Emerging Logistics Industry Trends Shaping the Future

You will see major logistics industry trends in 2025 that change how you operate.

Artificial Intelligence and data improve logistics decisions.

These trends push companies to invest in technology, manage costs, and focus on sustainability.

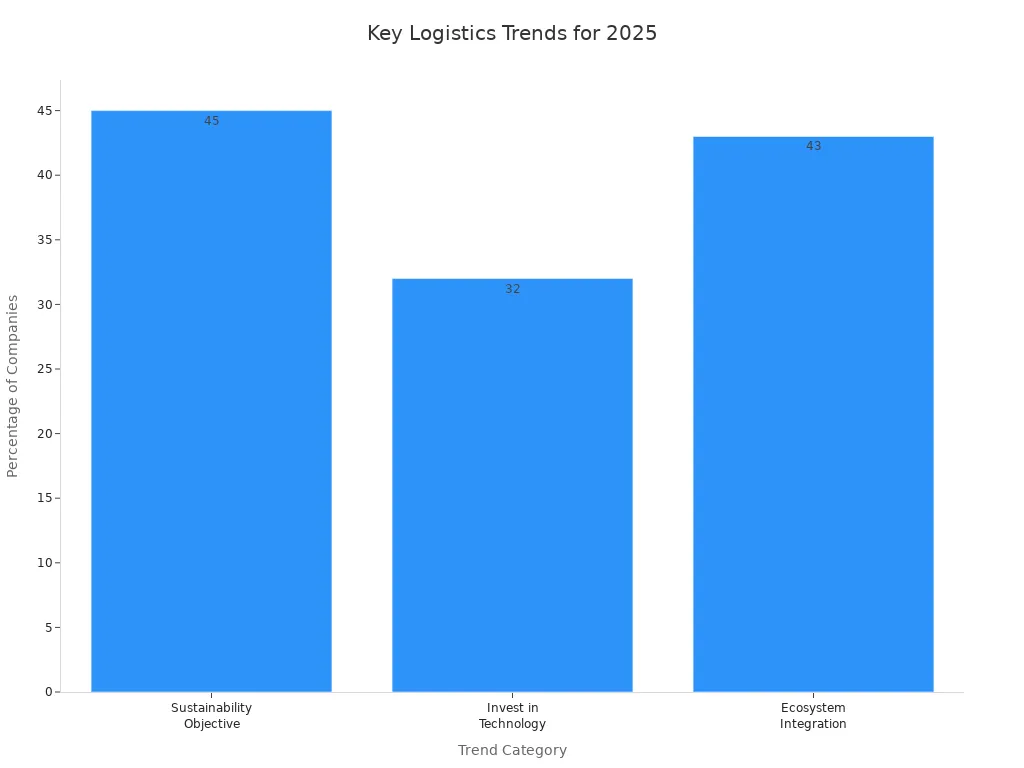

Evidence | Description |

|---|---|

Identified sustainability as a critical business objective for 2025. | |

32% of companies | Plan to invest in supply chain technology to combat rising costs. |

43% of companies | Believe ecosystem integration will help cut costs. |

You need to stay aware of logistics industry trends 2025 global supply chain updates May 2025 because these changes will shape your next steps.

Key Takeaways

AI and automation are transforming logistics. Companies using these technologies can save money and improve productivity.

Sustainability is crucial. Many consumers prefer eco-friendly options, and businesses can attract more customers by going green.

Real-time tracking enhances customer satisfaction. Customers expect to know where their shipments are at all times.

Diversifying suppliers reduces risks. Companies should build strong relationships with multiple suppliers to avoid disruptions.

Investing in technology is essential. Businesses that adopt new tools and practices stay competitive and efficient.

Logistics Industry Trends 2025

AI & Automation

You see AI and automation changing the way logistics companies work. Robots move goods in warehouses. AI helps you make better decisions about inventory and shipping. Many companies invest in these technologies to save money and boost productivity.

Statistic | Description |

|---|---|

Warehouse Automation Growth | Expected to grow by 1.5 times by 2025. |

Smart Manufacturing Market | Predicted to grow from $223.6 billion to $985.5 billion by 2032. |

Intralogistics Adoption | 75% of industry leaders expect to adopt by 2026. |

Increased Spending on Automation | 52% of warehouse managers anticipate increased spending. |

Productivity Improvement | Businesses implementing automation can see up to a 48% improvement. |

Operating Cost Reduction | Automation can lead to a 42% decrease in operating costs. |

Investment in AI Tools | 55% of supply chain leaders plan to invest more in AI-based tools. |

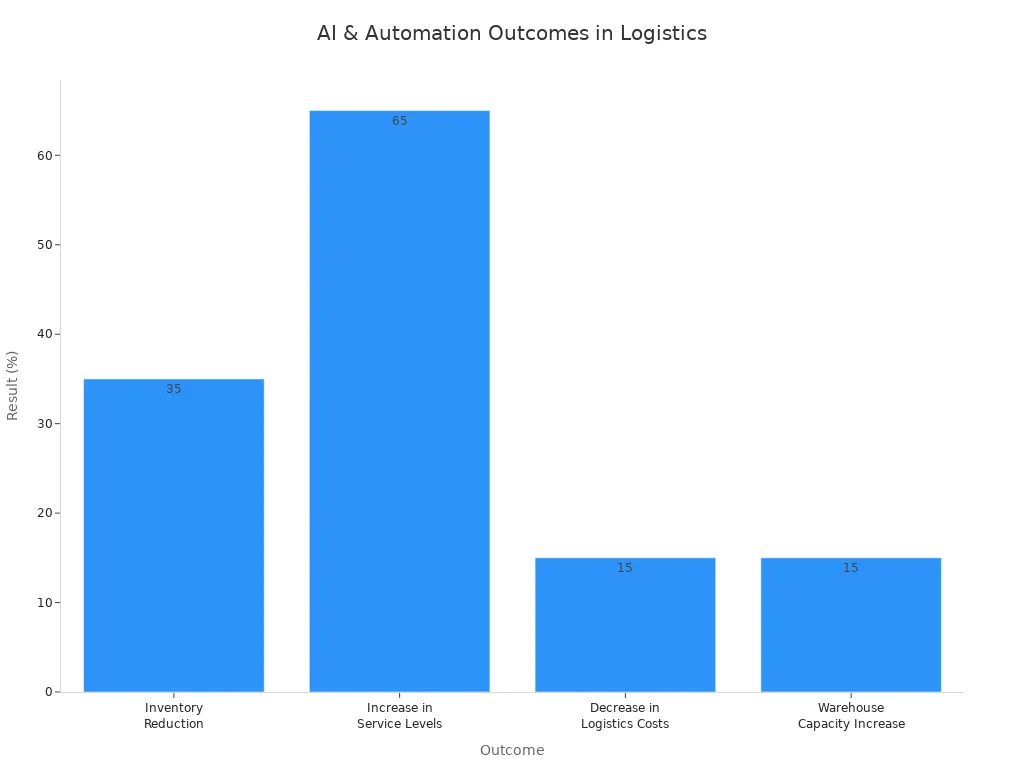

You notice real results when companies use AI and automation. For example, some logistics providers report a 35% reduction in inventory and a 65% increase in service levels. Costs drop by 15%, and warehouse capacity rises by 15%. These improvements help you keep up with logistics industry trends 2025 global supply chain updates May 2025.

Outcome | Measurable Result |

|---|---|

Inventory Reduction | 35% |

Increase in Service Levels | 65% |

Decrease in Logistics Costs | 15% |

Warehouse Capacity Increase | 15% |

Tip: You can use AI-powered tools to predict demand and optimize delivery routes. This helps you avoid delays and reduce costs.

Blockchain Integration

Blockchain technology brings more transparency and security to logistics. You use blockchain to track shipments and verify transactions. Records on the blockchain cannot be changed easily, so fraud becomes much harder. Every transaction gets checked by several parties before it goes into the system.

Evidence Type | Description |

|---|---|

Immutable Records | Blockchain records are immutable, making it extremely difficult for fraudsters to manipulate them. Altering one entry requires changing every subsequent block, which is nearly impossible. |

Secure Transactions | Financial transactions benefit from blockchain's secure framework, eliminating risks like chargebacks and fraud through a decentralized ledger. |

Verified Transactions | Each transaction is verified by multiple parties before being recorded, ensuring only legitimate transactions are approved and recorded in the public ledger. |

Data Access | All parties have access to the same data, allowing independent verification of transactions, reducing disputes, and strengthening partnerships. |

Error Minimization | Blockchain minimizes errors and miscommunications that often occur in traditional systems reliant on manual entries. |

Accurate Data | All data on the blockchain is accurate and immutable, requiring consensus for any changes, ensuring a trusted data source for all parties. |

You see companies like VeChain and Mediledger using blockchain to improve logistics. VeChain uses blockchain and AI to track errors and prevent theft. Mediledger combines blockchain with IoT to confirm financial transactions and automate tracking. Siemens uses IoT and GPS with blockchain to manage workflows and physical metrics. IBM Food Trust connects food manufacturers for better data storage and supply chain transparency. Yojee uses blockchain for real-time tracking, which reduces delays and fraud risks.

Company | Application Description | Impact on Logistics Efficiency and Fraud Prevention |

|---|---|---|

VeChain | Uses blockchain and AI for decentralized freight market and error tracking. | Enhances transparency and reduces theft. |

Mediledger | Combines blockchain with IoT for automated tracking and financial transaction confirmation. | Provides richer data and improves transaction efficiency. |

Siemens | Integrates IoT and GPS for managing workflows and physical metrics. | Improves operational efficiency and monitoring. |

IBM Food Trust | Cloud-based solution connecting major food manufacturers for data storage. | Optimizes costs and enhances supply chain transparency. |

Yojee | SaaS platform for logistics visibility with real-time tracking. | Reduces delays, improves efficiency, and minimizes fraud risks. |

Digitalization

Digitalization helps you solve old problems in logistics. You use cloud solutions, IoT, AI, and big data analytics to make your supply chain more visible. This helps you make faster decisions and keep customers happy. Many logistics leaders believe digital capabilities are essential for business survival.

The transportation sector has an average digitalization score of 2.875, compared to the overall average of 3.025.

72% of leaders in enterprise logistics companies report a lack of awareness and a roadmap for digitalization.

76% of logistics leaders believe that neglecting digital capabilities could jeopardize their business.

75% of logistics leaders still rely heavily on analog and manual processes.

You see digitalization improving efficiency. It makes your operations smoother and reduces costs. You can track shipments in real time and respond quickly to problems. Digitalization also helps you meet customer expectations and stay competitive with logistics industry trends 2025 global supply chain updates May 2025.

Digitalization addresses traditional challenges in logistics operations.

Enhances visibility across the supply chain, aiding decision-making.

Optimizes processes through technologies like cloud solutions, IoT, AI, and big data analytics.

Reduces costs and improves customer satisfaction by streamlining operations.

Note: You should start planning your digital transformation now. Early adoption helps you avoid falling behind competitors.

Supply Chain Visibility

Real-Time Tracking

You want to know where your shipments are at all times. Real-time tracking gives you this power. Today, 88% of customers expect to track their orders in real time. Companies that offer this service see higher customer satisfaction rates. You get up-to-the-minute updates on shipment locations, conditions, and arrival times. This helps you make better decisions and solve problems before they grow.

Real-time tracking of shipments and accurate demand forecasting lead to timely deliveries, which significantly boosts customer satisfaction and loyalty.

Customers today expect complete transparency and reliable delivery timelines, which can be achieved through real-time shipment tracking.

Robust supply chain visibility enables businesses to provide precise delivery estimates and proactively address potential issues, enhancing customer experience.

The future of supply chain visibility is being shaped by the continuous evolution of tracking technologies and the integration of emerging innovations such as artificial intelligence (AI), machine learning, predictive analytics, and 5G connectivity.

Data Analytics

You use data analytics to make your supply chain smarter. Advanced analytics looks at market trends and economic indicators. This helps you predict demand and avoid running out of stock or having too much inventory. You can analyze inventory turnover rates and storage costs to cut waste and save money. Real-time data from sensors on delivery vehicles lets you make quick decisions and keep your operations efficient.

Predicting Demand with Advanced Forecasting: Advanced analytics considers external variables like economic indicators and market trends, leading to precise demand forecasting that helps avoid stockouts and over-inventory situations.

Improving Inventory Management Efficiency: Data analytics helps analyze inventory turnover rates and storage costs, allowing businesses to reduce waste and cut costs effectively.

Real-Time Decision-Making with Big Data: Real-time data from sensors on delivery vehicles enables quick decision-making, crucial for maintaining efficiency in logistics.

Optimizing Inventory Levels: Accurate demand forecasting allows logistics providers to maintain optimal inventory levels, reducing carrying costs and enhancing operational efficiency.

Reducing Stockouts: Advanced forecasting techniques help identify potential stockout situations, allowing proactive measures to be taken.

Minimizing Excess Inventory: Improved forecasting capabilities help avoid excess inventory, which can tie up capital and increase costs.

Customer Experience

You want your customers to feel confident about their orders. Timely deliveries and transparency are essential for a seamless customer experience. Real-time tracking builds trust and reduces worry about late or lost shipments. Companies that improve supply chain visibility often exceed customer expectations and see fewer service-related inquiries.

Real-time tracking and proactive communication lead to a significant improvement in customer satisfaction.

C&S Wholesale Grocers reduced transportation-related customer service calls by 65% after implementing automated notifications for real-time tracking.

Leveraging technology for real-time tracking enhances transparency and empowers customers to plan for deliveries.

Improving communication channels helps manage customer expectations and builds trust.

Offering flexible delivery options makes the logistics experience more customer-friendly.

You see logistics industry trends 2025 global supply chain updates May 2025 driving these changes. When you focus on visibility, you create a better experience for your customers and a stronger supply chain for your business.

Sustainability

Green Logistics

You play a key role in making logistics greener. Many consumers now care about the environment. In fact, 80% of people say they will pay more for eco-friendly products. Companies see this shift and work to lower their carbon footprint. You can use electric trucks, optimize delivery routes, and choose packaging that creates less waste. The American sustainability retail market now grows 85.3% faster than the regular market. Governments also support green logistics. The EU plans to have 3 million charge points for electric vehicles by 2030, up from 500,000 today. The UK has set aside £31.8 million for hydrogen trucks and refill stations.

Statistic | Value |

|---|---|

Percentage of consumers willing to pay more for eco-friendly products | 80% |

Growth rate of American sustainability retail market compared to conventional | 85.3% faster |

Number of charge points EU aims to have by 2030 | 3 million |

Current number of charge points in the EU | 500,000 |

Funding reserved by the UK for hydrogen trucks and refill points | £31.8 million |

Note: You can attract more customers and meet new rules by making your logistics greener.

Alternative Fuels

You help cut emissions by using alternative fuels in your fleet. Fuels like compressed natural gas, methanol, ethanol, and electricity release fewer harmful gases than regular gasoline. These fuels also lower air toxins and greenhouse gases. Some cities, such as Madrid, use low-emission zones to encourage cleaner vehicles. This move increases the number of alternative fuel vehicles, but you still need more action to reach net-zero emissions by 2050. You should look at which fuels work best in your area, since results can change by region.

Alternative fuels reduce greenhouse gas emissions and air toxins.

Electricity, methanol, and natural gas are cleaner than gasoline.

Low-emission zones boost the use of cleaner vehicles.

Evidence Type | Description |

|---|---|

Low Emission Zones | The study analyzes the impact of low-emission zones in Madrid on the uptake of alternative fuel vehicles and CO2 emissions reduction. It shows a significant increase in alternative fuel vehicle registrations but notes that the average CO2 emissions of newly registered vehicles did not decrease significantly. A true zero-emission zone is suggested for effective decarbonization. |

Circular Supply Chains

You can make your supply chain more sustainable by reusing and recycling materials. Circular supply chains use smart tools like IoT sensors, blockchain, and AI to track products and recover materials. This approach cuts costs by 15-25% and uses resources more wisely. You also help the environment by reducing waste and pollution. Circular supply chains create new jobs in recycling and repair, which helps your community grow.

Benefit Type | Description | Measurable Impact |

|---|---|---|

Cost Reductions | Reduction in costs by 15-25% | Significant financial savings |

Resource Efficiency | Enhanced tracking and recovery of materials | Improved resource utilization |

Environmental Sustainability | Reduction in waste and pollution | Positive impact on community health |

Job Creation | Increased labor opportunities in recycling and repair industries | Economic growth and community benefits |

IoT sensors monitor product use and location.

Blockchain tracks where materials come from.

AI helps you recover and reuse more materials.

You see these changes as part of logistics industry trends 2025 global supply chain updates May 2025. By focusing on sustainability, you build a stronger, greener business for the future.

Diversification & Resilience

Risk Management

You face many risks in logistics. You need strong strategies to keep your supply chain safe. Companies now use risk assessment and planning to spot weak points and create backup plans. You can build better relationships with suppliers and vendors to avoid relying on just one source. Many businesses use software for real-time alerts and inventory tracking. This helps you respond quickly when problems arise.

Strategy | Description |

|---|---|

Risk Assessment and Planning | Evaluate weaknesses and create contingency plans for disruptions. |

Supplier and Vendor Management | Work with multiple suppliers to reduce dependency risks. |

Inventory Management | Use Just-In-Time practices and improve demand forecasting for optimal inventory levels. |

Tip: Diversifying suppliers and using backup contracts keeps your operations running when one source fails.

A U.S. food supplier used weather data to reroute deliveries during a hurricane. This quick action prevented spoilage and kept customers happy.

Labor Shortages

You see labor shortages affecting logistics everywhere. The industry expects a shortage of over 2 million workers in the U.S. by 2025. This leads to delays and higher costs. You may notice slower transportation and warehouse activities. Many companies now invest in upskilling workers and automation to solve these problems.

Labor shortages cause delays and increase costs.

Upskilling and automation help you keep operations smooth.

Companies that invest in their workforce stay ahead of challenges.

You can train your team and use technology to fill gaps. This keeps your supply chain strong and reliable.

Disruption Preparedness

You must prepare for disruptions to protect your business. Companies now assess situations quickly to understand the impact. You activate contingency plans for different types of disruptions. Good communication with stakeholders helps manage expectations. You prioritize critical needs to deliver essential products first.

Assess the situation and understand the disruption.

Activate your contingency plan.

Communicate with stakeholders.

Prioritize essential deliveries.

Explore alternative solutions.

Adapt as the situation changes.

Strong relationships and technology investments help you respond faster to supply chain challenges.

Managers say long-term customer relationships allow quick responses during crises. You build resilience by staying aware, keeping your supply chain visible, and learning from each disruption. This approach helps you adapt and thrive in a changing world.

Autonomous & Electric Vehicles

AV Technology

You see autonomous vehicle (AV) technology changing logistics quickly. Companies use AVs for last-mile delivery, long hauls, and warehouse fulfillment. For example, AVs now handle forklift operations, picking, packing, and inventory scanning. In Texas, AVs already complete 240-mile trips between Dallas and Houston. These vehicles help you move goods faster and safer.

The global autonomous logistics vehicle market is growing fast. It is expected to rise from $3.8 billion in 2024 to $29.3 billion by 2035. This means a compound annual growth rate of 20.42% from 2025 to 2035. You benefit from this growth through better efficiency, lower costs, and improved safety.

Benefit/Functionality | Description |

|---|---|

Real-time inventory tracking | IoT-enabled AVs update stock levels, reducing errors. |

Sensor-driven communication | AVs connect with warehouse systems and other robots. |

Automated maintenance alerts | AVs detect issues and schedule repairs before breakdowns. |

AI-driven predictive analytics | AVs forecast demand and help you allocate resources. |

Self-learning navigation | AVs learn from past trips to avoid obstacles and plan better routes. |

Enhanced decision-making | AVs use real-time data to optimize picking, storage, and transport. |

Safety compliance | AVs help reduce workplace accidents. |

Data privacy regulations | New rules protect how AV data is collected and used. |

Sustainability incentives | Governments offer tax breaks for energy-efficient AVs. |

You can use AVs to improve warehouse workflows and meet safety standards. Many governments now support AV adoption with financial incentives.

EV Adoption

You notice more logistics fleets switching to electric vehicles (EVs). Battery technology now gives EVs longer ranges, making them useful for longer trips. Charging speeds have improved, so you spend less time waiting. Public charging networks are growing, which makes it easier to keep your fleet running.

Evidence | Description |

|---|---|

Battery Technology | New batteries let EVs travel farther, even on long routes. |

Charging Speed | Faster charging helps you avoid long downtimes. |

Public Charging Networks | More stations make it easier to charge EVs on the road. |

Lower operating costs because electricity costs less than diesel.

Reduced maintenance since EVs have fewer moving parts.

You may see a return on investment, even if the upfront cost is higher.

The shift to electric vehicles helps you cut carbon emissions. Cleaner fleets mean less air pollution and better air quality.

You can get incentives for adopting electric fleets.

Investments in charging infrastructure support your transition.

New policies encourage sustainability in logistics.

You build a greener, more efficient operation by adopting AV and EV technology. These changes help you stay ahead in the logistics industry.

Nearshoring & Market Shifts

Nearshoring to Mexico

You see more companies moving their supply chains closer to home. Nearshoring to Mexico has become a major trend. In 2023, Mexico became the largest trading partner of the United States, passing China for the first time in twenty years. The value of U.S. imports from Mexico reached over $475 billion, while imports from China dropped to $427 billion. This shift shows how businesses want to reduce risks and shorten delivery times.

Demand for audits and inspections in Mexico grew by 17% year-over-year.

About 75% of companies in AMPIP’s industrial parks are foreign, showing strong interest in nearshoring.

"Even small missteps can stall inventory in Mexico for weeks due to compliance concerns."

You need to pay close attention to local rules and customs processes. Companies that plan well and follow regulations avoid costly delays.

Global Trade

You face new challenges as global trade changes. Geopolitical tensions and new trade policies affect how goods move around the world. Governments now set more trade restrictions and tariffs. These changes impact sectors like energy, technology, and agriculture. You must watch these trends to keep your supply chain running smoothly.

Geopolitical tensions disrupt trade flows, as seen in recent conflicts in Eastern Europe and the Middle East.

Governments impose trade restrictions and sanctions.

Companies diversify suppliers and adopt nearshoring or reshoring to reduce risks.

You can respond by building relationships with suppliers in different regions. This helps you stay flexible when trade rules change.

Geopolitical Changes

You see how politics shapes your supply chain. New laws and international conflicts can change where you get your products. Many companies now move production closer to their main markets. This strategy helps you avoid sudden disruptions and keeps your business strong.

Companies like Tesla and General Motors have expanded operations in Mexico to adapt to new trade policies. You can learn from these leaders by staying alert and ready to adjust your own supply chain strategies.

Freight Technology

Efficiency

You see freight technology making your logistics operations faster and smarter. Electric vehicles (EVs) help you cut carbon emissions and save money over time. Route optimization tools pick the best paths for your trucks, which lowers travel time and reduces fuel use. Energy-efficient warehousing systems use smart sensors to control lighting and temperature, helping you lower utility bills.

Electric vehicles reduce emissions and offer long-term savings.

Route optimization minimizes travel time and lowers emissions.

Energy-efficient warehousing conserves energy and cuts costs.

You use artificial intelligence to plan routes and forecast demand. AI helps you make quick decisions and avoid delays. The Internet of Things (IoT) lets you monitor shipments and equipment in real time. Automation and robotics speed up warehouse tasks and reduce mistakes. GPS gives you live updates on shipments and helps you plan better routes. Data analytics shows you where to improve your operations.

Technology | Impact on Efficiency |

|---|---|

Artificial Intelligence | Optimizes routes, forecasts demand, and automates decision-making. |

Internet of Things (IoT) | Enables real-time monitoring of shipments and equipment. |

Automation and Robotics | Streamlines warehousing and handling processes. |

GPS | Provides real-time shipment data and improves route planning. |

Data Analytics | Offers insights for strategic planning and operational improvements. |

Tip: You can combine these technologies to boost your speed and lower your costs.

Reliability

You want your shipments to arrive on time and without errors. Freight technology helps you reach this goal. Real-time tracking lets you see where your goods are at every moment. Automated customs documentation reduces mistakes and speeds up border crossings. Predictive analytics helps you plan for problems before they happen.

Description | Impact on Reliability |

|---|---|

Real-time tracking minimizes errors and streamlines operations. | Enhances visibility and reduces lead times. |

Automated customs documentation reduces human errors. | Improves efficiency and reliability. |

Predictive analytics aids in better decision-making. | Enhances operational reliability. |

Freight logistics software boosts supply chain efficiency by 30%. | Reduces human errors and improves communication. |

Web-based freight software integrates with other tools, reducing downtime. | Increases overall efficiency in logistics. |

You use web-based freight software to connect with other tools and keep your system running smoothly. This integration reduces downtime and improves communication. When you rely on these technologies, you build a supply chain that is strong and dependable.

Note: Reliable freight technology helps you meet customer expectations and grow your business.

Global Supply Chain Updates May 2025

Trends Overview

You see big changes in global supply chains this May. Many businesses shift their orders from China to the United States. This move changes how goods travel across oceans and affects when shipments arrive. Ground freight also feels the impact. Full Truckload and Brokerage segments adjust to new patterns, while Less Than Truckload and Home Delivery face pressure because imports drop.

Many companies pause new sailings from Asia. They want to avoid surprises from possible tariff changes. Some pull shipments forward to beat new rules. You notice more interest in bonded and Foreign Trade Zone warehousing. These solutions help you store goods without paying duties right away. Short-term demand stays steady, but ground freight volumes show more uncertainty. Trade policies keep changing, so you must watch for new updates.

Ground freight segments adjust to changing demand.

Companies pause new sailings and pull shipments forward.

Bonded and FTZ warehousing gain popularity.

Uncertainty grows in ground freight volumes.

Tip: Stay alert to logistics industry trends 2025 global supply chain updates May 2025. Quick action helps you avoid delays and extra costs.

Regulatory Changes

You face new rules that shape your supply chain. The United States-Mexico-Canada Agreement (USMCA) makes duty-free trade easier. If your company follows the rules, you save about 10% on tariff costs. This change helps many firms, but some small and medium businesses struggle. About 30% report cash-flow problems because they must adapt to new tariffs.

Nearshoring also brings benefits. A recent study shows that moving production closer to home cuts logistics emissions by 10% for some companies. You help the environment and save money at the same time. These regulatory changes push you to rethink your supply chain strategy.

USMCA supports duty-free trade and lowers tariff costs.

Some businesses face cash-flow issues from new tariffs.

Nearshoring reduces logistics emissions and supports sustainability.

Note: Watch for new regulations. Adapting quickly keeps your supply chain strong and competitive.

Security

Cybersecurity

You face new cybersecurity threats every year in logistics. Hackers target your systems with ransomware, phishing, and DDoS attacks. These attacks can stop your operations and cost you millions. You must protect your data and keep your supply chain safe.

You see the transport sector experience a 48% increase in cybersecurity incidents over the past five years. Ransomware now accounts for 38% of attacks. DDoS attacks make up 24% of incidents. Phishing makes up 18% of threats. Maritime ransomware attacks rose by 467% year-on-year. The shipping sector faced 64 state-sponsored attacks in 2024. The average cost of a breach in this sector is $4.18 million. You notice that 21% of all European DDoS incidents target the transport sector.

Ransomware: 38% of attacks

DDoS: 24% of incidents

Phishing: 18% of threats

48% increase in incidents in five years

Maritime ransomware up 467% year-on-year

64 state-sponsored attacks in shipping (2024)

$4.18 million average breach cost

21% of European DDoS incidents hit transport

You can protect your business by using strong passwords, updating software, and training your team. You should install firewalls and use multi-factor authentication. Regular security audits help you find weak spots before hackers do.

Tip: You can run cybersecurity drills to prepare your team for real attacks. Quick action helps you recover faster and avoid bigger losses.

Fraud Prevention

You must watch for fraud in logistics. Criminals try to steal goods, change shipping documents, or trick your team with fake emails. You can stop fraud by checking all transactions and using secure payment systems. You should track shipments with digital tools and verify every delivery.

Fraud Prevention Method | Benefit |

|---|---|

Secure payment systems | Stops fake transactions |

Digital shipment tracking | Prevents cargo theft |

Employee training | Reduces phishing risks |

Document verification | Blocks fake shipping records |

You can use blockchain to make records unchangeable. You should train your team to spot suspicious emails and requests. You build trust with your customers when you keep their data and shipments safe.

Note: You can lower your risk by updating your fraud prevention plan every year. Strong security keeps your business running smoothly.

You see new technology, sustainability, and resilience shaping logistics in 2025. These changes help you build stronger supply chains and improve customer service. You should invest in automation, digital tools, and green solutions. Stay alert to logistics industry trends 2025 global supply chain updates May 2025. Keep learning and adapt quickly. Your business grows when you prepare for change.

FAQ

What is the biggest logistics trend for 2025?

You will see AI and automation lead the way. These tools help you save time and money.

Tip: Start learning about AI-powered logistics tools now to stay ahead.

How can you improve supply chain visibility?

You can use real-time tracking and data analytics. These tools show you where your shipments are at any moment.

Real-time tracking

Data dashboards

Why does sustainability matter in logistics?

You help the planet by using green logistics. Customers want eco-friendly choices. You also meet new government rules.

Note: Green practices can attract more customers and lower your costs.

How do you protect your logistics business from cyber threats?

You should update your software, use strong passwords, and train your team.

Action | Benefit |

|---|---|

Update software | Blocks hackers |

Train employees | Stops phishing |

See Also

Enhancing Import Warehousing And Delivery On The East Coast

Exploring The Future Of LCL Shipping To Panama

Prepare For Holiday Demand With PGL’s Logistics Solutions