Effective Green Supply Chain Strategies Every Business Should Know

Green supply chain strategies help you make your business more sustainable. These strategies focus on using resources wisely and choosing suppliers who care about the environment. Supply chain sustainability means you look at how your products move from raw materials to finished goods, making sure each step protects the planet and supports your company’s future.

When you focus on sustainability, you can boost profits and manage risks better. The table below shows how many leaders see gains from these efforts:

Benefit | Percentage of Leaders |

|---|---|

Profit Expectation | |

Efficiency Gains | 31% (already), 51% (next 1-3 years) |

Shareholder Value | 54% |

Risk Management | 55% |

Choosing green supply chain strategies can help you grow your business and stay ready for the future.

Key Takeaways

Implement green supply chain strategies to boost profits and manage risks effectively.

Focus on resource efficiency by measuring current usage and setting clear improvement goals.

Choose eco-friendly sourcing to enhance your brand reputation and attract environmentally conscious customers.

Utilize technology like digital twins and blockchain to optimize your supply chain and reduce waste.

Collaborate with suppliers to strengthen partnerships and achieve sustainability goals together.

What Is Supply Chain Sustainability?

Supply chain sustainability means you include environmental, social, and governance values in every step of your sourcing, production, and delivery. You plan for reuse, recycling, and product retirement. This approach supports a circular economy, where you use resources again and again instead of throwing them away. You also focus on efficient and fair resource use, with clear and regulated processes. These ideas match the United Nations Sustainable Development Goals, which guide businesses toward a better future.

Key Principles of Sustainability

You can follow several key principles to make your supply chain more sustainable:

Legal Supply Chains: Always follow the law and meet all contract requirements. This includes building and environmental standards.

Ethical Supply Chains: Go beyond the law by following codes of conduct and voluntary guidelines. You show respect and honesty in your business.

Responsible Supply Chains: Keep improving and help your community. You listen to what your stakeholders need.

Sustainable Supply Chains: Make sure every partner acts legally, ethically, and responsibly.

Environment: Reduce your impact on nature at every stage.

Social: Treat workers fairly and support ethical labor.

Economic: Keep your business strong and able to last.

Business Benefits

When you use green supply chain strategies, you save money by using materials and energy more wisely. Companies that focus on sustainability often see better financial results. You can also improve your company’s image and attract customers who care about the environment. Following these practices helps you meet rules like the EU’s Green Deal, so you avoid legal trouble. You also encourage new ideas and research, which can help you find new partners and stay ahead in your industry.

Green Supply Chain Strategies Overview

Green supply chain strategies help you build a supply chain that protects the environment and supports your business goals. These strategies focus on using fewer resources, making smarter choices, and working with partners who share your values. You can use these methods to reduce waste, save money, and meet new rules about sustainability.

The main objectives of green supply chain management include:

Minimize environmental impact at every stage.

Enhance efficiency in how you use energy and materials.

Achieve your company’s sustainability goals.

Implement reverse logistics, so products can be reused or recycled.

Measure your carbon footprint to track progress.

Foster collaboration among all stakeholders.

You can use these objectives as a guide when you choose which strategies to use in your business. The next sections will show you how to put these ideas into action.

Resource Efficiency

Resource efficiency means you use less energy, water, and raw materials to make your products. You can start by looking at how much energy your suppliers use. For example, Walmart worked with its top suppliers in China to improve energy efficiency by 20%. This project showed that when you align supplier incentives with energy-saving goals, you can manage resources better across the whole supply chain.

You can improve resource efficiency by:

Enhancing energy efficiency in your supply chain.

Optimizing procurement, production, and distribution processes.

Leveraging digital technologies like AI and blockchain to improve visibility and decision-making.

When you focus on resource efficiency, you save money and reduce your impact on the environment. You also make your supply chain more resilient and ready for future challenges.

Tip: Start by measuring your current resource use. Set clear goals for improvement and track your progress over time.

Eco-Friendly Sourcing

Eco-friendly sourcing means you choose suppliers and materials that have a lower impact on the environment. You look for partners who use sustainable practices and offer products that are recycled, renewable, or certified by trusted organizations.

Businesses that use eco-friendly sourcing see real results. The table below shows some measurable outcomes:

Outcome | Description |

|---|---|

Financial Savings | Sustainable procurement can reduce costs by 9-16% through improved efficiency and resource management. |

Improved Brand Reputation | Companies that prioritize sustainability enhance their brand image and attract socially responsible investors. |

Enhanced Compliance | Adopting eco-friendly practices helps businesses comply with regulations, reducing risks related to supply chain disruptions. |

Environmental Impact | Reduces carbon footprints, conserves resources, and minimizes waste, supporting climate change efforts. |

When you choose eco-friendly sourcing, you help the planet and make your business stronger. You also show your customers and investors that you care about the future.

Note: Ask your suppliers about their sustainability certifications and look for ways to work together on green supply chain strategies.

In the next sections, you will learn more actionable steps to make your supply chain even greener, from smarter logistics to better packaging and technology.

Systems Thinking & Life Cycle Assessment

Applying Systems Thinking

You can make your supply chain greener by using systems thinking. This approach helps you see the big picture. You look at how each part of your supply chain connects to the others. When you understand these links, you can spot problems early and find better solutions. Systems thinking encourages you to see your supply chain as a whole, not just as separate steps.

When you use this method, you learn how your choices affect the entire system. For example, if you change a supplier, it might change your costs, delivery times, and even your environmental impact. Systems thinking helps you respond to challenges faster. You can also work better with your partners. Many experts say that knowing the structure and relationships in your supply chain leads to smarter decisions. You can handle crises better and make real progress with green supply chain strategies.

Tip: Draw a simple map of your supply chain. Mark how each part connects. This can help you spot areas for improvement.

Life Cycle Assessment Steps

A life cycle assessment (LCA) helps you measure the environmental impact of your products from start to finish. You can use LCA to make better choices for your business and the planet. Here are the main steps:

Compile a Life Cycle Inventory

List all the materials and energy used at each stage of your product’s life.Evaluate Environmental Impacts

Use science-based methods to find out where the biggest impacts happen.Interpret the Results

Review the data to understand what it means for human health and the environment.Select Impact Categories

Choose which types of impacts matter most, like carbon emissions or water use.Classify and Characterize Results

Group and measure the impacts to see which areas need the most attention.Life Cycle Interpretation

Summarize your findings and make recommendations for improvement.

The interpretation phase is important. You check and evaluate all your results. This step helps you share your findings clearly and make smart decisions for your supply chain.

Digital Twins for Supply Chains

Emissions and Waste Reduction

Digital twins use virtual models to mirror your real-world supply chain. You can see every step, from raw materials to delivery. This technology helps you spot problems and test solutions before making changes in the real world. When you use digital twins, you make your supply chain smarter and greener.

You can reduce emissions and waste by using digital twins in several ways:

Digital twins let you test different scenarios. You can try out changes without risk and find the best way to save energy and cut waste.

You get full visibility across your supply chain. This helps you optimize each part for efficiency and sustainability. You use less energy and create less waste.

By mapping your production processes, you can find places to reduce waste or start recycling programs. This supports a circular economy.

Digital twins give you real-time data on product movement and emissions. You can make better choices about where to source materials.

You can optimize transport routes and logistics. This cuts down on carbon emissions from shipping.

Modeling energy use with digital twins helps you save energy and lower greenhouse gas emissions.

Tip: Use digital twins to track your supply chain’s carbon footprint. This helps you set clear goals for improvement.

Implementation Tips

You can get the most from digital twins by following a few best practices. Start with careful planning. Define what you want to achieve and decide which parts of your supply chain to model. Gather the data you need and make a clear roadmap.

Next, test your digital twin with a pilot project. Check how well it works and see if it fits with your current systems. Make changes as needed.

Finally, scale up your digital twin. Roll it out step by step. Train your team and encourage everyone to work together. This approach helps you avoid problems and get the best results.

Planning: Set your goals, gather data, and make a plan.

Testing: Run a pilot and check how it works with your systems.

Scaling: Expand use, train your team, and support collaboration.

Note: Start small and build up. This helps you learn and improve as you go.

Sustainable Logistics & Transport

Smarter Transport Planning

You can make your supply chain greener by planning your transport smarter. When you optimize delivery routes, you cut down on travel distance and fuel use. This step lowers your carbon emissions and saves money. Many companies now use real-time data and advanced algorithms to plan the best routes. These tools help you avoid traffic, reduce idle time, and deliver goods faster.

You can also combine different types of transport, like trucks, trains, and ships. This method, called multimodal transportation, helps you move goods more efficiently. It often uses less fuel and creates fewer emissions. Smart transport planning also means using vehicles that run on electricity or alternative fuels. Electric trucks and biofuel vehicles produce less pollution and help you meet your sustainability goals.

Here is a table that shows some of the most effective strategies for reducing carbon emissions in logistics:

Strategy | Description |

|---|---|

Optimizing Routing | Streamlining delivery routes to minimize travel distance and fuel consumption. |

Transitioning to Renewable Energy | Using solar panels and other renewable sources in logistics facilities. |

Energy-Efficient Facilities | Using LED lighting and smart HVAC systems in warehouses. |

Carbon Offsetting Programs | Investing in projects like reforestation to balance out emissions. |

Data Analytics and IoT | Tracking emissions and setting reduction goals with real-time data. |

Multimodal Transportation | Combining different transport modes for better efficiency. |

Sustainable Packaging Practices | Using low-carbon packaging materials to reduce environmental impact. |

Tip: Start by tracking your current emissions. Set clear goals and use technology to monitor your progress.

Green Logistics Practices

You can adopt many green logistics practices to make your supply chain more sustainable. Leading companies use these steps to lower their impact on the environment:

Use advanced route planning to cut travel distance and fuel use.

Build green warehouses with energy-saving lights and smart systems.

Switch to electric trucks or vehicles that use alternative fuels.

Choose recyclable and biodegradable packaging to reduce waste.

Invest in projects that offset your carbon emissions.

Maximize vehicle loads to reduce the number of trips.

Set up reverse logistics for returns and recycling.

Use digital tools like IoT and AI to improve efficiency.

Manage inventory smartly to avoid waste.

Work with other companies to share transport and optimize shipments.

When you follow these practices, you help the planet and make your business stronger. You also show your customers that you care about the future.

Packaging & Materials Management

Reducing Packaging

You can make your supply chain greener by reducing the amount of packaging you use. When you cut down on packaging, you save money and lower your environmental impact. Many companies have found that small changes can lead to big results. For example, switching from foam trays to corrugated cardboard dividers in shipping boxes helped one business ship more products in each case. This change increased the number of cables shipped from 99 to 180 per case, which is an 82% increase.

Here are some benefits of reducing packaging:

The switch to cardboard dividers reduced plastic waste and made shipping more efficient.

The company expects to save over 1.3 tons of corrugated boxes and more than 200 tons of foam trays each year.

Less packaging means a lower carbon footprint and less waste in landfills.

Tip: Review your current packaging. Look for ways to use less material or switch to designs that fit more products in each shipment.

Compostable and Recycled Materials

You can also choose packaging made from compostable or recycled materials. These options help you cut down on waste and support a circular economy. Compostable packaging breaks down into natural elements in a composting environment. Recycled materials can be used again, which saves resources.

Material Type | Description |

|---|---|

High Barrier, Compostable | Breaks down into soil-enriching nutrients, replacing traditional plastics. |

PLA (Plant-based Polylactic Acid) | Decomposes in composting environments, made from plants. |

Kraft Paper with Compostable Coatings | Biodegradable and compostable, good for many packaging needs. |

Sugar Cane, Corn Starch, Potato Starch, Wood Pulp | Natural materials that microorganisms break down into compost. |

Recycled Paper and Cardboard | Can be reused and recycled, reducing the need for new materials. |

You can find compostable packaging made from PLA, Kraft paper, and even mailers made from sugar cane or wood pulp. These materials break down safely and enrich the soil. When you use recycled paper and cardboard, you help keep materials in use longer and reduce the need for new resources.

Note: Ask your suppliers about compostable and recycled packaging options. Switching to these materials can help you meet your sustainability goals and show your customers you care about the environment.

Technology in Green Supply Chains

Technology plays a big role in making your supply chain greener. Digital tools help you track, measure, and improve every step. When you use technology, you can save resources, cut costs, and make better choices for the planet.

Blockchain Applications

Blockchain gives you a secure and transparent way to track products as they move through your supply chain. You can see where each item comes from and how it was made. This helps you avoid illegal or unethical practices and proves your products meet sustainability standards.

Here is how blockchain can help your green supply chain:

Advantage | Description |

|---|---|

Freedom from Illegal Business Practices | Blockchain provides a transparent trail that helps reduce counterfeit goods and unethical practices. |

Enhancements in Operational Efficiency | Automation of processes through smart contracts improves efficiency in supply chain management. |

Prove Your Sustainability Performance | An immutable record enhances credibility of sustainability claims across the supply chain stages. |

You can use blockchain at any stage. It helps you share information with partners in real time. This builds trust and makes your supply chain more efficient.

Tip: Ask your partners if they use blockchain. This can help you work together to reach your sustainability goals.

Refurbishment and Waste Management

You can make your supply chain more sustainable by focusing on refurbishment and waste management. Refurbishing means fixing and reusing products instead of throwing them away. Waste management helps you recycle and keep materials in use longer.

Description | |

|---|---|

Closed Loop Supply Chain | Focuses on recycling and reusing materials to minimize waste. |

Environmental Impact | Highlights the positive effects of waste management on the environment. |

Circular Economy | Emphasizes sustainable practices within supply chains. |

When you use these strategies, you support economic growth and keep resources flowing. Circular supply chains help you balance environmental and business goals. Many companies now use closed-loop systems to cut waste and save money.

Note: Start small by setting up a recycling program or offering refurbished products. Every step helps build a greener supply chain.

Resilient Supply Chains

Building a resilient supply chain helps you handle disruptions and stay strong in changing times. You can prepare for risks and keep your business running smoothly. Resilient supply chains also support your green goals and help you meet new rules.

Risk Management

You can manage risks by planning ahead and using smart strategies. When you focus on risk management, you protect your business from surprises like natural disasters, new laws, or supply shortages. You also show your customers and partners that you care about the environment and your community.

Key factors that make your supply chain more resilient include:

Addressing environmental risks by managing resources wisely and reducing waste. This prepares you for future regulations.

Meeting regulatory requirements to avoid fines and show responsibility.

Enhancing your reputation by committing to sustainability. This attracts eco-conscious customers and investors.

You can use different strategies to manage risks. The table below shows some of the most effective methods:

Strategy | Description |

|---|---|

Diversified Sourcing | Work with multiple suppliers to lower risks from disasters or political issues. |

Flexible Logistics Networks | Use agile methods to change routes and delivery options when needed. |

Robust IT Systems | Use technology for real-time data and predictions. |

Proactive Risk Assessments | Find possible problems early and plan how to handle them. |

Employee Training | Teach your team how to respond to disruptions. |

Strategic Partnerships | Build strong relationships with partners to secure resources during tough times. |

Tip: Review your supply chain often. Update your plans as new risks appear.

Supplier Collaboration

Working closely with your suppliers helps you reach your green supply chain goals. When you share ideas and resources, you can solve problems faster and make better choices for the planet.

The table below shows how supplier collaboration supports sustainability:

Mechanism | Benefit to Green Supply Chain Goals |

|---|---|

Development of valuable resource sets | Builds unique resources that support long-term sustainability |

Engagement in social sustainability | Improves social performance and meets what stakeholders expect |

Importance of organizational justice | Creates trust and cooperation, leading to better and more sustainable results |

You can build strong partnerships by being fair, honest, and open with your suppliers. This teamwork helps everyone succeed and keeps your supply chain strong and green.

Sustainability Metrics

Measuring Performance

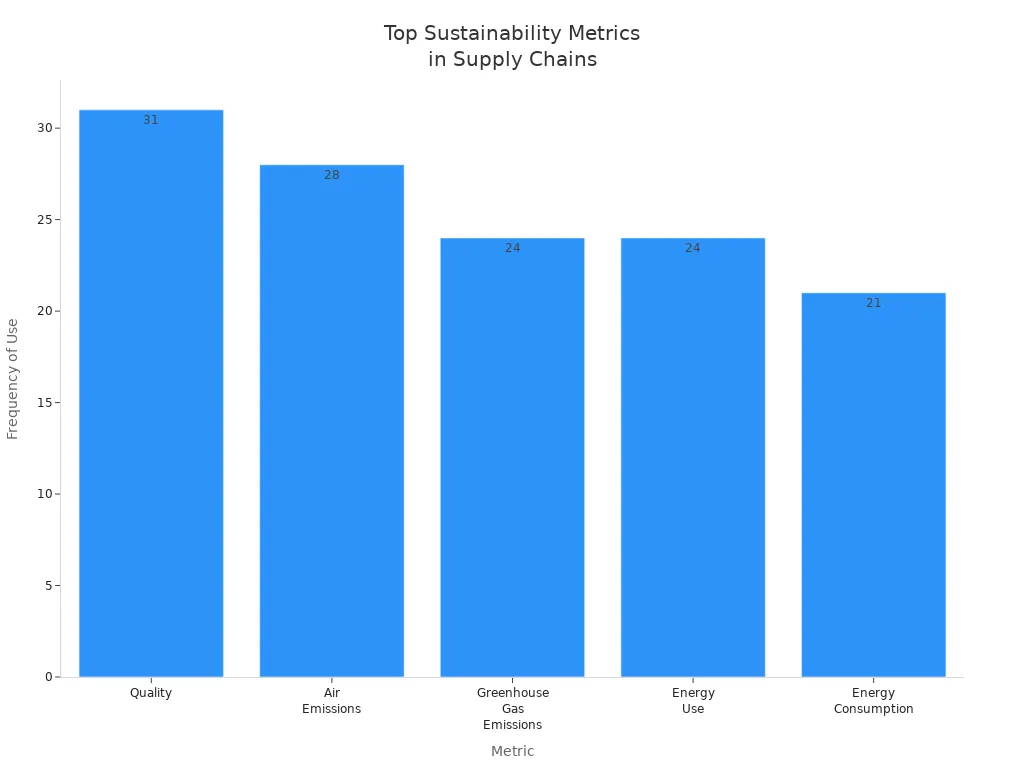

You need to measure your supply chain’s sustainability to see real progress. Metrics help you track how well you use resources and protect the environment. When you measure performance, you can set clear goals and show results.

Many companies use these common metrics:

Metric | Frequency of Use |

|---|---|

Quality | |

Air Emissions | 28 times |

Greenhouse Gas Emissions | 24 times |

Energy Use | 24 times |

Energy Consumption | 21 times |

You can also track other important numbers:

CO2 emissions reduction in kilotons

Energy consumption in kilowatt-hours

Water usage in metric tons

Waste reduction in cubic meters

Plastic reduction in metric tons

Material efficiency (MIPS)

Noise pollution in decibels

Compliance with chemical safety rules

Number of suppliers meeting environmental standards

Tip: Start with a few key metrics. Track them over time to see where you improve and where you need to focus.

Reporting to Stakeholders

You need to share your sustainability progress with your team, customers, and investors. Clear reporting builds trust and shows that you care about the planet. More than 90% of the world’s largest companies now report on their sustainability work.

You can use these common frameworks to guide your reports:

Global Reporting Initiative (GRI)

United Nations Sustainable Development Goals (SDGs)

Carbon Disclosure Project (CDP)

Corporate Sustainability Reporting Directive (CSRD)

Science Based Targets Initiative (SBTi)

These frameworks help you organize your data and tell your story. When you use them, you make it easier for others to understand your progress and support your goals.

Note: Choose a reporting standard that fits your business. Stay consistent so you can compare results year after year.

Overcoming Challenges

Cost and Complexity

You may face several challenges when you try to make your supply chain greener. Many businesses worry about the cost and complexity of these changes. The table below shows some of the most common challenges:

Challenge | Description |

|---|---|

Initial cost | Switching to a green supply chain model can be expensive initially due to new equipment and training. |

Learning curve | New green protocols increase the risk of mistakes, leading to product waste and poor planning. |

Complex logistics | Calculating transportation routes to minimize environmental impact is challenging and complex. |

You might need to buy new equipment or train your team. These steps can cost a lot at first. You may also see mistakes as everyone learns new ways of working. Planning green transport routes can take more time and effort. However, these challenges often lead to long-term savings and better results for your business.

Tip: Start small with pilot projects. Track your costs and savings. This helps you show the value of green supply chain changes over time.

Employee and Partner Engagement

You need your employees and partners to support your green supply chain goals. When everyone works together, you can make bigger changes and see better results. Here are some ways to boost engagement:

Foster a culture of sustainability: At Unilever, most employees feel they can help with sustainability. A supportive culture makes it easier for everyone to join in.

Cocreate sustainable practices: Unilever encourages employees to share their ideas for green projects. This leads to new investments and creative solutions.

Encourage healthy competition: BASF ran a program that asked employees to submit project ideas. This friendly competition led to over 500 new ideas.

You can use these methods to get your team excited about sustainability. When people feel involved, they work harder to reach your goals.

Note: Celebrate small wins and share success stories. This keeps everyone motivated and focused on building a greener supply chain.

You gain many benefits when you use green supply chain strategies. You lower costs, improve profits, and meet new rules. Most consumers now prefer brands that care about the environment. You can take action by using renewable energy, ethical sourcing, and circular supply chains. Keep improving by tracking your progress and working with your suppliers. Remember, ongoing evaluation helps you stay ready for future changes.

Stay committed to sustainability. Your choices today shape a better tomorrow.

FAQ

What is a green supply chain?

A green supply chain uses eco-friendly practices at every step. You choose sustainable materials, reduce waste, and save energy. You help protect the planet and make your business stronger.

How can you start making your supply chain greener?

You can begin by measuring your resource use. Set clear goals for improvement. Work with suppliers who follow sustainable practices.

Tip: Start small with one project and expand as you learn.

Does going green cost more?

You may see higher costs at first. Over time, you save money by using fewer resources and reducing waste.

Benefit | Long-Term Impact |

|---|---|

Lower Costs | Yes |

Better Image | Yes |

What are the biggest challenges in green supply chains?

You may face high initial costs, complex logistics, and a learning curve for new practices.

Cost of new equipment

Training your team

Planning green transport routes

How do you measure success in a green supply chain?

You track key metrics like energy use, waste reduction, and carbon emissions. You report results to your team and stakeholders.

Note: Use simple tools to monitor progress and share updates regularly.

See Also

Key Strategies for Effective Global Logistics Operations

Simplifying Supply Chain Optimization with U.S. Logistics Solutions

Connecting Warehouses and Enhancing Supply Chains with PGL

PGL’s Knowledge Ensures Smooth Operations for U.S. Supply Chains