Efficient Inventory and Distribution with Premier Global Logistics Warehousing

Los Angeles is the top logistics hub in the United States, featuring great ports, airports, and an extensive freight network. Premier Global Logistics operates secure warehouse California facilities in both Los Angeles and San Francisco. These modern and safe warehouses support the growing demand for advanced warehousing and fulfillment driven by expanding e-commerce and manufacturing sectors. Cloud-based systems provide real-time inventory control and robust data security, ensuring smooth and reliable operations for clients across various industries.

Key Takeaways

Premier Global Logistics has safe, high-tech warehouses in Los Angeles and San Francisco. These warehouses keep goods safe and make sure inventory is correct.

Flexible storage choices help businesses change space and costs fast. This helps them meet new market needs.

Advanced warehouse management systems track items in real time. Automation helps fill orders faster and makes fewer mistakes.

Special buildings and trained workers handle temperature-sensitive and hazardous products safely. They follow strict rules to do this.

The warehouses are close to ports, airports, and highways. This helps deliver goods quickly and reliably to customers in California.

California Challenges

Market Demands

Warehousing and distribution companies in California have special problems. Los Angeles is where many of these problems happen. The city is a big place for moving goods. Companies must change fast when the market changes.

There are not enough workers in los angeles, so warehouse jobs are hard to fill.

Union talks in los angeles make daily work more difficult.

Companies in los angeles try to keep the right amount of inventory after COVID-19. They also need to keep extra stock to avoid running out.

It is hard to find space in los angeles, and it costs more to rent and hire workers.

New rules like the WAIRE Program make some businesses think about moving. But being close to los angeles is still important for quick delivery.

Ports in los angeles sometimes have too much or too little work. Worker problems at the ports can slow down shipping.

Many companies work with third-party logistics providers in los angeles. This helps them save money and work better.

Food and consumer packaged goods companies in los angeles want ways to control inventory and costs. They also want to keep good service.

More people shop online in los angeles, so warehouses use more robots and machines. This helps them work faster.

Warehouses in los angeles now do many types of orders and focus on fast delivery to customers.

Note: More businesses in los angeles pick smaller, high-tech warehouses near customers. They want to deliver faster and be more flexible.

Compliance Needs

Warehouses in los angeles must follow many strict rules.

In los angeles, paperwork must show who owns goods, how they are delivered, and have real signatures.

Storage fees in los angeles must list basic prices, extra charges, and how to pay.

Disagreements in los angeles must say which laws to use and how to give notice.

The WAIRE Program in los angeles wants big warehouses to lower pollution. They must count truck visits and buy clean technology.

The California Air Resources Board makes rules in los angeles to cut down on truck pollution. This changes how warehouses work.

Storing chemicals in los angeles needs yearly permits, safety plans, and following anti-terrorism rules.

Proposition 65 in los angeles says products with chemicals must have warning labels.

The California Fire Code in los angeles has tough fire safety rules for tall storage and safe exits.

The Supply Chain Transparency Act in los angeles says big companies must show what they do to stop human trafficking and slavery.

Providers in los angeles need licenses, must keep good records, and train workers to follow all rules.

Tip: Doing regular checks and using digital inventory systems help los angeles warehouses follow rules and keep clients’ trust.

Secure Warehouse California

Security Systems

A secure warehouse california in los angeles needs strong security to keep goods safe. Premier Global Logistics uses high security in both los angeles and san francisco. These warehouses use technology, trained workers, and strict rules to protect inventory.

Security guards watch the los angeles warehouses all day and night. They check doors and act fast if something happens.

CCTV cameras work all the time inside and outside the secure warehouse california. The cameras use AI to find problems and stop false alarms.

Access control systems use ID badges, keypads, or fingerprint scans. Only allowed workers can go into special areas in los angeles warehouses.

Alarm systems have motion sensors and glass break detectors. These alarms warn staff and police if someone breaks in.

Emergency plans include safety drills and evacuation practice. Workers in los angeles learn what to do in any emergency.

Security checks and risk reviews happen often. These checks find weak spots and keep the secure warehouse california safe.

Bright lights, strong fences, and clear signs help stop intruders and make things easy to see.

Visitor systems track everyone who comes in or leaves the secure warehouse california. Visitors must sign in and show their ID.

Cybersecurity keeps digital inventory records and warehouse systems safe from online attacks.

Note: PGL’s secure warehouse california in los angeles follows OSHA rules and best practices. All security guards have licenses, training, and insurance. Workers get background checks and training to keep the place safe.

Inventory Protection

Protecting inventory in a secure warehouse california means more than stopping theft. PGL uses strict quality and safety steps in los angeles and san francisco to stop damage, loss, or contamination.

Fire safety includes regular checks, clear exits, and fire extinguishers. Workers in los angeles learn how to handle fires.

Strong shelves and safe stacking stop shelves from falling and products from breaking. Workers in los angeles do not overload shelves and use nets when needed.

Pest control keeps storage clean and free from bugs. Regular checks and cleaning rules are used in every secure warehouse california.

Clean walkways and non-slip mats stop slips and trips. Warning signs and good shoes help workers in los angeles stay safe.

Good air flow and dust control protect workers and stored goods in the secure warehouse california.

Clear signs and labels help workers in los angeles organize products and avoid mistakes. Items picked often are stored together to lower risks.

Ergonomic hoists and conveyor belts help workers avoid injuries and keep heavy or breakable goods safe.

Regular cleanouts remove dangerous materials and keep the secure warehouse california neat and safe.

PGL also lowers risk with strong insurance. The table below shows common insurance types for secure warehouse california:

Insurance Type | Coverage Description | Key Benefits |

|---|---|---|

Warehouse Legal Liability | Covers losses or damage to goods stored or handled due to warehouse negligence. | Protects against claims when goods are damaged due to warehouse operations. |

Business Interruption Insurance | Covers lost income from operational disruptions like fires or natural disasters. | Provides financial support during downtime. |

General Liability Insurance | Covers claims for bodily injury or property damage on premises. | Protects against legal costs and settlements from third-party claims. |

Employee Dishonesty Insurance | Covers losses from theft or fraud by employees. | Helps recover stolen funds or goods. |

Commercial Property Insurance | Covers damage to warehouse structure, equipment, and contents. | Protects assets and enables quick repair or replacement. |

Cyber Liability Insurance | Covers financial losses from cyber incidents affecting warehouse IT systems. | Manages financial impact of cyberattacks and protects customer trust. |

Tip: PGL’s secure warehouse california contracts explain insurance and risk sharing clearly. Clients know how their goods are protected in los angeles and san francisco.

A secure warehouse california in los angeles needs strong security, new technology, and strict safety rules. PGL’s way helps clients feel safe and keeps inventory protected at every step.

PGL Advanced Features

Warehouse Management System

Premier Global Logistics uses a modern Warehouse Management System in los angeles. This system lets workers see where every item is at any time. Staff use barcode scanners and computers to track items. This helps stop mistakes. The system helps with receiving, picking, packing, and shipping. Orders get done faster and with fewer errors.

Real-time tracking helps keep the right amount of stock.

Automation makes orders go out faster.

Robotics like AS/RS and AGVs help with accuracy.

Labor tools give jobs to the right workers.

The system connects with other business software.

Cloud systems let people work from anywhere.

IoT checks warehouse conditions all the time.

The system is easy for new workers to learn. Reports help managers see what needs to get better. These features help workers do more, make fewer mistakes, and fill orders faster for clients.

Flexible Storage

PGL gives flexible storage in los angeles for changing business needs. Companies can use more or less space as needed. This is good for busy or slow times.

Businesses pay only for the space they use.

Real-time tracking helps avoid too much or too little stock.

No long leases means lower costs.

Warehouses close to markets make shipping faster.

Shared spaces let companies focus on their main work.

PGL has both short-term and long-term storage. The table below shows how each type helps businesses in los angeles:

Warehousing Type | Use Cases | Benefits and Features |

|---|---|---|

Seasonal inventory surges, temporary overstock, just-in-time inventory, project-based storage | Flexibility, cost-efficiency, fast turnover, operational agility | |

Long-Term Warehousing | Bulk storage, steady inventory, durable goods, climate-controlled storage | Cost savings, stable costs, secure environments, supports large supply chains |

Hybrid Warehousing | Combines short- and long-term storage, cross-docking, freight consolidation | Scalability, cost optimization, enhanced segmentation, faster deliveries |

Flexible storage helps companies react fast to market changes. They can manage inventory better and keep customers happy with these solutions.

Special Goods Support

PGL’s los angeles warehouses can store special goods. This includes temperature-controlled and hazardous materials. Hazardous items are kept in separate areas to stay safe. Good air flow and fire sprinklers protect the warehouse. Staff use trays and extra containers to stop leaks.

Facilities follow rules for storing hazardous goods.

Safety Data Sheets are kept for all dangerous items.

Temperature controls protect sensitive products.

Staff get special training for handling and emergencies.

Drills and checks keep everyone safe.

Special rooms meet fire safety rules. Strong racks and special lifts help move goods safely. HAZMAT experts train staff and check that rules are followed.

Warehouses need special papers to store hazardous materials. Fire, air, and health departments check the warehouse often. Ventilation, fire doors, and sprinklers keep things safe. Staff keep chemicals apart and track them closely. OSHA rules and good records keep workers safe and informed.

Note: PGL’s los angeles warehouses give safe and legal storage for special goods. This helps companies meet rules and keep their products safe at every step.

Distribution Centers in Los Angeles and San Francisco

Strategic Locations

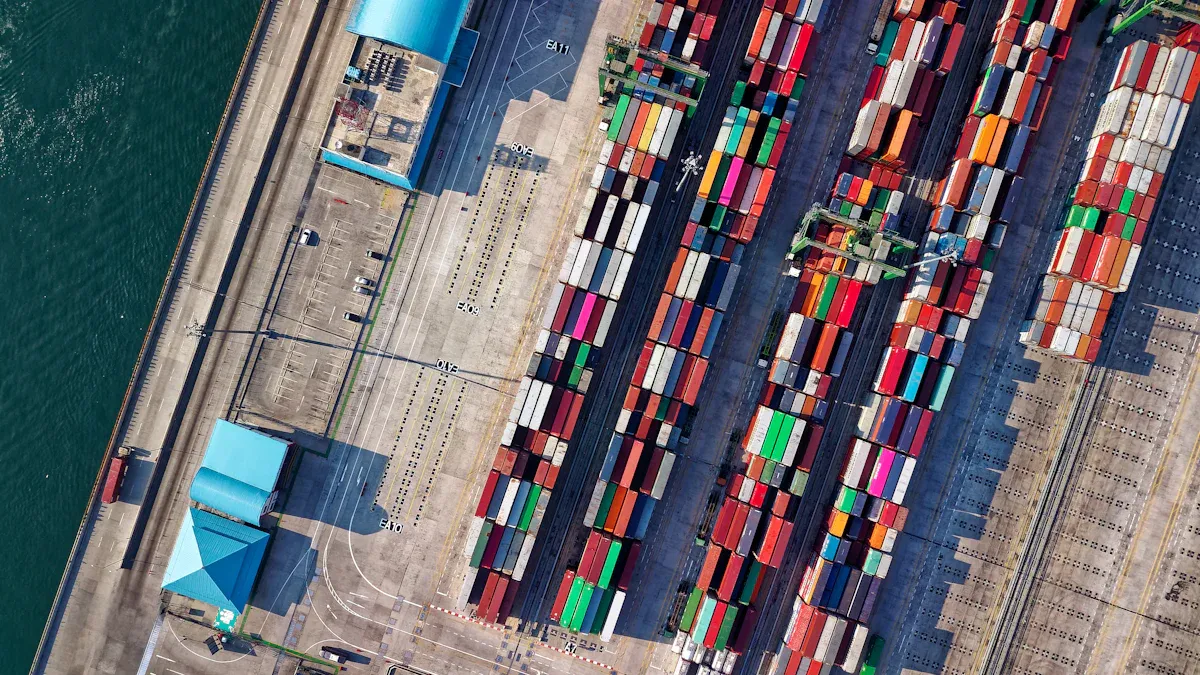

Distribution centers in los angeles and san francisco help deliver goods fast. These cities are close to big groups of people who buy things. Los angeles has many people and connects to highways, ports, and airports. San francisco also links to important markets and roads. Companies pick these places to keep inventory near customers. This helps lower shipping time and costs. Many centers in los angeles are very close to the Ports of Los Angeles and Long Beach. These ports move half of all container cargo on the West Coast. Being near these ports lets goods unload and move quickly.

A table below shows how location helps delivery:

Location Advantage | Benefit for Businesses |

|---|---|

Near ports | Faster import/export processing |

Close to airports | Rapid air freight for urgent shipments |

Access to highways | Quick ground transport to regional markets |

Urban proximity | Supports same-day and next-day delivery |

Distribution centers in los angeles and san francisco help e-commerce and retail companies ship orders fast. This makes customers happy and helps businesses grow.

Transport Integration

Distribution centers in los angeles connect to many ways to move goods. These places link to big ports like the Ports of Los Angeles and Long Beach. Los angeles international airport is one of the top air cargo hubs in the world. Centers use these places to send goods by air or sea quickly. The area has three main highways: I-5, I-10, and I-15. These highways let trucks move lots of goods and connect los angeles to other states.

Distribution centers in los angeles use trains and intermodal terminals to move freight well.

Local roads help with fast last-mile delivery.

Many centers in los angeles work with local carriers for better shipping prices and faster service.

Distribution centers in los angeles and san francisco help supply chains by cutting delays and making things work better. Businesses get smooth truck and air freight service. This network makes sure goods reach customers on time, every time.

Industry Solutions

E-commerce

E-commerce companies in los angeles have special problems. They need fast shipping, correct inventory, and easy returns. Premier Global Logistics helps online stores with storage that can grow or shrink. Their warehouses use machines and real-time tracking to keep inventory right. Workers fill orders fast, even when sales are high.

Flexible storage lets companies use more or less space.

Connecting to e-commerce platforms like Shopify and WooCommerce makes orders easier.

Automated systems help stop mistakes and make shipping faster.

Easy return rules and quick returns help customers trust the company.

PGL’s los angeles warehouses solve local problems like busy roads and tough rules. Their locations near ports and airports help with fast shipping. Secure warehouses keep goods safe from theft or damage. Companies can give same-day or next-day shipping to los angeles and other places.

Manufacturing

Manufacturers in los angeles need good warehouses for raw materials and finished products. PGL’s los angeles warehouses give more space and real-time inventory tracking. The Warehouse Management System follows every item and stops running out or having too much.

Fast order filling gets products to customers quickly.

Good los angeles locations save money on transport.

Flexible plans let manufacturers grow or shrink as needed.

PGL’s los angeles team uses machines and technology to make things more accurate. Safe warehouses and quality checks protect important inventory. Manufacturers get faster shipping and better service.

Case Example

A top electronics company in los angeles worked with PGL when online orders jumped. PGL grew fast, using machines and more workers for the holidays. The los angeles warehouse handled ten times more orders with no delays.

The client had 30% fewer shipping mistakes and happier customers. PGL’s los angeles team managed orders for both stores and direct buyers.

This story shows how PGL’s los angeles solutions help companies grow and change with the market.

Onboarding with PGL

Implementation Steps

Businesses in los angeles can join Premier Global Logistics with a simple process. The onboarding team meets each client to learn about their needs. They talk about the goods, storage, and delivery goals. After this, PGL makes a special plan for the los angeles warehouse. The team sets up the Warehouse Management System for the client’s products. Staff put labels on items and scan them when they arrive in los angeles. This helps track everything from the start.

PGL experts teach the client’s team how to use the system. They show how to check inventory, place orders, and track shipments in los angeles. The onboarding team helps connect the client’s software to the warehouse system. This lets clients get updates right away and makes orders easy to handle. Clients get a checklist to follow each step. The last step is a review to make sure everything works well in los angeles.

Tip: Planning early and talking often help los angeles businesses get the best results from PGL’s onboarding.

Ongoing Support

After onboarding, PGL keeps helping clients in los angeles with great service. Each client gets an account manager who answers questions fast. The los angeles support team checks inventory and orders every day. They use smart tools to find problems before they get big.

PGL gives regular training for new features and updates in los angeles. Clients can ask for reports or set up meetings to talk about how things are going. The support team helps with busy times, like holidays in los angeles. If clients need more space or special storage, PGL changes the plan quickly.

Note: Good support in los angeles helps businesses stay ready and grow with confidence.

Premier Global Logistics gives safe and smart warehousing in California. Their Los Angeles warehouse uses new technology and strong security. They also offer flexible choices for different needs. Companies can see their inventory right away and get fast shipping from good locations.

Modern warehouse management system

Safe buildings with quality checks

Flexible storage for any business

Want to make your supply chain better? Contact PGL now for a special meeting and see how their Los Angeles warehouse can help your business.

FAQ

What services do Los Angeles warehouse facilities offer?

PGL’s Los Angeles warehouse helps with many things. They use machines to track inventory and fill orders. They keep goods safe and pack them for shipping. They send out products to customers. These warehouses help online stores, factories, and shops. Businesses can pick how much space they need. They can also see their inventory at any time.

How does PGL ensure inventory security and accuracy?

PGL keeps inventory safe with strong security. Cameras watch the warehouse all day and night. Only certain people can go inside. The warehouse management system tracks every item right away. Staff check goods often and look for mistakes. This keeps inventory numbers correct.

Can PGL handle temperature-sensitive or hazardous goods?

Yes. PGL’s warehouses in Los Angeles and San Francisco can store special goods. They have cool rooms for items that need it. They also have safe places for hazardous materials. Workers get special training and follow safety rules. This keeps products safe and follows the law.

How quickly can businesses start using PGL warehouse services?

It only takes a few days to start. PGL makes a plan for each business. They set up the warehouse system and teach workers what to do. Companies can store and ship goods soon after everything is ready.

What makes PGL’s Los Angeles warehouse services stand out?

PGL’s warehouses are close to ports and airports. They use new technology and offer flexible choices. Clients get fast shipping and safe storage. Each business gets help that fits their needs. This helps companies grow and do well.

See Also

Efficient East Coast Import Warehousing And Delivery By Premier

Understanding B2B Warehousing And Distribution On East Coast

Boosting West Coast Operations With Premier LA Warehousing

Fast Order Fulfillment Through NJ And FL Warehousing Services

West Coast Multi-Channel Fulfillment Solutions By Premier Logistics