Temperature-Controlled Storage in South Florida by Premier Global Logistics

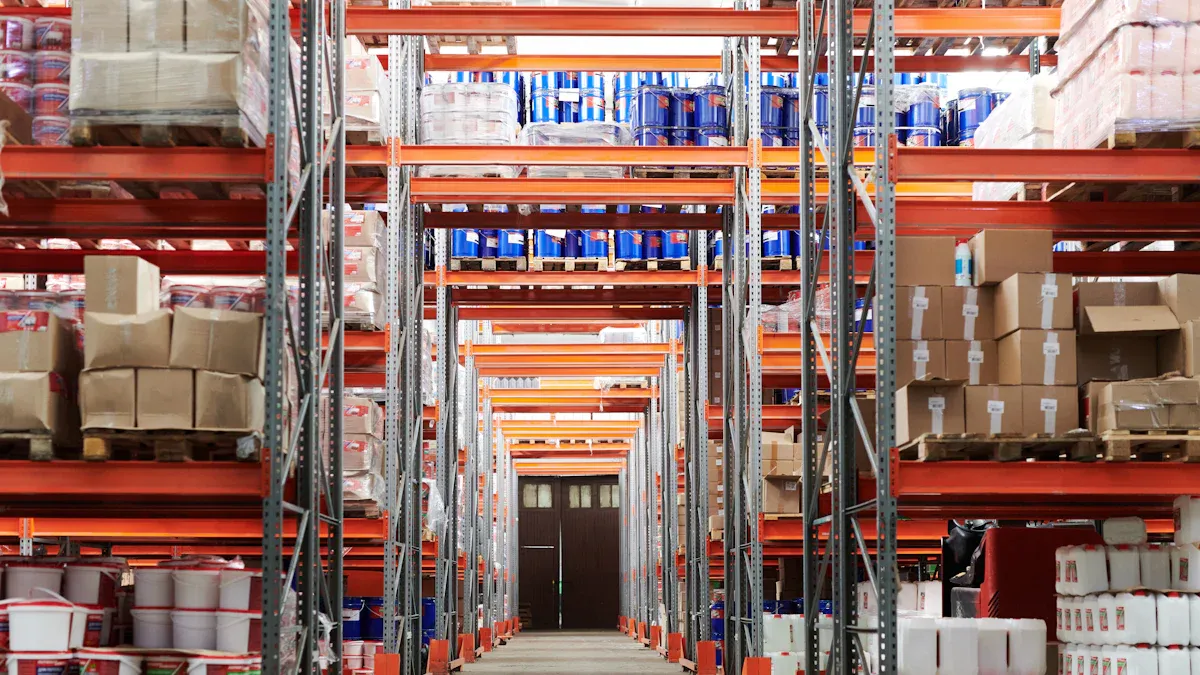

Premier Global Logistics provides safe and approved pharma and food grade temperature storage in Miami, addressing the city’s unique challenges with multiple temperature requirements, strict regulations, and high demand for cold chain solutions. Facilities in Miami must maintain precise control of temperature and humidity to prevent contamination. Effective solutions also require robust pest control, thorough cleaning, and meticulous verification of food-grade certifications. PGL’s expertise, advanced technology, and comprehensive services make them a trusted partner for pharma and food grade temperature storage, supporting businesses that rely on consistent temperature control.

Key Takeaways

Premier Global Logistics has special cold storage in Miami. There are different temperature zones for food, medicine, and chemicals. These zones help keep items safe and fresh.

The FDA, USDA, and FSMA have strict rules. PGL follows these rules to keep products high quality. This also helps stop contamination.

Real-time monitoring checks the temperature all the time. Backup systems help if something goes wrong. This stops goods from spoiling or being lost.

PGL also helps with labeling, sorting, and customs. These extra services make shipping and storage easier for clients.

Clients trust PGL for safe and reliable storage. The storage is efficient and keeps the right temperature. This helps with fast delivery and following the rules.

Cold Storage Challenges in Miami

Climate and Compliance

Miami is important for cold storage because it is a big trade center. Its tropical weather makes it a key place for storing goods that spoil easily. Many items like seafood, produce, medicines, and chemicals come through Miami. The city is very humid, often over 80%. In summer, it gets hotter than 90°F. These hot and wet conditions can harm perishable products. Cold storage buildings must keep the right temperature to protect these goods. Most places keep rooms between 68-72°F. Some special units go from -10°F to 55°F.

Following rules is very important here. The FDA, USDA, and FSMA have strict rules for cold storage. Facilities must obey these rules to keep products safe and high quality. This means they need regular checks, paperwork, and watching storage conditions. If the cold chain breaks, products can spoil. This can cause money loss and health problems. Because of Miami’s weather, checking and following rules is even more important.

Note: Cold storage in Miami needs advanced systems to control temperature and humidity. Buildings must use real-time checks and alarms to stop any breaks in the cold chain.

Multi-Temperature Needs

Different perishable goods need different storage temperatures. Some need to be frozen. Others need to be kept cool. Some just need steady room temperature. Miami’s cold storage places must have many temperature zones for these needs. For example, seafood shippers may need deep freezing. Medicine companies need exact temperatures for vaccines and drugs.

Facilities must keep goods apart by type and temperature need. This stops cross-contamination and helps follow the rules. Having many temperature zones helps many businesses, like food and medicine. Miami’s trade role means more need for flexible and dependable cold storage.

Pharma and Food Grade Temperature Storage

Temperature Zones

Premier Global Logistics runs a warehouse in Miami with top standards for pharma and food grade temperature storage. The building has different temperature zones to keep perishable goods safe and high quality. Each zone uses special monitors and backup systems to keep the right temperature all the time.

The table below lists the main storage types and their temperature ranges:

Storage Type | Temperature Range (°C) |

|---|---|

Room Temperature | |

Cool Storage | 8 – 15 |

Cold/Refrigerator Storage | 2 – 8 |

Freezer Storage | -25 – 10 |

PGL’s cold storage helps many kinds of perishable products. Seafood, dairy, and frozen foods stay safe in freezer storage. Vaccines and medicines are kept stable in refrigerated storage. Fresh fruits and special foods do well in cool and room temperature zones. The warehouse uses real-time sensors and alarms to stop any breaks in the cold chain. This makes sure every product gets the right care from when it arrives until it leaves.

Note: PGL’s temperature-controlled warehouse checks temperatures all the time and sends alerts right away to keep all perishable goods at the right temperature.

Segregated Storage

PGL’s food-grade warehouse keeps pharma and food grade temperature storage in separate areas. This stops cross-contamination and helps follow FDA, USDA, and FSMA rules. Each type of product has its own space and handling steps based on what it needs for safety and temperature.

Some important parts of PGL’s separated storage are:

Different zones for medicines and food, each with its own temperature controls.

Special climate systems that control both temperature and humidity in every area.

Strong cleaning and pest control to keep goods safe.

Workers trained in safety steps for both food and pharma.

Real-time tracking and inventory systems for full traceability.

PGL’s cold storage uses a warehouse management system to track every item. The system keeps records of temperature and where products move, helping with safety and following rules. Clear labels and paperwork help meet the rules for both food and medicines. The company also gives extra services like labeling, checking, and sorting, which helps clients handle complex supply chains.

PGL’s temperature-controlled warehouse helps clients feel confident. The building’s design, technology, and rules make sure every perishable product stays safe, fresh, and follows the rules from storage to shipping.

Temperature-Controlled Solutions by PGL

Monitoring Systems

Premier Global Logistics uses special systems to keep products safe in Miami’s tough weather. Their warehouse has temperature-controlled systems that work all day and night. These systems watch temperature, humidity, and light in each storage area. Sensors send quick alerts if there is a problem with temperature. Staff can fix issues fast before products get ruined.

PGL’s warehouse has backup cooling to keep things cold if something breaks. Real-time monitoring lets clients see and control their goods at any time. The system writes down every temperature change to help follow FDA, USDA, and FSMA rules. PGL’s solutions stop cold chain breaks that can hurt medicines, seafood, and other items.

Temperature control is very important for healthcare shipments. Real-time checks help PGL keep the right temperature for vaccines and chemicals. Their warehouse makes sure every shipment is safe and can be tracked. Clients trust PGL to protect their products from start to finish.

Tip: Real-time checks and good temperature control help PGL keep goods safe and high quality.

Value-Added Services

PGL’s warehouse does more than just store goods. They offer many extra services for food, pharma, and trade clients. These services help at every step, from when goods arrive to when they leave.

Labeling in many languages and for rules, with barcodes and SKUs.

Checking quality when goods come in or go out, with looks and samples.

Sorting and putting together orders for stores or shipping.

Custom packing with special or client materials.

Handling returns by checking and putting goods back in stock.

Moving freight for small boxes, big loads, and containers.

Helping with customs for shipping, including papers for Canada.

Fast service for urgent or busy orders, so they ship quickly.

Call center help for tracking, info, and returns.

PGL’s warehouse uses these services with temperature control and checks. Clients get smooth service, less risk, and better results. PGL helps businesses deliver on time and follow rules. Their skills in temperature control and extra services make them a top choice in Miami.

Note: PGL’s extra services make it easy for clients to get storage, shipping, and rule-following all in one place.

Client Benefits and Reliability

Product Safety

Premier Global Logistics always puts product safety first. The company trains its staff often. Workers know how to handle goods with care. Everyone follows strict rules to keep things safe. PGL has ISO 9001 and TAPA certifications. These show they have good quality control and safe handling. These awards help stop theft or damage. They make sure products stay safe in cold storage.

PGL’s cold storage uses new technology to watch temperature and humidity. Real-time sensors and backup systems keep things steady. This stops problems in the cold chain and keeps products good. The company also has programs to protect goods and follow security rules. This adds more safety for everything stored.

Staff get training and know how to handle cargo.

ISO 9001 and TAPA certified steps are used.

Real-time checks and backup systems are in place.

Asset protection and security rules are followed.

PGL has a record of very few accidents.

Note: PGL cares about safety and quality. Clients can relax, knowing their products are safe with experts.

Operational Efficiency

PGL makes its cold storage work better for every client. The warehouse is set up for fast receiving, sorting, and shipping. Different temperature zones keep all products at the right conditions. This helps keep quality from start to finish.

Clients get extra services like labeling, checking, and export help. These services make supply chains smoother and save time. The warehouse management system tracks every product. This gives full records and quick inventory checks.

The warehouse is built for fast work.

Many temperature zones fit different products.

Extra services help things run smoothly.

Advanced tracking keeps inventory correct.

Tip: Good cold storage helps clients send top-quality products on time, every time.

Why Choose Premier Global Logistics

Expertise

Premier Global Logistics is a top company for temperature-controlled logistics. The team has many years of experience with sensitive goods. They work with food, pharma, and chemical products. The staff knows the strict rules from the FDA, USDA, and FSMA. Every worker gets training in safety, quality, and following rules. This training helps clients trust that their products stay safe and fresh.

PGL uses advanced systems to control temperature. The warehouse has frozen, refrigerated, and ambient zones. Each zone has real-time checks and backup controls. The experts know how to handle many products, like seafood and vaccines. They use storage solutions that can be changed for each client. This means every shipment gets the right care.

Note: PGL’s focus on quality and following rules makes them a leader in temperature-controlled logistics.

End-to-End Solutions

PGL gives full solutions for clients who need more than storage. The Miami warehouse is close to air and sea ports. It takes less than an hour to reach them. This fast link helps exporters and importers move goods quickly. PGL’s services cover every step, like receiving, checking, labeling, sorting, and shipping.

Clients get all their temperature-controlled needs from one company. PGL’s services include:

Multi-temperature storage with strong quality checks

Real-time tracking and alerts for every shipment

Extra services like labeling, checking, and packing

Help with export, import, and customs papers

A seafood exporter can store goods while waiting for a ship. A pharma company can use the warehouse to send products across the country. PGL’s services keep goods safe, fresh, and on time. The company’s focus on quality and custom solutions helps clients grow with confidence.

Tip: PGL’s full solutions help clients relax and meet high quality standards.

Premier Global Logistics helps with Miami’s hardest cold storage problems for food, pharma, and chemical products. Their temperature-controlled warehouse in Florida gives:

Different zones for frozen, refrigerated, and room temperature goods

Around-the-clock checks and strong rule-following with FDA, USDA, and FSMA standards

Quick links to both air and sea ports

Clients feel calm, work faster, and know they follow all rules.

Want to keep your supply chain safe? Reach out to PGL for a custom cold storage Miami plan today.

FAQ

What temperature zones does PGL’s Miami warehouse offer?

PGL’s Miami warehouse has frozen, refrigerated, and ambient storage. Frozen storage is for -18°C and below. Refrigerated storage is for 2–8°C. Ambient storage is for 15–25°C. Each area uses real-time checks to keep products safe. Food, pharma, and chemical goods stay protected in every zone.

How does PGL ensure compliance with FDA and FSMA standards?

PGL follows all FDA and FSMA rules. Staff get training often to know the rules. The warehouse uses automatic checks and keeps good records. Food and pharma are stored in different places. This helps keep products safe and follow all rules.

Can PGL support urgent shipments or last-minute export needs?

Yes, PGL can help with urgent shipments. The Miami warehouse is close to air and sea ports. It takes less than an hour to reach them. The team works fast with labeling, checking, and export steps. Clients get quick and safe cold storage solutions.

What value-added services does PGL provide for temperature-sensitive goods?

PGL offers services like labeling, checking, sorting, and packing. The team also handles customs papers and tracks inventory. These services help clients move goods faster and meet all rules.

Who benefits most from PGL’s temperature-controlled warehouse Florida?

Seafood exporters, pharma companies, and chemical firms benefit most. Cross-border traders also use these services. PGL’s many temperature zones and strong rules help protect goods. Clients get safe storage and on-time delivery.

See Also

Reliable Cold Storage Solutions From Premier Global Logistics East Coast

Fast Order Fulfillment With Premier Global Warehousing In NJ And FL

Strategic Miami And Los Angeles Warehousing Boosts U.S. Supply Chains

Comprehensive East Coast B2B Warehousing And Distribution By Premier

Enhancing West Coast Supply Chains Through Premier LA Warehousing