Essential Guide to Optimizing Logistics Warehousing and Distribution for Small Businesses

You can boost your business by making smarter choices in logistics, warehousing, and distribution. When you run things efficiently, you save money and keep customers happy. Many small businesses struggle with limited budgets, changing markets, and handling returns. You might face issues like inventory control or returns management, which can impact customer loyalty. The logistics warehousing and distribution guide helps you spot these challenges and shows that you can find simple, affordable solutions to keep your business moving forward.

Key Takeaways

Assess your current logistics setup to identify challenges. Make a list of issues and prioritize them to improve efficiency.

Understand your customers' needs by gathering feedback. Use this information to shape your logistics strategy and enhance customer satisfaction.

Implement inventory management techniques to balance stock levels. Use forecasting and set minimum stock levels to avoid shortages or excess.

Utilize technology like warehouse management systems and automation tools. These can streamline operations, reduce errors, and save costs.

Track key performance indicators (KPIs) regularly. Monitor metrics like order accuracy and on-time delivery to identify areas for improvement.

Logistics Warehousing and Distribution Guide for Small Businesses

Assessing Current Operations

You want your logistics, warehousing, and distribution to run smoothly. The first step is to take a close look at your current setup. Start by asking yourself what challenges you face. Maybe you struggle with late deliveries or missing inventory. Make a list and rank these problems by how much they affect your business.

Here’s a simple way to assess your operations:

Figure out your biggest needs. Write down what slows you down or costs you money.

Decide what success looks like for you. Set clear goals and track them with key performance indicators (KPIs).

Check out the technology and software options that fit your business size. You don’t need fancy tools—just ones that work for you.

Make sure your team knows how to use these tools. Good processes and people make technology work better.

Pick the areas where you’ll use digital tools. Maybe you want to track inventory or speed up order packing.

Tip: Use a checklist or audit to spot inefficiencies. This helps you see where you can improve.

Here’s a table with some tools and checklists you can use to audit your logistics and warehousing processes:

Tool/Checklist | Description |

|---|---|

Warehouse Management Systems | Streamlines warehouse operations, making audits faster and more accurate. |

Barcode Scanning Technology | Speeds up inventory checks and reduces mistakes. |

Internet of Things (IoT) | Monitors equipment in real time and predicts when maintenance is needed. |

Data Analytics | Turns raw data into useful insights for better decisions. |

Mobile Applications | Lets you do audits on the go with real-time data. |

Artificial Intelligence (AI) | Looks at past data to predict problems and improve audits. |

Cloud-Based Solutions | Makes data easy to access and share with your team. |

When you use these tools, you make your logistics warehousing and distribution guide more effective. You spot problems faster and fix them before they grow.

Identifying Bottlenecks

Bottlenecks slow down your business and frustrate your customers. You need to find them and fix them quickly. Common bottlenecks include unexpected disruptions, inventory management challenges, and poor communication. Sometimes you run out of space or your team can’t keep up with demand.

Here are some signs you might have a bottleneck:

Costs keep rising.

Delivery times get longer.

Inventory goes missing or gets stuck.

Customers complain more often.

Your supply chain breaks down.

Your team feels overwhelmed.

To spot and address bottlenecks, try these steps:

Map out your workflows. Draw a flowchart or use a Kanban board to see each step.

Track performance data. Watch cycle times and throughput to find slow spots.

Talk to your team. Ask them what slows them down or causes mistakes.

Diagnose your workflow. Use diagrams and regular audits to find the root causes.

Monitor in real time. Use dashboards to catch problems as they happen.

Run ‘what-if’ tests. Try different scenarios to see how changes affect your process.

If you follow these steps, your logistics warehousing and distribution guide will help you keep things moving and avoid costly delays.

Understanding Customer Needs

Your customers expect fast, accurate deliveries. If you don’t meet their needs, they might shop somewhere else. You need to know what matters most to them.

60% of small businesses say better operational data is their biggest need.

You can gather customer feedback by talking to them, sending surveys, or checking reviews. Many small shippers like having a real person to help with problems or answer questions. Building strong relationships helps you solve issues quickly and keeps customers coming back.

Here are some ways to understand and meet customer needs:

Set clear goals for your logistics. Maybe you want to improve inventory accuracy or lower costs.

Look at your current processes. Find out where you can do better.

List what you need from logistics software. Think about features and your budget.

More than half of small businesses use software like Warehouse Management Systems, Transportation Management Systems, or fleet management tools. These help you track orders and deliveries, making your logistics warehousing and distribution guide more reliable.

Customers care about speed and reliability. About 65% of shoppers will pay more for faster deliveries. At the same time, 85% of online shoppers in the US have felt let down by delivery services. If you improve your logistics, you can stand out and build a better reputation.

Note: When you understand your customers, you can shape your logistics warehousing and distribution guide to meet their expectations and grow your business.

Inventory and Warehouse Optimization

Streamlining Inventory Management

You want to keep your shelves stocked but not overflowing. The right inventory management techniques help you avoid running out of products or having too much sitting around. Here are some smart ways to keep things balanced:

Forecast future inventory by looking at past sales and market trends. This helps you plan for busy times and slow periods.

Set minimum stock levels. When your inventory drops to a certain point, you know it’s time to reorder.

You can also use tools to make this easier. Check out the table below for some popular options:

Technique | Function | Benefits |

|---|---|---|

Inventory management software | Tracks inventory, orders, sales, and deliveries. | Gives you real-time data and better reporting. |

Automated reordering systems | Places orders automatically when stock runs low. | Stops you from running out and saves time. |

Forecasting future inventory | Predicts demand using past data and trends. | Keeps you ready for busy seasons. |

Set minimum stock levels | Sets a baseline for inventory. | Helps you avoid stockouts and lost sales. |

When you use these methods, you make your logistics warehousing and distribution guide more reliable and efficient.

Reducing Holding Costs

Holding costs can eat into your profits if you’re not careful. You can save money by making a few smart changes in your warehouse. Take a look at these strategies:

Strategy | Description |

|---|---|

High-Demand Product Placement | Store popular items close to packing stations for faster picking. |

Vertical Storage | Use tall shelves to fit more products in less space. |

Review and Adjust Layout | Change your layout as your needs change. |

Leverage Automation and Technology | Use machines and software to cut down on mistakes and labor costs. |

Train and Empower Your Workforce | Teach your team to work smarter and faster. |

Implement Energy-Efficient Practices | Switch to LED lights and smart systems to lower energy bills. |

Focus on Accurate Demand Forecasting | Use sales data to avoid buying too much stock. |

Streamline Order Processing | Pick and pack orders in batches to save time. |

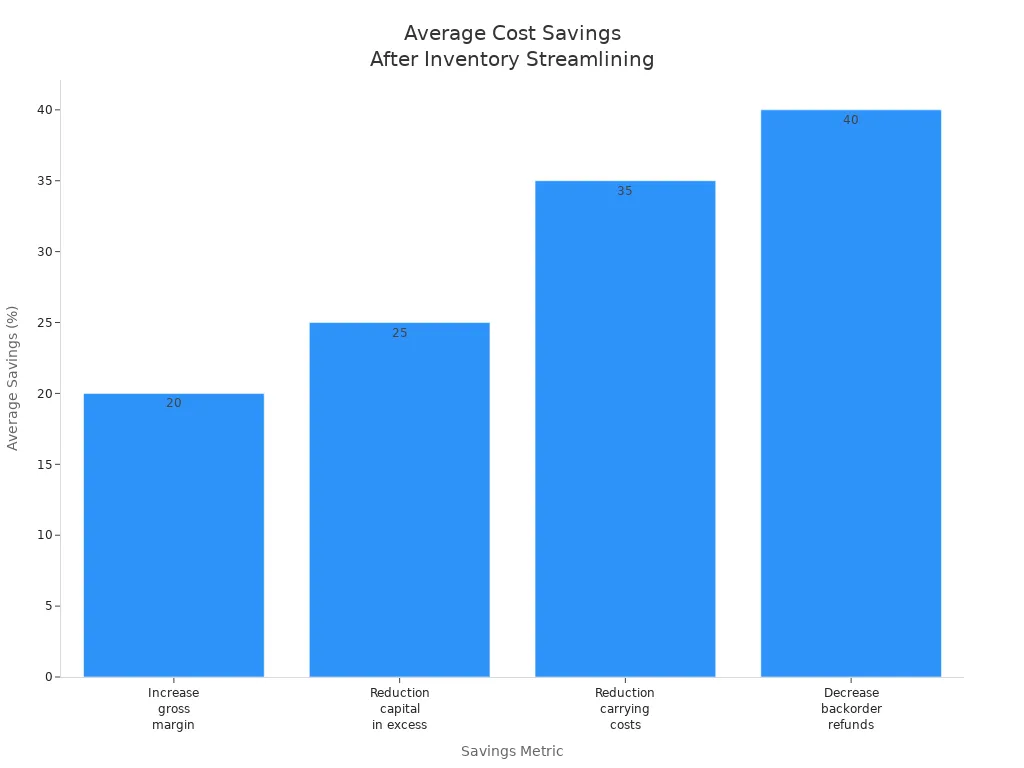

Many small businesses see big savings after making these changes. For example, some report a 30% drop in holding costs within six months. Others cut costs by up to 50% with new inventory management systems.

Agile Warehouse Solutions

You need a warehouse that can change as your business grows. Agile warehouse solutions let you scale up or down based on demand. You only pay for the space you need, which helps you avoid expensive long-term leases. These solutions also give you access to professional logistics services without breaking the bank.

Here’s how agile warehouses help you move faster:

You can handle more orders during busy times and scale back when things slow down.

Automated picking and real-time data analytics speed up order fulfillment.

Fewer mistakes mean happier customers and quicker deliveries.

If you want your logistics warehousing and distribution guide to keep up with your business, agile solutions are a smart choice.

Order Fulfillment and Delivery Strategies

Improving Order Accuracy

You want every order to be right the first time. Good inventory management helps you keep track of what you have, so you don’t send the wrong item or run out of stock. Start by reviewing your current inventory process and look for places where mistakes happen. Organize your products so you can find them quickly, especially if you sell items with lots of variations.

Here are some ways to boost order accuracy:

Identify the problems in your fulfillment process.

Use clear labels on every product.

Pack items carefully to avoid damage.

Automate repetitive tasks to cut down on errors.

Get inventory management software that tracks stock in real time.

Using handheld barcode scanners at both picking and packing stages makes sure you grab the right products every time.

If you use these strategies, you can reach order accuracy rates of 96-98%. Top-performing warehouses even hit 99.9%. Take a look at this table:

Order Accuracy Rate | Top-Performing Businesses | Best-in-Class Warehouse Operations |

|---|---|---|

Average Rate | 96-98% | 99.5-99.9% |

Route and Delivery Optimization

You want your deliveries to be fast and cost-effective. Route optimization algorithms help you plan the best way to get packages to your customers. Easy dispatcher controls and driver mobile apps make it simple to adjust routes on the fly. Real-time notifications keep your customers in the loop.

Here’s what you can use:

Route optimization algorithms

Driver mobile apps

Vehicle capacity management

API integrations

Small businesses save time and money with these tools. You can save up to 2 hours a week and nearly $10,000 a year just by planning smarter routes.

Delivery Management Planning

Smart delivery planning keeps your customers happy and your costs low. Pick vehicles that fit your delivery volume. Train your drivers to improve habits and reduce mistakes. Oversee the whole process so you can fix problems quickly. Use technology to keep everyone connected and informed.

Use the right vehicles for your needs.

Train your drivers for better performance.

Oversee delivery operations closely.

Equip drivers with communication tools.

Keep customers updated with automated notifications.

Optimize routes with planning software.

Your logistics warehousing and distribution guide works best when you combine accurate order fulfillment, smart route planning, and strong delivery management.

Technology and Tools for Small Business Logistics

Inventory Management Systems

You want to keep track of your products without spending a fortune. Affordable inventory management systems help you stay organized and avoid costly mistakes. Here are some popular options you can try:

BlueTally: Free forever plan, great for startups.

inFlow Inventory: Starts at $89/month, offers a 14-day free trial.

Cin7: Begins at $295/month, also with a 14-day free trial.

Sortly: Free plan available, paid plans from $29/month.

Ordoro: Good for multichannel sellers.

Veeqo: Free for unlimited orders and users.

These systems make your life easier by reducing errors, cutting costs, and keeping customers happy. Take a look at how they help:

Benefit | Description |

|---|---|

Centralized systems help you avoid double entries and mistakes. | |

Cost Reduction | You spend less on extra stock and avoid running out. |

Enhanced Customer Satisfaction | Products stay available, so orders ship on time. |

Real-time Data Access | You see inventory updates instantly and can react to changes fast. |

Tip: Pick a system that fits your budget and business size. You don’t need every feature—just the ones that help you work smarter.

Warehouse Management Software

You need warehouse management software that works with your other tools. Look for these features:

Seamless integration with accounting, supply chain, eCommerce, and ERP systems

Real-time tracking and barcode scanning

Automated reordering

Multi-location management

Mobile accessibility

Organization tools and reporting

User-friendly interfaces

Real-time tracking and barcode scanning help you see where your products are at all times. Your team can update stock levels quickly, which means fewer mistakes and less time spent counting by hand.

When you invest in warehouse management software, you can see big returns. For example:

Year | Result | |

|---|---|---|

1 | (12,000 - 12,000) / 12,000 | 0% (Breakeven) |

2 | (12,000 - 0) / 12,000 | 100% |

Automation and Mobile Solutions

Automation and mobile tools help you work faster and smarter. You can use:

Warehouse Management Systems (WMS): Track inventory and speed up order fulfillment.

Transport Management Systems (TMS): Cut delivery costs and keep shipments on time.

Automated Guided Vehicles (AGVs): Move products around your warehouse without extra labor.

Automated Storage and Retrieval Systems (AS/RS): Store and find items quickly.

When you use automation, you boost productivity, make fewer mistakes, and use your space better. Your team spends less time on boring tasks and more time on important work. Workers feel less stressed and more professional, which means they stay longer and work better.

Note: The right technology helps you grow your business and keep your customers coming back.

Warehouse Location and Distribution Network

In-House vs. Outsourced Warehousing

Choosing between in-house and outsourced warehousing can shape how your business grows. You might want full control, or you may prefer to save money and scale quickly. Here’s a quick look at the differences:

Aspect | In-House Warehousing | Outsourced Warehousing |

|---|---|---|

Cost | Significant capital investment required for building and running a warehouse. | Generally more cost-effective with lower initial investment. |

Control | Complete control over operations, staffing, and processes. | Less control over logistics and operations. |

Scalability | Limited scalability; difficult to adjust to rapid growth without incurring costs. | High scalability; can adjust operations quickly. |

Operational Flexibility | Easier to adapt operations to changing needs without red tape. | May involve back-and-forth communication with partners. |

Risk of Underutilization | Pressure to maximize space and efficiency, risking wasted resources. | Less pressure to utilize space effectively. |

You get more control and flexibility with in-house warehousing. You can design your space and change things fast. But you also face higher costs and risk having empty shelves. Outsourcing lets you scale up or down and keeps costs lower, but you give up some control.

Strategic Location Selection

Picking the right warehouse location helps you save money and deliver faster. You want to think about more than just rent. Here are some key things to consider:

Proximity to suppliers and customers for lower transport costs and quicker deliveries.

Workforce availability and labor costs to make sure you can hire the right people.

Access to transportation networks like highways, ports, or railways.

Real estate costs, which can vary a lot by city or region.

Building availability and room to expand as your business grows.

Safety and security to protect your goods.

Technology and operations—modern tools make your warehouse run smoother.

Market reach—a central spot helps you serve more customers.

Tip: A well-placed warehouse can help you reach more customers and keep your delivery promises.

Building a Flexible Network

You want your distribution network to handle changes fast. Technology helps you scale up or down and manage deliveries in real time. You can use your own drivers, hire contractors, or work with partners. This keeps your business nimble.

“Technology is a key enabler for scaling distribution efficiently. Flexible logistics capabilities enable companies to build and manage their own delivery fleets using in-house drivers, crowdsourced, independent contractors, 3PLs, or a combination of resources enabling flexible real-time resource and vehicle allocation.”

Here’s how you can build a flexible network:

Embrace technology to streamline your operations and reach more customers.

Make quick decisions when things change.

Offer different products or services so you’re not stuck if one slows down.

Build strong relationships with your suppliers and partners.

Keep learning and adapting as your business grows.

A flexible network helps you stay ready for anything the market throws your way.

Staff Training and Process Standardization

Training for Logistics Efficiency

You want your team to work smarter, not harder. Good training helps everyone understand their roles and do their jobs well. Start with the basics. Show your staff how to use your inventory system, scanners, and packing tools. Use short, hands-on sessions. People learn best when they can try things out.

Here are some ways to boost logistics skills:

Hold regular training sessions for new tools or updates.

Use videos and step-by-step guides for quick learning.

Pair new hires with experienced staff for on-the-job coaching.

Ask for feedback after each session to see what works.

Tip: Celebrate small wins. When someone learns a new skill, give a shout-out. This keeps your team motivated.

Uniform Procedures

You need everyone on the same page. Uniform procedures make your warehouse run smoothly. Write down each step for tasks like receiving goods, picking orders, and packing boxes. Use checklists so nothing gets missed.

Here’s a simple checklist for order picking:

Step | Task |

|---|---|

1 | Scan the order barcode |

2 | Find the correct product |

3 | Check product quality |

4 | Place item in order bin |

5 | Mark as picked in system |

When you use clear steps, you cut down on mistakes. You also make it easier to train new team members.

Improving Labor Productivity

You want your team to get more done in less time. Start by setting clear goals. Track how many orders each person packs or ships. Use friendly competitions to boost energy. Give your team the right tools, like barcode scanners or mobile apps.

Try these ideas to lift productivity:

Rotate tasks to keep work interesting.

Give short breaks to avoid burnout.

Ask your team for ideas on working faster.

Note: Happy, well-trained staff work harder and stay longer. Your business grows when your people grow.

Measuring Success and Continuous Improvement

Key Performance Indicators (KPIs)

You want to know if your logistics and warehouse work is paying off. Key Performance Indicators, or KPIs, help you see what’s working and what needs fixing. These numbers show how well you deliver orders, manage costs, and keep customers happy. Here’s a table with some of the most important KPIs for small businesses:

KPI | Description |

|---|---|

On-Time Final Delivery | Tracks if you deliver orders when promised. If you fall below 98%, it’s time to make changes. |

Cost Per Pound | Shows how much you spend to move each pound of goods. Helps you spot ways to save money. |

Inventory Accuracy | Checks if your records match what’s really in your warehouse. |

Yard/Dock to Stock | Measures how fast you move goods from the dock to storage. |

On-Time Shipping | Tells you if orders leave your warehouse on schedule. |

Order Accuracy | Counts how often you get orders right. |

Fill Rate | Shows if you can fill orders from your warehouse without delays or backorders. |

Tip: Track these KPIs every week or month. You’ll spot problems before they grow.

Tracking Delivery and Order Metrics

You need to keep an eye on your delivery and order numbers. Watch for late shipments, missing items, or rising costs. Use simple dashboards or reports to see trends. If you notice more mistakes or delays, you can act fast. Set up alerts for key metrics, so you never miss a problem.

Check on-time delivery rates.

Review order accuracy.

Watch cost per shipment.

Look for patterns in customer complaints.

When you track these numbers, you make smarter decisions and keep your customers happy.

Ongoing Process Improvement

You can always make your logistics better. Try using methods like Kaizen, which means making small changes every day. The 5S system helps you organize your space and work faster. Here are some ways to keep improving:

Kaizen: Make small, steady changes to improve your process.

5S: Sort, set in order, shine, standardize, and sustain your workspace.

You can also use these tools:

Method | Description |

|---|---|

Real-Time Warehouse Visibility | See where your products are at all times. |

Staff Training | Teach your team new skills to boost efficiency. |

Integration of WMS Systems | Use warehouse management software for better control and tracking. |

Note: Even small improvements add up. Keep looking for ways to work smarter, not harder.

You can make your logistics, warehousing, and distribution work better by following a few simple steps:

Check your current process and spot weak areas.

Use smart tools and technology.

Train your team and set clear routines.

Remember, every small change helps you save money and keep customers happy. Start today and keep improving. Your business will thank you!

FAQ

How can I lower my warehouse costs as a small business?

You can cut costs by using vertical storage, automating simple tasks, and reviewing your layout often. Place popular items near packing stations. Train your team to work smarter. Small changes add up fast!

What’s the best way to track inventory without spending a lot?

Try free or low-cost inventory management software like Sortly or BlueTally. These tools help you see what you have in real time. You avoid overstocking and missing items. Even a simple spreadsheet works if you keep it updated.

How do I choose between in-house and outsourced warehousing?

Ask yourself if you want more control or more flexibility. In-house gives you control but costs more. Outsourcing saves money and lets you scale up or down. Think about your budget and how fast you want to grow.

What technology should I start with for better logistics?

Start with inventory management software and barcode scanners. These tools help you track products and reduce mistakes. As you grow, add warehouse management software or delivery route planners. Pick tools that fit your needs and budget.

How can I make my deliveries faster and more reliable?

Plan your routes with delivery apps. Train your drivers well. Keep customers updated with real-time notifications. Use the right vehicles for your order size. Fast, reliable deliveries keep your customers happy and coming back.

See Also

Choosing The Right Warehousing Solution For Your Business Needs

Maximize Efficiency In Inventory With Global Logistics Solutions

Key Strategies For Effective Management Of Global Logistics

Optimizing Inventory Flow Through Premier Global Logistics Services