This means fewer empty trips and better use of each truck.

PGL’s route planning software cuts deadhead miles from 14%-35% to under 10%. This saves fuel and labor, so each trip costs less.

Key strategies are:

Setting regular weekly trips, like Monday, Wednesday, and Friday, to match what customers need.

Using a dispatch system to keep drivers and plans organized.

Putting shipments together for full truckloads to save money and time.

Changing routes fast if traffic or customer needs change.

Route Planning Strategy | Numerical Improvement / Outcome | Example / Case Study Description |

|---|---|---|

Dynamic Traffic Condition Management | Red Cross made routes better and delivered help 30% faster in emergencies. | |

Perishable Goods Route Optimization | 40% less spoilage | A company moved cold goods around traffic, so less food spoiled and customers trusted them more. |

Mileage Reduction and Fuel Savings | 8% fewer miles, $300,000+ saved each year | A food company planned better routes, drove less, and saved a lot of money on fuel. |

Advanced Route Optimization Software (e.g., UPS ORION) | Saved millions of miles and gallons of fuel each year | UPS uses ORION to plan routes, avoid left turns, and use less fuel. |

Machine Learning and Predictive Analytics | Better at changing routes and avoiding problems | A medicine company uses computers to guess weather delays and change routes. |

Collaborative Distribution | Fewer trips and fuller trucks | Stores share truck space, so there are fewer trucks on the road. |

Customer Expectation Alignment | On-time deliveries went up from 91% to 98% | A food company delivered on time more often, making customers happier. |

PGL’s focus on special lanes and smart routes helps customers know costs and delivery times. This planning works well for big shipments, like building supplies, furniture, and store restocks, where timing is very important.

Return-Route Optimization

Return-route optimization is a big part of PGL’s plan for truck routes. After dropping off goods in cities like Denver or Salt Lake City, PGL finds loads for the trip back. This way, trucks do not drive empty. This two-way plan helps make more money and lowers total costs.

AI tools look at old and new data to find the best loads for the way back. Computers help PGL guess when people will need things and match loads with empty space. This makes trucks work harder and saves fuel, labor, and repair money.

A big store, Macy’s, cut empty miles by 11% by using backhauls. This saved money and made trucks work better. PGL does the same by putting loads together and working with trusted partners. These ideas help fill trailers and keep trucks from driving empty.

With return-route optimization, PGL helps customers spend less and keep trucks running longer. This also helps the planet by lowering pollution and cutting extra trips.

Some real results from route and two-way planning are:

More repeat orders because service is quick and reliable.

Up to 30% lower fuel costs, which means more profit.

More on-time deliveries, up to 98%.

Companies like FedEx, DHL, and Domino’s also save money and work better with these plans.

PGL’s strong planning and return-route ideas make them stand out in project trucking. Their solutions help customers control costs, work better, and get steady shipments all over the West Coast.

Technology in Truck Route Optimization

AI and Real-Time Data

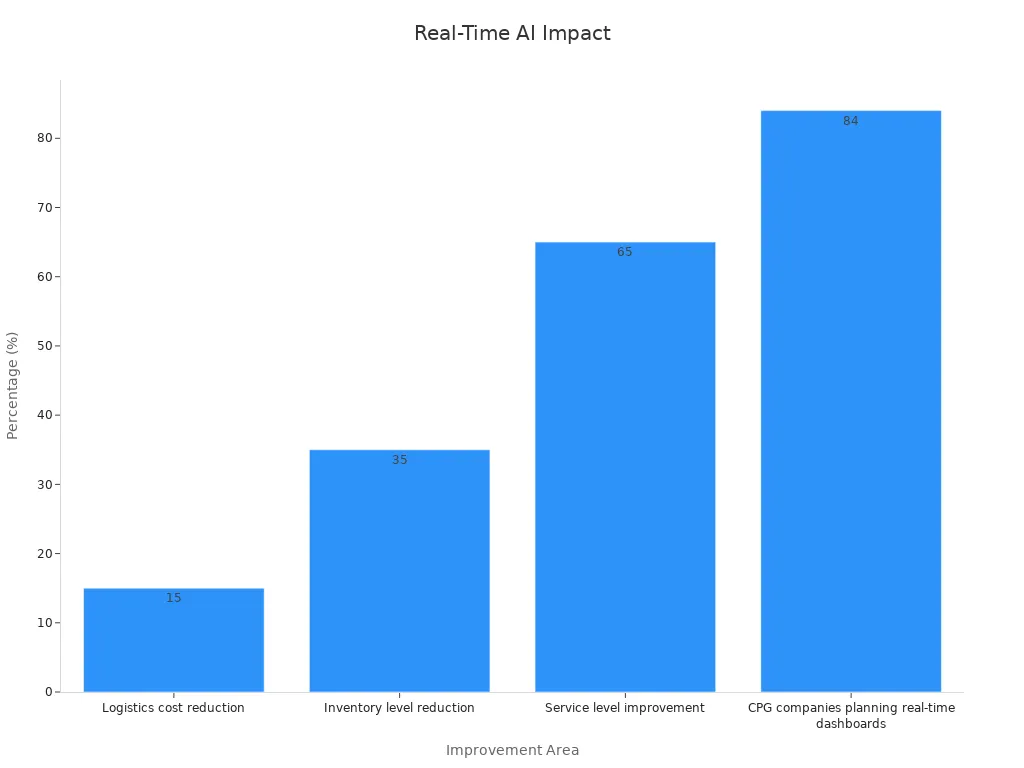

Today, logistics companies use new technology to make routes better. AI and real-time data help dispatchers and drivers choose the best paths. These systems connect to traffic, weather, and order data. They can change routes fast if there is a problem. Trucks avoid slow roads and get to places faster. This helps big shipments arrive on time.

Uber Freight uses AI to match loads for many trips. This lowers empty trailer miles from 35% to just 10%.

AI navigation software cuts costs by 30%. It also helps fleets use trucks 15% better.

West Coast carriers use tools to schedule and track trucks. Customers can see where their orders are and get better delivery times.

AI links loads together, so each trip is smarter and greener.

AI route planning works like a smart GPS. It checks orders, truck space, and road problems. Then it updates the route if needed. This helps fleets deliver faster and use less fuel. Companies save money and work better.

Metric | Improvement/Reduction |

|---|---|

Up to 15% | |

Average idle time reduction (real-time optimization) | 12% |

Asset utilization improvement | 8-10% |

Customer wait times reduction (optimized routing) | Up to 20% |

Compliance and Monitoring

Compliance and monitoring are very important in logistics today. Fleet managers use tech to watch trucks and check driver actions. Real-time systems show where trucks are, how fast they go, and how long they stop. Dispatchers can see drivers on a map and help fast if something goes wrong.

Compliance Metric | Description | How to Track / Monitor |

|---|---|---|

Shows how much a truck is used to help plan fleet size. | Track with mileage or time in use; use reports like Utilization Summary in Fleetio dashboard. | |

Idle Time | Checks engine idling to save fuel and keep trucks healthy. | Use telematics and GPS to watch engine idling over time. |

Accident Frequency Rate | Counts how often accidents happen to make things safer. | Calculate by days between accidents or accidents per million miles. |

Vehicle Inspection Compliance Rate | Checks if trucks get regular inspections for safety and rules. | Use fleet management tools to watch inspection data and compliance rates. |

Modern platforms also do compliance jobs automatically, like logging driver hours and planning inspections. These systems lower safety problems by up to 88% and cut costs by 15-20%. Predictive maintenance finds issues before trucks break down. This keeps trucks moving and helps fleets work better. Real-time data and reports make sure fleets follow safety rules and save money on project freight.

Implementation Best Practices

Stakeholder Collaboration

Working well with everyone is key for project freight trucking. Today, companies team up with many partners. These include shippers, carriers, and warehouse operators. Cooperative game theory helps share costs and rewards fairly. One way is using the Shapley value. This makes sure everyone joins in and shares the benefits. It is very important for big delivery jobs.

Horizontal collaboration means logistics companies work together. They share trucks, space, and information. Trust, good technology, and clear ways to share info are important. Logistics providers help by planning profit-sharing and bundling shipments. They also plan how trucks move. These steps help fleets work better and cover more places.

When everyone takes part, all partners stay active and loyal. This helps turn plans into real results.

A McKinsey study found that working together can cut transport costs by 15%. UPS and Coca-Cola used real-time data sharing. This helped them use less fuel and lower pollution. The table below shows ways teamwork makes truck routes better:

Strategy | Description | Benefit |

|---|---|---|

Fleet Sharing | Partners use trucks together to fill them up | Less waiting and lower costs |

Collaborative Warehousing | Companies share storage to group shipments | Inventory moves faster |

Data-Driven Partnerships | Partners share data right away to plan better | Smarter choices and better routes |

Continuous Improvement

Continuous improvement helps logistics stay fast and strong. Companies use data and track KPIs to guess demand and fix mistakes. This also helps keep customers happy. Change management helps teams learn new ways to work. Training makes workers feel proud and ready.

Some proven ways are:

Six Sigma uses numbers to find and fix mistakes.

Kaizen means making small changes all the time with help from workers.

Kanban uses boards to show work and stop slowdowns.

Value Stream Mapping finds and removes wasted steps.

The 5 Whys helps find out why problems happen.

These ideas help companies work better and change when needed. For example, LogiMaster worked 20% faster and saved 15% on costs by always improving. Customers were 25% happier after they started using feedback.

Important numbers to watch are on-time delivery, cost per pound, inventory accuracy, and order accuracy. These show how getting better helps companies deliver well and earn trust.

Case Study: PGL’s West Coast Project Trucking

Project Overview

A top American furniture brand needed help with shipping on the West Coast. The company had a big warehouse in California. It sent products to showrooms in Nevada, Arizona, and Utah. Every week, they needed three full truckloads to meet showroom needs and special sales. The company wanted deliveries to be on time, fewer empty truck trips, and lower costs.

Premier Global Logistics made special truck routes just for this company. The plan had set weekly trips that matched when showrooms needed more products. PGL used dispatch and driver schedules to make sure trucks left on time. The team also worked on filling trucks for the trip back to California with new items or other freight.

Solutions and Results

PGL used smart planning and technology for this project. The team used data and AI tools to make inventory and shipping easier. The client could see costs right after each delivery. PGL’s system found ways to cut waste and make buying better.

Key results were:

Shipments were regular and kept showrooms full and sales strong.

Filling trucks for the return trip cut empty miles by 28% and saved money.

Automation and good planning made work faster and easier.

The company spent 15% less on shipping in the first year.

Metric | Outcome |

|---|---|

Total margin improvement (3 years) | |

Days cash on hand increase (3 years) | $600 million |

One-time cash savings | $85 million |

Labor expense trend | Continuous decrease |

PGL’s special truck routes and project trucking skills helped the company get steady, low-cost shipping. This solution helped the business grow and set a new level for West Coast supply chains.

Dedicated truck routes help west coast supply chains work better. Companies have fewer empty miles and save more money. Deliveries arrive on time more often. Premier Global Logistics uses smart planning for both directions. They also use advanced tools to plan the best routes.

Deadhead miles go down to less than 10%. This saves fuel and cuts costs.

Drivers use the same roads often, so they are safer and more reliable.

Real-time planning helps with busy seasons and keeps shipments moving.

Want to make your supply chain better? Talk to Premier Global Logistics for custom project trucking plans that boost efficiency and get results.

FAQ

What types of shipments benefit most from dedicated truck routes?

Project freight and full truckload shipments get the most help. Regular store restocks also do well with these routes. They work best for things like building materials, furniture, electronics, and engineering equipment. Clients can plan costs better and know when shipments will arrive. Trucks drive fewer empty miles, so trips are more useful.

How does Premier Global Logistics optimize return routes?

PGL uses smart planning and scheduling tools. The team matches loads going out with loads coming back. This means trucks do not drive empty as much. It saves money and helps trucks work harder. Clients get project trucking that is efficient, reliable, and better for the environment.

Can PGL handle weekly or cyclical delivery needs?

Yes, PGL can set up weekly or repeating delivery routes. They make fixed schedules, like Monday, Wednesday, and Friday trips. The dispatch system matches when clients need products made or stores need more stock. This keeps deliveries on time and supply chains steady for big shipments.

What makes PGL different from standard LTL carriers?

PGL works with full truckload project freight, not just small loads. The team uses strict schedules and plans return trips to fill trucks. They make special routes for each client’s needs. Clients get steady costs, high efficiency, and strong results. This is great for big, repeating shipments.

How does route optimization impact shipping costs?

Route optimization means trucks drive fewer empty miles and use less fuel. Deliveries are faster and more on time. Clients can save up to 30% on shipping costs. Project shipments also run more smoothly and on schedule.

See Also

Maximizing West Coast Operations Through Premier Global Logistics Warehousing

Understanding East Coast B2B Warehousing And Distribution By Premier Global

Fast Order Fulfillment With Premier Global Logistics Warehousing In NJ And FL

Top Reasons To Select Premier Global Logistics For Export Shipments

Premier Global Logistics Provides Smooth Nationwide Trucking Across The USA