Warehouse Management Technologies Shaping the Future of Logistics

You see warehouse management technologies like AI-powered systems, autonomous mobile robots, and IoT tracking tools shape logistics in 2025. These tools boost efficiency, help you optimize resources, and support green initiatives. Facilities report higher accuracy and faster operations with robotics. Companies using predictive analytics improve forecasting and reduce downtime. The table below shows how new technologies drive results in key areas.

Aspect | Result |

|---|---|

Efficiency | Robotic solutions raise accuracy and speed in 78% of facilities. |

Workforce Productivity | Engagement strategies increase productivity by over 15%. |

Sustainability | Nearly half of companies use green initiatives for better energy efficiency. |

Key Takeaways

Warehouse management technologies like AI and robotics boost efficiency and accuracy, leading to faster operations and happier customers.

Predictive analytics help you forecast demand and manage inventory effectively, reducing costs and minimizing stockouts.

Collaborative robots (cobots) enhance safety and productivity by taking on heavy tasks, allowing workers to focus on more complex duties.

Cloud-based systems provide real-time data access, improving inventory management and reducing operational costs.

Sustainability initiatives, such as energy-efficient automation and green packaging, help lower your carbon footprint while saving money.

AI and Analytics in Warehousing

Artificial intelligence and analytics change how you manage warehouses. You see faster order fulfillment, smarter inventory control, and better decision-making. These tools help you respond quickly to market changes and customer needs.

AI Inventory Optimization

AI helps you place products in the best spots and choose the fastest picking routes. You use automated systems to restock items, which reduces mistakes and saves money. AI learns your customers’ buying habits and suggests where to put items for easy access.

AI-driven forecasting improves how you predict demand, so you keep the right amount of stock.

Automated replenishment makes sure you never run out of popular items.

Optimized operations lower holding costs and boost efficiency.

Real-world companies use these tools every day. Coca-Cola uses AI to forecast demand and manage inventory. Tata Steel relies on AI for real-time tracking and auto-allocation, which improves delivery times.

Predictive Analytics

Predictive analytics help you plan for the future. You look at past sales and market trends to decide how much stock to order. Retailers like Target and Unilever use AI to avoid running out of products or having too much inventory.

Here is a table showing how predictive analytics benefit your warehouse:

Benefit | Description |

|---|---|

Workers know what to pick and restock, making tasks faster and easier. | |

Reduced Holding Costs | You save space and lower the risk of damaged goods by keeping less extra inventory. |

Less Guesswork | You make decisions based on data, not just intuition. |

Decision Support Systems

Decision support systems (DSSs) help you make smart choices. You use them to check inventory levels and predict which products will sell. DSSs gather data from many sources, giving you up-to-date information.

DSSs automate data analysis, saving you time.

They help you work with others by sharing information easily.

DSSs let you plan for different outcomes by looking at past and current data.

You see better cash flow and higher profits when you use DSSs in your warehouse management technologies.

Robotic Automation

Robotic automation changes how you run your warehouse. You see robots working alongside people to make tasks faster and easier. Robots help you save money and boost productivity. You can use them for picking, moving, and storing items. This technology makes your warehouse more competitive.

Autonomous Mobile Robots

Autonomous mobile robots (AMRs) move goods around your warehouse without human help. You can rely on them to work all day and night. AMRs handle repetitive tasks, so your team can focus on important jobs. These robots move quickly and accurately, which helps you fill orders faster and reduce mistakes.

AMRs operate 24/7, increasing throughput.

They automate repetitive tasks and reduce manual labor.

AMRs lower labor costs and improve efficiency.

You see fewer errors in picking, which keeps customers happy.

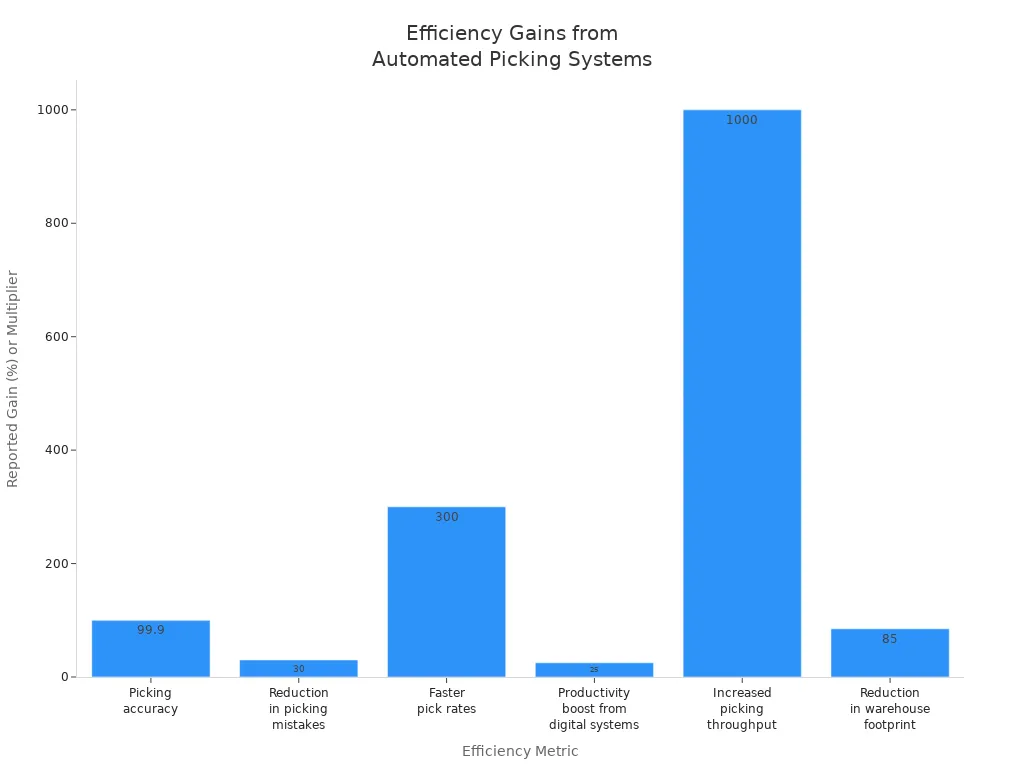

Automated Picking Systems

Automated picking systems use robots to select and move products. You get faster pick rates and fewer mistakes. These systems use computer vision and machine learning to find and grab items. You can trust them to handle products with care and accuracy.

Reported Gain | |

|---|---|

Picking accuracy | Up to 99.9% |

Reduction in picking mistakes | Over 30% |

Faster pick rates | 200–300% faster |

Productivity boost from digital systems | Up to 25% |

Increased picking throughput | Up to 10× |

Reduction in warehouse footprint | Up to 85% |

Computer vision helps robots see product sizes and avoid obstacles.

Machine learning lets robots improve and adapt in real time.

AI-driven picking increases speed and accuracy.

Automated Storage and Retrieval

Automated storage and retrieval systems (ASRS) help you use space better. You can store more items by building upward. ASRS reduces errors because fewer people touch the products. You get faster order picking and better inventory accuracy.

ASRS maximizes vertical storage and saves up to 85% of floor space.

You double or triple your storage capacity.

Streamlined picking reduces mistakes and boosts efficiency.

Robotic automation gives you a smarter, safer, and more efficient warehouse. You see lower costs and higher productivity every day.

Collaborative Robotics

Human-Robot Collaboration

You see collaborative robots, or cobots, working side by side with people in modern warehouses. Cobots help you with tasks that require strength, precision, or endurance. You can let robots handle heavy lifting and repetitive jobs, while you focus on problem-solving and decision-making. This teamwork creates a flexible and scalable workforce.

Cobots do not replace you. They support you by taking on the most physically demanding tasks. You stay safe and less tired, while robots move goods and handle dangerous duties. You use your skills to oversee operations and solve complex problems. Robots follow your instructions and learn from your feedback.

Here is how humans and robots work together:

Robots excel at lifting, sorting, and moving items across the warehouse.

You bring critical thinking and adaptability to manage unexpected challenges.

Cobots perform repetitive tasks without getting tired or injured.

You supervise, troubleshoot, and make decisions that keep operations running smoothly.

This partnership lets you get more done in less time. You see higher productivity and fewer mistakes.

Safety and Productivity

Warehouse work can be risky. The Bureau of Labor Statistics reports nearly six injuries for every 100 full-time warehouse workers. Four of these injuries often require days off or job restrictions. This costs businesses money and lowers productivity.

Cobots help you stay safe. They take over jobs that are too strenuous or dangerous. You avoid lifting heavy loads and reduce your risk of injury. Robots do not get tired or distracted, so they make fewer mistakes.

Benefit | How Cobots Help You |

|---|---|

Injury Reduction | Cobots handle heavy and risky tasks |

Less Fatigue | You avoid physical strain |

Higher Productivity | Robots work tirelessly |

Fewer Mistakes | Robots perform repetitive tasks well |

You work in a safer environment. You spend less time recovering from injuries and more time being productive. Cobots make your warehouse smarter, safer, and more efficient.

Cloud-Based Warehouse Management Technologies

Cloud-based solutions change how you manage your warehouse. You see faster updates, easier access to data, and lower costs. These systems help you keep up with demand and stay flexible. You do not need to buy expensive hardware or worry about software updates. Cloud platforms handle these tasks for you.

Cloud WMS and ERP Integration

You connect your warehouse management system (WMS) with your enterprise resource planning (ERP) platform in the cloud. This integration gives you a clear view of your supply chain. You track orders, shipments, and inventory from the warehouse to the customer. You get real-time updates, so you always know what is happening.

You improve inventory accuracy and reduce stock-outs.

You automate order processing and fulfillment, which saves time and prevents mistakes.

You maintain stock levels by analyzing past data and demand patterns.

Cloud WMS offers financial flexibility. You scale your operations up or down without extra software costs. This helps you maximize cost efficiency.

Benefit | How Integration Helps You |

|---|---|

Track orders and shipments easily | |

Inventory Accuracy | Reduce manual errors |

Real-Time Updates | Get instant data on receipts and orders |

Streamlined Fulfillment | Automate order transfer and processing |

Data Management and Accessibility

Cloud-based warehouse management technologies give you real-time visibility into your operations. You make quick decisions because you see inventory, orders, and labor data instantly. These systems sync information automatically, unlike older systems that rely on manual updates.

You enjoy unmatched flexibility and scalability.

You adapt to complex supply chains and changing demand.

You boost operational efficiency.

Research from Deloitte shows that real-time cloud data can improve inventory accuracy by up to 99%. You reduce errors in order processing and fulfillment. You spend less time fixing mistakes and more time serving your customers.

Cloud-based systems help you save money. You avoid large upfront investments and lower your total cost of ownership. You also reduce maintenance and IT support expenses. Automatic updates keep your software current, so you do not need to replace it every few years.

IoT and Connected Warehouses

You see the Internet of Things (IoT) changing how warehouses work. IoT connects devices, sensors, and equipment, creating a smart environment. This network helps you manage inventory, track assets, and make quick decisions. You improve efficiency and reduce mistakes by using real-time data.

Smart Sensors

Smart sensors play a big role in modern warehouses. You use them to monitor temperature, humidity, and light. These sensors help you protect sensitive products from spoilage. You also track inventory levels and equipment health with smart sensors.

Application | Benefits |

|---|---|

Environmental monitoring | Prevents spoilage, ensures compliance, and reduces write-offs for sensitive products. |

Inventory tracking | Enhances accuracy in stock management and reduces the risk of overstocking or stockouts. |

Condition assessment of equipment | Improves maintenance scheduling and reduces downtime by monitoring equipment health. |

You rely on sensors to capture data automatically. This process helps you find items quickly and keep your warehouse running smoothly.

Real-Time Data Access

IoT gives you instant access to data. You see inventory levels, shipment status, and equipment conditions in real time. This visibility helps you make better decisions and respond to changes fast.

You synchronize data with supply chain activities for better planning.

You track shipments accurately and adjust delivery routes as needed.

You reallocate inventory quickly when demand spikes.

Experts say IoT technology lets you make data-driven decisions. You optimize operations and handle inventory with more precision.

Asset Tracking

You use IoT devices like RFID tags and sensors to track assets. These tools show you where items are at any moment. You automate inventory management and reduce manual errors.

RFID tags monitor stock levels and locations.

Sensors on shelves provide real-time visibility.

IoT-equipped vehicles retrieve items automatically.

You improve operational efficiency and keep your warehouse organized. IoT helps you manage resources, reduce costs, and ensure safety for everyone.

3D Digital Twins

3D digital twins give you a powerful way to manage your warehouse. You create a virtual copy of your real warehouse. This digital model lets you test ideas, spot problems, and improve your space without stopping daily work. You see how changes will affect your operations before you make them in real life.

Virtual Simulation

With virtual simulation, you can run your warehouse in a digital world. You test new layouts, workflows, and equipment setups. This helps you find the best way to move goods and use your resources. You avoid costly mistakes because you see the results before making changes.

Virtual simulation tools help you minimize wasted resources and cut costs. You use real-time data to make smart choices and boost productivity.

Here are some key advantages of using digital twins for real-time simulation and optimization:

Advantage | Description |

|---|---|

Enhanced Operational Efficiency | Test operations virtually to find the most efficient processes and reduce wasted time. |

Predictive Maintenance | Monitor equipment status to catch problems early and lower repair costs. |

Improved Inventory Management | Get a real-time view of inventory to avoid stock-outs and use space better. |

Cost Reduction | Save money by optimizing resources and energy without stopping your warehouse. |

Enhanced Decision-Making | Simulate scenarios to make better choices and lower risks. |

Space Optimization

You use digital twins to plan your warehouse layout and improve how you use space. The digital model shows you where to place shelves, equipment, and workstations for the best flow. You can test different setups and see which one works best.

Feature | Benefit |

|---|---|

Layout Optimization | Try new arrangements to boost efficiency |

Resource Allocation | Find the best way to use people and equipment |

Process Improvement | Spot and fix bottlenecks in your workflow |

Virtual Experimentation | Test changes safely before making them real |

Real-Time Planning | Adjust plans quickly as things change |

Optimize warehouse layout to cut travel time and speed up the flow of goods.

Use lean practices to remove waste and make your processes better.

You get end-to-end visibility and can connect all your warehouse processes. Digital twins help you keep improving, so your warehouse stays efficient and ready for the future.

Sustainability in Warehouse Management

You play a key role in making your warehouse greener and more efficient. By using new warehouse management technologies, you can lower your carbon footprint and save money. Many companies now focus on sustainability to meet customer demands and protect the environment.

Energy-Efficient Automation

Energy-efficient automation helps you cut energy use and reduce emissions. You can use electric warehouse vehicles and smart lighting to lower costs. Automation systems adjust conveyor speeds and sortation logic to match demand, which saves energy. Smart power distribution stops machines from wasting electricity when not in use. Climate control systems work with automation to keep temperature-sensitive areas efficient.

Sustainable automation can help you reduce carbon emissions by up to 30%. You see big savings on energy bills and help the planet.

Here are some top technologies and their benefits:

Technology | Benefits |

|---|---|

Electric Warehouse Vehicles | |

AI-driven Transportation Management Systems | Optimizes delivery routes, reducing mileage and improving fuel efficiency. |

Real-time Data Analytics | Enables tracking of energy consumption and operational inefficiencies. |

Automated Storage and Retrieval Systems | Enhances efficiency in inventory management, reducing waste. |

Energy-efficient Lighting Solutions | Lowers electricity consumption and operational costs. |

Green Packaging

Green packaging helps you cut waste and protect the environment. You use recyclable and biodegradable materials instead of traditional packaging. Lighter and smaller packages make shipping more efficient and use less energy. By switching to green packaging, you lower greenhouse gas emissions and help keep oceans clean.

Green packaging reduces your carbon footprint.

You promote recycling and composting.

Advanced delivery technologies make your operations more efficient.

Innovations in packaging with recycled materials save energy and support a circular economy.

Waste Reduction

You can reduce waste by using smart warehouse management technologies. Automated storage and retrieval systems help you manage inventory better, so you throw away fewer products. Real-time data analytics show you where you can cut waste and improve efficiency. You also use energy-efficient lighting and electric vehicles to lower operational costs.

Try these steps to make your warehouse more sustainable:

Maximize natural light with skylights and clear panels.

Install solar panels to generate renewable energy.

You see less waste, lower costs, and a cleaner environment. Sustainability is now a key part of running a modern warehouse.

Workforce Technology

Warehouse technology helps you work smarter and safer. You use new tools to learn faster, avoid injuries, and get more done each day. Two of the most important advances are wearables and augmented reality training.

Wearables

Wearable devices change how you work in the warehouse. You wear smart watches, scanners, or glasses that give you real-time information. These tools let you keep your hands free and your eyes on your tasks. You move faster and make fewer mistakes.

Wearables help you stay safe. Ergonomic designs protect your body from strain. You avoid injuries because you do not need to bend or twist as much. If you feel pain, you can report it quickly. Companies see a big drop in restricted workdays when they use ergonomic wearables.

Wearable technology speeds up training for new hires. You learn warehouse operations by following simple instructions on your device. You join the team faster and start working right away.

Here is how wearables help you every day:

You get real-time data, so you know what to do next.

You spend less time on manual tasks and make fewer errors.

Ergonomic wearables keep you safe and comfortable.

Impact Area | Improvement Rate |

|---|---|

Injury Reduction | 53% |

Error Reduction | 67% |

Productivity Boost | 25% |

Augmented Reality Training

Augmented reality (AR) training uses smart glasses and digital guides to teach you warehouse skills. You see visual cues that show you where to go and what to pick. AR makes learning fun and interactive.

You train with AR simulations that look and feel like real warehouse tasks. You remember more because you practice with hands-on activities. If you make a mistake, you get instant feedback and can fix it right away.

AR smart glasses guide you to the right items, making picking faster.

You finish training with fewer errors and more confidence.

Picking efficiency goes up by 25% or more, with almost no mistakes.

You learn better with interactive lessons.

Real-time feedback helps you improve your skills quickly.

Workforce technology gives you the tools to work safely, learn faster, and boost productivity in every part of the warehouse.

Cybersecurity in Warehousing

You rely on digital systems to run your warehouse. These systems help you track inventory, manage orders, and keep your business moving. As you use more warehouse management technologies, you face new risks from cyber threats. Protecting your data and systems is now a top priority.

Data Protection

You need strong data protection to keep your warehouse safe. Cyber attackers use malware, phishing, and DDoS attacks to steal information or disrupt your operations. Unauthorized access can lead to lost data and business downtime. You can use several strategies to protect your warehouse:

Security awareness training teaches your team how to spot and stop cyber threats.

Zero-trust security models check every user and device before allowing access.

AI and machine learning help you find threats before they cause harm.

Blockchain technology adds extra security and traceability to your supply chain.

Tip: Regular training and updates help your team stay alert and ready to defend against new threats.

Secure Systems

You build secure systems to keep your warehouse running smoothly. Firewalls block unwanted traffic. Multi-factor authentication makes sure only trusted users get in. An Information Security Management System (ISMS) helps you set rules and monitor your security. You can use these tools to protect sensitive data and keep your business safe.

Security Tool | How It Helps You |

|---|---|

Firewalls | Stop harmful traffic from entering |

Multi-factor Authentication | Verify user identity |

ISMS | Set rules and monitor security |

AI Threat Detection | Spot problems before they spread |

You keep your warehouse management technologies safe by using these tools and strategies. You protect your data, your team, and your customers. Strong cybersecurity helps you avoid costly problems and keeps your warehouse running every day.

Flexible Modular Systems

Modern warehouses need to change quickly. You face new products, shifting demand, and busy seasons. Flexible modular systems help you keep up with these changes. You can adjust your warehouse layout and operations without slowing down your business. These systems let you build a tech-driven warehouse that grows with your needs.

Adaptable Layouts

You use adaptable layouts to make your warehouse more dynamic. Modular designs allow you to move shelves, workstations, and equipment with ease. You can create new storage areas or change workflows when demand rises. This flexibility helps you stay efficient and competitive.

You adjust storage solutions for peak seasons or new product launches.

You move equipment to fit changing inventory needs.

You create new picking zones for faster order fulfillment.

You reconfigure layouts to improve safety and traffic flow.

Tip: Adaptable layouts help you respond to market changes without major disruptions.

Scalable Solutions

Scalable solutions let you grow your warehouse operations step by step. You add new automation technologies, such as Autonomous Mobile Robots (AMRs) or Automated Storage and Retrieval Systems (AS/RS), when your business expands. You remove or reconfigure units if your needs change. This approach saves you money and keeps your warehouse running smoothly.

You integrate new automation tools as your order volume increases.

You scale up storage capacity for busy periods.

You adjust workflows to handle different product types.

You expand or shrink your warehouse footprint as needed.

Feature | Benefit |

|---|---|

Modular Automation | Easy to add or remove units |

Scalable Operations | Grow or shrink with demand |

Responsive Layouts | Quick adaptation to changes |

Flexible modular systems turn your warehouse into a responsive environment. You stay ready for anything the market brings.

Blockchain for Logistics

Blockchain technology changes how you track and share information in logistics. You use it to create a digital record that everyone in your supply chain can see. This record cannot be changed or erased. You build trust with your partners because everyone sees the same data. Blockchain helps you move goods faster, lower your costs, and keep your information safe.

Transparent Tracking

You want to know where your products are at every step. Blockchain gives you a clear view of your supply chain. Each time a product moves, you add a new entry to the blockchain. No one can change these records. This makes it easy to trace products from the warehouse to the customer.

You see the full journey of each product, which builds trust with your customers.

You check if products are real and not fake because records cannot be changed.

You spot problems quickly, like delays or lost items.

You share the same information with all partners, so everyone stays on the same page.

Blockchain lets you track products in real time. You know exactly where your goods are and who handled them.

Compliance and Security

You need to follow rules and keep your data safe. Blockchain helps you meet these goals. You use smart contracts to automate checks and approvals. This reduces paperwork and speeds up your work. Customs and other authorities can see your records right away, which helps clear shipments faster.

Benefit | How Blockchain Helps You |

|---|---|

Data Security | Records cannot be changed or deleted |

Fraud Prevention | Tamper-proof logs stop fake entries |

Faster Customs Clearance | |

Lower Costs | Less paperwork and fewer mistakes |

Better Collaboration | Everyone uses the same trusted data |

You protect your business from fraud and mistakes. You also save time and money by using blockchain for secure data exchange. Blockchain makes your supply chain stronger and more reliable.

Drones and Automated Cleaning

Drones and automated cleaning systems change how you manage your warehouse. These technologies help you work faster, save money, and keep your facility in top shape. You can use drones to scan inventory and robots to clean floors. This means you spend less time on manual tasks and more time on important work.

Inventory Scanning

You can use drones to scan your warehouse shelves from above. Drones fly through aisles and use cameras or sensors to read barcodes and RFID tags. This process gives you a real-time view of your inventory. You do not need to climb ladders or walk long distances to check stock.

Drones scan thousands of items in minutes.

You spot missing or misplaced products quickly.

Inventory counts become more accurate.

Tip: Drones help you find errors before they become big problems. You can fix mistakes right away and keep your customers happy.

Here is a quick comparison:

Method | Time Needed | Error Rate | Safety Risk |

|---|---|---|---|

Manual Scanning | High | Medium | High |

Drone Scanning | Low | Low | Low |

Facility Maintenance

Automated cleaning robots keep your warehouse clean without extra effort from your team. These robots sweep, mop, and vacuum floors on a set schedule. You do not need to stop work for cleaning crews.

Robots clean during off-hours, so you avoid downtime.

You reduce slips and falls by keeping floors spotless.

Maintenance costs drop because robots use less water and energy.

Note: Clean warehouses help you meet safety standards and create a better place to work.

Drones and automated cleaning systems let you focus on growing your business. You save time, lower costs, and keep your warehouse running smoothly every day.

You see warehouse management technologies change the way you run your business. These tools help you work faster, save money, and protect the environment. Start by reviewing your current systems. Test new solutions in small steps. Train your team and measure results. Stay open to new ideas. Keep learning and adapting to stay ahead in logistics.

FAQ

What is the biggest benefit of using warehouse robots?

You save time and reduce mistakes. Robots handle repetitive tasks. Your team can focus on important work. This leads to faster order fulfillment and happier customers.

How does IoT improve warehouse safety?

IoT sensors alert you to unsafe conditions. You get real-time updates about equipment and the environment. This helps you prevent accidents and keep your team safe.

Can small warehouses use cloud-based systems?

Yes, you can use cloud-based systems in small warehouses. These systems scale with your needs. You avoid large upfront costs and only pay for what you use.

How do wearables help warehouse workers?

Wearables give you instant instructions and safety alerts. You work faster and make fewer errors. Ergonomic designs also help you avoid injuries.

Is blockchain technology secure for logistics?

Yes! Blockchain creates records that no one can change. You track products and share data safely. This builds trust with your partners and customers.

See Also

Optimized Inventory Management and Distribution Through PGL Warehousing

Enhanced Inventory Control and Distribution via PGL Warehousing

The Role of Direct Logistics Systems in Global Efficiency

Transforming International Operations with Innovative Logistics Strategies