What Are the Key Components of Global Logistics Best Practices in Shipping and Logistics

You can improve your logistics operations by focusing on several key components of global logistics best practices in shipping and logistics. Centralize your logistics management to coordinate activities across regions. Use logistics software for better shipment visibility. Build flexibility into your supply chain to reduce risks. Prioritize sustainability with route optimization. Track performance with data analytics. Keep communication clear among all stakeholders. Adjust your approach to fit your industry and your customers. Benchmark your processes against these standards to identify areas for growth.

Key Takeaways

Centralize logistics management to improve coordination across regions and enhance efficiency.

Utilize logistics software for better shipment visibility and to track performance with data analytics.

Build flexibility into your supply chain to reduce risks and adapt to changing market conditions.

Prioritize sustainability by optimizing routes and using eco-friendly practices to lower your carbon footprint.

Foster collaboration among cross-functional teams to improve delivery rates and customer satisfaction.

Key Components of Global Logistics Best Practices

Efficient and reliable shipping and logistics depend on several key components. You need to focus on planning, cash flow, teamwork, and collaboration. These areas help you manage complex supply chains, control costs, and deliver goods on time. When you use the key components of global logistics best practices in shipping and logistics, you can avoid common problems and improve your results.

Planning and Strategy

You must start with a strong plan. A well-defined logistics strategy helps you manage the many moving parts in global supply chains. It streamlines your operations and reduces transit times. You control costs by planning ahead. You also lower risks by spotting problems early. Good planning keeps you in line with trade laws and helps your company build a strong reputation.

A well-defined logistics strategy is crucial for managing complexities in global supply chains.

It optimizes performance and ensures compliance with international trade laws.

Key benefits include:

Streamlined logistics operations that reduce transit times.

Cost control through strategic planning.

Risk mitigation by identifying potential disruptions.

Regulatory compliance to avoid shipment delays.

Sustainable operations that enhance brand reputation.

You can use frameworks like Transportation Management Systems (TMS) to make better decisions. Automated load consolidation and real-time analytics help you choose the best carriers and routes. Risk assessment frameworks let you prepare for disruptions by having backup suppliers and flexible inventory plans.

Tip: Regularly review your logistics strategies to keep up with changes in your business and customer needs.

Common challenges include keeping up with new technology and changing regulations. You should assess your transportation strategies, evaluate outsourcing options, and make sure your systems provide the data you need. Technology integration, such as IoT and AI, improves efficiency. Open communication with stakeholders strengthens relationships. Standards like EN 14943:2005 and ISO 23354:2020 guide your best practices.

Practical Tips:

Implement IoT for real-time tracking.

Use AI for predictive analytics.

Automate warehouse operations to reduce errors.

Cash Flow Management

Managing your cash flow is vital for daily operations and long-term success. You need to make smart decisions to keep your business running smoothly, even when markets change. Companies that manage cash flow well can adjust their supplier base and transportation methods quickly.

Efficient cash flow management helps you balance customer satisfaction with service costs. You must watch your accounts receivable and control expenses. A strong financial plan lets you spot problems before they grow.

Delayed payments can hurt your business. Speed up billing and use technology for faster invoicing.

Lack of data visibility slows decision-making. Invest in better data tools to improve forecasting.

High driver turnover increases costs. Offer competitive pay and use driver-friendly technology.

Inadequate financial planning leads to cash flow gaps. Build a robust financial plan to avoid surprises.

Common Challenges and Solutions:

Improve payment processes for accurate and timely invoicing.

Invest in technology to boost data visibility.

Diversify your client base to reduce risk.

Monitor accounts receivable closely.

Review costs and renegotiate contracts regularly.

Cross-Functional Teams

You need teams that work across different areas of your business. Cross-functional teams improve delivery rates and customer satisfaction. They also lower costs by reducing calls for help.

Enhanced customer satisfaction.

Reduced requests for help to the call center by one-third, leading to lower costs.

To build strong teams, move people between groups and use tools like Kanban boards and Gantt charts. Identify leaders and hold regular check-ins. Start with a few teams, then inspect, adapt, and grow. Celebrate successes to keep morale high.

Best Practices Table:

Practice | Benefit |

|---|---|

Move people between teams | Boosts skills and flexibility |

Use Kanban boards and Gantt charts | Improves visibility |

Regular check-ins | Maintains team dynamics |

Celebrate successes | Increases motivation |

You should create a clear plan for collaboration. Use frameworks like OKRs to define success. Make sure your teams have diverse backgrounds and skills. Recognize achievements to keep everyone motivated.

Collaboration

Collaboration is one of the key components of global logistics best practices in shipping and logistics. When you work with partners, you can find and fix problems faster. You save money and increase efficiency by sharing information and resources.

Collaboration leads to increased efficiency and cost savings by identifying and eliminating inefficiencies in the supply chain.

Enhanced visibility and transparency through shared digital platforms allows for better decision-making and quick responses to disruptions.

Collaboration in logistics provides numerous benefits that can positively impact all parties involved, including increased efficiency, cost savings, and enhanced visibility.

Successful models show how sharing resources can cut costs. For example, the European Food Network lets companies share warehousing and distribution. This reduces expenses and improves service. Digital twin technology helps you simulate supply chain scenarios and optimize operations. Reusable packaging solutions streamline workflows and lower environmental impact.

Bonded Logistics partnered with CargoShot to revolutionize how we capture and manage photographic data in our warehouse operations. This collaboration has significantly improved the speed, accuracy, and transparency of our shipping and receiving processes, highlighting the importance of leveraging technology and strong partnerships in logistics.

A global automated material handling company improved inbound logistics, inventory management, and global transportation by partnering with SCS. This collaboration streamlined operations and reduced costs, exemplifying effective collaboration in global logistics.

A leading multinational logistics company operates as a cornerstone of global trade infrastructure, managing complex supply chain operations. Their strategic focus on digital transformation and operational excellence positions them at the forefront of industry innovation.

Practical Tips:

Use digital platforms to share information.

Simulate supply chain scenarios with digital twin technology.

Adopt reusable packaging to save money and help the environment.

When you focus on the key components of global logistics best practices in shipping and logistics, you build a stronger, more reliable supply chain. You can overcome challenges and deliver better results for your customers.

Transportation and Inventory

Carrier Selection

Choosing the right carrier is one of the key components of global logistics best practices in shipping and logistics. You should look at several factors when making your choice:

Performance

Reliability

Shipping price

Customer service costs

Transit times

SLA compliance

You also need to check if the carrier offers good insurance options. Some carriers include basic coverage, but extra insurance can help you get faster claims and full coverage for your goods. Pick carriers with strong customs handling skills. This helps you avoid delays and makes sure your products enter other countries smoothly. Carrier transit-time performance can affect your logistics costs and service. The right carrier and transportation mode help you control costs and keep your customers happy.

Shipping Methods

You have different shipping methods to choose from. Each method has its own cost and speed. Here is a simple table to help you compare:

Shipping Method | Cost | Speed |

|---|---|---|

Air Freight | Most Expensive | Fastest |

Sea Freight | Least Expensive | Slowest |

Land Shipping | Moderate Cost | Moderate Speed |

Multimodal shipping, which uses more than one type of transport, can reduce transit times. The impact of multimodal transport can vary by region, but it often helps goods move faster, especially in international trade.

Tip: Use multimodal shipping if you want to balance cost and speed for your shipments.

Inventory Control

Good inventory control helps you avoid running out of stock or having too much. You need to track your items, manage space, and use clear policies. Many companies use automation and regular audits to keep things running smoothly.

Control stock levels to keep products fresh and avoid markdowns.

Use automated reorder points to prevent stockouts.

Keep safety stock for times of disruption.

Use economic order quantity models to lower costs.

Shorten lead times to respond quickly to market changes.

Build strong relationships with suppliers.

You can also use a warehouse management system (WMS) for real-time tracking and data analytics. This helps you make better decisions and keep your inventory accurate.

Warehouse Management

Warehouse management is another key part of global logistics. You need to design your supply chain to handle goods across countries. Use inventory policies that match global demand. Make sure you follow trade rules and manage risks. Train your staff well and use modern technology like robotics and data analytics.

Use automation to speed up picking and packing.

Mobile solutions can improve cycle counting and order speed.

Quality checks and cycle counts reduce errors.

Order picking accuracy is very important. Advanced warehouse management systems and barcode scanners help you pick the right items and fill orders quickly.

Compliance and Risk

Trade Regulations

You face many rules when you ship goods across borders. Trade regulations shape how you move products and how much you pay. Some of the most important rules include:

Customs Trade Partnership Against Terrorism (CTPAT)

International Maritime Organization (IMO) regulations

General Data Protection Regulation (GDPR)

United States-Mexico-Canada Agreement (USMCA)

Registration, Evaluation, Authorization and Restriction of Chemicals (REACH)

Advanced Filing Rules (AFR) in Japan

Saudi Standards, Metrology and Quality Organization (SASO) regulations

You must prepare and check all shipping documents. Customs clearance must meet every rule. You need to watch for sanctions and restricted goods. Trade agreements can help you lower tariffs and save money.

Staying informed about international agreements and country-specific standards helps you avoid costly mistakes.

Shipping delays and extra costs often come from trade regulations. For example, insurance and freight costs for energy products rose from 4.4% to 5.7% of landed duty-paid value. In December 2020, insurance and freight costs per kilogram increased by 26% compared to the previous year.

Description | Data |

|---|---|

Decline in containers handled by top U.S. ports (2019-2020) | 0.5% decrease |

Increase in insurance and freight costs for energy-related products | 4.4% to 5.7% |

Increase in insurance and freight costs per kg (Dec 2020 vs Dec 2019) | 26% increase |

Customs Knowledge

You need strong customs knowledge to keep your shipments moving. Every country has its own rules and paperwork. You must know how to fill out commercial invoices, packing lists, and import licenses. You should understand tariffs, duties, and taxes to calculate costs. Trade compliance and security protocols protect your goods and your reputation.

Learn customs procedures for each country.

Prepare all required documents.

Know tariff rates and duty structures.

Follow export controls and security rules.

Avoid penalties by meeting every requirement.

Customs mistakes can lead to delays, fines, and damage to your company’s reputation.

Risk Mitigation

You can lower risks in global logistics by planning ahead. Diversify your suppliers and manufacturing locations. Use technology to track assets and shipments. Build strong partnerships with reliable carriers. Train your team to handle problems quickly.

Vet suppliers and carriers before you work with them.

Plan for emergencies and disruptions.

Use asset tracking tools for real-time updates.

Set up incident response protocols.

Invest in ongoing training and education.

Building a resilient supply chain helps you respond to crises and keeps your business running smoothly.

Technology and Data

Supply Chain Visibility

You need strong supply chain visibility to keep your logistics running smoothly. When you use the right technology, you can track goods in real time and spot problems before they grow. Most customers—88%—expect to track their orders as they move. Companies that offer this feature see higher customer satisfaction. Real-time tracking also helps you reduce delays and plan better routes. For example, Amazon increased its customer satisfaction scores by 25% after adding real-time order tracking.

Here are some common technologies that boost supply chain visibility:

Technology | Description |

|---|---|

AI | Finds trends and predicts demand, making your supply chain more efficient. |

IoT | Uses sensors to monitor goods, giving you real-time updates. |

RFID | Tracks items with tags, cutting down on manual errors. |

Cloud Connectivity | Lets you share data and work together across the supply chain. |

Advanced Analytics | Offers insights for better decisions. |

Automation | Handles repetitive tasks, reducing mistakes and saving time. |

Data Analytics

You can use data analytics to make your logistics smarter. Data helps you find bottlenecks and fix them fast. Companies like UPS use analytics to plan better routes, saving fuel and time. Toyota uses data to watch production and catch problems early. Maersk Line uses analytics to pick the best shipping routes, which cuts emissions and boosts efficiency.

Demand forecasting lets you predict what customers want, so you keep the right amount of stock.

Route optimization helps you deliver faster and save money.

Quality control improves when you spot issues early.

Sustainability grows as you use data to lower waste and emissions.

You also improve customer experience by giving real-time updates. Data analytics helps you manage risks by spotting problems before they happen.

Demand Forecasting

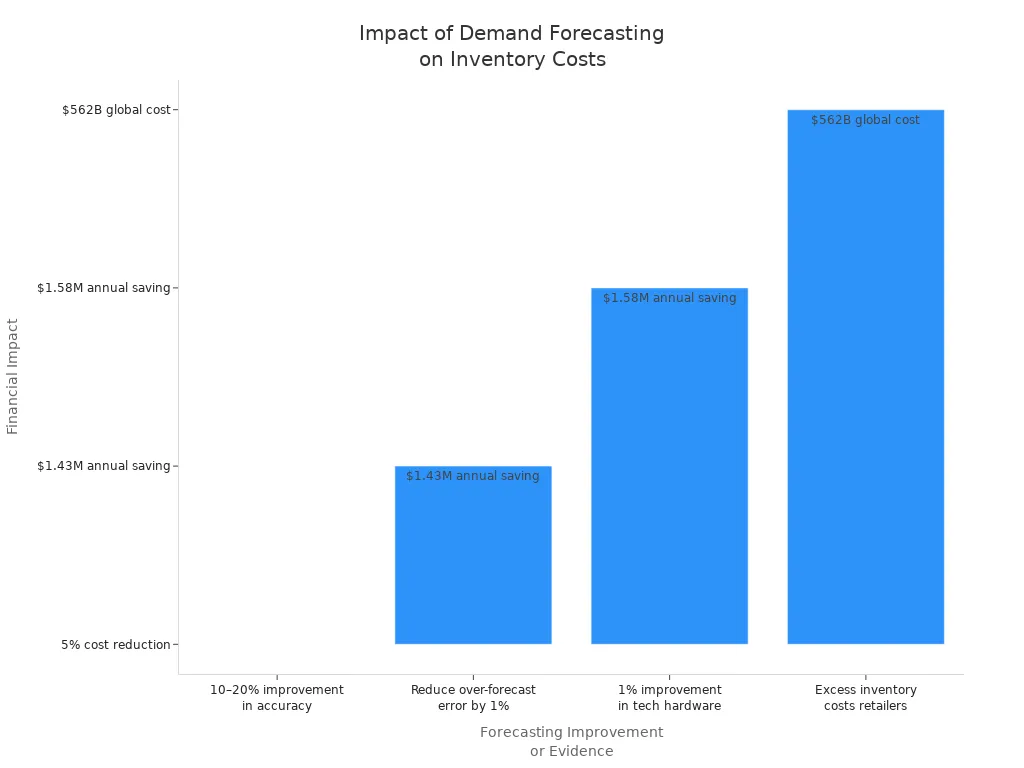

Demand forecasting helps you match your inventory to what customers need. When you improve your forecast accuracy by 10–20%, you can cut inventory costs by about 5%. Even a 1% improvement in forecast accuracy can save companies over $1 million each year. In 2023, retailers lost about $562 billion worldwide because of excess inventory.

Evidence Description | Impact |

|---|---|

10–20% improvement in demand forecast accuracy | Can trim inventory costs by about 5% |

Reducing over-forecasting error by 1 percentage point | Yields an average $1.43 million annual saving for consumer products companies |

1% improvement in over-forecast accuracy in technology hardware | Saves about $1.58 million per year for mid-sized firms |

Excess inventory costs retailers globally in 2023 | Approximately $562 billion through markdowns and spoilage |

Tip: Use demand forecasting tools to keep your inventory balanced and avoid costly mistakes.

Sustainability and Excellence

Lean Principles

You can make your logistics more efficient by using lean principles. Lean methods help you cut waste and improve your workflow. When you use just-in-time (JIT) inventory management, you order only what you need, when you need it. This reduces storage costs and stops overproduction. You find tasks that do not add value and remove them. You also streamline your processes to save time and resources.

JIT inventory management lowers storage costs.

You avoid overproduction by ordering only what is needed.

Lean principles help you spot and remove redundant tasks.

You optimize resources and timelines for better results.

Waste reduction leads to cost savings and higher customer satisfaction.

Lean principles align your operations with lean manufacturing. You see better product quality and happier customers. You also save money and reduce wasted effort.

Green Logistics

Green logistics helps you protect the environment while running your business. You use eco-friendly practices to lower your carbon footprint. You can switch to electric vehicles, use alternative fuels, and reuse materials in your supply chain. IoT and AI help you track fuel usage and optimize routes, which cuts emissions.

Strategy | Impact on Carbon Emissions |

|---|---|

Transition to electric vehicles | Significant reduction in emissions from transportation |

Use of alternative fuels | Promising alternatives to traditional energy sources |

Integration of IoT and AI | Optimizes logistics, reducing fuel usage and emissions |

Adoption of circular supply chains | Ensures materials are reused, impacting overall emissions |

Green logistics means you use energy-efficient vehicles, better packaging, and smart waste management. These steps help you lower fuel use and reduce harm to the environment.

IoT monitors fuel and vehicle performance.

AI improves demand forecasting and route planning.

Automation and robotics cut energy use in logistics.

Advanced inventory software tracks goods and streamlines operations.

Continuous Improvement

You should always look for ways to improve your logistics. Continuous improvement means you review your processes and find areas to make better. You set goals, measure results, and adjust your methods. You train your team and use feedback to guide changes. Small improvements add up over time and help you stay ahead in global logistics.

Tip: Encourage your team to share ideas for improvement. Celebrate small wins to build momentum and keep everyone motivated.

You build a culture of excellence by making improvement a daily habit. This helps you deliver better service and keep your business strong.

You can boost your global logistics performance by using these best practices. Strong planning, teamwork, and smart technology help you deliver goods on time and cut costs.

Take time to review your current logistics process.

Stay open to new ideas and keep checking your results.

Try new strategies to improve your supply chain.

Keep learning to stay ahead in global shipping and logistics.

FAQ

What is the most important factor in global logistics?

You need strong planning. Good planning helps you avoid delays and control costs. You can use technology to track shipments and improve your supply chain.

How can you reduce shipping costs?

You can compare carriers and choose the best option. Use route optimization tools. Negotiate contracts and review them often. Automation helps you lower errors and save money.

Why does compliance matter in shipping?

You must follow trade laws to avoid fines and delays. Compliance keeps your goods moving and protects your business. You should check regulations for every country you ship to.

What technology improves supply chain visibility?

You can use IoT sensors, RFID tags, and cloud platforms. These tools give you real-time updates. You see where your goods are and spot problems early.

See Also

Understanding East Coast B2B Warehousing By Premier Global Logistics

Efficient Project Trucking Solutions Offered By Premier Global Logistics

Diverse Trucking Solutions For West Coast Freight By Premier Global Logistics

Efficient Inventory Management Through Premier Global Logistics Warehousing

Exploring Future Trends in LCL Shipping To Panama By Premier Global Logistics