Understanding First and Last Mile Container Logistics

First and last mile container logistics describe how you move goods at the very beginning and end of the supply chain. You start by sending containers from the origin point, and you finish by delivering them to the final destination. These stages play a big part in how fast you receive your shipments and how satisfied you feel as a customer. Last mile delivery alone makes up 41% of total supply chain costs.

Mode of Transport | Influence on Delivery Speed |

|---|---|

Roadways | Dominates first and last mile deliveries, providing flexibility and speed, especially in urban areas. |

Railways | Critical for bulk goods; integrates with first-mile operations to enhance efficiency. |

Airways | Essential for time-sensitive shipments; advancements improve efficiency and reliability. |

Waterways | Vital for first-mile operations; enhances efficiency in global trade. |

E-commerce growth and changing consumer demands push logistics companies to deliver faster and more reliably.

Key Takeaways

First and last mile logistics are crucial for efficient supply chain management. They impact delivery speed and customer satisfaction significantly.

Investing in technology like GPS tracking and AI can enhance visibility and reduce costs by up to 20%. This leads to faster and more reliable deliveries.

Effective first mile logistics involve careful order picking, accurate labeling, and timely transportation to avoid delays and errors.

Last mile delivery faces unique challenges such as traffic congestion and customer expectations. Using route optimization tools can help navigate these issues.

Collaboration with local logistics providers can improve service quality and reduce costs. Sharing resources leads to better efficiency in deliveries.

First Mile Logistics

Key Activities

You start the journey of your goods with first mile logistics. This stage moves products from the manufacturer or supplier to a warehouse or distribution center. You handle several important tasks to make sure shipments move smoothly:

Order picking: You select the right products for each shipment.

Consolidation: You group items together to save space and time.

Audit: You check the accuracy of orders and documents.

Transport preparation, packaging, and labeling: You pack goods to prevent damage and label them for easy tracking.

Preparation of accompanying documents: You get all paperwork ready for transport.

Handover and loading: You give the shipment to the transport team and load it onto vehicles.

Transportation to the next hub: You move goods from the production site to a central warehouse or distribution center.

You need to monitor shipments and keep documents accurate. These steps help you avoid mistakes and delays.

Tip: Accurate labeling and careful packaging reduce damage and speed up processing.

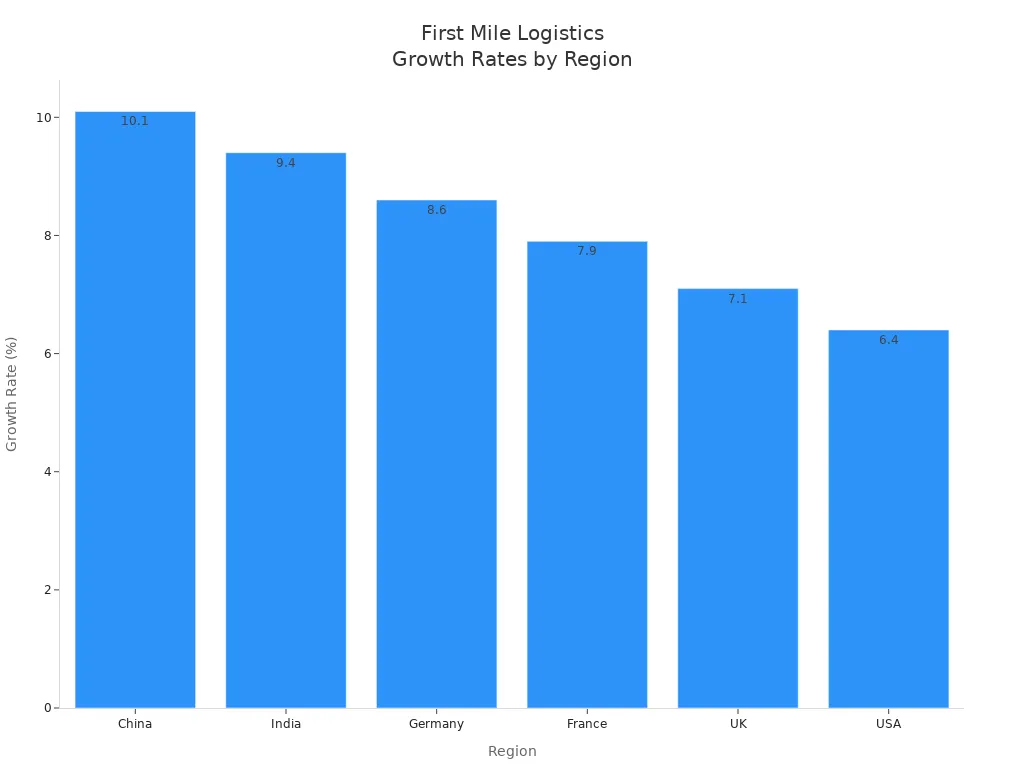

First mile logistics practices can look different around the world. Here is a table showing how regions focus on different areas:

Region | Growth Rate (CAGR) | Key Focus Areas |

|---|---|---|

China | 10.1% | Large-scale warehousing, supplier integration |

India | 9.4% | Digital-first logistics solutions |

Germany | 8.6% | Automation, fleet diversification |

France | 7.9% | Regulatory compliance, efficiency enhancement |

UK | 7.1% | Operational bottlenecks reduction |

USA | 6.4% | Predictive analytics, route optimization |

BRICS | N/A | High demand for logistics infrastructure investments |

OECD | N/A | Focus on automation and compliance |

Challenges

You face many challenges in first mile logistics. Manual processes can cause errors. Lack of visibility makes it hard to track shipments. Packaging and labeling mistakes slow down deliveries. Coordination with vendors and transport teams can be complex.

Common causes of delays include:

Vendor coordination issues

Lack of shipment visibility

Transportation delays from traffic or weather

Freight inefficiencies, like shipping partial loads

Communication breakdowns

Traffic and infrastructure problems

Customs and regulatory issues

Incorrect address or documentation

Peak season demand

Mechanical failures

Labor strikes or shortages

Carrier capacity constraints

You also need to follow many rules. Here are some common regulatory challenges:

Regulatory Challenge | Description |

|---|---|

Compliance with transportation laws | You must follow different rules in each region. |

Taxation policies | You need to manage taxes that change by state or country. |

Documentation requirements | You must prepare many documents, which can take time and lead to mistakes. |

When you manage first and last mile container logistics well, you help your business run smoothly and keep customers happy.

Last Mile Logistics

Complexities

You face many challenges in last mile logistics. Deliveries often happen in busy cities or remote areas, and each environment brings its own problems. Urban deliveries can get stuck in traffic jams, and drivers may struggle to find parking. Rural areas might have poor roads or hard-to-reach addresses. You must also deal with changing customer demands and strict rules about vehicle emissions.

Here is a table that shows what makes last mile container logistics more complex than other supply chain stages:

Factor | Description |

|---|---|

Variable Delivery Environments | Unpredictable conditions due to urban congestion, rural accessibility, and diverse property types. |

Demand Volatility | Seasonal changes and shifting consumer habits make planning difficult. |

Customer Expectations | People want faster deliveries, accurate time windows, and real-time tracking. |

Operational Inefficiencies | Failed deliveries and poor routing can hurt profits. |

Regulatory Constraints | Emissions rules and vehicle limits reduce flexibility. |

Data Integration Challenges | You must connect many data sources from different partners. |

Urban deliveries bring extra hurdles. You often face traffic congestion, limited parking, and strict environmental rules. Drivers need to stay safe while moving through crowded streets. Densely populated areas mean more stops and higher chances of delays. These problems can increase costs and frustrate customers.

Tip: Use route optimization tools to help drivers avoid traffic and find better parking spots.

Customer Impact

Your customers care most about how quickly and safely their orders arrive. Last mile delivery plays a big role in their satisfaction. If you deliver on time and keep packages safe, people trust your business. Delays, missed deliveries, or damaged goods can lead to complaints and lost sales.

Key performance indicators help you measure success in last mile logistics:

KPI | Description |

|---|---|

On-Time In-Full Delivery Rate (DIFOT) | Shows how often you deliver orders on time and in full. |

Customer Complaint Rate | Tracks how many customers report problems. |

Fuel Consumption Rate (FTR) | Measures how much fuel you use for each delivery. |

Carbon Emissions | Helps you monitor your impact on the environment. |

Delivery Attempts per Stop (DAPS) | Counts how many tries it takes to deliver each package. |

You can improve customer satisfaction by focusing on fast, accurate, and eco-friendly deliveries. Many shoppers now prefer companies that care about sustainability. Governments also push for cleaner delivery methods. Investing in green vehicles and better planning may cost more at first, but you save money over time and build customer loyalty.

First and last mile container logistics shape the entire delivery experience. When you manage these stages well, you boost efficiency and keep your customers happy.

Why First and Last Mile Container Logistics Matter

Supply Chain Efficiency

You play a key role in making the supply chain work smoothly when you focus on first and last mile container logistics. These stages help you move goods quickly from the starting point to the final destination. When you optimize these steps, you can reduce costs, improve customer satisfaction, and boost how well your business runs. Recent studies show that last-mile delivery can make up as much as 53% of the total delivery cost. This means that even small improvements in these areas can lead to big savings.

You can see how these logistics stages affect lead times. Delays at border crossings, extra customs checks, and changes in warehouse locations can slow down shipments. If you use data-driven routing, you can raise your on-time delivery rates from 75% to 95%. You also save money when you succeed in delivering packages on the first attempt. Urban congestion can waste over 200 hours each year for delivery vans, which hurts productivity and slows down the supply chain.

Note: When you use smart routing and real-time tracking, you help your team avoid delays and keep customers happy.

You also make your supply chain stronger by managing disruptions. If you face a sudden problem, like a traffic jam or a weather event, you need to restore service quickly. Many business leaders believe that companies must improve their supply chain resilience to survive in the future. You can do this by focusing on visibility and control in first and last mile container logistics.

Cost and Visibility

You need to watch costs closely in first and last mile container logistics. The last mile alone can account for 41% to 53% of total supply chain costs. Labor, fuel, and complex routes all add up. If you deliver fresh produce, you may need special vehicles, which increases expenses. Traffic jams and poor planning can also drive up costs.

Cost Component | Percentage of Total Supply Chain Costs | Influencing Factors |

|---|---|---|

Last Mile Delivery | 41% - 53% | Labor, Fuel, Complexity of Routes |

You can control costs better when you have real-time visibility. Tracking shipments lets you spot problems early and respond quickly. Automated alerts keep everyone informed, so you can adjust plans and avoid surprises. When you see transportation costs in real time, you can manage your budget and prevent hidden charges.

Early issue detection helps you fix problems before they grow.

Automated notifications improve communication between teams.

Better visibility helps you control costs and avoid unexpected fees.

Security also matters. As goods move closer to their final destination, they face more risks. You need to protect shipments from theft and damage, especially in busy urban areas. Each transfer point increases the chance of something going wrong. If you lose sight of your containers after they leave the port, you may face blind carrier selection and hidden charges. This can hurt your reputation and make customers lose trust.

Tip: Investing in technology, like RFID systems, can help you track shipments and reduce mistakes. UPS cut its misload rate by 67% after using RFID, showing how technology can improve first mile efficiency.

You build a stronger, more reliable supply chain when you focus on cost control and visibility in first and last mile container logistics. You keep customers satisfied, protect your goods, and make your business more resilient.

Optimizing First and Last Mile Container Logistics

Technology Solutions

You can make your logistics process smarter by using the latest technology. GPS-enabled tracking lets you see where your containers are at any time. Many companies now use AI to predict delays and suggest better routes. Real-time IoT tracking helps you keep high-value goods safe and makes sure perishable items arrive on time. You can also use blockchain for secure records and predictive analytics to plan for busy times. Automating paperwork reduces mistakes and saves time.

Benefits | |

|---|---|

Cellular (2G/3G/4G/5G) | Good coverage in cities and industrial areas |

Satellite | Tracks containers during ocean trips or in remote places |

LPWAN | Saves energy in ports and last-mile areas |

Tip: Use route optimization tools to plan the fastest and most fuel-efficient delivery paths.

Collaboration Strategies

Working together with other companies can help you deliver faster and save money. You can join networks that let you share trucks, warehouses, and data. This teamwork means fewer empty trucks and better use of resources. When you partner with local logistics providers, you get drivers who know the area and fleets built for city streets. These partnerships also give you access to smart lockers and same-day delivery options, which make customers happy.

Share transit lanes to cut down on travel time.

Use local fleets for better service in busy cities.

Share real-time tracking data to keep everyone updated.

Cost Reduction Tips

You can lower your costs by making smart choices at every step. Negotiate shipping terms and use free trade zones to save on taxes. Maximize how much you load into each container and avoid using pallets when possible. Choose the right warehouse partners and ocean carriers. For last mile delivery, plan routes to avoid traffic and group deliveries by area. Use nearby rail ramps instead of long truck trips to save fuel.

Lower container turn-times to avoid extra fees.

Deconsolidate loads at warehouses near the port.

Track labor and fuel costs to spot savings.

When you use these best practices in first and last mile container logistics, you improve efficiency, save money, and keep your customers satisfied.

You shape the supply chain when you manage first and last mile container logistics. These stages help you deliver goods quickly and keep customers happy. Optimizing your process brings many benefits:

AI and smart technology can lower costs by up to 20% and improve delivery speed.

Real-time tracking meets customer demand for updates and boosts satisfaction.

Automation makes deliveries faster and more reliable.

Micro-fulfillment centers and flexible delivery models help you respond to changing needs.

Stay updated on new trends like sustainability and advanced technology. You build a stronger business when you use best practices and watch for new solutions.

FAQ

What does first mile logistics mean?

First mile logistics moves goods from the manufacturer or supplier to a warehouse or distribution center. You start the supply chain here. This step sets the pace for the rest of your delivery process.

Why is last mile delivery so expensive?

You pay more for last mile delivery because it involves many stops, traffic, and special handling. Drivers must reach homes or businesses quickly. Fuel, labor, and failed deliveries add to your costs.

How can you track containers during delivery?

You use GPS, RFID, or IoT devices to track containers. These tools show you real-time locations. You get alerts if delays or problems happen. Tracking helps you keep shipments safe and on schedule.

What is the biggest challenge in first mile logistics?

You often struggle with poor visibility and manual errors. Mistakes in labeling or paperwork slow down shipments. You need accurate data and strong coordination to avoid delays.

How do you improve customer satisfaction in last mile logistics?

You deliver packages on time and keep them safe. You offer real-time tracking and flexible delivery options. Fast, reliable service builds trust and keeps your customers happy.

See Also

Efficient Final Mile Delivery Services Across East Coast Cities

Optimizing Import Warehousing And Delivery For East Coast Operations

Key Strategies For Effective Management Of Global Logistics

Enhancing Global Efficiency Through Point-To-Point Logistics Systems

PGL's Miami Warehouse Solutions For Rapid East Coast Deliveries