Protect What Matters – Temperature-Controlled Freight by Premier Global Logistics

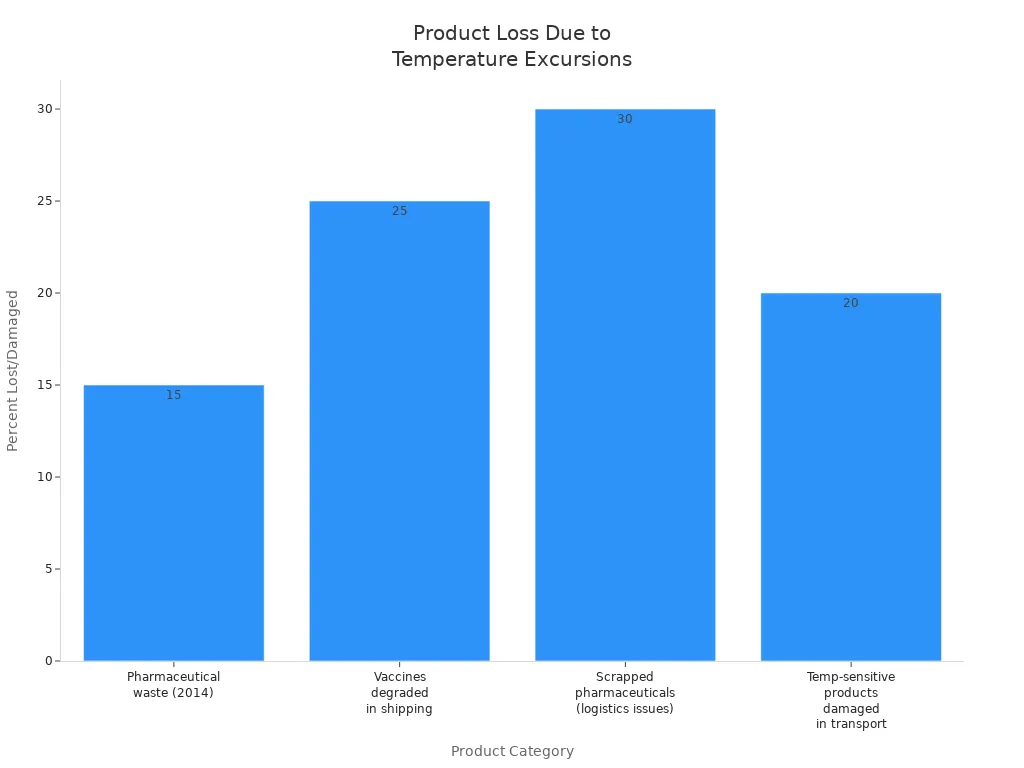

Strict temperature control is essential to keep food, medicine, and other sensitive items safe during shipping. Even a slight temperature change can ruin up to 30% of sensitive medicines, with vaccines being even more vulnerable.

Product Category | Percentage Lost/Damaged Due to Temperature Excursions |

|---|---|

Pharmaceutical waste (2014) | 15% |

Vaccines degraded in shipping | 25% |

Scrapped pharmaceuticals | 30% |

Temp-sensitive products | 20% |

FDA and GMP regulations require companies to maintain records and monitor temperatures in real time. Premier Global Logistics provides a reliable Food and pharma reefer trucking service nationwide. Their advanced cold chain logistics ensure product safety, regulatory compliance, and protection at every stage of transport.

Key Takeaways

Temperature-controlled freight keeps food, medicine, and sensitive items safe. It does this by keeping the right temperature from pickup to delivery.

Premier Global Logistics uses advanced technology like GPS. They also use real-time temperature sensors to watch shipments. This helps stop spoilage.

There are strict rules from the FDA and GMP. These rules make sure products stay safe. Premier Global Logistics follows these rules. They use clean trucks and keep detailed records.

Multi-temperature trucks and cold chain warehouses help move different products together. Each product stays at the right temperature.

Careful planning, real-time tracking, and expert handling lower risks. These steps save money and protect product quality during shipping.

Temperature-Controlled Freight

How It Works

Temperature-controlled freight keeps products at the right temperature. This happens from pickup until delivery. Many industries need this, like pharmaceuticals, food and beverage, cosmetics, and chemicals. These businesses must control temperature to stop spoilage or contamination. It also helps items work as they should.

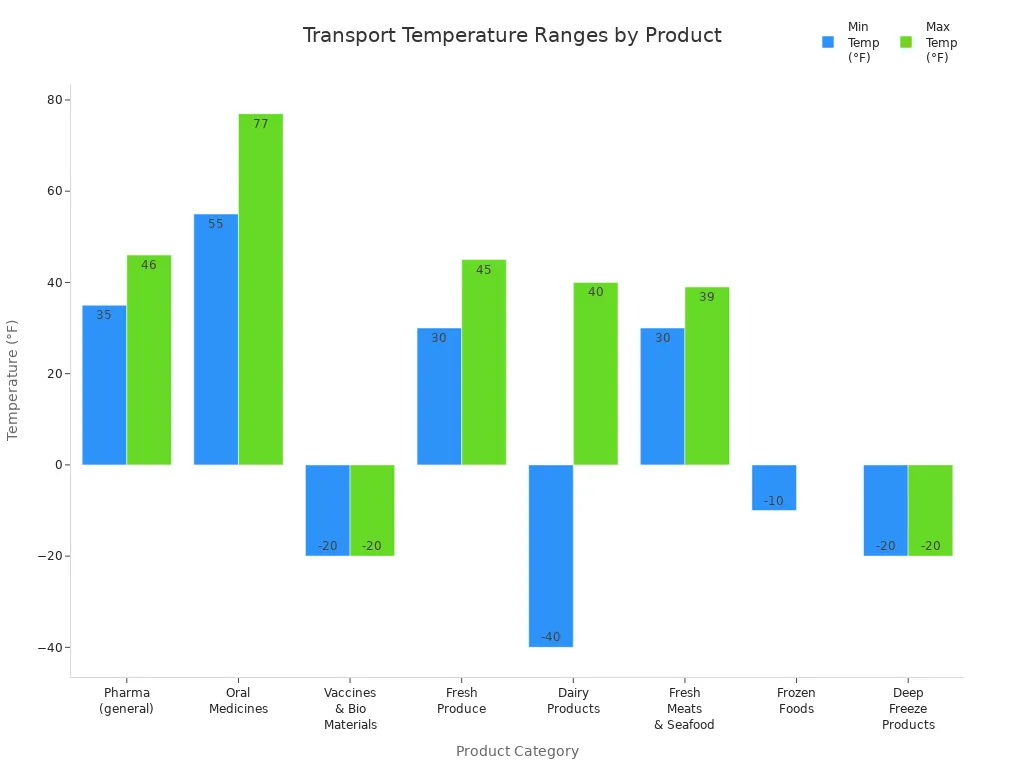

Keeping the right temperature is about safety and following rules. Some medicines need to stay between 35°F and 46°F. Vaccines and biological materials sometimes need to be colder than -20°F. Foods like dairy, fresh produce, and seafood need cold trucks too. This keeps them fresh and safe to eat.

Product Category | Temperature Range (°F) | Notes |

|---|---|---|

Pharmaceuticals (general) | 35 to 46 | Refrigerated conditions for most drugs |

Oral Medicines | 55 to 77 | More relaxed temperature range |

Vaccines & Biological Materials | Below -20 | Deep freeze required to preserve potency |

Fresh Produce | 30 to 45 | Refrigerated to maintain freshness and humidity |

Dairy Products | Below 40 | To prevent bacterial growth |

Fresh Meats & Seafood | 30 to 39 | Exact temperature regulation to maintain quality |

Frozen Foods | -10 to 0 | Frozen to preserve texture, flavor, and safety |

Deep Freeze Products | Below -20 | For ice cream, frozen desserts, certain pharmaceuticals, seafood, and biological samples |

Premier Global Logistics has a smooth process for every step. They handle pickup, loading, transport, and storage. Their reefer trucks can deliver every day or on a schedule. The trucks have different temperature zones for many product types.

Key Technologies

Reefer truck services use special technology to keep things cold. Each truck has sensors and data loggers to check temperature. GPS tracking shows where the truck is at all times. This helps keep shipments safe.

Temperature monitors send alerts if it gets too hot or cold.

Battery backups keep sensors working if power goes out.

Software puts together temperature and GPS data. This helps follow FDA and GMP rules.

Feature | Description |

|---|---|

50+ days with 60 min transmission; 100+ days with 6 hour transmission; shelf life 6 months. | |

Real-time visibility | Enables monitoring of every package in a consignment, improving shipment oversight. |

Sensors | Temperature, light, shock, humidity sensors monitor environmental conditions and detect damage. |

Temperature accuracy | ±0.5°C, ensuring precise monitoring of temperature-sensitive freight. |

Operating temperature | -30°C to 60°C, with special probes for temperatures below -30°C. |

Location technology | Uses cellular, WiFi, and GPS for location tracking with accuracy down to 20 meters. |

Water resistance | IP67 rating ensures device durability in wet and harsh environments. |

Connectivity | LTE-M with 2G fallback, global coverage over 95% with 400+ networks. |

Premier Global Logistics watches shipments all day and night. They have teams ready to help fast if there is a problem. Their rules and checks help keep food, medicine, and chemicals safe.

Food and Pharma Reefer Trucking Service

Compliance Standards

Food and pharma reefer trucking must follow strict rules to keep people safe. The FDA and GMP make rules for moving food and medicine in cold trucks. These rules stop food and medicine from getting spoiled or dirty. They also help keep products valuable.

Keep the right temperature at every step.

Clean trucks and tools to stop germs.

Use pest control to keep bugs away.

Clean well when loading and unloading.

Pick good packaging and pallets to protect items.

Talk clearly with shippers, drivers, and receivers.

Teach workers about food safety and security.

The Food Safety Modernization Act and 21 CFR 110.93 say food must stay safe from harm. This means food should not get dirty, poisoned, or have germs. Medicine needs the right temperature to work and keep people safe. Premier Global Logistics uses special reefer trucks to meet these rules. Their team writes down every step and gives proof for each shipment.

Note: Bad cooling, dirty trucks, and no training can cause problems and waste. Premier Global Logistics fixes these risks with set steps and watches shipments all day.

Compliance Area | PGL Approach |

|---|---|

Temperature Control | Real-time checks, trucks with many temperature zones |

Sanitation | Clean often, use pest control, do checks |

Documentation | Digital records, temperature logs, chain of custody |

Employee Training | Teach food safety and security often |

Communication | Give updates to everyone involved |

Product Integrity

Product integrity is very important for food and pharma reefer trucking. Food and medicine need the right temperature to stay safe and work well. Reefer trucks use smart systems to keep cargo at the right temperature. This stops spoilage, keeps food fresh longer, and protects people.

Reefer trucks help product integrity in many ways:

Keep food and medicine good by holding the right temperature.

Use trailers with more than one temperature for different items.

Watch temperature in real time and send alerts if it changes.

Cut down on waste and spoilage, saving money.

Help farms, stores, and medicine companies.

Some medicines like vaccines, insulin, and biologics need cold trucks to stay safe. Without cold trucks, these medicines would not work and could be dangerous. This could cause shortages, higher prices, and health risks. Foods like dairy, seafood, and fresh produce also need reefer trucks to stay safe and fresh.

Premier Global Logistics uses insulated trailers, airflow control, and GPS tracking for safety. Their team checks every shipment, looks at seals, and watches conditions from start to finish. New technology like IoT sensors and telematics helps show what is happening and follows the rules.

🚚 Here is a real story: A company used Premier Global Logistics to move frozen meat from Miami to stores in the Southeast. The delivery took less than two days, had no temperature problems, and had all the right paperwork.

Premier Global Logistics ships all over the country, offers flexible times, and handles sensitive items with care. Their food and pharma reefer trucking keeps products safe, follows rules, and protects quality.

Cold Chain Logistics Solutions

Multi-Temp Reefer Truck Services

Premier Global Logistics has trucks that can carry things at different temperatures. These trucks help move medicine, food, and chemicals safely. Each truck has special areas for different temperatures. This means frozen foods, cold drinks, vaccines, and flowers can go together in one trip.

Feature/Option | Description | Support for Product Requirements |

|---|---|---|

Different temperature zones in one truck | Transports frozen, chilled, and ambient goods together | |

Temperature Range Options | -10°F to 86°F | Maintains freshness and safety for a wide range of products |

Built-in Refrigeration Units | Self-contained cooling, works even when truck is off | Protects sensitive goods at all times |

Insulated Cargo Area | Thermal insulation in cargo walls | Prevents spoilage, especially in hot weather |

Real-Time Temperature Monitoring | Sensors and GPS tracking | Provides transparency and quick response to issues |

Backup Power Systems | Battery backup for cooling units | Maintains temperature during power loss |

Customizable Configurations | Shelving, single or multi-temp zones, backup power | Meets specific needs for food, pharma, floral, and catering industries |

Premier Global Logistics lets you pick LTL, FTL, or FCL shipping. LTL is good for small loads and saves money. FTL is for big or urgent shipments. FCL gives you your own container for special or overseas cargo. Their team watches shipments all day and night. This helps make sure things arrive on time and stay safe.

Cold Chain Warehousing

Premier Global Logistics has special storage buildings in Miami, Los Angeles, and Dallas. These places keep products cold and safe. They use new technology to watch temperatures and follow the rules.

They check temperatures often and fix sensors when needed.

Workers clean, wear special clothes, and keep things sanitary.

They fix cooling machines before they break.

They follow rules from FDA, OSHA, HACCP, FSMA, USP, and GDP.

Workers learn about safety and what to do in emergencies.

Smart systems send alerts if temperatures change.

Loading docks are run carefully to keep things cold.

They write down details for tracking and checking.

Warehouses have different cold areas for many products. Staff put on labels and tags and store sensitive items with care. They help move goods from planes and ships to trucks. This makes sure cold chain logistics work smoothly.

Premier Global Logistics gives safe reefer truck and warehouse services for medicine, food, and chemicals. Their solutions keep products valuable and follow the rules from start to finish.

Cold Chain Transportation Challenges

Risk Management

Cold chain transportation has many risks that can hurt products. If the temperature changes, products can spoil or lose value. Delays and not knowing where shipments are can also cause problems. Food, pharma, and chemical companies must stop these risks to keep cargo safe.

Not enough cold chain buildings in far places can slow down shipments and cost more.

Trucks without the right equipment may not keep things cold.

If you cannot see what happens during the trip, you might miss temperature changes.

Writing things down by hand can lead to mistakes and fines.

Premier Global Logistics works hard to manage risks. Their team plans early and checks every step of the cold chain. They use real-time tools to watch temperature, humidity, and location. If the temperature goes wrong, the system sends a warning so the team can fix it fast. PGL looks at shipment data to find problems and get better next time. By working with good partners and following GMP and GDP rules, PGL keeps products safe and follows the law.

Tip: Watching shipments in real time helps stop spoilage and keeps things moving. PGL’s team checks shipments all day and night. They fix problems fast, so there is less waste and the company’s name stays strong.

Route Planning

Good route planning is very important for cold chain shipping. Picking the best route helps stop delays and keeps the right temperature. PGL uses smart software to plan routes by looking at traffic, weather, and distance. This helps avoid slow spots and makes sure things arrive on time.

Route tools pick the fastest and safest way to go.

Real-time info lets the team change plans if needed.

Drivers follow strict rules when loading, unloading, and handling goods.

PGL’s route planning also thinks about last-mile delivery. Their team watches every shipment from start to finish with GPS and temperature sensors. This keeps the right temperature and follows the rules. Customers get better service, fewer delays, and safer products.

Note: With PGL’s smart tools and skilled team, cold chain shipping is safer, faster, and meets all the rules.

Choosing a Cold Chain Partner

What to Look For

Picking the right logistics company is very important. This is true for businesses that ship items needing certain temperatures. You need a good plan to keep products safe and follow the rules. Here are the main steps to help you choose a good refrigerated logistics partner:

Figure out what you need. Know your product types, temperature needs, shipment sizes, and when you need deliveries.

Look up companies. Use the internet, talk to people in your industry, and go to trade shows to make a list.

Check if companies have experience and a good name. Find ones that know cold chain logistics and use tracking technology.

Ask for detailed offers. Compare prices, services, and special ways they handle products.

Go see their buildings and trucks. Make sure warehouses, vehicles, and equipment are clean and follow the rules.

Ask about how they handle problems. Find out about backup plans, insurance, and if they have the right certificates.

Read the contracts. Look at service promises, what happens if things go wrong, and how to end the deal.

Try them out first. Test if they can keep the right temperature and deliver on time.

Keep checking their work. Do regular checks and give feedback to keep standards high.

Tip: If you skip any of these steps, you might lose money or products. Taking your time helps protect your business and your customers.

The PGL Advantage

Premier Global Logistics is a top company in cold chain logistics. Their team has many years of experience moving sensitive goods for food, pharma, and chemical companies. PGL uses smart technology like GPS and real-time temperature checks. This makes sure every shipment stays at the right temperature.

Their network covers big cities and faraway places. PGL gives full cold chain services, from pickup to delivery and storage. They offer flexible times, trucks with different temperature zones, and help any time of day. PGL always follows the rules and puts safety first. This is why many trust them for refrigerated logistics.

Temperature-controlled logistics keeps food and medicine from going bad. It also helps stop health problems. Expert logistics providers use new technology to keep things safe. They follow strict rules to make sure products stay good.

Explanation | |

|---|---|

Critical for safety and efficacy | Keeping the cold chain whole stops spoilage and health problems |

Advanced technology use | AI, IoT, and telematics help watch and track shipments |

Strict regulatory compliance | Following rules keeps products safe and legal |

Specialized handling | Good packaging and careful handling stop contamination |

Premier Global Logistics is known for safe shipping and real-time tracking. They give help all day and night. Their team makes sure every shipment is safe and follows the rules. You can trust PGL for cold chain logistics across the country. They keep your cargo safe.

Want to keep your sensitive goods safe? Contact Premier Global Logistics for expert cold chain help and top safety.

FAQ

What types of products require temperature-controlled freight?

Medical devices, vaccines, and biological samples need cold shipping. Fresh foods, dairy, frozen goods, and sensitive chemicals do too. If these products get too warm or cold, they can go bad. They might lose value or become unsafe for people.

How does Premier Global Logistics ensure compliance with FDA and GMP standards?

PGL checks temperatures in real time and keeps digital records. Their team follows rules from FDA, GMP, and FSMA for each shipment. They clean everything well and write down every step. This helps them prove they follow all the rules.

Can PGL handle multi-temperature shipments in one truck?

Yes, PGL has trucks with different temperature zones. This means they can move frozen, chilled, and room-temperature goods together. Each zone stays at the right temperature. This keeps every product safe and good.

What technology does PGL use to protect sensitive cargo?

PGL trucks have GPS, temperature sensors, and battery backups. The system sends alerts if the temperature changes. The team watches shipments all day and night. They can fix problems right away.

Where are PGL’s cold chain warehouses located?

PGL has cold chain warehouses in Miami, Los Angeles, and Dallas. These places help send products across the country and to other countries. Each warehouse has different temperature areas, labels, and safe handling for sensitive items.

See Also

Reliable Cold Storage Solutions From Premier Global Logistics East Coast

South Florida Temperature-Regulated Warehousing Offered By Premier Logistics

Premier Global Logistics Provides Refrigerated Transport For Perishables

Fast Order Fulfillment With Premier Logistics Warehousing In NJ And FL

Premier Logistics Warehousing Ensures Timely Deliveries Without Delays