Top Strategies for Efficient Global Supply Chain Management in 2025

You need to focus on several key strategies for efficient global supply chain management in 2025:

Build strong relationships with your partners.

Use technology and automation.

Diversify your sources and partners.

Make decisions using data.

Stay agile and improve constantly.

Recent surveys show that most boards do not discuss supply chain issues formally. Many leaders say their boards do not understand supply chain risks. Fewer companies now invest in resilience and digital upgrades. You should consider how you can apply these strategies to protect your business.

Key Takeaways

Build strong relationships with suppliers to enhance trust and collaboration. This teamwork helps identify risks early and solve problems together.

Invest in technology like AI and blockchain to improve efficiency and transparency. These tools help you make better decisions and track goods in real time.

Focus on sustainability by choosing ethical suppliers and reducing waste. This approach builds trust with customers and meets growing environmental demands.

Stay agile by diversifying suppliers and maintaining extra inventory. This flexibility helps you respond quickly to disruptions and market changes.

Regularly assess your supply chain performance. Track key metrics to identify gaps and make improvements for better efficiency.

2025 Supply Chain Challenges

Geopolitical Risks

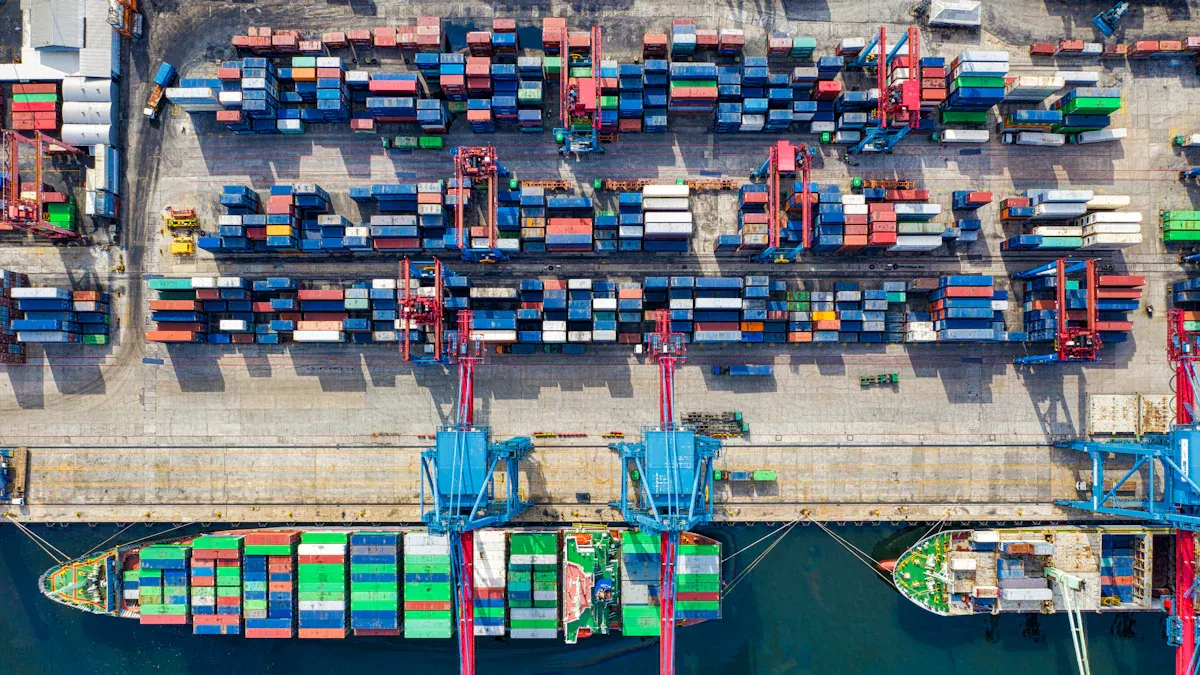

You face growing geopolitical risks in 2025. Conflicts like the Russia-Ukraine war and tensions in the Middle East disrupt shipping routes. Cyber-attacks linked to international disputes can halt operations. These events make it harder for you to plan and keep goods moving smoothly.

Geopolitical unrest affects your supply chain’s stability.

Economic instability is rising, with over half of chief economists expecting weaker conditions this year.

Extreme weather events also threaten ocean freight and global trade.

Disruptions and Uncertainty

You must prepare for sudden disruptions. Economic outlooks remain uncertain. Inflation and global tensions continue to impact your business.

Delays at ports and in shipping are above long-term trends.

Extreme weather, such as hurricanes and floods, can stop shipments.

Financial pressures are a top concern for most supply chain leaders.

Rising Costs

You see costs rising across your supply chain. Geopolitical tensions force shipping companies to avoid certain routes, which increases expenses.

Delays and disruptions add to logistics costs.

Volatile raw material prices make budgeting difficult.

Many companies now pay more for faster delivery to keep customers happy.

A major disruption can lead to a loss of up to 42% of annual EBITDA for your company.

Technology Integration

You need to adopt new technology to stay competitive. The digital supply chain market is growing fast.

Real-time data helps you make better decisions.

AI and blockchain improve transparency and efficiency.

Blockchain is especially important for tracking goods in sectors like pharmaceuticals and agriculture.

Sustainability Demands

You face more pressure to make your supply chain sustainable. Customers and governments expect you to use ethical and green practices.

The COVID-19 pandemic showed how your sourcing decisions can affect people and the planet.

Multinational corporations must follow new laws and meet public expectations.

Ignoring sustainability can lead to reputational damage, loss of trust, and even legal trouble.

Working with local partners and NGOs can help you reach your sustainability goals.

You must address these challenges to achieve efficient global supply chain management in 2025.

Strategies for Efficient Global Supply Chain Management

Lean Thinking

Lean thinking helps you remove waste and improve every step in your supply chain. You focus on what adds value for your customer. By using lean methods, you can cut down on delays, reduce extra inventory, and save money. Lean thinking also helps you spot problems early and fix them before they grow. When you use lean tools, you make your supply chain faster and more flexible. This approach supports efficient global supply chain management by making sure every process works smoothly.

Supplier Relationships

Strong supplier relationships give you a big advantage. When you work closely with your suppliers, you build trust and share important information. This teamwork helps you spot risks early and solve problems together. For example, GE uses supplier relationship management to keep its global operations running smoothly. By talking often and working together, you can tailor your plans to fit each supplier’s needs. This approach helps you manage risks and improve performance. Good supplier relationships are key to efficient global supply chain management.

Better communication and teamwork with suppliers

Custom strategies for each supplier

Early risk detection and shared problem-solving

AI and Blockchain

AI and blockchain change how you manage your supply chain. AI helps you predict demand, spot trends, and make smart decisions fast. Blockchain gives you a safe way to track goods and share data. You can see where your products are at any time. This technology makes your supply chain more transparent and secure. When you use AI and blockchain, you improve efficiency and build trust with your partners. These tools are now essential for efficient global supply chain management.

Logistics Best Practices

You can save time and money by using the best logistics practices. Focus on three main areas:

Transportation cost optimization can lower your costs by up to 25% while keeping service high.

Warehouse efficiency improvements can cut expenses by up to 35% and help you move goods faster.

Last-mile delivery cost reduction can save up to 40% by making routes smarter and service better.

When you use these methods, you deliver products faster and keep your customers happy. Good logistics practices help you stay ahead in a fast-changing world.

Sustainability and Ethics

Sustainability and ethics matter more than ever. Customers and governments want you to use green and fair practices. You can choose suppliers who care about the environment and treat workers well. By using less energy and cutting waste, you help the planet and save money. Working with local partners and following new laws keeps your business safe. When you focus on sustainability, you build trust and protect your brand.

Tip: Start small by measuring your carbon footprint and setting clear goals for improvement.

Supply Chain Visibility

Supply chain visibility lets you see every part of your supply chain in real time. You can track products, spot delays, and fix problems quickly. This clear view helps you make better decisions and work well with your partners. When you know what is happening at every step, you can manage risks and respond fast to changes. Supply chain visibility is a must for efficient global supply chain management.

Better teamwork across the supply chain

Proactive risk management

Skilled Professionals

You need skilled professionals to run your supply chain well. In 2025, the most important skills include using AI, analyzing data, and managing automation. You also need leaders who can solve problems and think critically. Many companies now train their workers to fill talent gaps. Upskilling and reskilling help your team stay ready for new challenges.

Leadership skills: problem-solving, critical thinking, emotional intelligence

Training programs for current employees

Team Alignment

When your teams work together, you get better results. You should organize teams around the value they bring to customers. Make sure everyone knows who makes decisions and who owns each task. Set common goals so all teams work toward the same outcome. Give your teams the right tools and data to help them work together.

Strategy | Description |

|---|---|

Design for the Work | |

Clarify decision authority | Define who makes decisions. |

Define cross-team handoffs | Set clear ownership for work transitions. |

Align the Incentives | Use common goals for all teams. |

Align rewards with cooperation | Create shared metrics for teamwork. |

Enable the Collaboration | Provide tools and data for effective teamwork. |

Risk Mitigation

You can reduce supply chain risks by using smart strategies. Diversify your suppliers so you do not rely on just one. Keep extra inventory as a buffer for tough times. Use flexible transport options to adapt when routes change. Work closely with your suppliers to share risks and solve problems. Plan for different scenarios and test your plans often. Build up stockpiles of key goods and join industry groups to share ideas. Local sourcing can also help you avoid transport risks and respond faster.

Increase inventory buffers

Flexible transportation

Strong supplier partnerships

Scenario planning and stress testing

Strategic stockpiles

Industry alliances

Local sourcing

Supplier Alliances

Supplier alliances help you build a strong and stable supply chain. When you form alliances, you and your suppliers share goals and resources. This teamwork leads to better prices, faster problem-solving, and more innovation. You can work together on new products or find ways to cut costs. Supplier alliances make your supply chain more flexible and ready for change.

By using these strategies, you can achieve efficient global supply chain management in 2025. Each step helps you build a supply chain that is strong, flexible, and ready for the future.

Implementation Steps

Performance Assessment

You should start by checking how your supply chain works today. Track your performance and measure results all the time. Review your planning processes often. Look for gaps and fix them quickly. Watch key numbers like forecast accuracy, on-time delivery, inventory turnover, resource use, and cost-to-serve. These steps help you see where you need to improve.

Track performance and measure results continuously

Review planning processes regularly

Identify gaps and make improvements

Monitor key KPIs:

Forecast Accuracy

On-Time Delivery

Inventory Turnover

Resource Utilization

Cost-to-Serve

Setting Objectives

Set clear goals for your supply chain. Decide what you want to achieve, such as faster delivery or lower costs. Make sure your goals match your business needs. Share these goals with your team so everyone knows what to work toward. Use simple targets that you can measure, like cutting delivery times by 10% or improving inventory turnover.

Tip: Write down your objectives and review them every quarter to stay on track.

Technology Investment

Invest in technology to make your supply chain stronger. Start with a detailed plan for rolling out new software. Train your team so they know how to use all the features. Get everyone involved early to make adoption easier. Keep your data clean and accurate for better analytics. Review how your software works and ask users for feedback. Update your systems often to use new features.

Train users with comprehensive programs

Create a clear implementation plan

Engage stakeholders early

Manage data quality

Stay updated with software upgrades

Training and Development

Build a skilled team with strong training programs. Offer vocational training to students and underserved groups. Use hands-on learning, like Kellanova’s 16-month program, to teach technical skills. Pair interns with mentors and give plant tours, as Pella does, to spark interest in manufacturing. Support adults with special needs through programs like the Uniquely Abled Project, which provides certifications and job placements.

Program Name | Focus Area | Unique Feature |

|---|---|---|

Vocational Training | Early tech skills | Pathways for students |

Kellanova Curriculum | Electrical/Instrumentation | Factory-like environment |

Pella Approach | Manufacturing interest | Intern-mentor pairing, plant tours |

Uniquely Abled Project | Special needs employment | Certifications, job partnerships |

Strategic Collaboration

Work closely with your partners to boost supply chain results. Use digital tools to share data and improve communication. This can raise efficiency by 30% and cut costs by 35%. Share more information with suppliers to build trust. Negotiate contracts openly to create strong partnerships. Use technology to make teamwork easier and faster.

Use digital technologies for better communication

Share information with suppliers for transparency

Negotiate contracts openly

Implement tech tools to streamline collaboration

Real-World Examples

Lean Supply Chain Success

You can learn a lot from companies that use lean strategies. These businesses focus on removing waste and improving every step. The table below shows how top companies use lean thinking to get better results:

Company | Lean Strategy Description | Outcomes |

|---|---|---|

Amazon | Just-in-Time inventory system to minimize inventory on hand. | Reduces costs and lowers risk of unsold goods. |

Nike | Dynamic inventory management and workspace organization. | Improves efficiency and ensures timely delivery. |

Toyota | Toyota Production System with waste reduction and continuous improvement. | Achieves high profits through optimized operations. |

Caterpillar Inc. | Accelerates project processes with the Caterpillar Production System. | Streamlines production and boosts product quality. |

John Deere | Invests in lean manufacturing to remove non-value-added activities. | Increases productivity and efficiency in machinery manufacturing. |

Intel | Uses lean manufacturing in semiconductor fabrication. | Delivers higher quality products and lowers production costs. |

Lean supply chain methods help you cut costs, improve quality, and deliver products faster.

AI-Driven Efficiency

Many companies now use artificial intelligence to make their supply chains smarter. You can see how these leaders use AI to save time and money:

Company | AI Application | Efficiency Gain Description |

|---|---|---|

Amazon | Customer demand forecasting | Optimizes stock for over 400 million products with little input. |

Walmart | Optimized driver routing | Cuts 30 million driver miles and saves 94 million pounds of CO2. |

GXO | Automated inventory counting | Scans up to 10,000 pallets per hour for real-time counts. |

JD Logistics | Warehouse space optimization | Triples storage units, boosting efficiency by 300%. |

AI helps you predict demand, manage inventory, and reduce waste. You can use these tools to make better decisions every day.

Sustainable Practices

You can see more companies choosing green and ethical supply chain practices. For example, Unilever works with local farmers to source raw materials responsibly. Apple uses recycled materials in its products and checks that suppliers follow strict labor rules. These actions help protect the planet and build trust with customers.

Tip: Start by measuring your carbon footprint and set small goals for improvement.

Supplier Diversification

You lower your risks when you work with many suppliers. During the COVID-19 pandemic, companies like Procter & Gamble and Samsung added new suppliers in different regions. This move helped them avoid shortages and keep products on shelves. You can use supplier diversification to stay flexible and respond quickly to changes in the market.

You can boost efficient global supply chain management by focusing on continuous improvement and adaptability. Many executives now see new-gen supply chains and agentic AI as top trends. Most organizations use sustainability strategies and find that green practices lower costs. Flexible production and regular evaluations help you stay resilient and agile. The table below shows why updating your supply chain matters:

Key Aspect | Explanation |

|---|---|

Efficiency | Streamlined processes reduce waste and lower costs, enhancing profit margins and customer satisfaction. |

Resilience | Strong supply chains can withstand disruptions, minimizing downtime and revenue loss. |

Agility | Flexibility to respond to market changes allows businesses to seize new opportunities. |

Strategic Supplier Relations | Collaboration with suppliers fosters innovation and long-term success. |

Regular Evaluations | Ongoing assessments identify vulnerabilities and ensure operational continuity in volatile markets. |

Keep reviewing your supply chain strategies to stay competitive in 2025 and beyond.

FAQ

What is the biggest risk to global supply chains in 2025?

Geopolitical tensions pose the largest risk. You may see disruptions from conflicts, trade restrictions, or cyber-attacks. Stay alert and update your risk plans often.

How can you improve supply chain visibility?

Use real-time tracking tools and dashboards. Share data with your partners. You will spot delays faster and make better decisions.

Why should you invest in AI for supply chain management?

AI helps you predict demand, optimize routes, and reduce waste. You save money and respond quickly to changes. Many top companies use AI for better results.

What steps help you build strong supplier relationships?

Talk with your suppliers often. Share goals and solve problems together. You build trust and create a more reliable supply chain.

See Also

Key Strategies for Effective Global Logistics Operations

Enhancing Global Operations Through Innovative Logistics Solutions

Simplifying Supply Chain Optimization with U.S. Logistics Solutions

Boosting Global Efficiency with Point-to-Point Logistics Systems