What is a Logistics Carrier Facility and How Does It Work

A logistics carrier facility acts as a central hub where your packages arrive, get sorted, and prepare for the next step in delivery. These facilities help move shipments quickly by using advanced tracking and strong networks. You see faster delivery in some areas, like Zone 1 with 1-2 days, while Zone 8 may take 5-7 days:

Delivery Zone | Typical Delivery Time |

|---|---|

Zone 1 | 1-2 days |

Zone 8 | 5-7 days |

Many factors influence timing, such as network size, weekend options, and weather. The logistics carrier facility guide helps you understand how these hubs keep your packages moving.

Key Takeaways

Logistics carrier facilities act as central hubs for sorting and dispatching packages, ensuring faster delivery times.

Advanced technology, like barcode scanning and automated systems, helps track packages in real time and reduces errors.

Different types of logistics facilities serve unique roles, from local carriers for small deliveries to national carriers for broader reach.

Understanding the package journey through these facilities helps manage expectations and improves customer satisfaction.

Real-time tracking updates keep you informed about your package's status, enhancing trust and reducing complaints.

Logistics Carrier Facility Guide

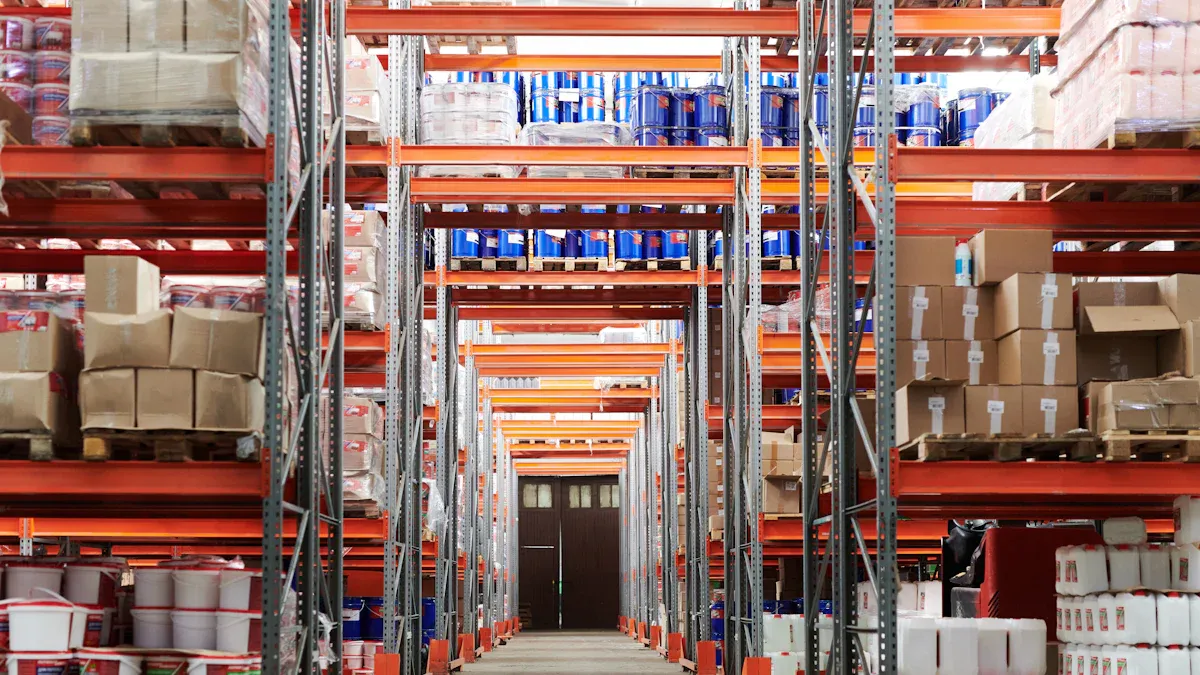

Definition

A logistics carrier facility is a large warehouse or distribution center managed by shipping companies. You can think of it as a central hub where packages arrive before moving to their next stop. These facilities handle the sorting, processing, and dispatching of packages. When you use a logistics carrier facility guide, you learn how these hubs keep your shipments on track and help reduce delivery times.

Carrier facilities play a key role in the logistics network. They make sure your package moves quickly and safely from the seller to your door.

Purpose

The main goal of a logistics carrier facility is to move packages efficiently through the supply chain. You benefit from faster deliveries and fewer mistakes because these facilities use advanced technology and organized systems. Here is a table that shows the main functions of a logistics carrier facility:

Function | Description |

|---|---|

Scanning | Carrier facilities scan packages to track their movement through the supply chain. |

Sorting | They sort packages based on destination to streamline the delivery process. |

Transportation | Facilities transport packages to various locations, ensuring timely delivery. |

You can see that each step helps your package reach you faster. Facilities also manage shipment requirements, select the right carriers, design efficient networks, and work to reduce risks in the supply chain.

Facilities efficiently manage the flow of packages from sellers to buyers.

They use barcode scanners and automated systems for real-time tracking.

Packages get sorted by destination and priority, which reduces errors and speeds up delivery.

Types

You will find different types of logistics carrier facilities, each with a special role in the supply chain. The logistics carrier facility guide helps you understand these types and why they matter. Here is a table that explains the main types:

Carrier Type | Description |

|---|---|

Common Carriers | Provide freight shipping services to the public, available to any organization. |

Contract Carriers | Operate under specific contracts with shippers for a set period. |

Local Carriers | Operate within a smaller radius, using small trucks for flexible door-to-door services. |

Regional Carriers | Cover a wider area with larger trucks, ensuring faster deliveries. |

National Carriers | Operate across the entire country, partnering with local and regional carriers. |

Private Carriers | Transport freight exclusively for a single company, ensuring safety and quick issue resolution. |

For-Hire Carriers | Provide services on a fee basis, often specializing in specific types of freight. |

Freight Brokers | Connect companies with suitable carriers, streamlining the process. |

Freight Forwarders | Act as intermediaries to consolidate freight services and optimize transportation. |

Third-Party Logistics (3PLs) | Coordinate and optimize the fulfillment process, reducing delays and streamlining operations. |

Some facilities focus on speed, like cross-dock centers. These centers move goods directly from incoming trucks to outgoing trucks with almost no storage time. This method works well for time-sensitive items. Other facilities, like regional sorting hubs, handle more complex sorting and can store packages for longer periods. You can use the logistics carrier facility guide to see which type of facility handles your package and how it affects your delivery time.

How It Works

A logistics carrier facility runs like a busy machine. Every day, you see millions of packages move through these centers. The process follows a clear path to make sure your package arrives on time. Here is how each step works:

Receiving

When your package first arrives at a logistics carrier facility, workers unload it from trucks or planes. The facility handles a huge number of packages every day. You can see just how busy these places get in the table below:

Metric | Value |

|---|---|

Daily packages shipped | |

Packages shipped per hour | 833,000 packages |

Packages shipped per minute | 13,888 packages |

Packages shipped per second | 231 packages |

You can imagine the high activity levels as workers and machines move packages quickly to keep up with demand. The logistics carrier facility guide helps you understand why speed and accuracy matter so much at this stage.

Sorting

After receiving, your package goes to the sorting area. Here, advanced machines and systems organize packages by destination. Automated sortation systems connect to a Warehouse Management System (WMS). This system tracks inventory and orders, making sure each package goes to the right place. Facilities use several types of sorting equipment:

Merges and combiners to bring packages together from different lines

Conveyor sortation, like tilt trays and cross belt sorters, for smooth flow

Linear, loop, and pusher sortation systems for different package sizes and needs

Consistent sorting performance improves delivery reliability and reduces errors. When your package gets sorted correctly, you receive it on time, which builds trust and keeps you coming back.

Scanning

Next, workers and machines scan your package. This step tracks your shipment and updates its status. Facilities use several technologies to track incoming shipments:

Barcode scanning

GPS

RFID technology

You benefit from these tools because they help track your package in real time. The table below shows how barcode and RFID technologies compare:

Feature/Benefit | Barcode | RFID |

|---|---|---|

Scanning Requirement | Requires line-of-sight | No line-of-sight needed |

Scanning Efficiency | Individual item scanning | Bulk scanning possible |

Data Storage | Limited to static information | Can store dynamic data |

Error Rate | Prone to scanning errors | Reduced manual errors |

Cost | Low cost | Higher cost but more efficient |

The logistics carrier facility guide explains how these technologies reduce mistakes and speed up the process.

Loading

Once sorted and scanned, your package moves to the loading area. Workers coordinate transportation by scheduling pickups, creating shipping labels, and arranging routes. They track shipments to make sure everything stays on schedule. Efficient loading helps drivers leave on time and reach your address faster.

Impact of Loading Efficiency on Last-Mile Delivery Times | Description |

|---|---|

Coordination of Deliveries | Efficient loading helps in better scheduling and routing of deliveries, reducing delays. |

Utilization of Loading Spaces | Proper management of loading bays maximizes space usage, leading to quicker loading and unloading. |

Traffic Flow in Urban Areas | Improved loading efficiency reduces congestion and emissions by minimizing unnecessary driving. |

You see faster deliveries when facilities load packages quickly and use space well.

Dispatch

The final step is dispatch. Here, the facility sends out delivery vehicles based on optimized schedules. Staff assess demand, coordinate with suppliers, and allocate resources. They use delivery scheduling software to plan the best routes and avoid traffic during busy hours. Good communication between drivers, warehouse staff, and suppliers helps prevent delays.

Coordinate with suppliers for the best delivery windows

Allocate resources based on warehouse capacity and staff

Optimize routes with scheduling software

Time departures to avoid peak-hour congestion

Keep everyone informed to prevent delays

When you follow the logistics carrier facility guide, you see how each step works together. High efficiency at every stage means your package arrives faster and with fewer errors.

Package Journey

Status Updates

You receive several status updates as your package moves through a logistics carrier facility. These notifications help you track your shipment and know what to expect next. Here are the most common updates you might see:

The Package Has Arrived at the Carrier Facility: You get a message when your package reaches the facility.

Parcel is Being Processed at Carrier Facility: You see this update while your package is sorted and scanned.

Package Transferred to Another Carrier Facility: You receive this alert when your package leaves for the next destination.

Delay in Order Processing: You get notified if there is a delay in sorting or processing.

Real-time tracking systems let you monitor your package’s location and status. You can check movement details, timestamps, and locations using tracking portals. Unique barcodes on shipping labels help update your package’s status every time it gets scanned. Automatic notifications keep you informed about estimated arrival times and any changes.

Time at Facility

The time your package spends at a logistics carrier facility depends on several factors. You might notice that some packages move quickly, while others take longer. Here are the main reasons for different stay durations:

Customs Clearance Procedures: Packages may wait for customs checks or paperwork.

Terminal Infrastructure and Equipment: Modern facilities process packages faster.

Intermodal Connectivity: Smooth transfers between trucks, planes, or trains speed up movement.

Labor Availability and Productivity: Skilled workers help packages move quickly.

Weather and Environmental Factors: Storms or snow can slow down operations.

Cargo Characteristics and Handling Requirements: Fragile or special items may need extra care.

Tip: If your package needs customs clearance or special handling, expect a longer stay at the facility.

Delays

Delays can happen for many reasons at logistics carrier facilities. You might see your package status change or get a notification about a delay. Common causes include:

Missed routing windows, which make packages wait for the next shipment.

Operational or weather disruptions, such as storms or staff shortages.

Carrier network congestion, when too many packages arrive at once.

Customs and regulatory issues, like missing paperwork or inspections.

Equipment and capacity problems, such as limited space or broken machines.

Weather events cause about 23% of all road delays in the United States. Snow and ice in northern regions often close roads and create unpredictable delays. These disruptions can cost trucking companies billions of dollars each year.

If you notice a delay, check your tracking portal for updates. Most carriers send instant notifications to keep you informed.

Customer Concerns

Pickup Options

You have several ways to pick up your package from a logistics carrier facility. Many carriers offer flexible pickup locations to fit your needs. The table below shows common pickup options from major carriers:

Carrier | Pickup Options |

|---|---|

USPS | Local post offices |

UPS | Retail locations for package pickup, Alternate Delivery Program at 5,000+ locations (ID required) |

FedEx | Retail locations including FedEx stores, Walgreens, Dollar General, Hold at Location service |

Amazon | Various pickup points including Amazon Lockers |

You can also choose between scheduled pickups and on-call pickups. Scheduled pickups happen daily and work well if you ship packages often. On-call pickups let you request a pickup when you need it, usually with a four-hour window.

Service Type | Description |

|---|---|

Scheduled Pickup | Daily pickups for efficient shipping |

On-Call Pickup | Pickup on an as-needed basis, four-hour window |

When you pick up a package, the facility must verify your identity. This keeps your package safe. Facilities use several methods to check who you are:

Verification Method | Description |

|---|---|

Unified Registration System (URS) | Requires personal or business ID, biometric data, and ownership details |

Selfie Verification & Biometric Authentication | Confirms your identity in real time using a photo or fingerprint |

Device Intelligence | Checks for unusual device use or account sharing |

Continuous Monitoring | Uses regular check-ins to make sure the right person picks up the package |

Document-Based Receiver Verification | Ensures the package goes to the correct person, reducing fraud risks |

Tip: Always bring a valid photo ID when picking up your package. Some locations may ask for extra proof, like a code sent to your phone.

Delivery Speed

You want your package to arrive quickly. Logistics carrier facilities work hard to speed up delivery times. In November 2024, the average delivery time for parcel shipments was 3.7 days. This is much faster than in previous years. Delivery times improved by 27% from November 2023 and by 33% from November 2022. Carriers made these improvements because more people shop online and expect fast shipping.

Most packages now arrive in less than four days.

Faster delivery helps you get what you need sooner.

Carriers use better technology and smarter routes to save time.

If you need your package even faster, you can request expedited shipping. Facilities handle these requests by checking their current workload, working with special carriers, and using advanced tracking systems. They also keep you informed about what to expect and any limits on fast shipping.

Note: Expedited shipping may cost more, but it gives your package priority and often guarantees a faster delivery window.

You rely on logistics carrier facilities to keep your packages moving quickly and safely. These hubs play a vital role in shipping reliability. Many factors can affect your delivery, such as weather, road conditions, and technology issues.

Poor communication and equipment problems can cause delays.

Labor shortages and safety concerns may also impact delivery times.

Understanding each step in the process helps you manage your expectations. Tracking tools give you real-time updates and help resolve issues faster:

Benefit | Description |

|---|---|

Reduces complaints | Tracking lowers late arrival and poor communication complaints. |

Enhances customer trust | 70% of people feel more confident when they can track their orders. |

Cuts service time | Tracking reduces "Where is my order?" calls by up to 30%. |

Automates resolutions | AI chatbots can solve half of delivery questions instantly. |

Flags anomalies | Tracking systems spot delays and problems early. |

Stay informed by checking your tracking portal and contacting your carrier if you have concerns.

FAQ

What does “Arrived at Carrier Facility” mean?

You see this status when your package reaches a logistics carrier facility. Workers scan and sort your package here before sending it to the next location or out for delivery.

Can you pick up a package from a carrier facility?

Yes, you can pick up your package from many carrier facilities. You need a valid photo ID. Some locations may ask for a pickup code or extra proof.

Why do packages sometimes stay longer at a facility?

Packages may stay longer because of customs checks, bad weather, or high package volume. Special handling or missing paperwork can also cause delays.

How can you track your package at a carrier facility?

You can track your package using the carrier’s online tracking portal. Enter your tracking number to see real-time updates, including when your package arrives, gets sorted, and leaves the facility.

See Also

Understanding B2B Warehousing And Distribution On The East Coast

Enhancing International Operations With Innovative Logistics Strategies

Boosting Global Efficiency Through Point-to-Point Logistics Systems

Simplifying Supply Chain Optimization With American Logistics Solutions