Emerging trends redefining Chicago logistics in 2025

You see the most transformative trends in Chicago logistics industry insights 2025 changing how you do business. Companies now use AI to optimize delivery routes, which helps you save time and money. Electric trucks are being tested across Chicago, showing a big move toward green logistics. The overall vacancy rate in the city’s industrial market increased to 4.7%, so understanding supply, demand, and pricing matters more than ever.

Sustainability is now essential for your operations. Adopting energy-efficient practices can improve your brand reputation and cut costs. You will find practical recommendations to help you adapt to these changes.

Key Takeaways

Embrace AI and predictive analytics to enhance logistics efficiency. These tools help forecast demand and optimize delivery routes, saving time and money.

Switch to electric vehicles to reduce emissions and operating costs. Start with a pilot program for urban routes to track benefits before expanding.

Stay updated on new regulations affecting logistics. Monitor changes and train your staff to ensure compliance and avoid penalties.

Utilize localized logistics to speed up deliveries. Storing products closer to customers can lower transportation costs and improve inventory management.

Focus on sustainability by adopting eco-friendly practices in warehousing. Use energy-efficient systems and recycling programs to enhance your brand's reputation.

Technology Shaping Logistics

AI and Predictive Analytics

You can use AI and predictive analytics to make your logistics operations smarter and faster. AI tools help you forecast demand, plan routes, and manage inventory. For example, Uber Freight’s AI reduces empty truck miles by up to 15%. This means you save money and lower emissions. Predictive analytics also help you spot risks before they become problems. You can adjust your supply chain quickly if something goes wrong.

Here is how Chicago companies use AI and analytics:

Application Type | Description |

|---|---|

AI-powered Demand Forecasting | Forecasts demand and adjusts inventory levels automatically. |

Logistics & Network Optimization | Finds the best routes and network designs for your shipments. |

Predictive Supply Chain Risk Management | Spots and reduces risks in your supply chain. |

Automated Warehouse Operations | Speeds up order processing and reduces mistakes. |

Tip: Start with AI-powered demand forecasting tools. These tools help you keep the right amount of stock and avoid costly shortages.

Quantum Computing Applications

Quantum computing is starting to change logistics in Chicago. You can use quantum algorithms to solve complex problems, like finding the fastest delivery routes or balancing supply and demand. Companies such as Unisys work with the Chicago Quantum Exchange to create new solutions for logistics. Quantum computing can help you work more efficiently, reduce risks, and boost output.

It helps you solve problems that regular computers cannot handle.

You can expect faster and smarter decisions as this technology grows.

Blockchain and IoT Integration

You can improve transparency and traceability in your supply chain by combining blockchain with IoT devices. Blockchain keeps secure and unchangeable records of every product movement. IoT sensors give you real-time updates on shipments. This combination reduces fraud and errors. You can track goods from the warehouse to the customer with confidence.

Note: Start by using IoT sensors for real-time tracking. Add blockchain for secure records as your system grows.

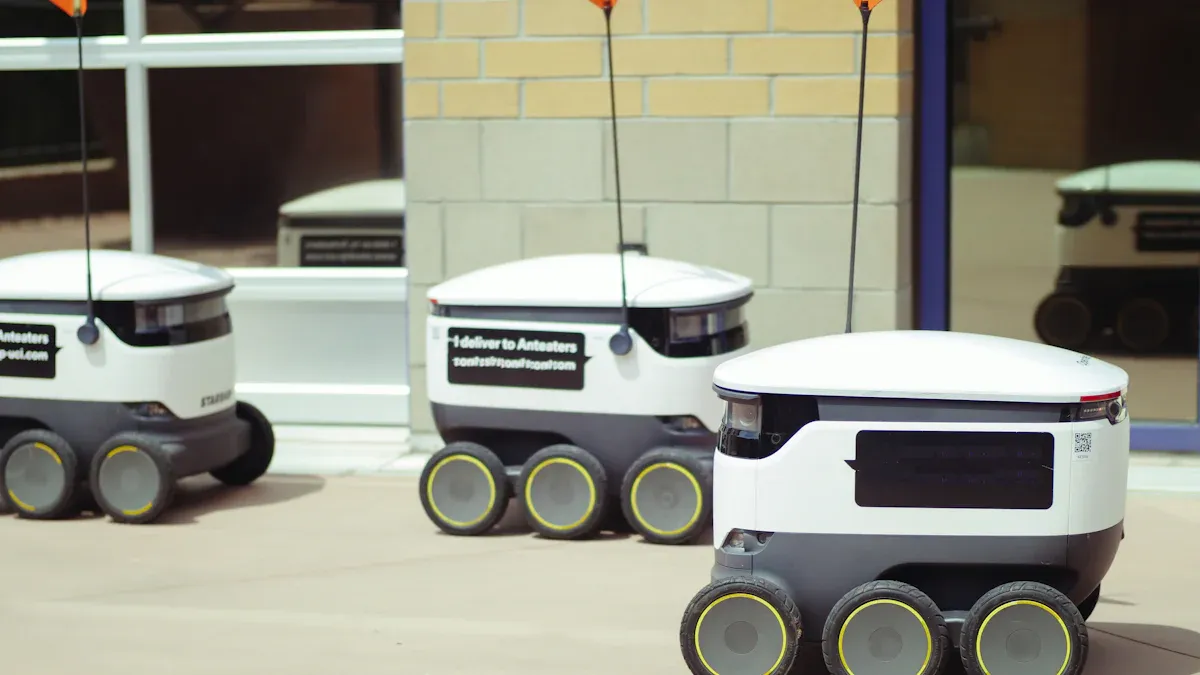

Autonomous Vehicles in Chicago

Autonomous vehicles are becoming more common in Chicago’s logistics. You see delivery robots, drones, and electric trucks in action. The Advancing Smart Logistics program supports these changes. It focuses on automating truck routes and last-mile deliveries. Some people worry about safety and privacy, so you need to follow local rules and listen to community feedback.

Use autonomous vehicles for repetitive routes.

Test electric delivery vans for city shipments.

Work with technology partners to stay ahead.

You can lead the way by adopting these technologies early. This will help you stay competitive and meet customer needs in 2025.

Sustainability and Green Initiatives

Fleet Electrification

You can lower emissions and operating costs by switching to electric vehicles. Many Chicago logistics companies now test electric trucks and vans for city deliveries. Lazer Logistics works with manufacturers and energy partners to deploy zero-emission vehicles. They also use route optimization to save energy. When you choose electric fleets, you help reduce air pollution and meet new environmental standards.

Tip: Start with a pilot program for electric vehicles on short, urban routes. Track your results and expand as you see benefits.

Eco-Friendly Warehousing

You can make your warehouses greener by adopting energy-saving practices. Many providers in Chicago use LED lighting, high-efficiency HVAC systems, and better insulation. Some install solar panels to cut carbon emissions. Water conservation also matters. You can use low-flow fixtures and collect rainwater. Recycling programs and green building certifications like LEED or Energy Star show your commitment to sustainability.

Eco-Friendly Practice | Description |

|---|---|

Energy Efficiency | Use LED lighting, high-efficiency HVAC, and improved insulation to lower energy use. |

Renewable Energy | Install solar-ready roofs or solar panels to cut carbon emissions. |

Water Conservation | Use low-flow fixtures and harvest rainwater to reduce water use. |

Waste Reduction | Set up recycling and efficient waste management systems. |

Certifications | Get LEED, Energy Star, or other green building certifications. |

Regulatory Drivers

You must keep up with new rules that push for greener logistics. In March 2024, the SEC adopted rules for climate-related disclosures by public companies. The logistics industry faces more scrutiny because of its emissions. You need to monitor regulations, train your staff, and use technology for compliance. Flexible processes help you adjust quickly when rules change.

Strategy | Description |

|---|---|

Continuous monitoring | Track and review regulatory updates at all levels. |

Leveraging technology | Use supply chain tools for compliance management. |

Training and awareness | Train staff on compliance and best practices. |

Building flexibility | Design adaptable logistics processes for quick changes. |

Sustainable Strategies

You can use several strategies to make your logistics business more sustainable. Reduce your carbon footprint by using fuel-efficient vehicles and renewable energy. Optimize routes with advanced software to save fuel. Set up recycling programs and work with suppliers who value sustainability. Focus on employee well-being and support your local community. Companies like IDI Logistics build LEED-certified warehouses and track carbon intensity. Lazer Logistics partners with others to test zero-emission solutions and drive industry change.

Note: Form an ESG committee and set clear goals for continuous improvement. Monitor your progress and celebrate your achievements.

Supply Chain Resilience

Nearshoring and Reshoring

You see more companies bringing manufacturing closer to Chicago. This trend, called nearshoring and reshoring, helps you reduce shipping times and costs. Chicago’s logistics industry benefits as new factories open and more jobs appear. In 2022, the city added 12,000 manufacturing jobs, and the sector grew by $11 billion. Investment in local manufacturing startups also increased by over 26%. As you shift your sourcing, you need to adjust to new trade routes and use technology like real-time tracking and AI-powered route planning. These tools help you move goods efficiently, whether you ship locally or across borders.

Risk Management

You can protect your business from disruptions by using smart risk management strategies. Many Chicago logistics firms use a mix of inventory buffering, strong partner communication, and advanced technology. The table below shows some top strategies:

Strategy | Description |

|---|---|

Strategic Inventory Buffering | Keep a safety buffer of popular products to avoid stockouts during busy times. |

Transparent Partner Communication | Share updates with partners to spot risks early and act fast. |

Technology as a Risk Tool | Use real-time tracking and analytics to monitor shipments and predict demand changes. |

Tip: Use predictive analytics to forecast demand and set the right inventory levels.

Localized Logistics

You can speed up deliveries and cut costs by storing products closer to your customers. Localized logistics means you use regional warehouses and co-located supply chains. This approach leads to faster order fulfillment and better inventory management.

Benefit | Description |

|---|---|

Faster Delivery Times | Products reach customers quickly because they travel shorter distances. |

Lower Transportation Costs | Shorter routes mean you spend less on fuel and shipping. |

Improved Inventory | You can match stock to local demand and reduce waste. |

Co-located supply chains can cut lead times by up to 50%.

You may see a 20–30% drop in inventory levels, saving money.

Cross-Border Trade Challenges

You face new hurdles when moving goods across borders. Recent rules require truck drivers to prove English proficiency, which changes how you manage US-Mexico shipments.

President Trump’s executive order now requires commercial truck drivers to demonstrate English proficiency for reading signs, talking to officials, and following safety rules. This aims to improve safety and efficiency in cross-border logistics.

Customs regulations can be complex and may cause delays if you make mistakes.

Tariffs and duties can raise your costs and affect your pricing.

Seamless data flow and integrated technology are key for smooth international operations. Real-time tracking and accurate inventory management help you avoid costly errors.

Labor and Regulatory Dynamics

Driver Shortages

You face a growing challenge in finding enough truck drivers for Chicago logistics. The American Trucking Associations expects a shortfall of about 115,000 truck drivers by 2025. This number could rise to over 160,000 by 2030. In 2023, the shortage was around 60,000, which was less than the 80,000 in 2021. The shortage changes with market conditions and long-term trends. The demand for truck drivers is higher than ever because of the e-commerce boom and an aging workforce. You need about 3.5 million truck drivers to meet current needs.

Possible increase to 160,000 by 2030

Demand driven by e-commerce and aging workforce

3.5 million drivers needed to meet demand

Tip: You can attract new drivers by offering better pay, flexible schedules, and training programs.

Skills Gaps

You notice that skills gaps affect your ability to fill logistics jobs. The COVID-19 pandemic showed how important it is to match education and training with job needs. You need workers with middle-skills certifications to succeed in logistics. Local programs help you train new talent and upskill current employees.

Program Name | Description | Impact |

|---|---|---|

ICATT Apprenticeship Program | Trains logistics specialists and freight forwarding apprentices. | Tripled in size since 2015; 70 apprentices at 58 companies. |

Funds career training in transportation, distribution, and logistics. | Supports demand for skilled workers. |

The Chicago Cook Workforce Partnership uses Individual Training Account dollars for logistics training.

Certification is required for local programs to meet industry needs.

Labor Regulations

You must follow new labor regulations that affect your operations. Chicago’s minimum wage is now $15.80 for large businesses and $15.00 for smaller ones. Employees working more than 7.5 hours must get a 20-minute meal break. The Paid Leave for All Workers Act gives up to 40 hours of paid leave each year starting January 1, 2024.

Regulation Type | Details |

|---|---|

Minimum Wage | $15.80 for large businesses, $15.00 for smaller ones |

Meal and Rest Breaks | 20-minute meal break for shifts over 7.5 hours |

Paid Leave Requirements | Up to 40 hours of paid leave per year starting January 1, 2024 |

Note: You should review your policies to stay compliant and avoid penalties.

Automation’s Workforce Impact

You see automation changing the types of jobs you need to fill. Technology creates new roles like Automation Technician, Supply Chain Specialist, and Logistics Analyst. Since February 2020, over 72,000 jobs in logistics and related fields have been created. By 2025, you could see 770,000 more jobs. Companies compete for skilled workers who can manage automated systems and data.

Rising demand for skilled workers in supply chain automation

770,000 more jobs projected by 2025

Key roles: Automation Technician, Supply Chain Specialist, Logistics Analyst

Tip: You can partner with local colleges to develop training programs for automation skills.

Infrastructure and Urban Growth

Inland Ports and Cold Storage

You see inland ports and cold storage facilities growing fast in Chicago. These assets now act as economic anchors for the region. E-commerce and food processing companies drive the need for better supply chain solutions. States that invest in logistics gain more jobs and a stronger competitive edge.

Inland ports help you lower real estate and operating costs.

They offer a greener choice by easing congestion at seaports.

You can manage capacity issues at traditional ports with these facilities.

Customers use Chicagoland for both import and export goods, with containers both loaded and unloaded at our facilities there, and that includes domestic distribution.

Chicago invests $170 million in infrastructure and capacity improvements. Projects like the Chicago Logistics Hub and upgrades at Homewood Campus support this growth.

Investment Amount | Purpose | Key Projects |

|---|---|---|

$170 million | Infrastructure and capacity improvement | Construction of the Chicago Logistics Hub, upgrades to technology and training facilities at Homewood Campus |

Air Cargo Expansion

You benefit from Chicago’s expanding air cargo operations. The city expects a 4.4% increase in air cargo capacity in 2025. The overall air cargo market will likely grow at a 5.3% compound annual rate from 2025 to 2035. This growth helps you move goods faster and meet rising customer demands.

Port Modernization

Chicago’s ports are modernizing to boost logistics efficiency. You see new rooftop solar arrays and microgrids that improve energy use. Real-time monitoring and digital twins help you track assets and manage operations better. Predictive maintenance prevents equipment failures. The city invests nearly a billion dollars in these upgrades.

Initiative | Description |

|---|---|

Rooftop solar arrays | Solar energy solutions for sustainability |

Microgrids | Localized energy grids for efficiency |

Real-time monitoring | Continuous tracking of assets |

Digital twin | Digital replicas for better management |

Predictive maintenance | Prevents equipment failures |

Capex near a billion USD | Major investment in port modernization |

The CREATE Program, a $4.6 billion project, upgrades rail infrastructure and reduces congestion. Modern inland ports now act as advanced logistics ecosystems, connecting you to high-capacity transportation networks.

Last-Mile Delivery

You see new last-mile delivery solutions in Chicago. E-commerce growth increases demand for fast and flexible delivery. Amazon Prime offers one- and two-hour delivery options in the city. DoorDash works with Coco to use emission-free delivery robots. Companies like Grubhub and Uber Eats also test autonomous delivery methods.

Amazon Flex lets you earn money by delivering packages, boosting delivery capacity.

These programs show a strong focus on innovation and sustainability in last-mile logistics.

Tip: Explore partnerships with tech companies to pilot new delivery solutions and stay ahead in the market.

Chicago Logistics Industry Insights 2025

Customer-Centric Trends

You see customer expectations changing fast in the chicago logistics industry insights 2025. People want deliveries to arrive quickly and with more options. Omnichannel logistics lets you offer faster and more customized services. You can scale your operations up or down with elastic logistics models, so you always meet demand.

Customers expect fast, personalized deliveries.

You need flexible supply chains that use multiple delivery channels.

Autonomous vehicles and drones help you meet last-mile delivery needs.

You notice more home deliveries than ever before. One retail partner set a record with 13,000 home deliveries in a single day. Customers also ask for 'white glove' services, such as inside delivery, unpacking, and debris removal. You see more demand for rail and inland routes, which link reliable solutions to ocean transport and reduce transit time variations.

Trend Description | Evidence |

|---|---|

Increased volume in home deliveries | A record of 13,000 home deliveries in one day for a retail partner. |

Demand for 'white glove' services | Customers request inside delivery, unpacking, and debris removal. |

Growth of rail and inland routes | More intermodal options connect to ocean transport, reducing delays. |

You can stay ahead by listening to your customers and adapting your services. The chicago logistics industry insights 2025 show that flexible, customer-centric supply chains are key to success.

Data-Driven Decision Making

You use data to make smart choices in the chicago logistics industry insights 2025. Big data analytics help you manage thousands of SKUs and improve warehouse efficiency. Demand forecasting systems let you predict what customers want and when they want it.

IoT sensors and RFID tags give you real-time updates on inventory movement.

AI-based platforms show you stock levels and spot errors quickly.

Automation tools, like autonomous mobile robots and AI-powered picking systems, help you respond to changes in demand.

You work with third-party logistics providers who use advanced technology to analyze your data. This analysis helps you make informed decisions and stay competitive. You see instant visibility into your supply chain, so you can fix problems before they grow.

Tip: Use real-time data feeds from multiple providers to improve your situational awareness. Keep your technology simple to avoid complex integrations.

Actionable Takeaways for Stakeholders

You want to succeed in the chicago logistics industry insights 2025. Focus on strategies that cut costs and improve efficiency. Use technology and AI to make your logistics processes better. Build a resilient supply chain by diversifying your sourcing and managing risks.

Cut costs and boost efficiency with smart operational strategies.

Use technology and AI to streamline logistics processes.

Strengthen supply chain resilience by diversifying sourcing and improving risk management.

You can collect and standardize real-time data feeds from different providers. Automate notifications to stay aware during disruptions. Simple technology landscapes help you avoid problems with complex integrations.

Action Step | Benefit |

|---|---|

Collect real-time data feeds | Better visibility and faster decisions |

Automate notifications | Quick response to disruptions |

Simplify technology landscape | Easier management and fewer errors |

Note: The chicago logistics industry insights 2025 highlight the importance of innovation, flexibility, and data-driven strategies. You can lead your business by adopting these best practices.

You see Chicago logistics changing fast in 2025. New technology, green practices, and shifting regulations shape your daily work. To stay ahead, you should:

Diversify your supply chains to reduce risk from political changes.

Keep operations in different regions for better resilience.

Watch for new trade policies and adjust quickly.

Track political and economic news.

Build a plan for new rules.

Stay curious, keep learning, and lead with innovation and sustainability.

FAQ

What is the biggest technology trend in Chicago logistics for 2025?

AI and automation lead the way. You see smarter route planning, faster deliveries, and fewer mistakes. Companies use AI to predict demand and manage inventory. This helps you save money and improve service.

How can you make your logistics business more sustainable?

You can switch to electric vehicles and use green warehouses. Start recycling and save energy with LED lights. Track your progress and set clear goals. Small changes add up to big results.

Why does supply chain resilience matter in Chicago?

Supply chain resilience helps you avoid delays and shortages. You can respond quickly to disruptions like weather or new rules. Strong supply chains keep your business running and your customers happy.

How do new labor laws affect your logistics operations?

You must follow higher minimum wages and new paid leave rules. Review your policies and train your team. Staying compliant helps you avoid fines and keeps your workers satisfied.

See Also

Effective Strategies by PGL for Efficient U.S. Warehousing

PGL's Miami Warehouse Solutions Ensure Quick East Coast Shipping

PGL's Miami And L.A. Warehousing Boosts U.S. Supply Chain Efficiency

Enhancing Global Operations Through Innovative Logistics Strategies

PGL Transforms West Coast Freight for Scalable Supply Chains