What Comprehensive Distribution Logistics Solutions Include and How They Work

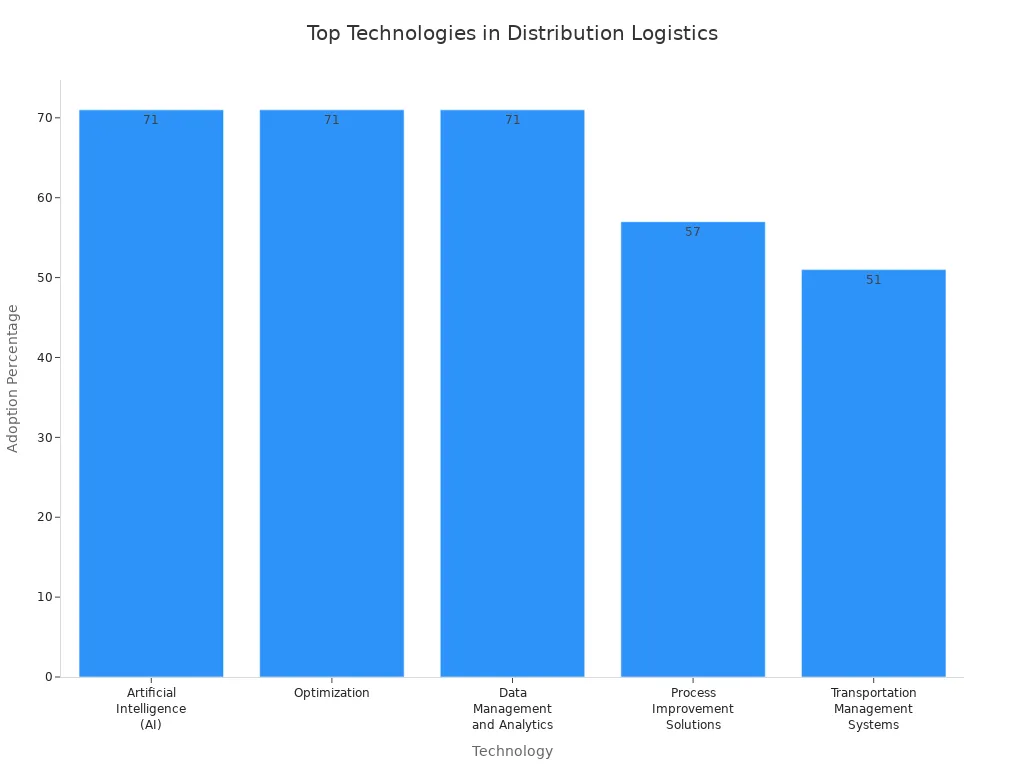

You need reliable systems to move products from your warehouse to your customers. Comprehensive distribution logistics solutions help you manage every step, from inventory to delivery. These solutions use technologies like improved demand forecasting, route optimization, real-time tracking, and advanced analytics. With tools such as automation, artificial intelligence, and the Internet of Things, you can boost speed and accuracy in your supply chain.

You can improve efficiency and keep your customers satisfied with these smart strategies.

Key Takeaways

Comprehensive distribution logistics solutions streamline your supply chain, improving efficiency from inventory management to delivery.

Utilize technologies like real-time tracking and automation to enhance accuracy and speed in your logistics operations.

Effective inventory control helps you match stock levels with demand, reducing costs and preventing stockouts.

Partnering with third-party logistics providers (3PLs) can save you money and time while providing expert support and advanced technology.

Regularly measure logistics performance using key metrics to identify areas for improvement and boost customer satisfaction.

Components of Comprehensive Distribution Logistics Solutions

Comprehensive distribution logistics solutions help you manage every step of your supply chain. You can use these solutions to move products quickly, keep track of inventory, fulfill orders, and handle returns. Each part works together to make your business more efficient and keep your customers happy.

Transportation and Shipping

You need strong transportation and shipping strategies to deliver products on time. These strategies affect how fast you can get goods to your customers and how much you spend on shipping. If you use smart shipping methods, you can lower costs and avoid delays.

Route optimization helps you find the fastest and cheapest way to deliver goods. GPS technology lets you choose the shortest routes, saving time and fuel.

Load consolidation allows you to combine shipments, so you make fewer trips and spend less money.

Real-time tracking gives you updates on where your products are at all times. You can adjust routes if there are delays.

Multi-warehouse systems let you store goods closer to your customers, which reduces shipping costs and speeds up delivery.

Tip: Quick delivery times help you keep production schedules on track and prevent costly downtime.

If you use effective transportation and shipping strategies, you can improve customer satisfaction and reduce the need for extra inventory.

Inventory Control

Inventory control is a key part of comprehensive distribution logistics solutions. You need to know how much stock you have and where it is. Good inventory control helps you avoid running out of products or having too much stock.

Automated inventory management systems track your stock in real time and send alerts when you need to reorder.

Demand forecasting uses data to predict what customers will buy. Many retailers say forecasting tools help them avoid stockouts.

ABC analysis sorts your inventory into high, medium, and low-value items. You can focus on managing the most important products.

Just-in-Time (JIT) inventory means you order products only when you need them, which lowers storage costs.

Vendor-managed inventory lets suppliers keep track of stock and send more products when needed.

If you control your inventory well, you can match stock levels to actual demand. This reduces costs and makes your supply chain more agile. You can also move products closer to high-demand areas, which lowers shipping distances and last-mile expenses.

Order Fulfillment

Order fulfillment is the process of getting products from your warehouse to your customers. You need to follow several steps to make sure orders are accurate and arrive on time.

Step | Description |

|---|---|

Receiving Inventory | You unload shipments, check items against purchase orders, inspect for damage, and store products. |

Storing Inventory | You organize and store inventory in the right locations to make picking faster. |

Processing Inventory | You verify order details, check inventory availability, and confirm payment. |

Picking Inventory | You select items from shelves based on customer orders using efficient picking strategies. |

Packing Inventory | You pack items securely and include any needed documents. |

Shipping Inventory | You arrange for shipment, choose carriers, and print shipping labels. |

Advanced order fulfillment systems help you improve delivery reliability and order accuracy. You can keep customers informed with real-time updates about their orders. These systems reduce mistakes and make customers more satisfied.

Returns and Tracking

Handling returns is important for keeping customers happy and protecting your profits. You need clear processes to manage returns and track products as they move back through your supply chain.

Step | Description |

|---|---|

1 | You receive the returned product, either by delivery or in person. |

2 | A quality assurance employee sorts and inspects the product based on the reason for return. |

3 | If the product is in good condition, you restock it. If not, you mark it as a loss. |

4 | You use best practices to optimize the returns process. |

5 | You study the reasons behind returns to help decrease return rates. |

6 | Speed, visibility, and control are key for handling returns well. |

7 | Automation and warehouse management technology can make returns faster and easier. |

8 | Good returns management helps you stay profitable and keep customers satisfied. |

You can use technology like GPS, RFID, and barcode scanners to track returns. These tools give you real-time updates and help you make better decisions. AI-powered robots can sort and inspect returned items, making the process faster and more accurate. Advanced platforms process data and provide insights, so you can plan smarter routes and improve your logistics.

Note: Real-time tracking and automation make returns easier to manage and help you keep customers loyal.

Comprehensive distribution logistics solutions combine these components to create a smooth, efficient supply chain. You can use these solutions to lower costs, improve delivery times, and keep your customers coming back.

Technology in Distribution Logistics

Warehouse Management Systems

Warehouse Management Systems (WMS) help you control your warehouse with smart technology. You get real-time updates about your inventory using tools like RFID and barcode scanning. This keeps your stock levels accurate and prevents losses. WMS guides your workers to the best picking routes and uses robotics and conveyor systems to make order fulfillment faster and more precise. You can connect your WMS with suppliers and distributors, which improves the flow of goods in and out of your warehouse. Artificial intelligence and machine learning in WMS analyze demand patterns and optimize storage layouts. These features help you manage inventory better and make smarter decisions.

Here are some benefits of using WMS in your logistics operations:

Benefit Type | Description |

|---|---|

Operational Cost Reduction | WMS reduces costs by streamlining workflows and automating tasks. |

Inventory Accuracy | Real-time tracking keeps your inventory counts correct. |

Order Fulfillment Speed | Faster picking and packing means quicker deliveries. |

Data-Driven Optimization | WMS gives you insights to boost productivity and cut waste. |

Scalability | You can handle more orders without needing extra staff. |

Compliance and Reporting | Accurate records help you meet regulations and avoid legal trouble. |

Integration | WMS works with other systems to improve overall efficiency. |

You also see improved customer satisfaction and a stronger brand reputation when you use WMS.

Automation and RFID

Automation and RFID technology make your logistics operations faster and more accurate. RFID tags let you track shipments and inventory with high precision. For example, Levi's Brazil increased inventory accuracy from 67% to nearly 100% after using RFID. The Siman Group raised its accuracy from 65-70% to 95%. Automated scanning at checkpoints speeds up the movement of goods and reduces errors. You can process up to 20,000 items per hour and cut inventory cycle count times by 96 percent. Receiving time improves by 90 percent, and picking and shipping accuracy goes up by 80 percent.

RFID helps in many areas:

Use Case | Description |

|---|---|

Dock-to-Stock Process | RFID captures data from tagged goods instantly. |

Returns Management | RFID makes it easy to identify and process returned items. |

Cross-Docking | RFID tags help route products quickly, lowering storage costs. |

Temperature Control | RFID monitors temperature for sensitive goods. |

Loading Verification | RFID checks that products are loaded onto the right trucks. |

Yard Management | RFID tracks trailers and reduces check-in times. |

Real-Time Tracking | RFID gives accurate shipment updates to customers. |

Real-Time Tracking

Real-time tracking technology gives you constant updates about your shipments. You can see where your goods are and fix problems before they cause delays. This reduces delivery errors and improves customer satisfaction. If a delivery truck breaks down, you can quickly send another vehicle and update your customer with a new arrival time. Real-time tracking helps you manage deliveries more reliably.

You can use GPS, mobile apps, and IoT devices to track shipments across different transportation modes. RouteManager, for example, lets you optimize thousands of orders each day and provides automatic updates to drivers. You get clear information about delivery locations and times, which helps you plan and forecast better.

Comprehensive distribution logistics solutions use these technologies to make your supply chain smarter and more efficient. You can deliver products faster, reduce mistakes, and keep your customers happy.

Role of Third-Party Logistics Providers (3PLs)

Third-party logistics providers, or 3PLs, play a key role in helping you manage your supply chain. They bring specialized knowledge and scalable solutions to your business. You can use their services to streamline your operations and add value for your customers. When you work with a 3PL, you can focus on your main business goals while experts handle the logistics.

End-to-End Solutions

You can rely on 3PLs for end-to-end solutions. They manage warehousing, distribution, and transportation for you. Their experience helps you overcome supply chain challenges and improve efficiency. By using their services, you save money and time. You also gain access to advanced technology and established systems.

Here are some advantages of using 3PLs for end-to-end distribution:

Advantage | Description |

|---|---|

Cost Savings | 3PLs lower shipping, warehousing, and labor costs by using their buying power. |

Operational Efficiency | They use automation and proven systems to reduce errors and manual work. |

Speed and Service Quality | Dedicated teams and technology help you deliver orders faster and keep customers happy. |

Scalability and Flexibility | 3PLs adjust to your busy seasons and business growth without extra investment. |

Specialized Expertise | You get help from professionals who know shipping rules and compliance. |

Risk Mitigation and Resilience | 3PLs use strong networks and backup plans to keep your supply chain running smoothly. |

Freight Forwarding and Brokerage

Freight forwarding and brokerage services help you move goods across regions and borders. You can count on freight brokers to adjust quickly to market changes. They find the best shipping routes and combine shipments to save you money. These services also give you better control and visibility with real-time tracking and updates.

Freight brokers help you adapt to new demands in the market.

They lower costs by optimizing routes and consolidating shipments.

You get real-time updates, so you always know where your goods are.

Distribution Centers Coordination

Coordinating distribution centers is important for smooth operations. You need clear communication and strong management to keep everything running well. 3PLs use best practices to make sure your products move efficiently.

Best Practice | Description |

|---|---|

Effective Communication | Keeps everyone informed and prevents mistakes. |

Data-Driven Performance Management | Tracks how well your centers work and finds ways to improve. |

Advanced Scheduling Systems | Makes staffing and operations flexible and visible. |

Peak Season Scheduling | Plans ahead for busy times and adjusts as needed. |

Technology Integration | Uses platforms for real-time updates and better decisions. |

You can use comprehensive distribution logistics solutions with 3PLs to make your supply chain stronger, faster, and more reliable.

Achieving Efficiency and Service Goals

Cost Optimization

You can lower your logistics costs by using smart strategies. Faster delivery windows and reduced dwell time help you save money. Increased route density means you deliver more packages in fewer trips. Lower fuel and labor costs also make a big difference. Try these steps to optimize costs:

Re-route drivers based on real-time traffic.

Adjust ETAs automatically.

Prioritize high-value loads in real time.

You should set clear goals, perform regular audits, and automate your processes. Negotiating with suppliers can also reduce expenses. Working with manufacturers and distributors helps you share data and manage supply better. Strategic alliances and logistics pooling can further cut costs. Regional routing and dynamic route planning lower delivery distances. Tiered service planning lets you balance speed and cost.

Source | Reported Savings |

|---|---|

Envista Corp | 10-20% annual savings |

Upper Inc | 15-30% logistics reductions |

Many companies see 10% to 30% savings each year after optimizing their logistics.

Service Level Improvement

You can improve your service levels by using real-time tracking systems. These systems give customers up-to-date information about their shipments. Most shoppers expect regular updates about their purchases. Automated notifications keep customers informed when a shipment is dispatched, delayed, or delivered.

Real-time tracking systems allow companies to provide up-to-date information on shipment status, which leads to improved consumer satisfaction. A survey by Convey found that 98% of customers believe that shipping impacts their loyalty to a brand, highlighting the critical role of logistics in customer satisfaction.

UPS’s ORION system saves millions of miles each year. This leads to more precise delivery times and happier customers. Comprehensive distribution logistics solutions help you meet customer expectations and build loyalty.

Performance Metrics

You need to measure your logistics performance to find areas for improvement. Use these common metrics:

Net promoter score (NPS)

Repeat customer rate

Delivery accuracy

Lead time

Inventory turnover

Transportation costs

Cost per delivery

Cost per stop

Fuel cost per delivery

Logistics costs

Revenue growth

Metric | Description |

|---|---|

Delivery accuracy | Precision of deliveries against promised timelines |

Lead time | Time from order placement to delivery |

Inventory turnover | Rate at which inventory is sold and replaced |

Transportation costs | Total costs for moving goods |

Customer satisfaction | Measured by surveys and repeat purchases |

Continuous improvement practices help you boost these metrics. You can use methods like kaizen and PDCA to make your operations more efficient. Regular analysis lets you spot problems and fix them quickly. This leads to better delivery times, lower costs, and higher customer satisfaction.

You gain real benefits when you use comprehensive distribution logistics solutions. These systems combine technology and smart processes to cut costs, improve delivery times, and boost accuracy. For example, real-time tracking and AI tools help you avoid delays and manage inventory better.

When you choose a partner, look for strong technology, proven experience, and great customer service.

Many businesses see fewer returns, faster shipping, and lower costs after making these changes. Review your logistics needs and pick solutions that fit your goals.

FAQ

What is a comprehensive distribution logistics solution?

You use a comprehensive distribution logistics solution to manage every step of your supply chain. It helps you control inventory, shipping, order fulfillment, and returns with advanced technology.

How does real-time tracking improve delivery?

Real-time tracking lets you see where your products are at any moment. You can fix problems quickly and keep your customers updated about their orders.

Why should you work with a third-party logistics provider (3PL)?

You gain expert help and advanced tools when you work with a 3PL. They handle shipping, warehousing, and distribution so you can focus on your business.

Tip: 3PLs often lower your costs and improve delivery speed.

What technology helps you manage inventory better?

You use warehouse management systems, automation, and RFID tags to track inventory. These tools help you avoid mistakes and keep your stock levels accurate.

Technology | Benefit |

|---|---|

WMS | Real-time updates |

RFID | Fast tracking |

Automation | Fewer errors |

See Also

Optimized Inventory Management Through Premier Global Logistics Solutions

Simplified Inventory Control Using Premier Global Logistics Services

Enhancing Global Operations With Cutting-Edge Logistics Innovations

Simplifying Supply Chain Efficiency With American Logistics Services

Understanding East Coast B2B Warehousing By Premier Global Logistics